2

Contents

1 Preliminary note���������������������������������������������������������������������������������������������������4

1�1 Symbols used ������������������������������������������������������������������������������������������������4

2 Safety instructions �����������������������������������������������������������������������������������������������4

3 Items supplied������������������������������������������������������������������������������������������������������5

4 Functions and features ����������������������������������������������������������������������������������������6

4�1 Operation with coaxial probe �������������������������������������������������������������������������6

4�2 Applications ���������������������������������������������������������������������������������������������������6

4�2�1 Restriction of the application area ��������������������������������������������������������7

5 Function���������������������������������������������������������������������������������������������������������������8

5�1 Measuring principle ���������������������������������������������������������������������������������������8

5�2 Features of the unit����������������������������������������������������������������������������������������8

5�2�1 Easy set-up�������������������������������������������������������������������������������������������8

5�2�2 Display functions ����������������������������������������������������������������������������������9

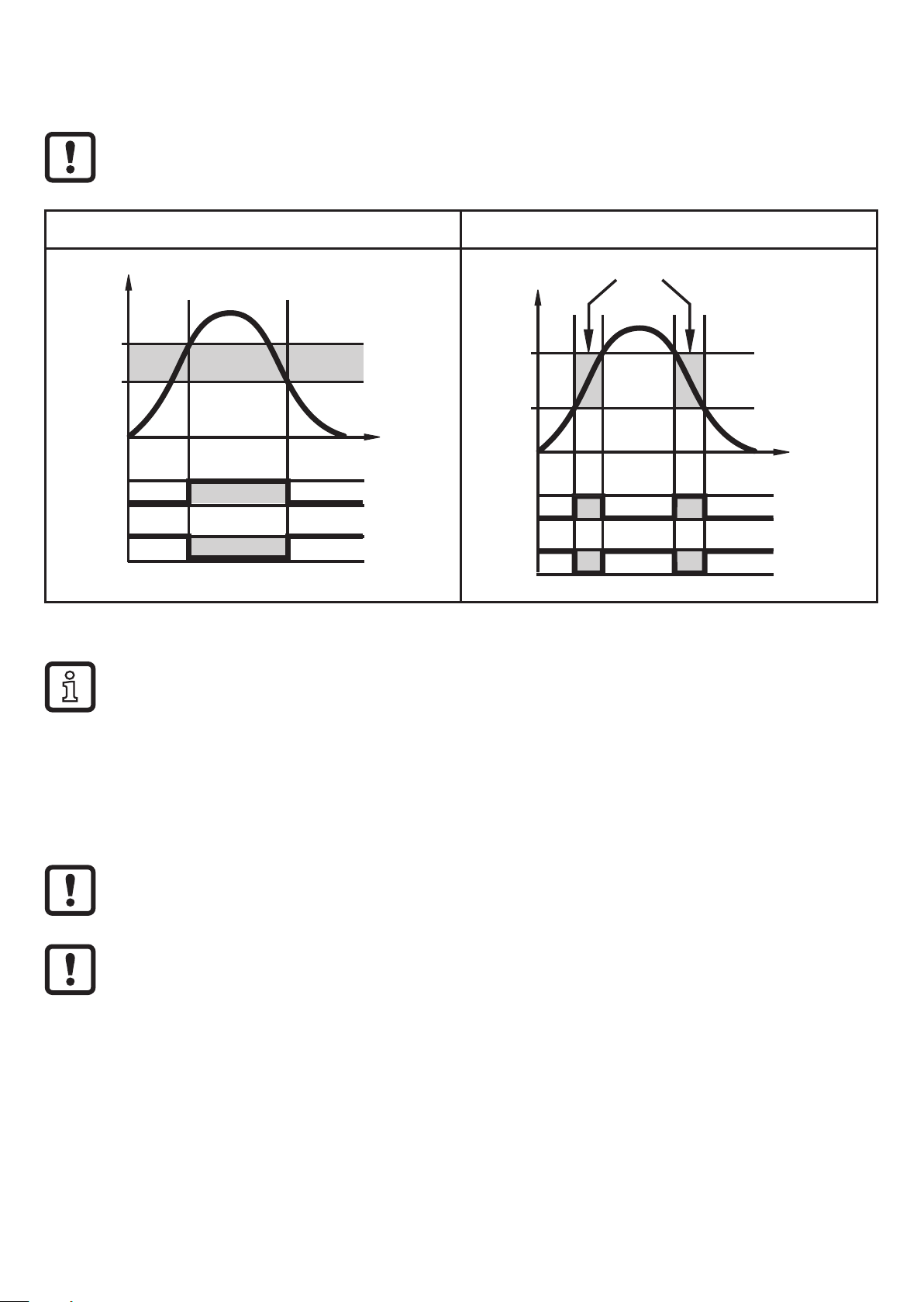

5�2�3 Switching functions�������������������������������������������������������������������������������9

5�2�4 Offset for indicating the real level in the tank��������������������������������������10

5�2�5 Probes for different tank heights��������������������������������������������������������� 11

5�2�6 Safe state ������������������������������������������������������������������������������������������� 11

5�2�7 IO-Link function ����������������������������������������������������������������������������������12

5�3 Password protection against inadvertent manipulation �������������������������������12

6 Installation����������������������������������������������������������������������������������������������������������12

6�1 Installation location / environment ���������������������������������������������������������������12

6�1�1 Coaxial probe �������������������������������������������������������������������������������������13

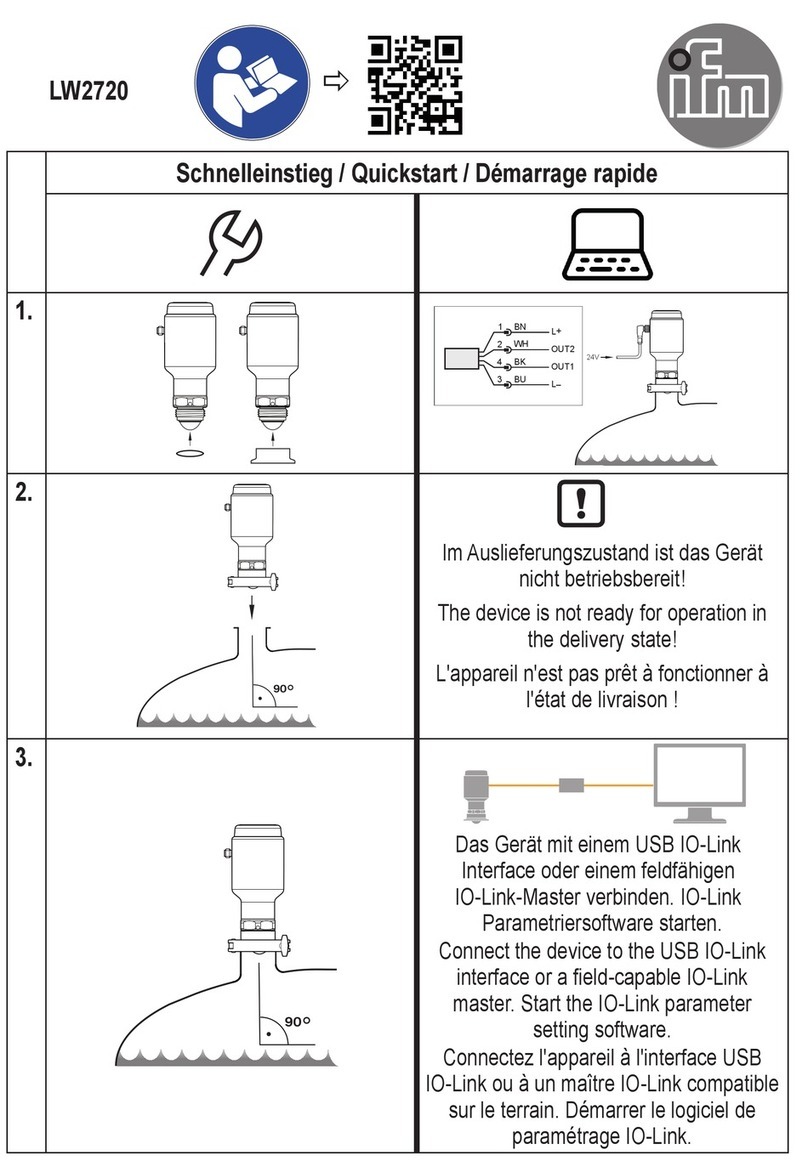

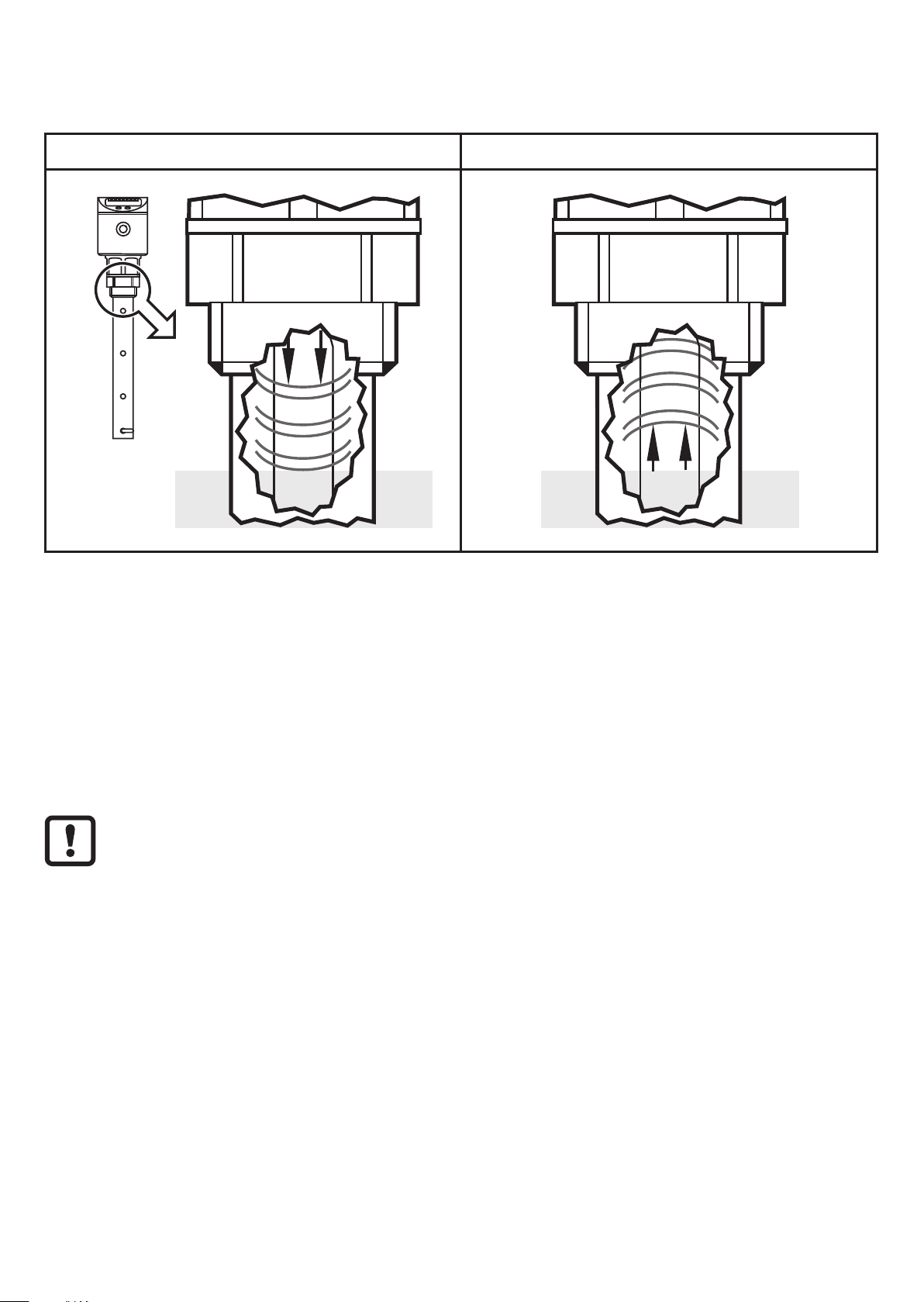

6�2 Probe installation �����������������������������������������������������������������������������������������13

6�2�1 Attaching the probe�����������������������������������������������������������������������������13

6�2�2 Installation of the coaxial pipe ������������������������������������������������������������14

6�3 Shortening of the probe �������������������������������������������������������������������������������15

6�3�1 How to shorten the probe and to determine its length������������������������15

6�3�2 Shortening of the coaxial pipe ������������������������������������������������������������16

6�3�3 Determination of the probe length L if the coaxial probe is mounted��16

6�4 Installation of the unit with coaxial probe in the tank �����������������������������������17

6�5 Alignment of the sensor housing �����������������������������������������������������������������17

7 Electrical connection������������������������������������������������������������������������������������������18

8 Operating and display elements ������������������������������������������������������������������������19