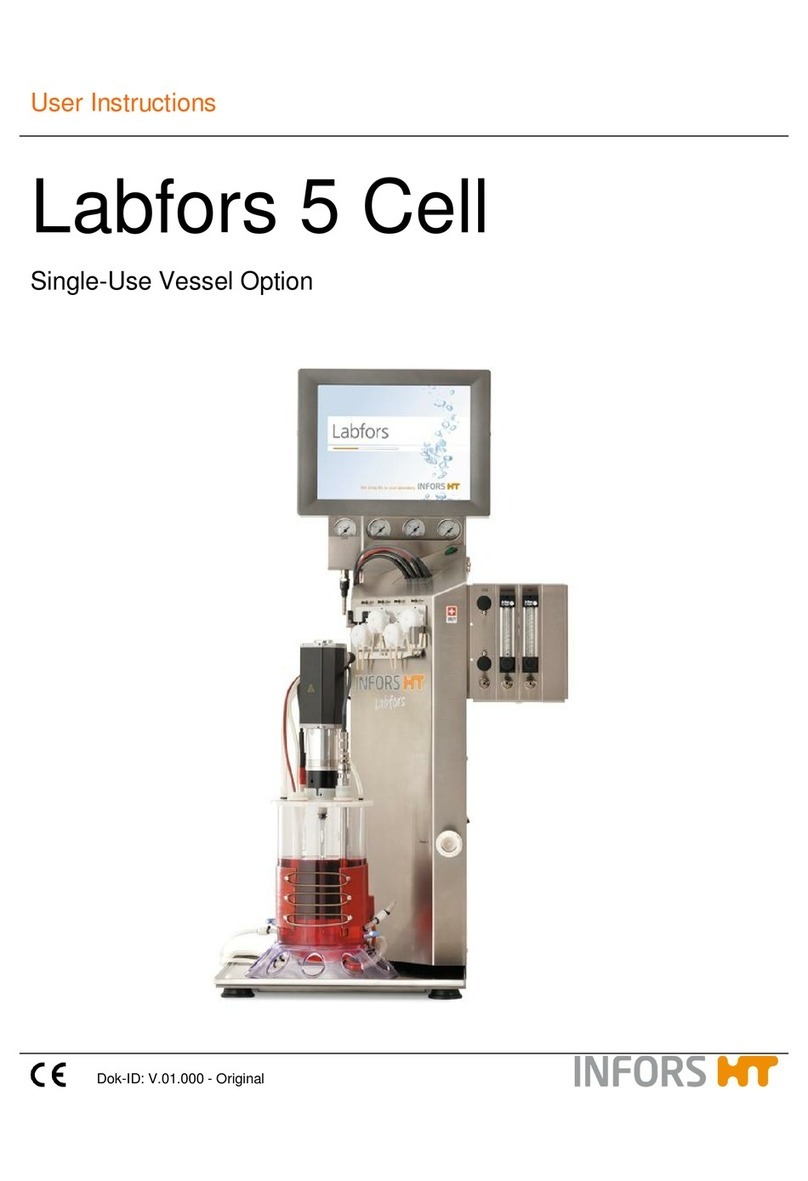

Infors HT Labfors 5 User manual

Operating Manual

2019-01-22

Labfors 5

Bench-Top Bioreactor - Version for Microorganisms

Dok-ID: 76561 / V.02.00 - Original

Infors AG

Headoffice, Schweiz

Rittergasse 27

CH-4103 Bottmingen

T +41 (0)61 425 77 00

F +41 (0)61 425 77 01

info@infors-ht.com

service@infors-ht.com

Infors GmbH

Dachauer Str. 6

D-85254 Einsbach

T +49 (0)8135 8333

F +49 (0)8135 8320

infors.de@infors-ht.com

Infors UK Ltd

The Courtyard Business Centre

Dovers Farm, Lonesome Lane,

Reigate

Surrey, RH2 7QT, UK

T +44 (0)1737 22 31 00

F +44 (0)1737 24 72 13

infors.uk@infors-ht.com

Infors Sarl

2, rue du Buisson aux Fraises

Bâtiment D13

F-91300 Massy

T +33 (0)1 69 30 95 04

F +33 (0)1 69 30 95 05

infors.fr@infors-ht.com

www.infors-ht.fr

Infors Benelux BV

Markweg 9-A, NL-6883 JL

Velp (GLD)

P.O. Box 125, NL-6880 AC

Velp (GLD)

T +31 (0)26 369 31 00

F +31 (0)26 369 31 09

infors.bnl@infors-ht.com

Infors USA Inc.

9070 Junction Drive, Suite D

Annapolis Junction, MD20701

T +1 301 362 3710 /

T +1 855 520 7277 (toll-free USA)

F +1 301 362 3570

infors.usa@infors-ht.com

www.infors-ht.us

Infors Canada

8350 rue Bombardier

Anjou, Quebec

Canada H1J 1A6

T +1 514 352 5095

F +1 514 352 5610

infors.ca@infors-ht.com

Infors Bio-Technology

(Beijing) Co., Ltd.

Room 505C, Building 106

Lize Zhongyuan

Wangjing New Industrial Zone

Chaoyang District, Beijing

100102 P.R. of China

T +86 10 51652068

F +86 10 64390585

info@infors-ht.com.cn

Infors South East Asia

16, 1st Floor, Taman City

MY-51200 Kuala Lumpur

Malaysia

T +603 625 771 81

F +603 625 067 48

info@infors-ht.com.my

Infors LATAM Ltda.

Rua Dr. Alceu de Campos

Conjunto 205

CEP: 04544-000

São Paulo – SP

Brasil

T +55 (11) 95304-0201

F +55 (11) 98585-5334

Infors.br@infors-ht.com

Contact details of our local dealers worldwide can be found

on our website.

www.infors-ht.com

Engineering and production in Switzerland

Labfors 5 – Version for Microorganisms

Table of Contents

22 January 2019 Page 1of 205

1General Information ...............................................................9

1.1 About this Manual ..........................................................9

1.2 Explanation of Special Notices ......................................9

1.2.1 Warning Notices .............................................9

1.2.2 Other Notices................................................10

1.3 Equipment Identification (Standard Identification Plate)

.....................................................................................10

1.4 Declaration of Conformity ............................................11

1.5 Customer Service and Services ..................................11

2Safety and Responsibility ...................................................12

2.1 Intended Use, Incorrect Use and Misuse ....................12

2.2 Qualified Personnel .....................................................13

2.2.1 Provider ........................................................13

2.2.2 User ..............................................................13

2.2.3 Operator .......................................................14

2.3 Unauthorised Persons .................................................15

2.4 Responsibility of the Provider ......................................15

2.5 General Hazards..........................................................15

2.5.1 Electrical Current..........................................16

2.5.2Unauthorised Spare Parts and Accessories 16

2.6 Particular Hazards .......................................................16

2.6.1 Hot Surfaces.................................................17

2.6.2 Dangerous Gases ........................................17

2.6.3 Flammable or Explosive Substances ...........17

2.6.4 Corrosive or Toxic Substances ....................17

2.6.5 Bioactive Substances or Pathogenic

Organisms ....................................................18

2.6.6 Overpressure or Vacuum .............................18

2.7 Warning Symbols on the Equipment ...........................18

2.8 Declaration of Decontamination...................................18

3Setup and Function..............................................................20

3.1 Basic Unit.....................................................................20

3.1.1 Main Switch ..................................................21

3.1.2 Pumps ..........................................................21

3.1.3 Identification Plate ........................................22

3.1.4 Mains Connection.........................................22

3.1.5 Water Connections .......................................23

3.1.6 Gas Connections ..........................................23

3.1.7 Signal Connections ......................................24

3.1.8 Connections for Single or Double Walled

Vessels .........................................................24

Labfors 5 – Version for Microorganisms

Table of Contents

Page 2of 205 22 January 2019

3.1.8.1 Connections for Single Walled

Vessels......................................... 25

3.1.8.2 Connections for Double Walled

Vessels......................................... 26

3.1.9 Gassing Connection (Sparger) .....................27

3.1.10 Sensor Connections (Sensor Cables) ..........27

3.1.11 Connections and Valve for Water Flow

Regulation of the Exit Gas Cooler ................28

3.2 Operating Panel ...........................................................29

3.2.1 Monitor Keys.................................................29

3.2.2 Operating Panel Connections.......................30

3.3 Culture Vessels ............................................................31

3.3.1 Double walled Culture Vessels.....................31

3.3.2 Single walled Culture Vessels ......................32

3.3.3 Top Plate ......................................................33

3.3.4 Ports in the Vessel Top Plate and their

Configuration ................................................33

3.3.5 Top Plate DN 115 .........................................34

3.3.6 Top Plate DN 150 .........................................35

3.3.7 Top Plate DN 200 .........................................36

3.4 Temperature Control System.......................................36

3.4.1 Water Temperature Control..........................37

3.4.2 Temperature Control with Heater Pad and

Cold Finger ...................................................37

3.5 Stirrer ...........................................................................38

3.6 Gassing System ...........................................................39

3.6.1 Gassing Strategy ..........................................40

3.6.2 Gasmix System.............................................40

3.6.3 Gas Entry......................................................40

3.7 Exit Gas........................................................................40

3.8 pH Control ....................................................................41

3.8.1 Measurement System...................................41

3.8.2Calibration.....................................................42

3.8.3 Mounting of the Sensor ................................42

3.9 pO2Control...................................................................42

3.9.1 Measuring System ........................................43

3.9.2 Measurement and Calibration ......................43

3.9.3 Mounting of the Sensor ................................44

3.10 Antifoam Control ..........................................................44

4Options..................................................................................45

4.1 Pump(s)........................................................................45

4.2 Servomotor (High Torque) ...........................................45

4.3 Level Measurement......................................................47

Labfors 5 – Version for Microorganisms

Table of Contents

22 January 2019 Page 3of 205

4.4 Exit Gas Analysis .........................................................48

4.4.1 Measuring Systems (Gas Sensors) .............48

4.4.2 Connecting the Gas Sensors .......................48

4.4.3 Calibration ....................................................50

4.4.4 Replacing the BlueVary Gas Sensor Cartridge

......................................................................50

4.5 Multiplexer (Gas Switching Module) ............................50

4.6 Turbidity Measurement ................................................51

4.6.1 Sensors ........................................................51

4.6.2 Calibrating the Zero Point.............................52

4.6.3 Mounting the Sensor ....................................52

4.6.4 Cleaning and Storing the Sensor .................53

4.6.5 Interferences Turbidity Measurement ..........53

4.6.6 Specifications ...............................................54

4.7 Permissive Measurement ............................................54

4.8 Redox Measurement ...................................................55

4.8.1 Measuring Systems (Sensors) .....................55

4.8.2 Calibration ....................................................55

4.8.3 Mounting the Sensor ....................................56

4.9 pCO2Measurement .....................................................56

4.10 Pressure Control ..........................................................57

4.11 LabCIP, CIP/SIP Unit...................................................59

5Accessories ..........................................................................61

5.1 Base Tray.....................................................................62

5.2 Reagent Bottle and Pump Holder................................62

5.3 Sampling System Super Safe Sampler .......................64

5.4 Sparger ........................................................................66

5.5 Impellers ......................................................................68

5.6 Pocket for Temperature Sensor (Pt100)......................68

5.7 Baffles ..........................................................................69

5.8 Lock Nut.......................................................................70

5.9 Blanking Plugs .............................................................71

5.10 Addition Port Adapters .................................................72

5.11 Inoculation Needles .....................................................73

5.12 Septum Collars ............................................................76

5.13 Dip Tubes.....................................................................77

5.14 Clamping Adapters ......................................................79

5.15 Electrode Holder ..........................................................81

5.16 Threaded Adapter ........................................................81

5.17 Adapter ........................................................................81

5.18 Heater Pad...................................................................82

5.19 Cold Finger ..................................................................83

Labfors 5 – Version for Microorganisms

Table of Contents

Page 4of 205 22 January 2019

5.20 Exit Gas Cooler ............................................................85

5.21 Reagent Bottles............................................................87

5.22 Antifoam Sensor...........................................................89

5.23 Pump Heads ................................................................89

5.24 Sterile Filters ................................................................90

5.25 O-Rings and Gaskets...................................................91

5.26 Hoses and Accessories ...............................................92

5.27 Inoculation Accessories and Tools ..............................93

6Transport and Storage.........................................................94

6.1 Transport......................................................................94

6.2 Storage.........................................................................95

7Installation and Initial Operation ........................................96

7.1 General Location Requirements for Installation...........96

7.2 Minimum Distances......................................................97

7.3 Power Supply...............................................................97

7.4 Water Supply and Return.............................................97

7.5 Gas Supply...................................................................98

7.6 Exit Gas........................................................................99

7.7 Test Run.......................................................................99

7.7.1 Preparation Test Run ...................................99

7.7.2 Filling the Water Circuit ..............................102

7.7.3 Stirring ........................................................103

7.7.4 Heating and Adjusting Temperature...........103

7.7.5 Gassing.......................................................104

7.7.6 End of Test .................................................104

8Before Fermentation/Cultivation ......................................106

8.1 Preparing and Autoclaving the Culture Vessel ..........106

8.1.1 Checking Gaskets (O-Rings)......................106

8.1.2 Mounting the Impellers ...............................107

8.1.3 Mounting Dip Tubes and Spargers.............108

8.1.4 Mounting the Baffles ...................................109

8.1.5 Moistening/Filling the Culture Vessel .........110

8.1.6 Fitting the Vessel Top Plate........................111

8.1.7 Mounting a Threaded Adapter....................112

8.1.8 Mounting the Blanking Plugs ......................113

8.1.9 Mounting Addition Port Adapters................114

8.1.10 Mounting the Pocket for Temperature Sensor

(Pt100) ........................................................115

8.1.11 Preparing an Inoculation Needle ................115

8.1.12 Preparing the Dip Tube/Addition Port Adapter

for Inoculation .............................................116

Labfors 5 – Version for Microorganisms

Table of Contents

22 January 2019 Page 5of 205

8.1.13 Equipping Port with Septum Collar and

Septum for Inoculation ...............................116

8.1.14 Mounting and Preparing the Exit Gas Cooler

....................................................................117

8.1.15 Mounting the Cold Finger ...........................119

8.1.16 Checking Lubrication of the Mechanical Seal

....................................................................119

8.1.17 Preparing the Sensors................................119

8.1.17.1 Calibrating the pH Sensor...........120

8.1.17.2 Mouting a Sensor into a 12 mm

Port..............................................121

8.1.17.3 Mounting Sensors with Electrode

Holder..........................................121

8.1.17.4 Mounting the Antifoam Sensor....124

8.1.18 Preparing the Super Safe Sampler ............127

8.1.19 Mounting the Sparger Hose and the Inlet Air

Filter............................................................128

8.1.20 Preparing the Gassing Hose Line on the Basic

Unit .............................................................129

8.1.21 Calibrating the Pumps ................................129

8.1.22 Preparing the Reagent Bottles, Pumps and

Hoses .........................................................130

8.1.23 Sterile Hose Connections...........................133

8.1.24 Removing the Pump Heads .......................133

8.1.25 Checklist Before Autoclaving......................134

8.1.26 Autoclaving .................................................135

8.2 Connecting the Culture Vessel and Preparing the

Cultivation ..................................................................137

8.2.1 Connecting a Single Walled Vessel ...........137

8.2.2 Connecting a Double Walled Culture Vessel

....................................................................139

8.2.3 Mounting the Pump Heads.........................140

8.2.4 Filling the Reagent Hoses ..........................140

8.2.5 Connecting the Gassing .............................141

8.2.6 Connecting the Exit Gas Cooler .................142

8.2.7 Coupling the Motor .....................................143

8.2.8 Filling the Culture Vessel............................143

8.2.9 Inserting the Temperature Sensor (Pt100) into

the Pocket...................................................144

8.2.10 Connecting the Antifoam Sensor................144

8.2.11 Connecting the pH Sensor .........................145

8.2.12 Connecting the pO2Sensor........................146

8.2.13 Polarising the pO2Sensor (METTLER)......147

8.2.14 Calibrating the pO2Sensor.........................147

Labfors 5 – Version for Microorganisms

Table of Contents

Page 6of 205 22 January 2019

8.2.15 Checking the Hoses and Hose Connections

....................................................................148

9Fermentation/Cultivation ...................................................149

9.1 Preparing the Medium................................................149

9.2 Sampling ....................................................................150

9.3 Inoculation..................................................................153

9.3.1 Inoculation with Inoculation Needle ............154

9.3.2 Inoculation with a Syringe...........................155

9.3.3 Inoculation Using Dip Tube / Addition Port

Adapter .......................................................155

9.4 Harvest .......................................................................156

9.5 Emptying the Culture Vessel......................................157

9.6 Emptying the Reagent Hoses ....................................157

9.7 Switching off the Equipment ......................................157

9.8 Autoclaving the Culture Vessel After

Fermentation/Cultivation ............................................158

10 Cleaning and Maintenance................................................160

10.1 Cleaning Agent and Disinfectant................................160

10.2 Cleaning the Culture Vessel - Routine Cleaning .......160

10.3 Removing the Vessel Top Plate and Accessories .....162

10.3.1 Removing the Exit Gas Cooler ...................162

10.3.2 Removing the Sensors ...............................162

10.3.3 Removing Hoses, Filters and Pump Heads

....................................................................163

10.3.4 Removing Blanking Plugs...........................164

10.3.5 Removing Threaded Adapters....................164

10.3.6 Removing the Inoculation Needle, Septum

Collar and Septum ......................................164

10.3.7 Removing Addition Port Adapters ..............165

10.3.8 Removing the Vessel Top Plate .................165

10.3.9 Removing the Pocket for Temperature Sensor

(Pt100) ........................................................167

10.3.10 Removing the Sparger and the Dip Tube(s)

....................................................................167

10.3.11 Removing the Baffles .................................167

10.3.12 Removing the Impellers..............................168

10.3.13 Removing the Stirrer Shaft .........................168

10.4 Cleaning and Storing Individual Parts........................169

10.5 Cleaning the Sensors.................................................170

10.6 Cleaning the Hoses and Pump Heads.......................171

10.7 Cleaning the Super Safe Sampler .............................171

10.8 Cleaning the Exit Gas Cooler.....................................172

10.9 Cleaning the Basic Unit and Operating Panel ...........172

Labfors 5 – Version for Microorganisms

Table of Contents

22 January 2019 Page 7of 205

10.10 Cleaning the Heater Pad ...........................................173

10.11 Maintenance Plan ......................................................173

10.12 Lubricating the Mechanical Seal................................175

10.13 Decalcifying the Equipment .......................................175

10.14 Decalcifying Equipment via Vessel Jacket ................177

11 Interferences.......................................................................178

11.1 Interferences Basic Unit and Operating Panel ..........178

11.2 Interferences Drive System .......................................179

11.3 Interferences Temperature Control System ..............179

11.4 Interferences Gassing System...................................181

11.5 Interferences pH-System ...........................................182

11.6 Interferences pO2 System ..........................................183

11.7 Interferences Antifoam or Level Sensor and Antifoam

Pump..........................................................................184

11.8 Interferences Feed and Pump ...................................185

11.9 Returning for Repair ..................................................186

12 Disassembly and Disposal................................................187

12.1 Disassembly...............................................................187

12.2 Disposal .....................................................................187

13 Technical Data....................................................................189

13.1 Dimensions 1 Unit......................................................189

13.2 Dimensions Master Unit and Satellite Units ..............191

13.3 Dimensions of Culture Vessels in Vessel Holder ......192

13.4 Weights (net)..............................................................194

13.5 Connection Values.....................................................194

13.5.1 Electrical .....................................................194

13.5.2 Water IN .....................................................194

13.5.3 Water OUT .................................................195

13.5.4 Gas(es) IN ..................................................195

13.5.5 Exit Gas ......................................................195

13.6 Specifications.............................................................195

13.6.1 Operating Unit ............................................195

13.6.2 Culture Vessel ............................................196

13.6.3 Stirrer..........................................................196

13.6.4 Temperature ...............................................198

13.6.5 Gassing ......................................................199

13.6.6 Antifoam .....................................................200

13.6.7 pH ...............................................................201

13.6.8 pO2..............................................................201

13.6.9 Pumps ........................................................202

13.6.10 Sterile Filters...............................................203

Labfors 5 – Version for Microorganisms

Table of Contents

Page 8of 205 22 January 2019

13.6.11 Heater Pads for Single Walled Vessels......204

13.7 Operating Conditions .................................................204

13.8 Emissions...................................................................204

13.9 Utilities........................................................................204

13.10 Auxiliary Supplies.......................................................205

Labfors 5 – Version for Microorganisms

General Information

22 January 2019 Page 9of 205

1 General Information

1.1 About this Manual

This manual enables the safe and efficient handling of the equip-

ment.

All the information and instructions in this operating manual comply

with the current standards, legal regulations, the latest technologi-

cal and scientific developments and the knowledge gained from the

manufacturer’s many years of experience in this field.

This operating manual is a component part of the equipment.

It must be kept near to the equipment and must be accessible

to the operators at all times.

The users must read the operating manual thoroughly and fully un-

derstand its contents before beginning any work.

Adhering to all the safety and operating instructions in this manual

is essential to ensure that work is carried out safely.

The scope of delivery may differ from the explanations, descrip-

tions and figures in this operating manual due to special designs,

additional options specified on ordering and the latest tech-

nical/mechanical modifications.

This manual contains illustrations to aid general understanding.

These may differ from the actual equipment as supplied.

1.2 Explanation of Special Notices

1.2.1 Warning Notices

Warning notices in this manual are indicated by a coloured bar and

begin with a signal word that signifies the degree of the hazard.

DANGER

The signal word “DANGER” indicates a dangerous situation that

will lead to severe or even fatal injuries if not avoided.

Labfors 5 – Version for Microorganisms

General Information

Page 10 of 205 22 January 2019

WARNING

The signal word “WARNING” indicates a potentially dangerous

situation that may result in severe or even fatal injuries if not

avoided.

CAUTION

The signal word “CAUTION” indicates a potentially dangerous

situation that may result in minor injuries if not avoided.

1.2.2 Other Notices

ATTENTION

The word “ATTENTION” on a blue bar indicates a situation that

may result in significant damage to property if not avoided.

INFORMATION

Texts located below a grey bar bearing the notice “INFOR-

MATION” provide useful tips and recommendations for ensuring

efficient, fault-free operation of the equipment.

1.3 Equipment Identification (Standard Identification Plate)

The identification plate is designed to allow clear identification of

the equipment. It contains the following information:

Manufacturer name

Designation = Category of equipment

Type = Equipment type (name)

S/N = Serial number

Year = Year of manufacture

Mains = Nominal voltage and frequency

Current = Current consumption

Manufacturer address

CE marking

Labfors 5 – Version for Microorganisms

General Information

22 January 2019 Page 11 of 205

1.4 Declaration of Conformity

The equipment is in compliance with the essential requirements of

the following Directives:

Machinery Directive 2006/42/EC

EMC Directive 2014/30/EU

The Declaration of Conformity according to EC Machinery Directive

2006/42/EC, annex II 1 A is included in the general documentation

supplied with the equipment.

1.5 Customer Service and Services

Our Customer Service is at your disposal for technical advice and

specialist enquiries. For contact information, see page 2.

Due to their familiarity with the potential applications of the equip-

ment, the Customer Service team is able to provide information on

whether the equipment can be used for a specific application or

modified to handle the planned process.

Experience of working with the equipment will be published semi-

regularly on the manufacturer’s website in the form of “application

notes”.

Furthermore, our colleagues are always interested in new infor-

mation and experiences resulting from user’s applications for the

equipment that may be valuable for the continued development of

our products.

Labfors 5 – Version for Microorganisms

Safety and Responsibility

Page 12 of 205 22 January 2019

2 Safety and Responsibility

This section describes general considerations relating to user

safety that must be taken into account when working with the

equipment.

In the remaining sections, warning notices are used only to high-

light particular hazards directly arising from the actions being de-

scribed in the section in question.

It is essential to read the operating manual carefully – espe-

cially this section and the warning notices in the text – and to

follow the instructions therein.

This section also refers to areas that are the responsibility of the

provider due to certain risks arising from particular applications for

which the equipment is used deliberately and with full awareness

of the associated risks.

2.1 Intended Use, Incorrect Use and Misuse

The bench-top bioreactor Labfors 5 from INFORS HT is de-

signed especially for running bio processes with microorgan-

isms or animal cells for research and development in a bio-

technology laboratory.

The equipment is designed and constructed exclusively for the in-

tended use described above.

Intended use also includes following all the instructions in this op-

erating manual, especially those relating to:

The installation site

User qualifications

Correct operation and maintenance

The use of undamaged tubing and glass vessels

Any failure to observe the requirements specified in this manual

shall be deemed incorrect use.

Any use of the equipment outside the scope of the intended use as

described above shall be deemed misuse.

This also applies to applications for which the equipment is not de-

signed, such as the use or production of explosive gases, which is

not permitted because the equipment is not explosion-proof.

Labfors 5 – Version for Microorganisms

Safety and Responsibility

22 January 2019 Page 13 of 205

For use for special applications not covered by conventional, in-

tended use, the equipment must be modified and certified accord-

ingly by the manufacturer.

Any use of the equipment outside of a biotechnology laboratory,

i.e. in any environment in which the conditions required for the

safety of the users cannot be fulfilled or cannot be fulfilled to their

full extent, shall also be deemed misuse.

2.2 Qualified Personnel

Due to the complexity of the equipment and the potential risks aris-

ing from its operation, the equipment may only be used by quali-

fied, specialist personnel.

2.2.1 Provider

The term “provider” applies to all persons who are responsible for

making the equipment and the necessary infrastructure available.

These persons may also be included in the group of people known

as “users”, though this is not always the case.

Irrespective of whether a provider is a member of the company’s

board of management or a supervisor, they bear a special level of

responsibility with regard to the processes and the qualification and

safety of the users.

2.2.2 User

General

The term “user” applies to all persons who come into contact with

the equipment in any way and perform work on or with it. This pri-

marily applies to the following activities, which can be performed by

the manufacturer’s own specialists or a variety of other persons (it

is not always possible to distinguish clearly between the different

types of person):

Assembly, installation and commissioning

Definition and preparation of the process

Operation

Troubleshooting and remedying of faults

Maintenance and cleaning (autoclaving, if necessary)

Service work and repairs

Disassembly, disposal and recycling

Labfors 5 – Version for Microorganisms

Safety and Responsibility

Page 14 of 205 22 January 2019

Qualified personnel

On account of their specific education, training and – in many

cases – experience, the qualified personnel required for this work

are able to recognise risks and respond accordingly to potential

hazards.

The qualified personnel (either internal or external) who cannot be

categorised under the separate “operators” group are made up of

the following groups of persons:

Electricians (electrical engineers)

Decontamination specialists

Repair specialists

Specialists in disassembly and (environmentally friendly) dis-

posal

Recycling specialists

2.2.3 Operator

The “operators” are a specific sub-group of users distinguished by

the fact that they work with the equipment. They are the true target

audience for this operating manual.

Qualified technicians

Only technicians who have been trained for working in a biotech-

nology laboratory can be considered for the role of operator. These

include:

Process technicians in the fields of biotechnology and chemis-

try

Biotechnologists (biotechnicians)

Chemists with a specialisation in biochemistry; chemists in the

field of organic chemistry or biochemistry

Life scientists (biologists) with special education in cytology,

bacteriology, molecular biology, genetics, etc.

Lab assistants (lab technicians) from various fields

In order to be classed as a “sufficiently qualified technician” for the

operation of the equipment, the persons in question must have re-

ceived thorough training and have read and understood the operat-

ing manual.

The operator must be informed in a training session provided by

the provider of the tasks delegated to the operator and the poten-

tial risks of improper conduct. Tasks that go beyond the scope of

operation under normal conditions may only be performed by the

operator if this is specified in the manual and the provider has ex-

plicitly entrusted said tasks to the operator.

Labfors 5 – Version for Microorganisms

Safety and Responsibility

22 January 2019 Page 15 of 205

Technicians in training

Persons in this group who are undergoing training or apprentice-

ships are only permitted to use the equipment under supervision

and in accordance with the instructions of a trained and qualified

technician.

2.3 Unauthorised Persons

The term “unauthorised persons” applies to all persons who can

access the work area but are not qualified to use the equipment in

accordance with the aforementioned requirements.

Unauthorised persons are not permitted to operate the equipment

or use it in any other way.

2.4 Responsibility of the Provider

The equipment is used for industrial and scientific purposes. As

such, the provider of the equipment is individually liable with regard

to the legal requirements relating to occupational health and safety

in a biotechnology laboratory. In particular:

The provider is responsible for ensuring that the work and en-

vironmental regulations applicable in a biotechnology labora-

tory are observed.

The provider must ensure that the equipment remains in safe

and proper working condition throughout its entire term of use.

The provider must ensure that all safety equipment is fully

functional and is not disabled.

The provider must ensure that the equipment is only worked

on by qualified users, and that said users receive sufficient

training.

The provider must ensure that the protective equipment re-

quired for working with the equipment is provided and worn.

The provider must ensure that this operating manual remains

in the immediate vicinity of the equipment throughout its entire

term of use.

2.5 General Hazards

This section covers general hazards and residual risks that are al-

ways present when using the equipment in accordance with nor-

mal, intended use.

Labfors 5 – Version for Microorganisms

Safety and Responsibility

Page 16 of 205 22 January 2019

The following notices are general in nature. As such, with a few

exceptions they are not repeated in the remaining sections.

2.5.1 Electrical Current

The equipment runs on electrical power. There is an immediate

risk of fatal injury if contact is made with live parts.

The following points must be observed in order to avoid the risk of

fatal injury:

In case of damage to insulation, disconnect the equipment

from the mains immediately and arrange for it to be repaired.

Disconnect the equipment from the mains before commencing

any work on the electrical system.

Always use qualified electricians for any work on the electrical

system.

Keep moisture away from live parts. It may lead to a short cir-

cuit.

2.5.2 Unauthorised Spare Parts and Accessories

Incorrect or imitated spare parts and accessories as well as spare

parts or accessories that have not been authorised by the manu-

facturer represent a significant safety risk. As such, we recommend

procuring all spare parts and accessories from an authorised

dealer or directly from the manufacturer. For the contact details of

the manufacturer’s representatives, see page 2.

2.6 Particular Hazards

This section covers particular hazards and residual risks that may

arise when using the equipment for special applications in accord-

ance with normal, intended use.

Since the use of the equipment for such applications is deliberate,

it is the responsibility of the operators and the provider to ensure

that all personnel are protected from potential damage to health.

The provider is responsible for ensuring that the appropriate pro-

tective equipment for such applications is provided, and that the

necessary infrastructure is in place.

Labfors 5 – Version for Microorganisms

Safety and Responsibility

22 January 2019 Page 17 of 205

2.6.1 Hot Surfaces

For processes that are carried out with temperatures over 55 °C,

there is a danger of burns on hot surfaces.

Since the equipment is intended for applications at high tempera-

tures, it is the responsibility of the users to ensure that they have

sufficient protection.

The motor gets hot during operation. There is a risk of burns if it is

touched.

2.6.2 Dangerous Gases

The use or production of dangerous gases i.e. toxic or asphyxiant

gases entails a significant health risk, especially in enclosed

spaces.

In order to prevent high emissions of dangerous gases, the follow-

ing measures must be taken:

The gas connections on the equipment must be checked be-

fore any cultivation processes using dangerous gases are initi-

ated.

The gaskets on the equipment must be checked at regular

intervals and replaced if necessary.

Siphon off exit gas safely.

2.6.3 Flammable or Explosive Substances

The use or production of flammable or explosive substances is not

covered under “intended use” of the equipment, as the equipment

is not explosion-proof.

If the provider intends to use the equipment for such purposes, he

must check its suitability for the planned application with the re-

sponsible local authorities.

2.6.4 Corrosive or Toxic Substances

The use or production of corrosive or toxic substances entails a

significant health risk. As such, special measures must be taken to

protect the users for such applications.

Since the equipment is used deliberately for such applications, it is

the responsibility of the users to ensure that they have sufficient

protection.

Labfors 5 – Version for Microorganisms

Safety and Responsibility

Page 18 of 205 22 January 2019

2.6.5 Bioactive Substances or Pathogenic Organisms

The use or production of bioactive substances, pathogenic organ-

isms or genetically modified cultures entails a significant health

risk. As such, special measures must be taken to protect the users

for such applications.

Since the equipment is used deliberately for such applications, it is

the responsibility of the users to ensure that they have sufficient

protection.

2.6.6 Overpressure or Vacuum

Glass vessels may break or shatter when subjected to overpres-

sure or vacuums.

2.7 Warning Symbols on the Equipment

The following warning symbols (stickers) are attached to the equip-

ment:

Position

Motor

WARNING

Illegible or missing warning symbols on the equipment will lead

to the user being exposed to risks that the warning symbols in

question were designed to make him or her aware of.

It is the provider’s responsibility to ensure that all the stickers

with warning symbols on the equipment are always intact.

2.8 Declaration of Decontamination

When returning the equipment for repair, disassembly or disposal,

it is required for the safety of all parties involved and because of

legal provisions that a lawful declaration of decontamination is pre-

sent.

Other manuals for Labfors 5

1

Table of contents

Other Infors HT Laboratory Equipment manuals

Infors HT

Infors HT Multitron User manual

Infors HT

Infors HT Labfors 5 Cell User manual

Infors HT

Infors HT Labfors 5 User manual

Infors HT

Infors HT Multitron Standard User manual

Infors HT

Infors HT Multitron Pro User manual

Infors HT

Infors HT Ecotron User manual

Infors HT

Infors HT Multifors 2 User manual

Infors HT

Infors HT Minifors 2 User manual