SI5012 Flow monitor

2

Contents

1 Preliminary note ............................................................. 3

1.1 Symbols used.......................................................... 3

1.2 Warnings used ......................................................... 3

2 Safety instructions............................................................ 4

3 Intended use................................................................ 5

4 Function ................................................................... 6

5 Installation.................................................................. 7

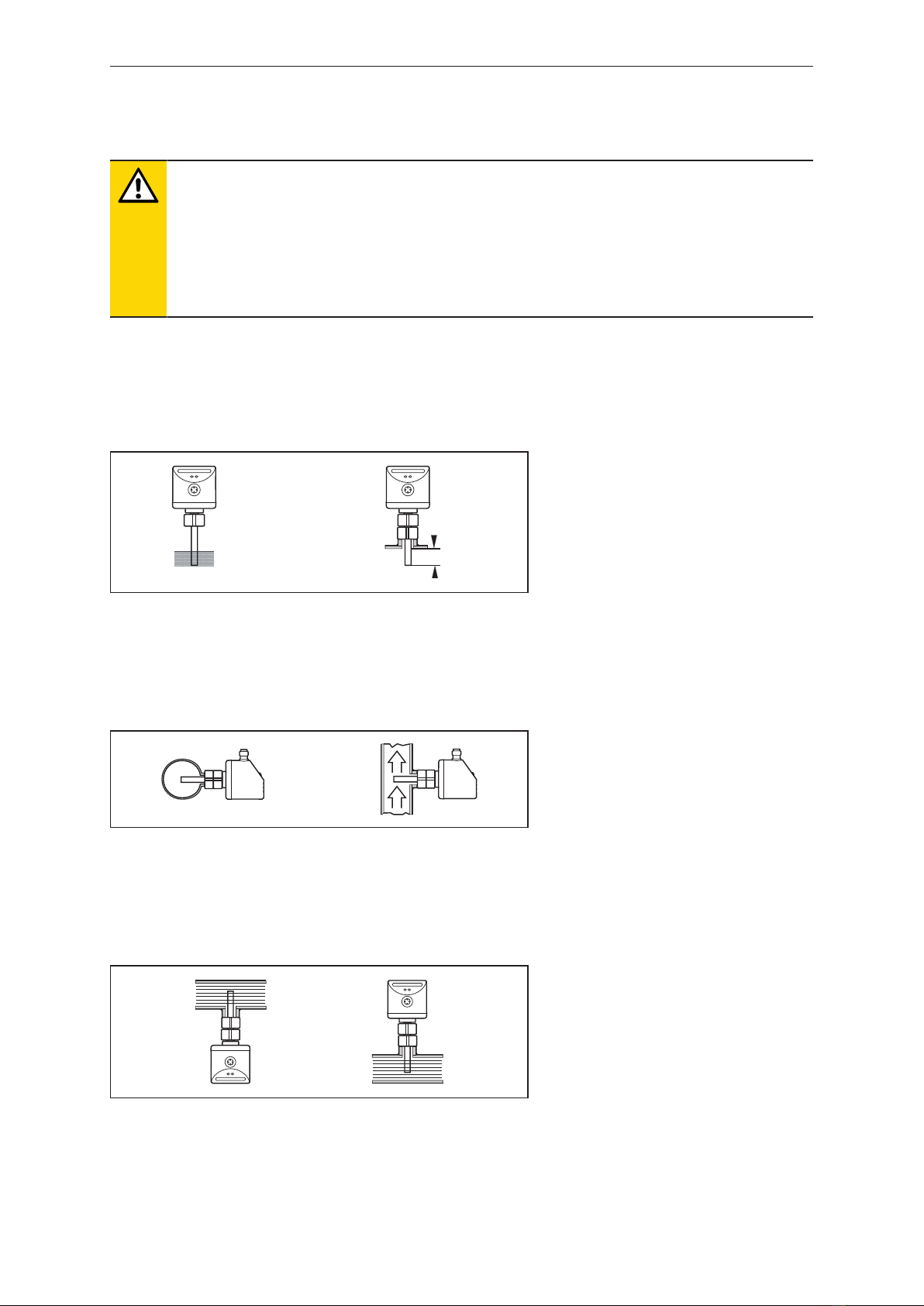

5.1 Installation position...................................................... 7

5.1.1 Immersion depth.................................................... 7

5.1.2 Recommended mounting position....................................... 7

5.1.3 Conditionally possible installation position. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5.1.4 Impermissible installation position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.2 Interference............................................................ 8

5.3 Process connection...................................................... 8

6 Electrical connection.......................................................... 10

7 Operating and display elements................................................. 11

8 Set-up..................................................................... 12

9 Settings.................................................................... 13

9.1 Changing the switch point................................................. 13

9.2 High-flow adjustment..................................................... 13

9.3 Low-flow adjustment..................................................... 13

9.4 Changing the switching logic............................................... 14

9.5 Restoring factory settings (reset)............................................ 14

9.6 Lock / unlock........................................................... 14

9.7 Remote calibration ...................................................... 14

10 Operation .................................................................. 15

11 Troubleshooting ............................................................. 16

12 Maintenance, repair and disposal................................................ 17