KI0063 Capacitive sensor

10

7 Settings

7.1 Basic teach empty state

Using the basic teach empty state, the device suppresses the installation environment. The basic

teach empty state resets the device, an adjustment teach already carried out is deleted.

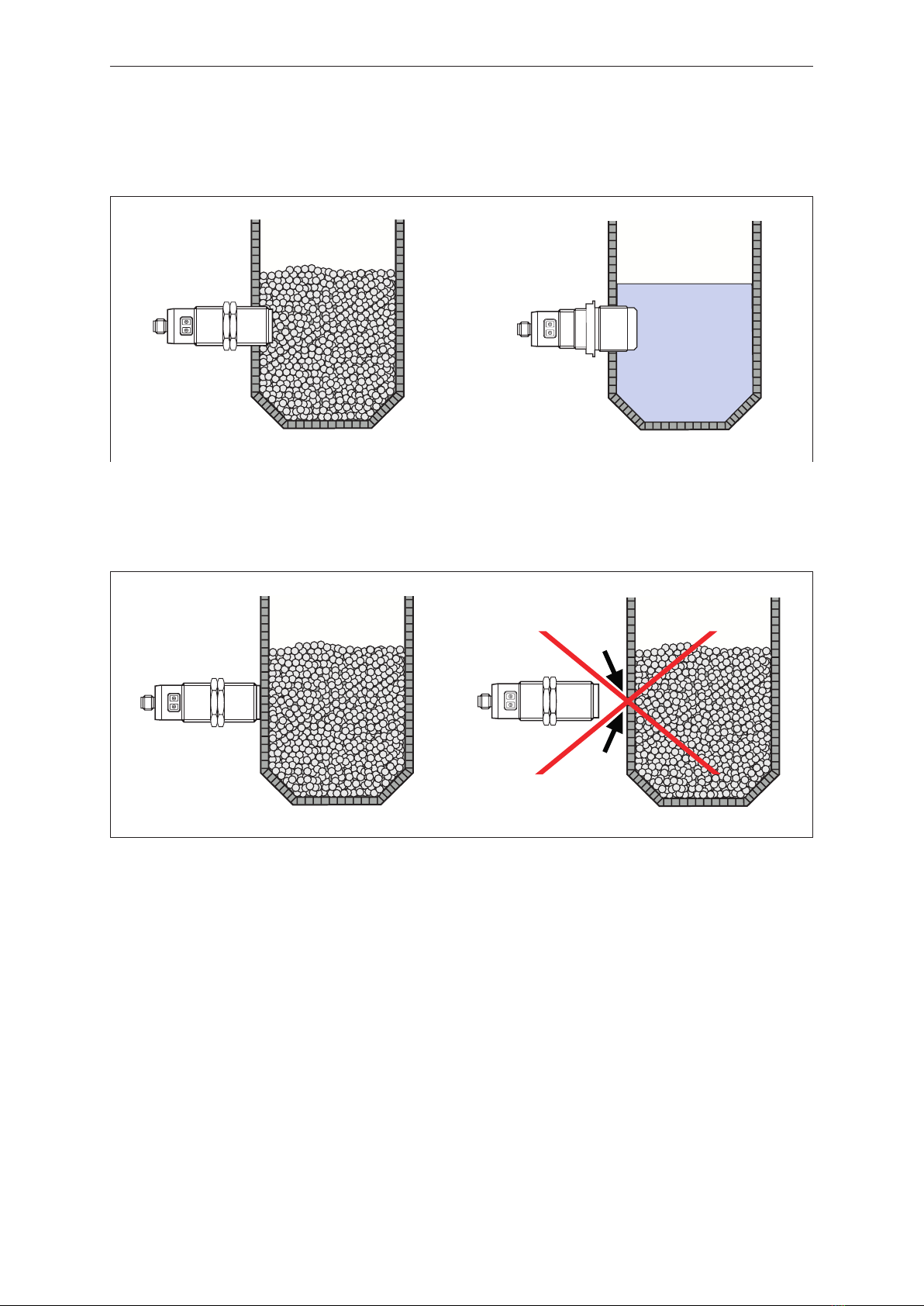

uEmpty the tank until the level is at least 20 mm below the device.

Set the device as normally open (output closes when the tank is full):

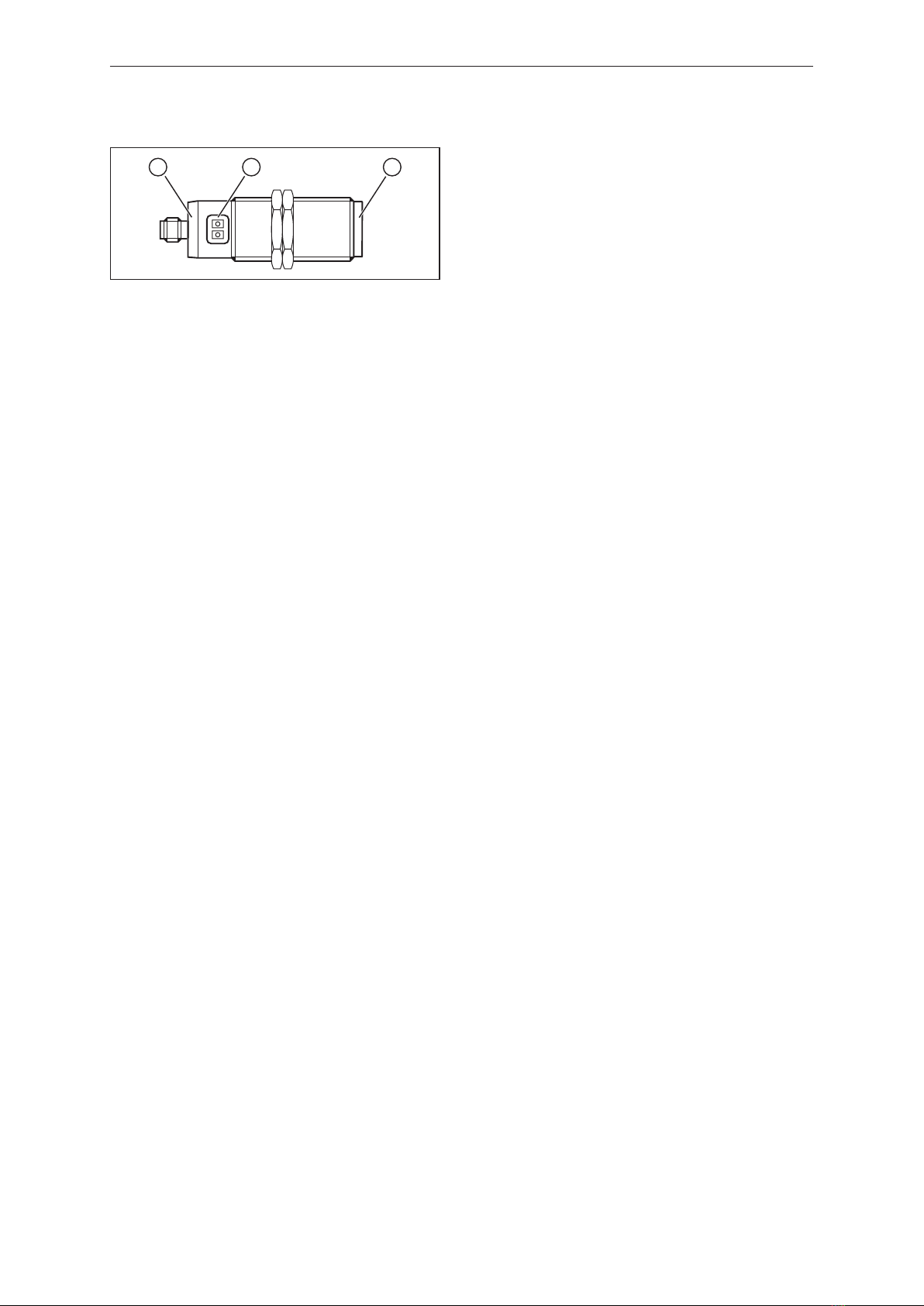

uPress the button [OUT OFF] for 2-6 seconds.

wWhile pressing the pushbutton the LED flashes slowly. After releasing the pushbutton, the LED

goes out.

Set the device as normally closed (output opens when the tank is full):

uPress the button [OUT ON] for 2-6 seconds.

wWhile pressing the pushbutton the LED flashes slowly. After releasing the pushbutton, the LED

lights continuously.

The device is now ready for operation.

For the detection of media with a low dielectric constant (e.g. plastic granulates or oils) no further

setting is required.

7.2 Adjustment teach full state

An adjustment teach full state is necessary for aqueous media. The sensitivity of the device is

optimised. The adjustment teach full state can be repeated at any time, a basic teach empty state

already carried out is not affected.

A basic teach empty state must be carried out prior to the adjustment teach full state!

If it is not possible to empty the tank, a basic teach empty state can be carried out by simulating

the empty state (e.g. adjustment when not installed, adjustment at a higher position).

uFor optimum function of the device, carry out a modified basic teach empty state when the

tank is emptied the next time.

uFill the tank until the sensing face of the device is covered.

wFor NO the LED lights, for NC it goes out.

Set the device as normally open (output closes when the tank is full):

uPress the button [OUT ON] for at least 6 seconds.

wWhile pressing the pushbutton the LED first flashes slowly, after 6 seconds more quickly. After

releasing the pushbutton, the LED lights continuously.

Set the device as normally closed (output opens when the tank is full):

uPress the button [OUT OFF] for at least 6 seconds.

wWhile pressing the pushbutton the LED first flashes slowly, after 6 seconds more quickly. After

releasing the pushbutton, the LED goes out.

7.3 Modified basic teach empty state

The modified basic teach empty state is recommended in case of deposits in the tank. It allows

deposits to be largely suppressed.