Heavy Duty & OBDII Diagnostic Tool HD V3.0

II

Table of contents

1 Introduction...............................................................................................1

2 General Information..................................................................................1

2.1 On-Board Diagnostics (OBD) II .........................................................1

2.2 Diagnostic Trouble Codes (DTCs).....................................................2

2.2.1 OBDII DTC.................................................................................2

2.2.2 DTCs for J1587 /J1708 and J1939.............................................3

2 .3 J1708/J1587/J1939.......................................................................... 4

2.4 OBD Definitions.................................................................................5

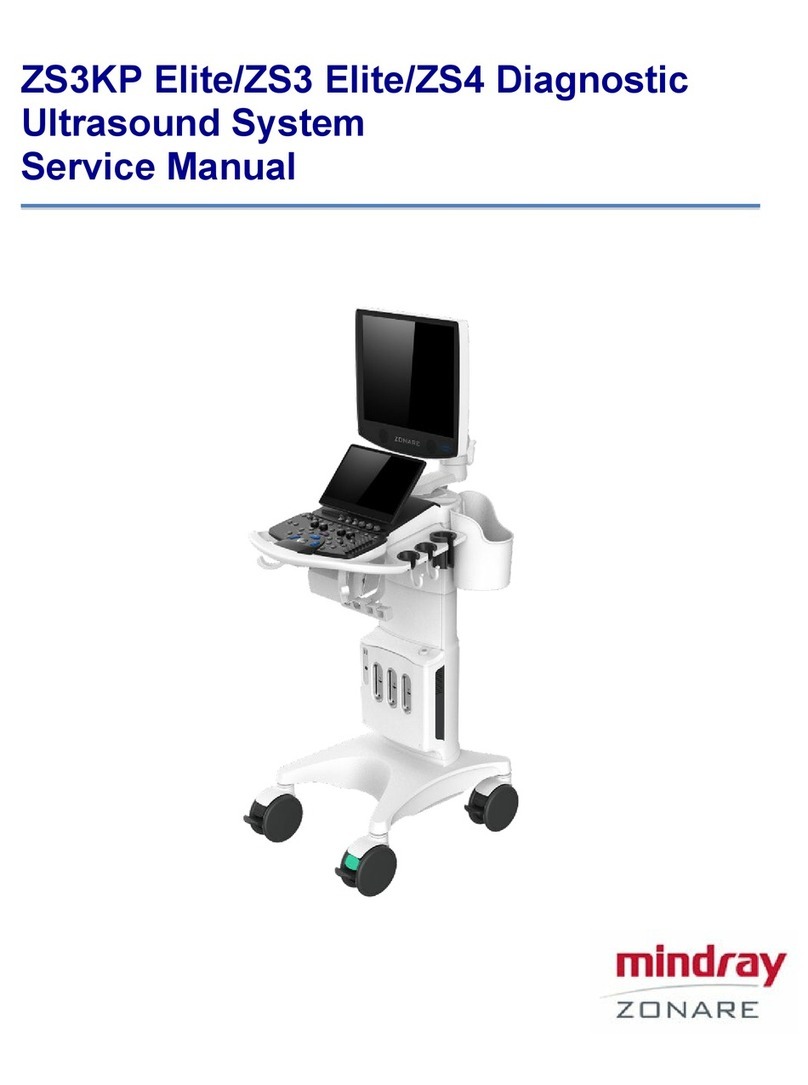

3 Product Descriptions.................................................................................6

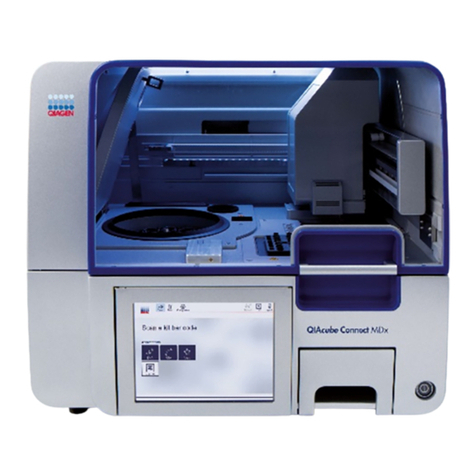

3.1 Outline of HD V3.0.............................................................................7

3.2 Specifications....................................................................................8

3.3 Accsessories.....................................................................................9

3.4 Power supply.....................................................................................9

4 Connections & General Operations......................................................... 11

4.1 Connections .................................................................................... 11

4.2 Battery.............................................................................................12

4.3 DTC Library.....................................................................................13

4.4 Settings ...........................................................................................13

4.5 About...............................................................................................14

5 Diagnose ................................................................................................14

5.1 Truck OBD Diagnosing.....................................................................16

5.1.1 Read DTC.................................................................................17

5.1.2 Clear DTC................................................................................18

5.1.3 Live Data..................................................................................18

5.2 Car OBDII Diagnosing.....................................................................19

5.2.1 Read Codes..............................................................................19

5.2.2 Erase Codes ............................................................................20

5.2.3 I/M Readiness..........................................................................21

5.2.4 Live Data...................................................................................21

5.2.5 View Freeze Frame...................................................................21

5.2.6 Oxygen sensor test...................................................................21

5.2.7 On-board monitor test...............................................................22

6 How to Upgrade HD V3.0 .......................................................................22

6.1 Upgrading flowchart.........................................................................22

6.2 User registration..............................................................................23

6.3 Upgrading:.........................................................................................24

7 FAQ ........................................................................................................24