S 10XĆXPAGE 2 OF 8

OPERATING

AND SAFETY PRECAUTIONS

READ, UNDERSTAND AND FOLLOW THIS INFORMATION TO AVOID INJURY AND PROPERTY DAMAGE.

WARNING EXPLOSION HAZARD. Do not exceed maximum

fluid inlet pressure of 100 p.s.i. (6.9 bar). Ope ating at highe

p essu e can cause explosion, esulting in p ope ty damage o seĆ

ve e inju y.

WARNING USE ONLY WITH COMPRESSED AIR. Do not use

bottled gas products to run the Shock locker. Un egulated

high p essu e bottled gas has the potential fo ove Ćp essu ization.

Ce tain gasses, such as Nit ogen, can cause unp edictable esults.

The p essu e sou ce MUST BE REGULATED.

WARNING TEMPERATURE LIMITATIONS. Do not exceed

maximum temperature limits of; (POLYPROPYLENE 150_F),

(CONDUCTIVE ACETAL 180_F), (KYNAR 200_F). Excessive opĆ

e ating tempe atu es can weaken the body mate ial. Limits a e

based on mechanical st ess only.

WARNING CHEMICAL COMPATI ILITY HAZARD. Do not

use with certain fluids. Incompatible fluids may attack and weakĆ

en the housing, causing uptu e o explosion, which can esult in

p ope ty damage o seve e inju y. Fo specific fluid compatibility,

consult the chemical manufactu e .

WARNING DISASSEM LY HAZARD. Do not disassemble

this unit when it is under pressure. Relieve all mate ial p essu e

in the pumping system befo e attempting se vice o disassembly.

Disconnect ai lines and ca efully bleed any p essu e off the sysĆ

tem. Be ce tain the system is not maintaining p essu e due to a maĆ

te ial est iction in the hose, line, dispensing device o the sp ay o

ext usion tip. Failu e to elieve p essu e both up st eam and downĆ

st eam may esult in an inju y upon disassembly.

WARNING MATERIAL ATOMIZATION. The relief / exhaust

valve must be piped away from the work area. In the event of a

bladde uptu e, the mate ial can be atomized and fo ced out the

elief / exhaust valve.

CAUTION NOT FOR STRUCTURAL SUPPORT. Do not use

this product to support other system components or use as a

step. Imp ope suppo t can esult in f actu e of the housing, causĆ

ing damage. Plumbing must be suppo ted to p event st esses upon

it. Install using the mounting ha dwa e supplied.

NOTICE Replacement warning label (PN 93793) is availĆ

able upon request.

WARNING

CAUTION

NOTICE

= Hazards or unsafe practices which could

result in severe personal injury, death or

substantial property damage.

= Hazards or unsafe practices which could

result in minor personal injury, product or

property damage.

= Important installation, operation or

maintenance information.

INSTALLATION INSTRUCTIONS

WARNING HEED WARNINGS AS SHOWN IN ``OPERATING

AND SAFETY PRECAUTIONS'' A OVE.

AIR REQUIREMENTS

Clean, d y ai should be used to cha ge the unit.

A filte capable of filte ing out pa ticles la ge than 50 mic ons should be

used on the ai supply.

INSTALLATION INSTRUCTIONS

Position the Shock Blocke pulsation dampene as close to the pump

discha ge as possible.

Use the g ound lug and optional 66885Ć1 g ounding cable kit with the

Conductive Acetal models (SB10DĆXDSĆX) in applications whe e flamĆ

mable fluids a e used, to help gua d against static spa k haza d esultĆ

ing in possible fi e o explosion. The te minal on the end of the g ound

wi e must be emoved and the wi e st ipped back 1/2'' (13 mm) to be

accepted by the Shock Blocke g ound fitting.

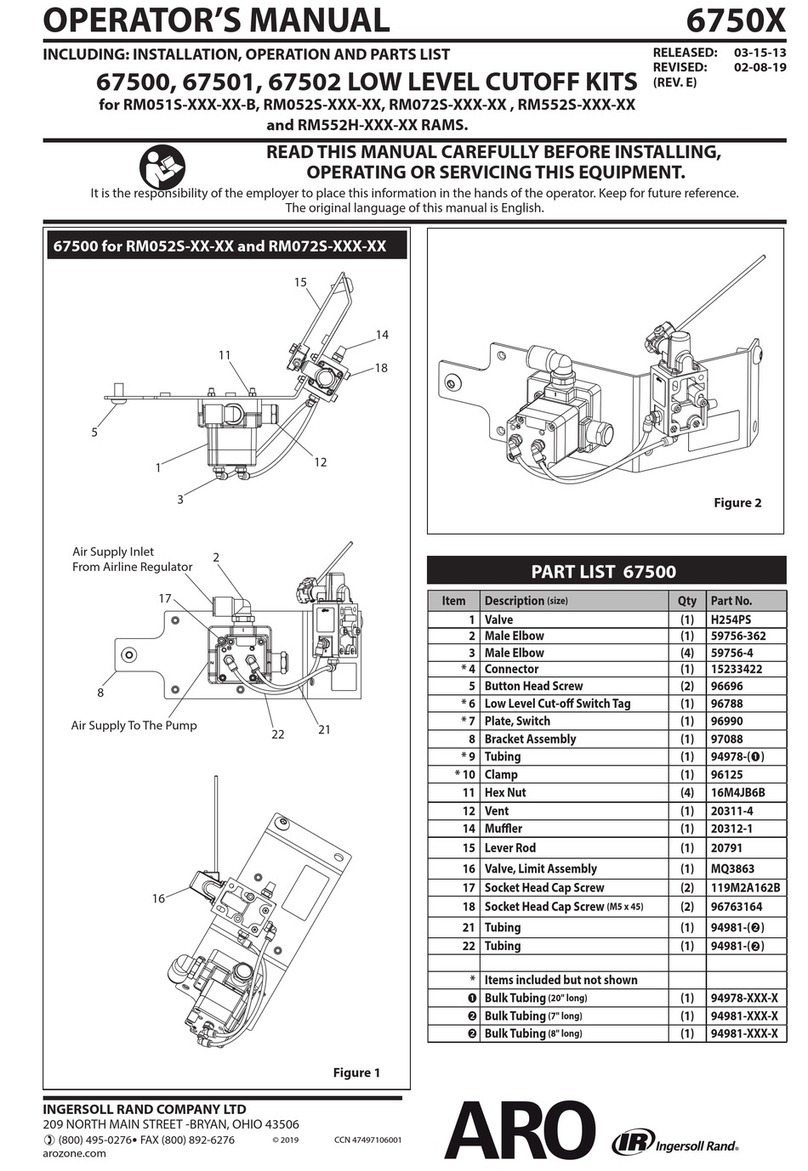

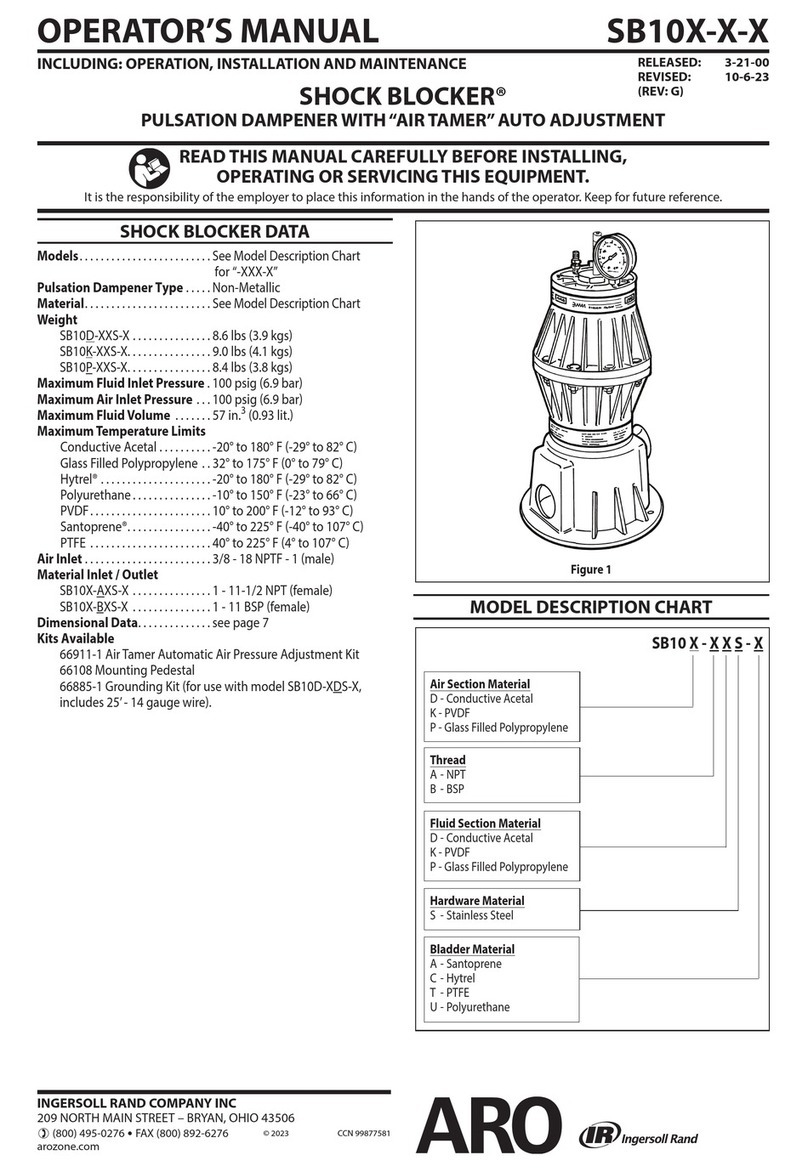

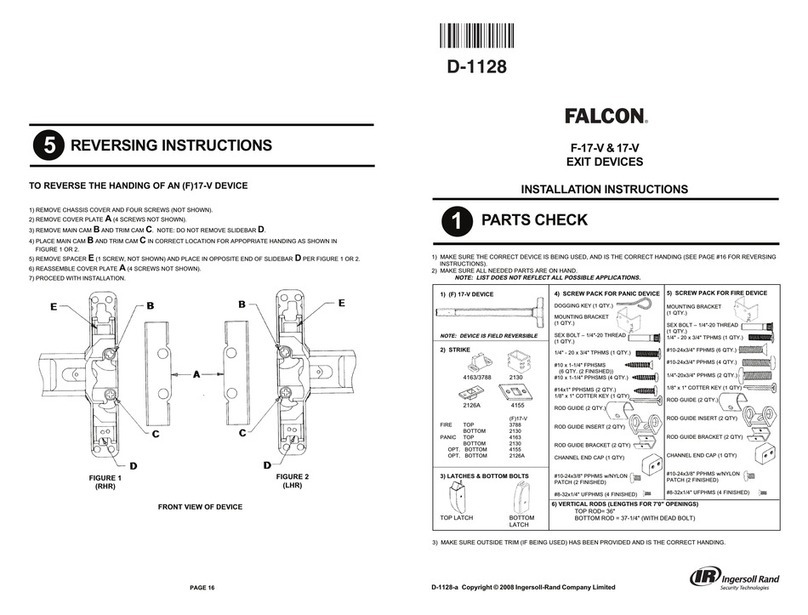

Mount the Shock Blocke in one of the ecommended positions as illusĆ

t ated in figu e 1, page 3.

Diffe ent mate ials affect the mounting configu ation. Fo best pe fo Ć

mance and typical applications, mount the Shock Blocke up ight ve Ć

sus ho izontally. Heavie pa ticles in some fluids may settle out. G avity

will help discha ge heavie pa ticles when mounted ve tically.

In many situations, mounting the unit di ectly to the pump outlet would

not be advisable due to the added weight of the unit. It should be indeĆ

pendently mounted and plumbed using flexible tubing and not exĆ

pected to physically suppo t othe components.

The mate ial flow should be in the di ection of the Shock Blocke , fo

best esults, not passing by at ight angles (see figu e 1, page 3).

Use the mounting base as p ovided and additional mounting kit 66108

is also available to gain ext a ve tical height. This may be necessa y

when using pumps with outlets 1" and la ge , because of the inc eased

size and space equi ements of the fittings. The second mounting kit is

inve ted to p ovide an elevated base (see page 7).

When connecting pipe, cut o p ess the ``knockĆout'' panels f om the

pedestal base as needed to accommodate piping. Do not alte o cut

out othe pa ts of the pedestal.

Shock Blocke s used in se ies should be installed as illust ated in figu e

1, page 3.

All models a e completely automatic, no fu the adjustment is needed

afte initial setĆup. The cont ol device is activated by changes in the maĆ

te ial p essu e and it will selfĆadjust the ai p essu e to the co ect level

ega dless of the mate ial used. Refe to ope ating inst uctions on page

3.

Connect the ai tame 3/8 Ć 18 n.p.t. ai inlet to the egulated ai inlet

supply hose.

When pumping fluids that may pose a haza d to human health, connect

a d ain line to the 1/8 Ć 27 n.p.t. exhaust po t as a safety p ecaution.

Tubing and fittings a e not supplied.

WARNING In the event of a bladde uptu e, the mate ial being

pumped could leak f om the exhaust po t. Route the d ain line to a

location whe e escaping ai , mate ial o ai containing atomized

mate ial will not ha m pe sonnel o p ope ty.