2

Contents

1 Preliminary note���������������������������������������������������������������������������������������������������3

1�1 Symbols used ������������������������������������������������������������������������������������������������3

2 Safety instructions �����������������������������������������������������������������������������������������������4

3 Functions and features ����������������������������������������������������������������������������������������4

3�1 Applications ���������������������������������������������������������������������������������������������������4

4 Function���������������������������������������������������������������������������������������������������������������5

4�1 Processing of the measured signals��������������������������������������������������������������5

4�2 Pressure monitoring / switching function �������������������������������������������������������6

4�3 Pressure monitoring / analogue function �������������������������������������������������������7

4�4 Customer-specific calibration ������������������������������������������������������������������������8

5 Installation������������������������������������������������������������������������������������������������������������9

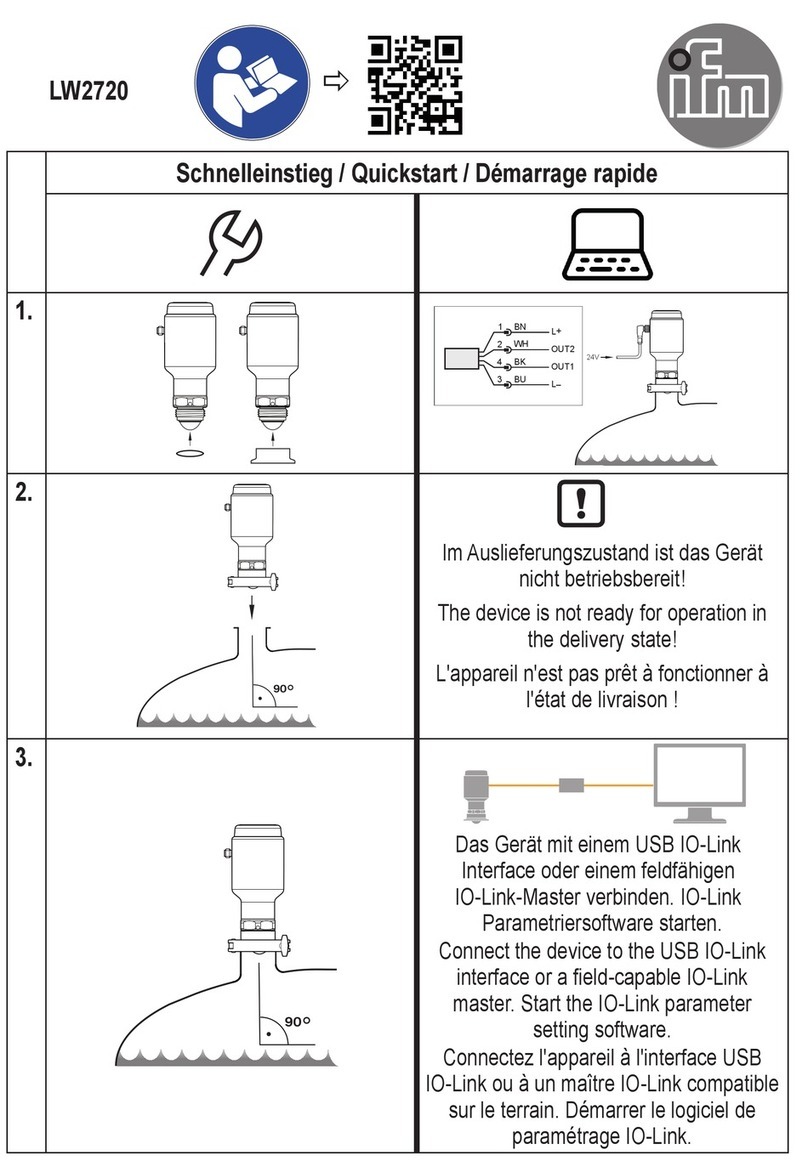

6 Electrical connection������������������������������������������������������������������������������������������10

7 Operating and display elements ������������������������������������������������������������������������ 11

8 Menu������������������������������������������������������������������������������������������������������������������12

8�1 Menu structure: main menu�������������������������������������������������������������������������12

8�2 Explanation of the main menu ���������������������������������������������������������������������13

8�3 Menu structure: level 2 (extended functions)�����������������������������������������������14

8�4 Explanation of the menu level 2 ������������������������������������������������������������������15

9 Parameter setting ����������������������������������������������������������������������������������������������16

9�1 General parameter setting���������������������������������������������������������������������������16

9�2 Configuration of the digital display (optional)�����������������������������������������������18

9�3 Set output signals ����������������������������������������������������������������������������������������19

9�3�1 Set output functions����������������������������������������������������������������������������19

9�3�2 Set switching limits ����������������������������������������������������������������������������19

9�3�3 Scale analogue value for OUT2 ���������������������������������������������������������19

9�4 User settings (optional)��������������������������������������������������������������������������������20

9�4�1 Carry out zero point calibration ����������������������������������������������������������20

9�4�2 Set delay time for OUT1 ���������������������������������������������������������������������20

9�4�3 Set switching logic for OUT1 ��������������������������������������������������������������20

9�4�4 Set damping for the switching signal ��������������������������������������������������20

9�4�5 Set damping for the analogue signal ��������������������������������������������������21

9�4�6 Calibrate curve of measured values ���������������������������������������������������21