i

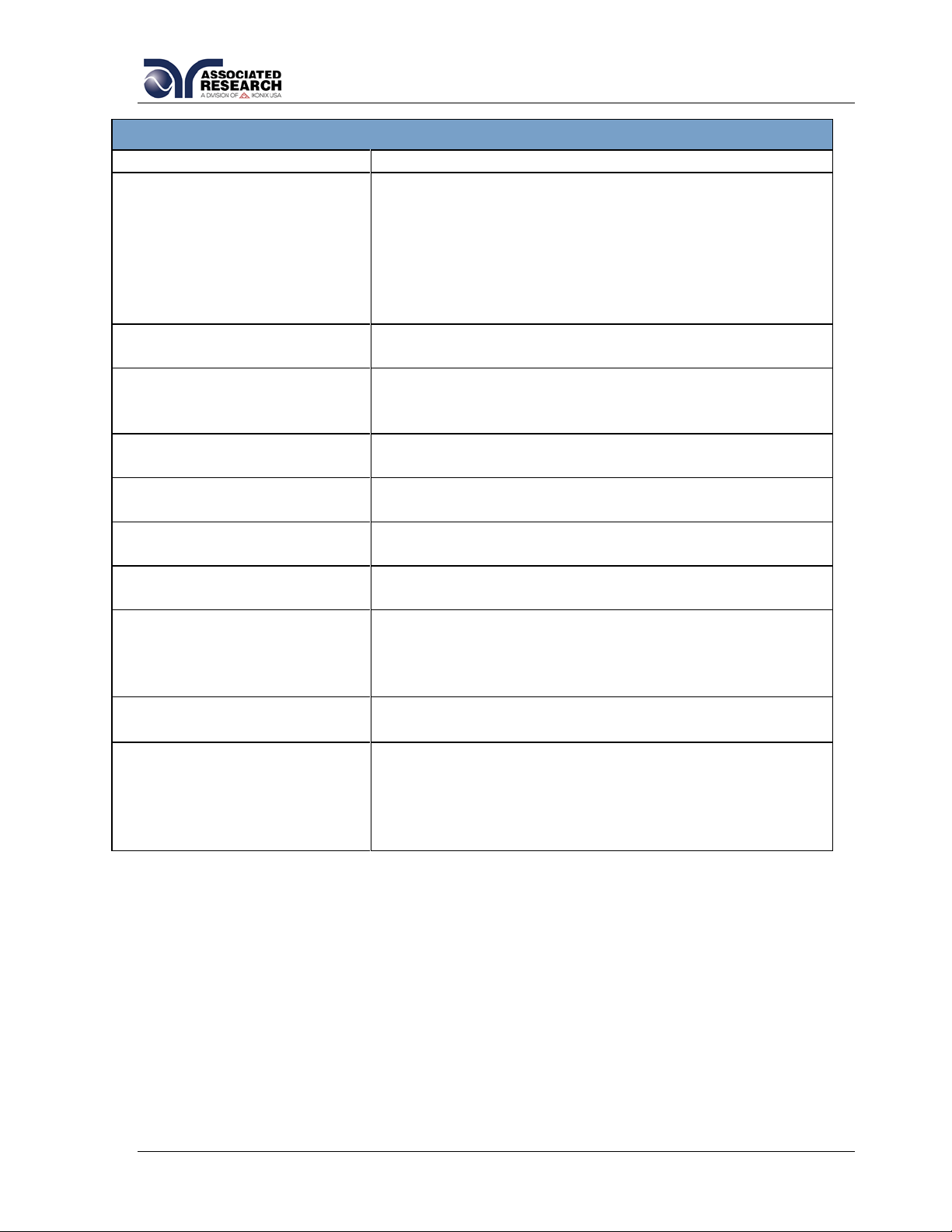

TABLE OF CONTENTS

1. INTRODUCTION ..............................................................................................1

1.1. Warranty Policies...........................................................................................1

1.2. Safety Symbols..............................................................................................3

1.2.1. Product Marking Symbols..................................................................3

1.2.2. Caution and Warning Symbols..........................................................3

1.3. Glossary of Terms.........................................................................................3

1.4. Safety ..............................................................................................................5

1.4.1. Service and Maintenance ..................................................................5

1.4.2. Test Station..........................................................................................6

1.4.3. Test Operator.......................................................................................7

1.5. Key Features and Benefits...........................................................................9

2. GETTING STARTED......................................................................................10

2.1. Unpacking and Inspection..........................................................................10

2.1.1. Packaging...........................................................................................10

2.1.2. Contents of Carton............................................................................10

2.1.3. Returning the Instrument for Service or CalibrationError! Bookmark

not defined.

2.2. Installation.....................................................................................................12

2.2.1. Work Area...........................................................................................12

2.2.2. Power Requirements........................................................................12

2.2.3. Basic Connections ............................................................................13

2.2.4. Environmental Conditions................................................................13

3. SPECIFICATIONS AND CONTROLS............................................................15

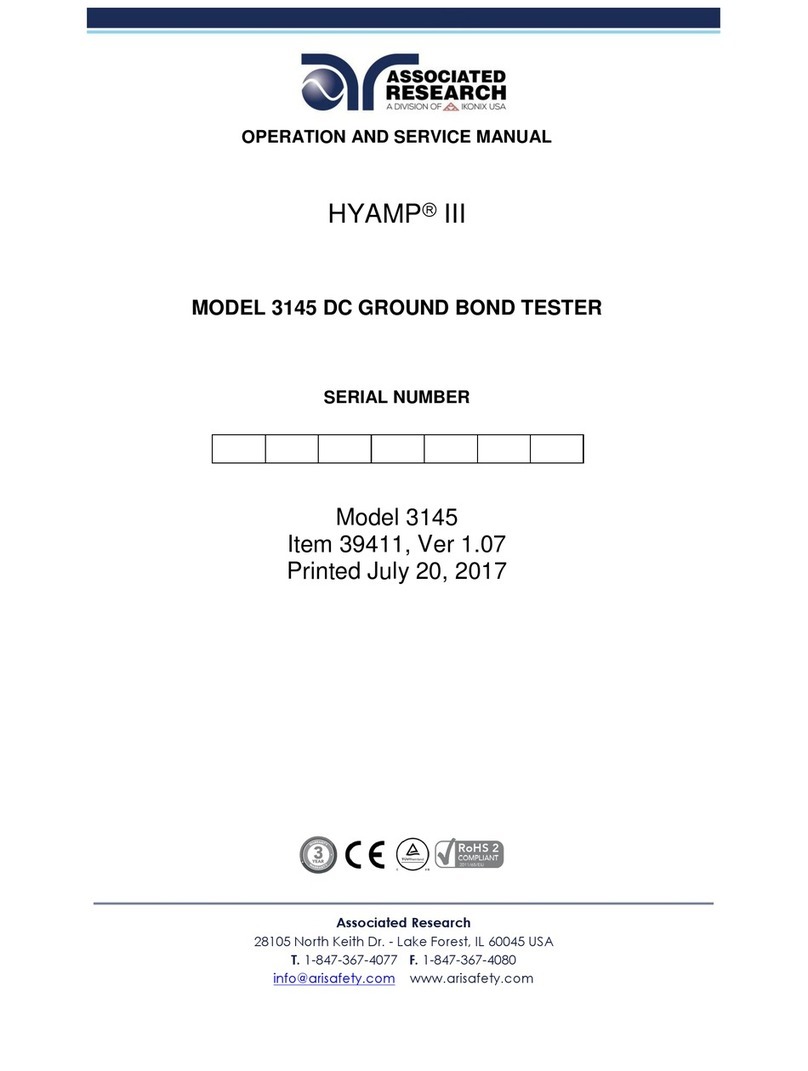

3.1. HYAMP III Functional Specifications........................................................15

3.2. Instrument Controls.....................................................................................17

3.2.1. Front Panel Controls.........................................................................17

3.2.2. Rear Panel Controls .........................................................................18

4. PROGRAMMING INSTRUCTIONS................................................................20

4.1. Power Up......................................................................................................20

4.1.1. Memory, Step and Connected Step Indicator...............................20

4.1.2. Main Menu..........................................................................................20

4.1.3. Results, Tests and System Selections ..........................................21

4.2. System Setup...............................................................................................22

4.2.1. System Setup Soft keys...................................................................23

4.2.2. System Parameters ..........................................................................23

4.2.3. Default System Parameters.............................................................28

4.2.4. Memory, Step, and Default System Parameter Initialization......28

4.3. Test Setup ....................................................................................................28

4.3.1. Test Setup Soft Keys........................................................................29