7

Fork Setup Information

Read this first for a general under-

standing of fork set-up or skip straight

to the air pressure charts if you just

want to go ride.

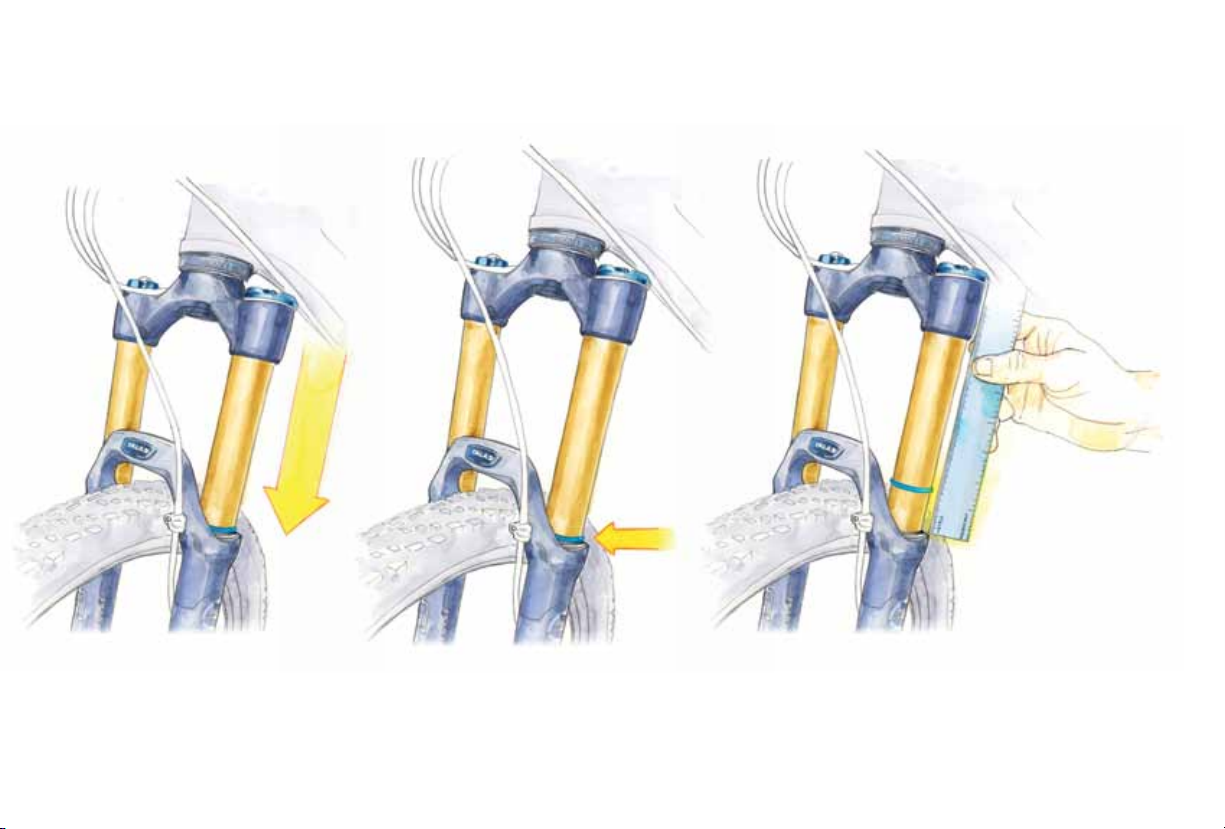

Positive Pressure

This is the main air spring that sup-

ports your weight. Adjust the air

pressure so that you come close to

using all the travel on a typical ride.

Usually you can mimic your maximum

impacts by grabbing the front brake

and pushing down HARD on the bars.

If you are getting 80–90% of the

fork’s travel doing this, your positive

air spring is in the right range. Actual

riding will often push the fork a little

further than this test.

Low Speed Compression Damping

Low speed compression damping is

used to reduced unwanted movement

and over travel due to low speed

changes like out of the saddle pedal-

ing and subtle variations in the trail

that can cause wallowing etc. Adjust

to your preference.

Lockout

As the name implies this turns the fork

rigid (or close to it) for out of the sad-

dle efforts or riding on the road. Most

forks have a “blowoff” so that the fork

will move if a large enough impact is

felt. The threshold or “blowoff” when

the lockout lets the fork start to move

is often adjustable. It’s called Gate

in Rock Shox parlance and Blowoff

Threshold in Fox’s language. Usually

the goal is to have the lockout at the

minimum setting needed to stop the

fork movement while pedaling out of

the saddle, but allowing it to still move

fairly easily when an impact is felt.

High Speed Compression Damping

If your fork has a high speed com-

pression damping control, this would

usually be used to slow things down

during big hits to avoid bottoming.

It would usually be set at the lowest

level needed to avoid bottoming out.

Rebound

Adjust the rebound so that the front

end does not bounce off the ground

after a drop off or large bump.

If adjusted too slow, the fork may

“pack down” and feel sluggish.

In order to conserve momentum and

remain compliant the suspension

needs to recover fairly quickly and

push off the back side of bumps and

holes. If the rebound is adjusted too

slow, rolling energy is lost to damping

and vibration. If it is adjusted too fast

the bike will bounce after bumps and

drops. Adjust to your preference.

Fox Float CTD

For 2013 Fox added features to

their line of Float forks and shocks to

make it easier for the user to adjust to

changing trail conditions. It’s called

CTD (Climb Trail Descend) and is

changed by the lever at the top of the

right fork leg. As with prior Fox forks,

cranking the blue lever clockwise

increases the amount of force it takes

to make the fork move. Just think of

‘Righty Tighty, Lefty Loosie’ (same

goes for the shock).

Fork Setup