Page 4 of 8 67168 (en)

67390 COUNTER INSTALLATION

1” and 1-1/2” DIAPHRAGM PUMP WITH

NON-METALLIC CENTER BODY

Kit Models

67390

Non Metallic Models: PD10E-XXX-XXX, PD10P-XXX-

XXX, PE10P-XXX-XXX, PD15E-XXX-XXX, PD15P-XXX-

XXX and PE15P-XXX-XXX.

Metallic Models:

PD10R-XXX-XXX, PE10R-XXX-XXX,

PM10R-CSS-XXX-A02, PD15R-XXX-XXX,

PE15R-XXX-XXX and PM15R-CSS-XXX-A02.

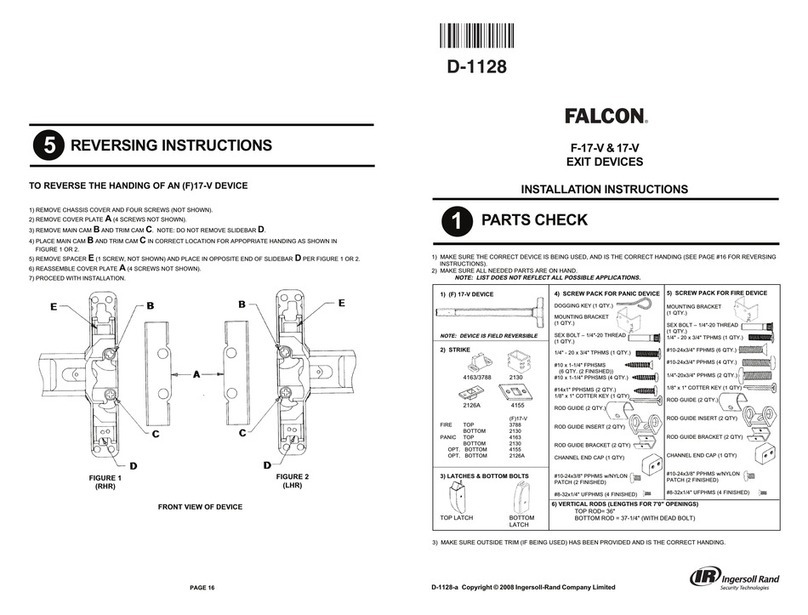

Refer to figure 6. NOTE: Apply Lubriplate FML-2 grease

(94276) to all “O” rings, “U” cups and mating parts upon as-

sembly.

1. Remove (134) screws and remove (135) valve block.

2. Insert a small at blade screwdriver into the notch in the

side of (135) valve block and push in on tab to remove

(233) adapter plate, releasing (140) valve insert, (141)

valve plate and (200) gasket.

3. Remove (236) nuts from the major valve and remove (107)

end plate.

4. Remove (136) end cap and (111) spool and replace with

67394 spool assembly as shown.

5. Place 95276 sensor and 96581 mounting plug thru hole in

(107) end plate.

6. Install (137) gasket on (136) end cap and assemble end

cap and (107) end plate to (135) valve block, securing (105)

screws and (236) nuts. NOTE: Torque (105) screws to 35 -

40 in. lbs (4.0 - 4.5 Nm).

7. Install (140) valve insert and (141) valve plate in (135)

valve block. NOTE: Assemble (140) valve insert with

“dished” side toward (141) valve plate. Assemble (141)

valve plate with part number identication toward (140)

valve insert.

8. Assemble (200) gasket and (233) adapter plate to (135)

valve block. NOTE: Assemble (233) adapter plate with

notched side down.

9. Attach (135) valve block to (101) motor body, using (133)

washers and (134) bolts. NOTE: Torque to 35 - 40 in. lbs (4.0

- 4.5 Nm).

135

133

134

Torque to 35 -40in. lbs(4.0-4.5 Nm).

111

136

67394

Includedbut not shown:

94276 Lubriplate grease

107

236

137

105

96581

95276

Notch

k

.

g

g

.

g

g

Assemblewith part number identication

toward(140) valve insert.

Insert screwdriver here to

remove (233) adapter plate

Figure 6

67391 COUNTER INSTALLATION

2” AND 3” DIAPHRAGM PUMP WITH

NON-METALLIC CENTER BODY

Kit Models

67391

Metallic Models: PD20R-XXX-XXX, PD20Y-XXX-XXX,

PD20R-XXX-XXX-B, PE20R-XXX-XXX-B, PD20Y-XXX-

XXX-B, PE20Y-XXX-XXX-B, PF20R-XXX-XXX,

PF20Y-XXX-XXX, PF20R-XXX-XXX-B, PF20Y-XXX-XXX-B,

PM20R-CSS-XXX-A02, PM20R-CSS-XXX-B02, PD30R-

XXX-XXX-B, PD30R-XXX-XXX-C, PE30R-XXX-XXX-C,

PM30R-CSS-XXX-B02 and PM30R-CSS-XXX-C02.

Non Metallic Models: PD20E-XXX-XXX, PE20E-XXX-XXX

PD20P-XXX-XXX, PE20P-XXX-XXX, PD30P-XXX-XXX and

PE30P-XXX-XXX.

Refer to gure 7. NOTE: Apply Lubriplate FML-2 grease (94276)

to all “O” rings, “U”cups and mating parts upon assembly.

1. Remove (134) screws and remove (135) valve block.

2. Remove (233) adapter plate, releasing (140) valve insert,

(141) valve plate and (200) gasket.

3. Remove (236) nuts from the major valve and remove (107)

end plate.

4. Remove (136) end cap and (111) spool and replace with

67395 spool assembly as shown.

5. Place 95276 sensor and 96582 mounting plug thru hole in

(107) end plate.

6. Install (137) “O” ring on (136) end cap and assemble end

cap and (107) end plate to (135) valve block, securing with

(105) screws and (236) nuts. NOTE: Torque (105) screws to

15 - 20 in. lbs (1.7 - 2.3 Nm).

7. Install (140) valve insert and (141) valve plate in (135)

valve block. NOTE: Assemble (140) valve insert with

“dished” side toward (141) valve plate. Assemble (141)

valve plate with identication dots toward (199 and 200)

gaskets.

8. Assemble (232, 243 and 244) “O” rings, (199 and 200) gas-

kets and (233) adapter plate to (135) valve block.

9. Attach (135) valve block and components to (101) motor

body, using (133) washers and (134) bolts. NOTE: Torque

to 40 - 50 in. lbs (4.5 - 5.6 Nm).

135

133

134

Assemblewith2identicationdots

toward (199 and 200) gaskets.

111

136

67395

Included but not shown:

94276Lubriplategrease

107

236

137

105

96582

95276

200 232

k

g

g

g

Torque (105) to 15 -20in. lbs(1.7-2.3Nm).

Torque (134) to 40 -50in. lbs(4.5-5.6Nm).

.

.

g

Figure 7