IKA HB digital User manual

Other IKA Laboratory Equipment manuals

IKA

IKA IKATRON ETS-D6 User manual

IKA

IKA KMO 3 basic User manual

IKA

IKA RH basic 1 User manual

IKA

IKA T 10 basic User manual

IKA

IKA Vortex 4 digital User manual

IKA

IKA LR 1000 basic User manual

IKA

IKA Algaemaster 10 User manual

IKA

IKA Color Squid User manual

IKA

IKA HS 260 Basic User manual

IKA

IKA HB 10 basic User manual

IKA

IKA MS 450 Swirler User manual

IKA

IKA RCT basic safety control User manual

IKA

IKA ULTRA-TURRAX T 25 digital User manual

IKA

IKA RCT basic User manual

IKA

IKA ElektraSyn 2.0 User manual

IKA

IKA Big Squid User manual

IKA

IKA RO 5 User manual

IKA

IKA ULTRA-TURRAX T 50 basic User manual

IKA

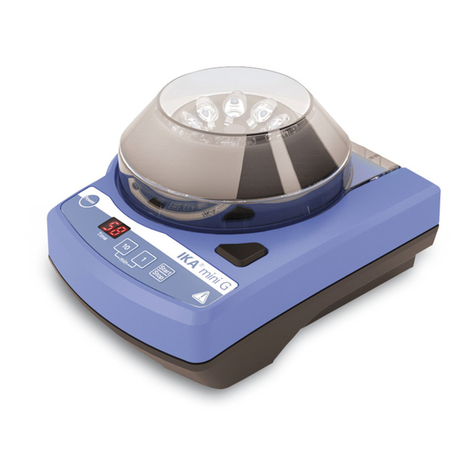

IKA mini G User manual

IKA

IKA 50198.01 User manual

Popular Laboratory Equipment manuals by other brands

Qiagen

Qiagen DML 3000 user manual

Queensgate

Queensgate NANOSCAN OP400 Quick start instructions

Conviron

Conviron GEN1000-GE Operator's manual

Parr Instrument

Parr Instrument 4560 Operating instructions manual

Integra

Integra DOSE IT operating instructions

Agilent Technologies

Agilent Technologies 5800 ICP-OES user guide

Endress+Hauser

Endress+Hauser Cleanfit CPA875 operating instructions

NI

NI PXI-5422 CALIBRATION PROCEDURE

Collomix

Collomix Aqix operating instructions

SPEX SamplePrep

SPEX SamplePrep 6875 Freezer/Mill Series operating manual

Ocean Insight

Ocean Insight FLAME-NIR+ Installation and operation manual

Parker

Parker ALIGN-MG-NA Installation, operation and maintenance manual