ifs NS3552-16P-2T-2S-V2 User manual

P/N 1073645-EN • REV E • ISS 04JUL22 1 / 6

NS3552-16P-2T-2S-V2 Quick Installation Guide

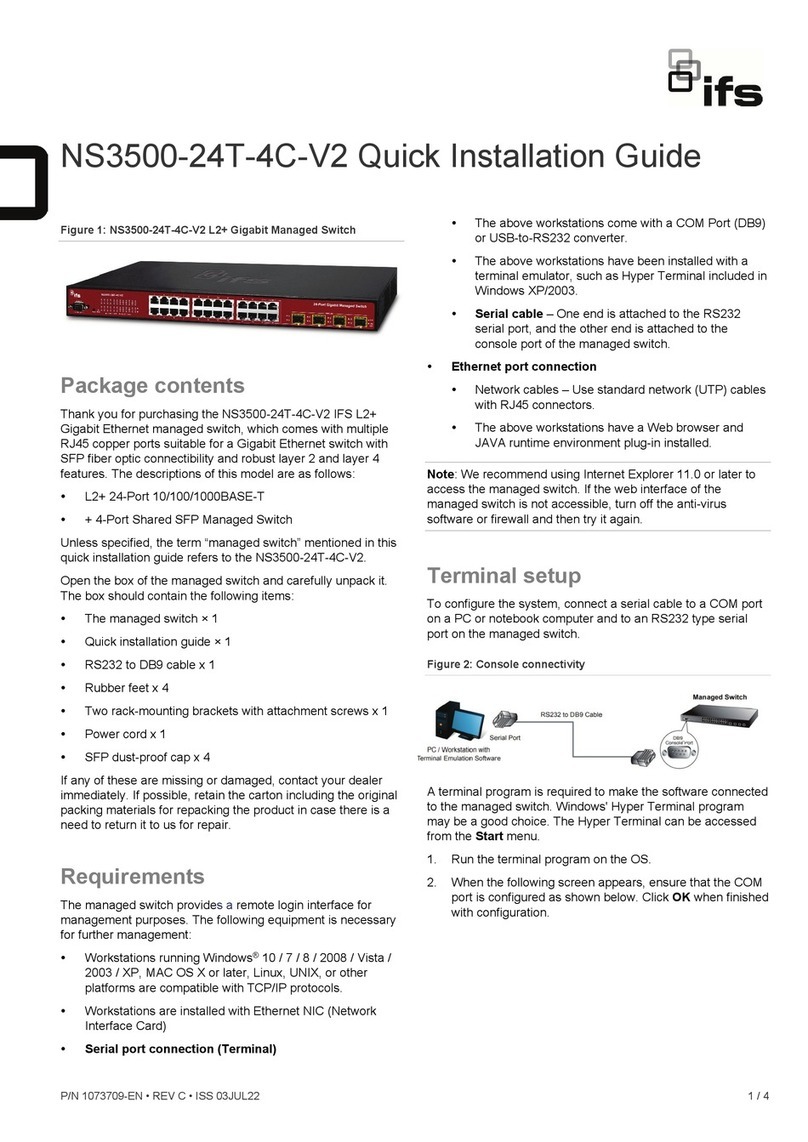

Figure 1: NS3552-16P-2T-2S-V2 Industrial L2+ Multi-port Full

Gigabit Managed Ethernet Switch

Package contents

Thank you for purchasing the NS3552-16P-2T-2S-V2 IFS L2+

industrial managed switch. The descriptionsof this model are

as follows:

Industrial 16-Port 10/100/1000T 802.3at PoE +

2-Port 10/100/100T

+ 2-Port 100/1000X SFP Managed Switch

Unless specified, the term “industrial managed switch”

mentioned in this quick installation guide refers to the NS3552-

16P-2T-2S-V2.

Open the box of the industrial managed switch and carefully

unpack it. The box should contain the following items:

The industrial managed switch × 1

Quick installation guide × 1

DIN rail kit × 1

Wall mounting kit × 1

DB9 to RJ45 interface RS232 console cable × 1

Dust cap (see the table below)

RJ45 Dust Cap SFP Dust Cap

NS3552-16P-2T-

2S-V2

19 2

If any of these are missing or damaged, contact your dealer

immediately. If possible, retain the carton including the original

packing materials for repacking the product in case there is a

need to return it to us for repair.

Requirements

The industrial managed switch providesaremote login

interface for management purposes. The following equipment

is necessary for further management:

Workstations running Windows®XP / 2003 / Vista / 7 / 8/

2008 / 10, MAC OS Xor later, Linux, UNIX,or other

platforms are compatible with TCP/IP protocols.

Workstations are installed with Ethernet NIC (Network

Interface Card)

Serial port connection (Terminal)

The above workstations come with aCOM Port (DB9)

or USB-to-RS232 converter.

The above workstationshave been installed with a

terminal emulator, such as Tera Term, PuTTY, or

Hyper Terminal included in Windows.

Serial cable – One end is attached to the RS232

serial port, and the other end is attached to the

console port of the managed switch.

Ethernet port connection

Network cables – Use standard network (UTP) cables

with RJ45 connectors.

The above workstations have a web browser and

JAVA runtime environment plug-in installed.

Note: We recommend using Internet Explorer11.0 or later to

access the industrial managed switch. If the web interface of

the industrial managed switch is not accessible, turn off the

anti-virus software or firewall and then try it again.

Wiring the power inputs

The upper panel of the industrial managed switch indicates a

DC inlet power socket and consists of one terminal block

connector within six contacts. Follow the steps below to insert

the power wire:

1. Insert the positive/negative DC power wires into contacts 1

and 2 for Power 1, or 5, and 6 for Power 2.

NS3552-16P-2T-2S-V2 : DC 48~56V

2 / 6 P/N 1073645-EN • REV E • ISS 04JUL22

Figure 2: NS3552-16P upper panel

2. Tighten the wire-clamp screws to prevent the wires from

loosening.

1

2

3

4

5

6

Power 1

Power 2

Positive (+) Pin Negative (-) Pin

NS3552-16P Pin 1/5 Pin 2/6

Note: The wire gauge for the terminal block should be in the

range from 12 to 24 AWG.

Mounting

Note: Ensure that the industrial managed switch is mounted

vertically with the power connectors on the top and a minimum

of three inches above and below the switch to allow for proper

air flow. This device uses a convection flow of hot air which

rises and brings cold air in from the bottom and out of the top

of the device. Do not mount the switch horizontally as this does

not allow air to flow up into the device and will result in damage

to the switch. Do not tie DC1 to DC2. DC2 is for secondary

power redundancy. Do not plug DC power into the device while

the AC power cord is plugged in. This is not a hot-swappable

switch. Hot-swapping this device will result in damage.

DIN-rail mounting installation

To replace the wall-mount application with DIN-rail application

on industrial gigabit Ethernet switch, refer to the following

figuresto screw the DIN-rail on the industrial gigabit Ethernet

switch.

To hang the industrial gigabit Ethernet switch, follow the steps

below:

1. Screw the DIN-rail on the industrial gigabit Ethernet

switch.

2. Place the bottom of DIN-rail lightly into the track.

3. Ensure that the DIN-rail is secured to the track.

To remove the industrial gigabit Ethernet switch from the track,

carefully pull out the bottomof the DIN-rail to remove it from

the track.

Wall-mount plate mounting

To install the industrial gigabit Ethernet switch on the wall,

follow the steps below.

P/N 1073645-EN • REV E • ISS 04JUL22 3 / 6

1. Remove the DIN-rail from the industrial gigabit Ethernet

switch. Loosenthe screws to remove the DIN-rail.

2. Place the wall-mount plate on the rear panel of the

industrial gigabit Ethernet switch.

3. Use the screws to screw the wall-mount plate on the

industrial gigabit Ethernet switch.

4. Use the hook holes at the corners of the wall-mount plate

to hang the industrial gigabit Ethernet switch on the wall.

5. To remove the wall-mount plate, reverse the steps above.

Terminal setup

To configure the system, connect a serial cable to a COM port

on a PC or notebook computer and to RJ45 type serial

(console) port of the industrial managed switch. The console

port of the industrial managed switch is DCE already so that

you can connect the console port directly through acomputer

without the need of null modem.

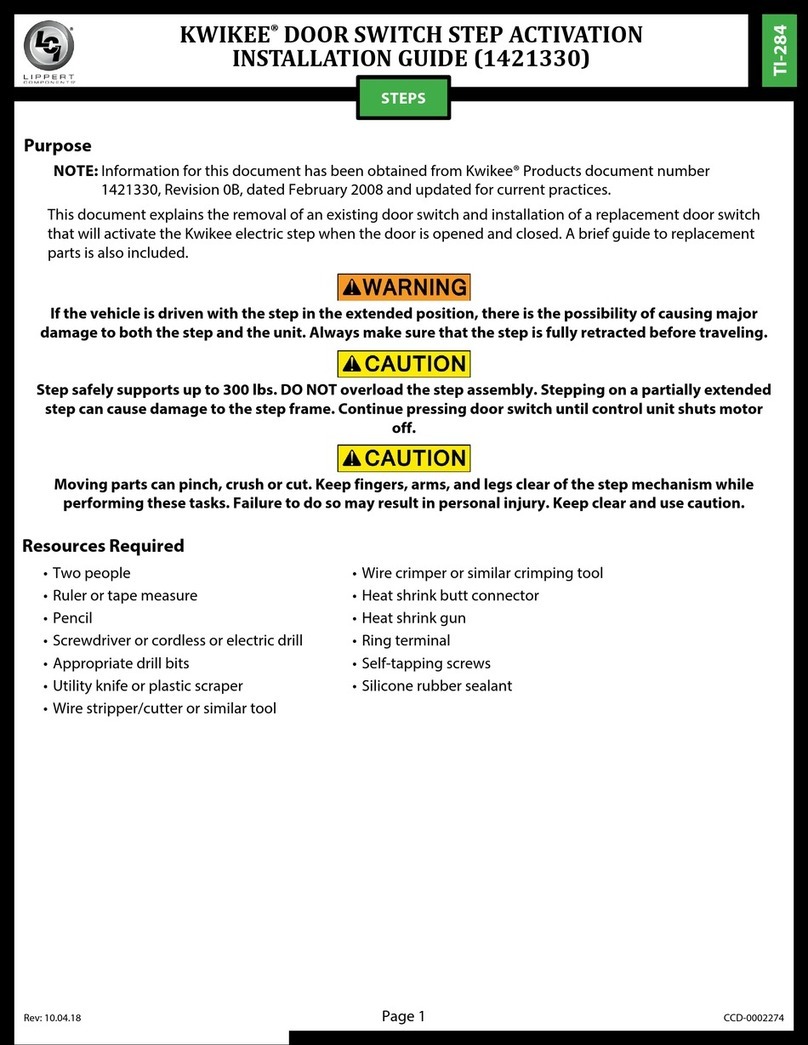

Figure 3: Managed industrial switch console connectivity

A terminal program is required to make the software connected

to the industrial managed switch. Windows' Hyper Terminal

program may be a good choice. The Hyper Terminal can be

accessed from the Start menu.

1. Click Start > Programs > Accessories > Hyper

Terminal.

2. When the following screen appears, ensure that the COM

port is configured as shown below. Click OK when finished

with configuration.

3. Log in to the console.

After the terminal has been connected to the device, power on

the industrial managed switch. The terminal displays“running

testing procedures”.

When the following dialog box in Figure 4 below appears, type

the factory default user name "admin" and password “admin”.

User name: admin

Password: admin

Figure 4: Console login screen

After logging on to the console with default account

(admin/admin), a user name and password change is required

using the “newsername” command.

After a successful user name and password change, the new

user name and password must be used for subsequent logins.

Note:

1. For security purposes, memorize the new password after

this first setup.

2. Only commandsin lowercase letters are accepted in the

console interface.

Configuring the IP address

The industrial managed switch is shipped with the default IP

address shown below:

IP Address: 192.168.0.100

Subnet Mask: 255.255.255.0

Note: Before connecting to a TruVision Navigator video

surveillance system network, the default IP address must be

changed to the IP address assigned for TruNav by the network

administrator.

4 / 6 P/N 1073645-EN • REV E • ISS 04JUL22

To check the current IP address or modify a new IP address

for the industrial managed switch, use the following

procedures:

Display of the current IP Address

1. At the “#” prompt, type “show ip interface brief”.

2. The screen displays the current IP address.

Figure 5: IP information screen

Configuration of the IP address

3. At the “#” prompt, type the following command and press

Enter as shownin Figure 6.

NS3552-16P-2T-2S-V2# configure terminal

NS3552-16P-2T-2S-V2 (config)# interface vlan 1

NS3552-16P-2T-2S-V2 (config-if-vlan)# ip address

192.168.1.100 255.255.255.0

The previous command would apply the following settings

for the industrial managed switch.

IP Address: 192.168.1.100

Subnet Mask: 255.255.255.0

Figure 6: Configuring the IP address screen

4. Repeat step 1 to check if the IP address has changed.

Store the current switch configuration

5. At the “#” prompt, type the following command and press

Enter.

# copy running-config startup-config

Figure 7: Saving current configuration command screen

If the IP is successfully configured, the industrial managed

switch applies the new IP address setting immediately. Access

the web interface of the industrial managed switch through the

new IP address.

Note: If unfamiliar with the console command or the related

parameter, type “help” in the console to obtain the Help

description.

Starting web management

The section describes how to start up the web management

function for the industrial managed switch. Note that the

industrial managed switch is configured through an Ethernet

connection. Ensure that the manager computer is set to the

same IP subnet address.

For example, if the default IP address of the industrial

managed switch is 192.168.0.100, then the manager computer

should be set to 192.168.0.x (where x is a number between 1

and 254, except 100), and the default subnet mask is

255.255.255.0.

Figure 8: IP management diagram

Logging in to the industrial managed switch

1. Use the Internet Explorer 11.0 or later web browser and

type the IP address http://192.168.0.100 (the factory-

default IP address) to access the web interface.

2. When the following dialog box appears, enter the default

user name “admin” and password “admin” (or the

password you have changed before)as shown in Figure 9

below.

Default IP Address: 192.168.0.100

Default User Name: admin

Default Password: admin

Note: Before connecting to a TruVision Navigator video

surveillance system network, the default IP address must be

changed to the IP address assigned for TruNav by the network

administrator.

Figure 9: Login screen

3. Click OK to begin the process of changing the default

username and password.

4. Type a new username and password in the Edit User

page, following the guidelines as shown. Click Apply.

P/N 1073645-EN • REV E • ISS 04JUL22 5 / 6

5. When the success window appears, click OK.

6. After typing the new username and password in the login

window,the main screen appears.

Figure 10: Main web interface screen

7. The switch menu on the left side of the web page permits

access all the functions and status provided by the

industrial managed switch.

Refer to the User Manual for further information about using

the web management interface.

Note: For added security, a logged in user is automatically

logged out after five minutes of inactivity.

Saving the configuration

The running configuration file is stored in the RAM of the

industrial managed switch. In the current version, the running

configuration sequence of running-config can be saved from

the RAM to FLASH by executing the Save Configuration

command. After doing this, the running configuration sequence

becomes the startup configuration file (i.e., the saved

configuration).

To save all applied changes and set the current configuration

as a startup configuration, the startup-configuration file is

loaded automatically across a system reboot.

1. Click System > Save Startup Config.

2. Click the Save Configuration button.

Resetting the switch to default

To reset the IP address to the default IP address

“192.168.0.100” and the userpassword to factory default mode

(default password is “admin”), press the hardware reset button

on the front panel for about 10 seconds. After the device is

rebooted, log in to the management web interface within the

same subnet of 192.168.0.xx and default password. Note that

all the previous setups are erased after the factory default

reset.

Figure 11: Industrial managed switch reset button

6 / 6 P/N 1073645-EN • REV E • ISS 04JUL22

Contact information

Europe, Middle East, and Africa

W

Go to www.firesecurityproducts.com/en/contact

Australia

E

cs@firesecurityproducts.zendesk.com

W

www.firesecurityproducts.com.au/support

Legal and regulatory information

Copyright

©

2022 Carrier. All rights reserved.

Specifications subject to change w

ithout prior

notice

.

This document may not be copied in whole or in

part or otherwise reproduced without prior

written consent from

Carrier, except where

specifically permitted under US and

international copyright law.

Trademarks and

patents

IFS

names and logos are a product brand of

Aritech, a part of

Carrier.

Other trade names used in this document may

be trademarks or registered trademarks of the

manufacturers or vendors of the respective

products.

Manufacturer

PLACED ON THE MARKET BY:

Carrier Fire & Security Americas Corporation

Inc.

13995 Pasteur Blvd, Palm Beach Gardens, FL

33418, USA

AUTHORIZED EU REPRENSENTATIVE:

Carrier Fire & Security B.V.

Kelvinstraat 7, 6003 DH Weert, Netherlands

Certification

2012/19/EU (WEEE directive):

Products

marked with this symbol cannot be disposed of

as unsorted municipal waste in the European

Union. For proper recycling, return this product

to your local supplier upon the

purchase of

equivalent new equipment, or dispose of it at

designated collection points. For more

information see: www.recyclethis.info.

Product

documentation

Please consult the following web link to retrieve

the electronic version of the product

documentation.

The manuals are available in

several languages.

Table of contents

Other ifs Switch manuals

ifs

ifs NS3502-8P-2T-2S-V3 User manual

ifs

ifs NS4702-24P-4X-V2 User manual

ifs

ifs NS3562-8P-2S-V2 User manual

ifs

ifs NS3503-16P-4C-V2 User manual

ifs

ifs NS4750-24S-4T-4X-V2 User manual

ifs

ifs NS2052-8P-2C User manual

ifs

ifs NS4802-24P-4S-2X User manual

ifs

ifs ES2402-V3 Series User manual

ifs

ifs POC2502 Series User manual

ifs

ifs NS3562-8P-2S-V2 User manual

Popular Switch manuals by other brands

ZWaveProducts

ZWaveProducts ZW500D installation instructions

Leonton

Leonton EG5-0702-SFP Series user manual

Asus

Asus GIGAX 1008B Quick installation guide

3One data

3One data IES206 Series Quick installation guide

SMC Networks

SMC Networks TigerSwitch 1000 Specifications

Pickering

Pickering 40-193A user manual