3

UK

9�1 Parameter setting in general �����������������������������������������������������������������������18

9�1�1 Extended menu 1 �������������������������������������������������������������������������������19

9�1�2 Extended menu 2 �������������������������������������������������������������������������������19

9�1�3 Locking / unlocking �����������������������������������������������������������������������������19

9�1�4 Timeout�����������������������������������������������������������������������������������������������20

9�2 Settings for volumetric flow monitoring��������������������������������������������������������20

9�2�1 Adjustment to the internal pipe width��������������������������������������������������20

9�2�2 Configure limit value monitoring with OUT1 ���������������������������������������20

9�2�3 Configure limit value monitoring with OUT2 ���������������������������������������20

9�2�4 Configure analogue value for volumetric flow�������������������������������������20

9�3 Settings for consumed quantity monitoring �������������������������������������������������21

9�3�1 Configure quantity monitoring via pulse output ����������������������������������21

9�3�2 Configure quantity monitoring via the preset counter �������������������������21

9�3�3 Configure program-controlled meter reset������������������������������������������21

9�3�4 Deactivate meter reset �����������������������������������������������������������������������21

9�3�5 Configure meter reset using an external signal ����������������������������������21

9�4 Settings for temperature monitoring ������������������������������������������������������������22

9�4�1 Configure limit value monitoring with OUT2 ���������������������������������������22

9�4�2 Configure analogue value for temperature �����������������������������������������22

9�5 User settings (optional)��������������������������������������������������������������������������������22

9�5�1 Set standard unit of measurement for volumetric flow �����������������������22

9�5�2 Configure standard display�����������������������������������������������������������������23

9�5�3 Set output status in fault condition������������������������������������������������������23

9�5�4 Set measured value damping�������������������������������������������������������������23

9�5�5 Set low flow cut-off �����������������������������������������������������������������������������23

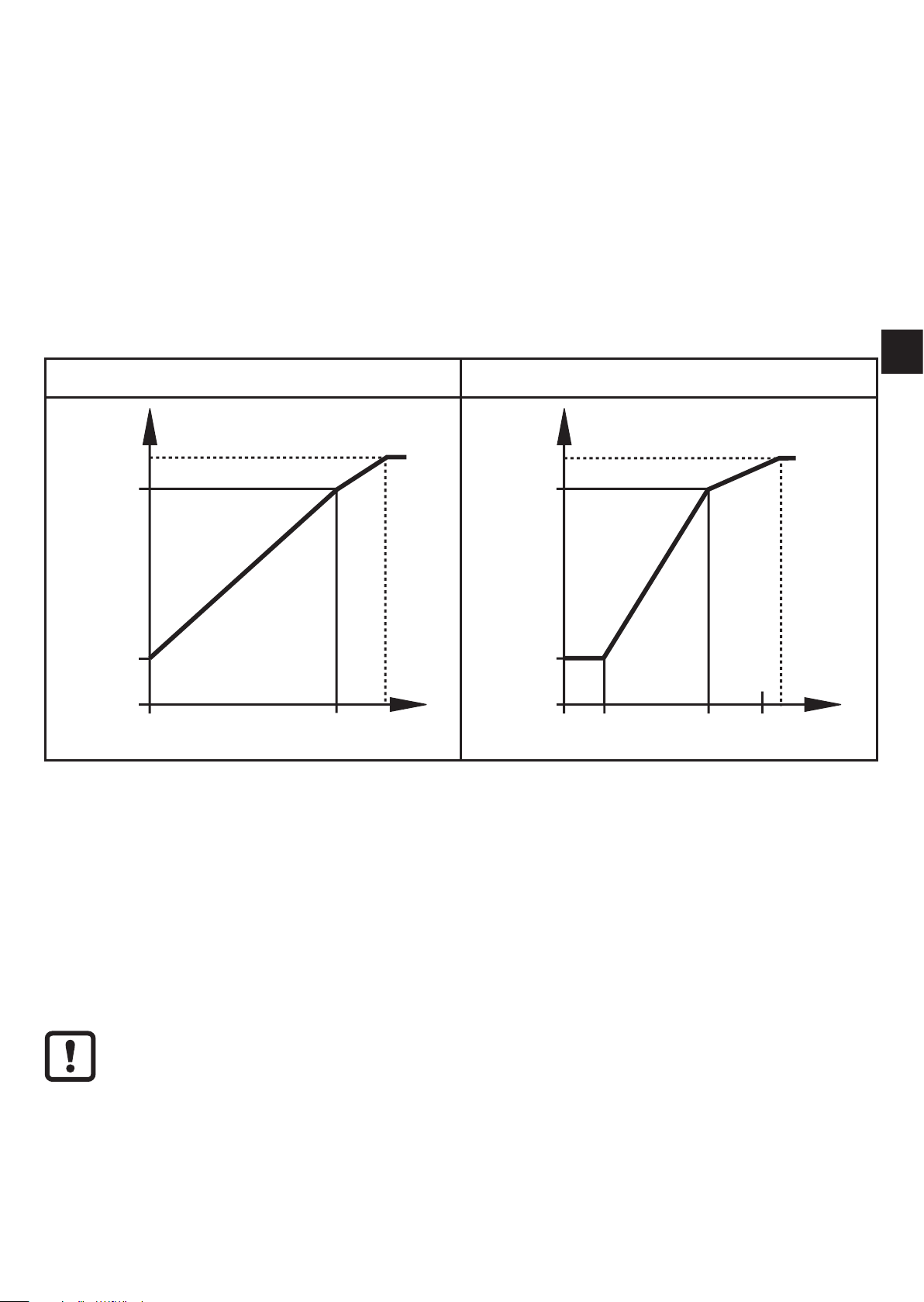

9�5�6 Calibrate curve of measured values ���������������������������������������������������23

9�5�7 Reset calibration data�������������������������������������������������������������������������24

9�5�8 Set standard pressure which serves as a reference for measured and

display values for volumetric flow�����������������������������������������������������������������24

9�5�9 Set standard temperature which serves as a reference for measured

and display values for volumetric flow����������������������������������������������������������24

9�6 Service functions �����������������������������������������������������������������������������������������24

9�6�1 Read min/max values for volumetric flow �������������������������������������������24

9�6�2 Reset all parameters to factory setting �����������������������������������������������24

9�7 Set preset counter / pulse value (ImPS)������������������������������������������������������25

10 Operation���������������������������������������������������������������������������������������������������������27

10�1 Read set parameters ���������������������������������������������������������������������������������27