2

Contents

1 Preliminary note���������������������������������������������������������������������������������������������������3

1�1 Symbols used ������������������������������������������������������������������������������������������������3

2 Safety instructions �����������������������������������������������������������������������������������������������3

3 Functions and features ����������������������������������������������������������������������������������������4

3�1 Application area ��������������������������������������������������������������������������������������������4

3�2 Operating principle flow monitoring ���������������������������������������������������������������4

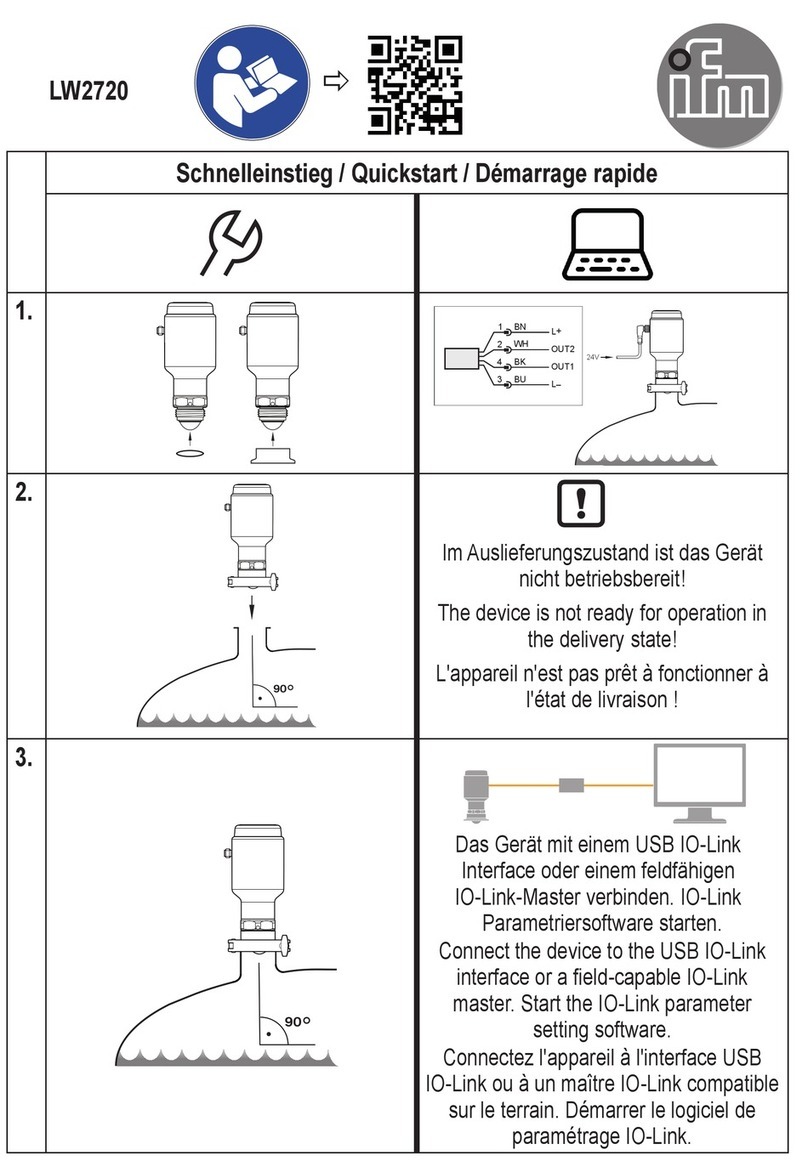

4 Installation������������������������������������������������������������������������������������������������������������5

4�1 Installation location ���������������������������������������������������������������������������������������5

4�2 Interference in the pipe system ���������������������������������������������������������������������6

4�3 Installation procedure ������������������������������������������������������������������������������������6

4�3�1 Installation using an adapter with sealing ring (hygiene-compliant) ����6

4�3�2 Installation using a welding adapter with sealing ring (hygiene-

compliant)�������������������������������������������������������������������������������������������������������7

4�3�3 Installation using a process adapter with metal-to-metal seal ��������������7

4�3�4 Installation to G 1 flange�����������������������������������������������������������������������7

4�4 Use in hygienic areas to 3-A��������������������������������������������������������������������������8

4�5 Use in hygienic areas to EHEDG ������������������������������������������������������������������8

5 Electrical connection��������������������������������������������������������������������������������������������9

6 Operating and display elements ������������������������������������������������������������������������10

7 Set-up and settings for water�����������������������������������������������������������������������������10

7�1 Change the switch point (optional) �������������������������������������������������������������� 11

7�2 High-flow adjustment (optional) ������������������������������������������������������������������� 11

8 Additional settings (optional) ����������������������������������������������������������������������������� 11

8�1 Low-flow adjustment������������������������������������������������������������������������������������ 11

8�2 Configure the switching output ��������������������������������������������������������������������12

8�3 Restore the factory setting (reset) ���������������������������������������������������������������12

8�4 Lock / unlock the unit�����������������������������������������������������������������������������������12

9 Error during adjustment �������������������������������������������������������������������������������������13

10 Operation���������������������������������������������������������������������������������������������������������14

11 Maintenance ����������������������������������������������������������������������������������������������������14