Page 2 of 4 PM0450L2XXXXXXXX(en)

INSTALLATION

The PM0450L2XXXXXXXX pail mounted comes completely

assembled. Remove the unit from the crate and place on a

level surface. Install the material hose and dispensing device

as required.

When the following instructions are observed, heavy paste

materials can be pumped directly from their original drum

without air inclusion or excessive waste. The follower plate

creates an air tight seal as well as clean-wiping action in its

progressive downward movement into the drum.

OPERATING AND SAFETY PRECAUTIONS

READ TH E GE NE R AL I NF OR MAT I O N

MANUAL INCLUDED FOR OPERATING AND SAFETY

PRECAUTIONS AND OTHER IMPORTANT INFORMATION.

EXCESSIVE INLET PRESSURE. Can cause ex-

plosion resulting in severe injury or death. Do not exceed

maximum operating pressure of 7500 psig (517.2 bar) at

150 psig (10.3 bar) inlet air pressure. Do not run pump

without using a regulator to limit air supply pressure to

the pump.

PUMP RATIO X INLET = MAXIMUM PUMP

PRESSURE TO PUMP MOTOR FLUID PRESSURE

Pump ratio is an expression of the relationship between the pump mo-

tor area and the lower pump end area. EXAMPLE: When 150 psig (10.3

bar) inlet pressure is supplied to the motor of a 50:1 ratio pump, it will

develop a maximum of 7500 psig (517 bar) uid pressure (at no ow) -

as the uid control is opened, the ow rate will increase as the

motor

cycle rate increases to keep up with the demand.

EXCESSIVE MATERIAL PRESSURE. Can

cause equipment failure resulting in severe injury or

property damage. Do not exceed the maximum material

pressure of any component in the system.

Thermal expansion hazard. This can occur when the uid

in the material lines is exposed to elevated temperatures.

Example: Material lines located in a non-insulated roof

area can warm due to sunlight. Install a pressure relief

valve in the pumping system.

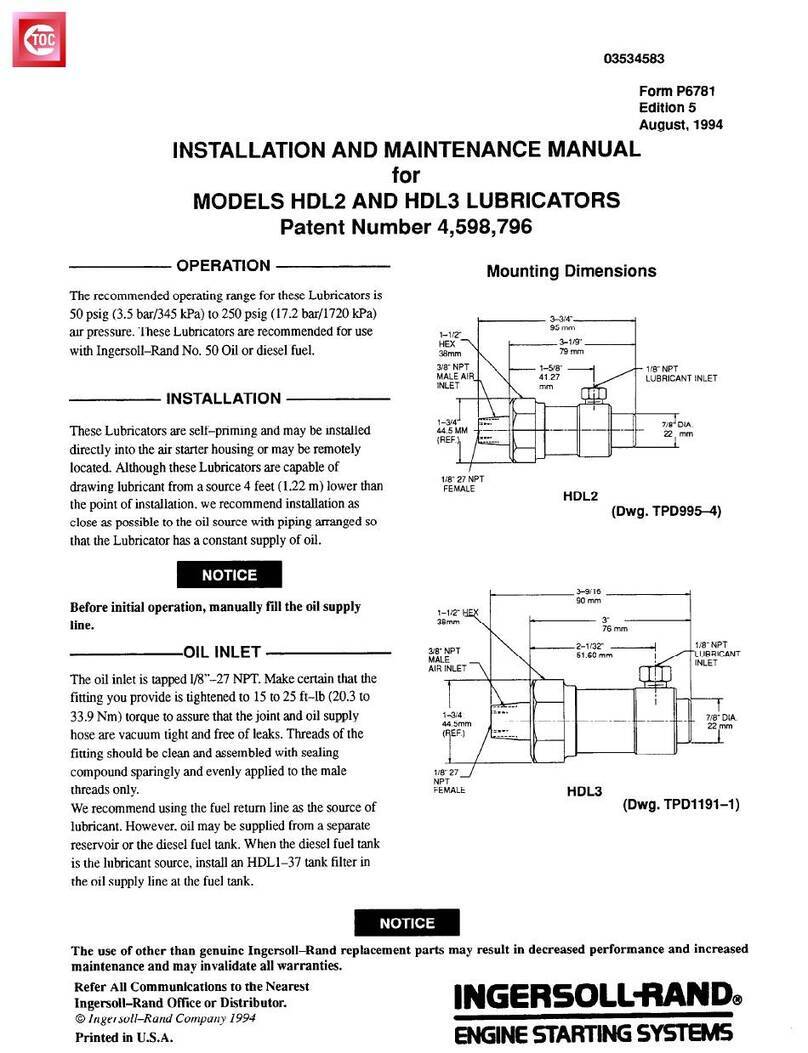

AIR AND LUBE REQUIREMENTS

Filtered air will help extend the life of the pump, allowing the

pump to operate more eciently and yield longer service life

to moving parts and mechanisms.

Use an air line lter to provide good quality clean and dry

air. Install it up stream from the air regulator.

Use an air regulator on the air supply to control the

pump cycle rate. Install the regulator as close as possible

to the pump.

In most installations, lubrication is not required. If the

pump needs to have lubrication, install an air line lubrica-

tor between the pump and the air regulator and supply it

with a good grade of non-detergent oil or other lubricant

that is compatible with Nitrile seals. Set at a rate not to

exceed one drop per minute.

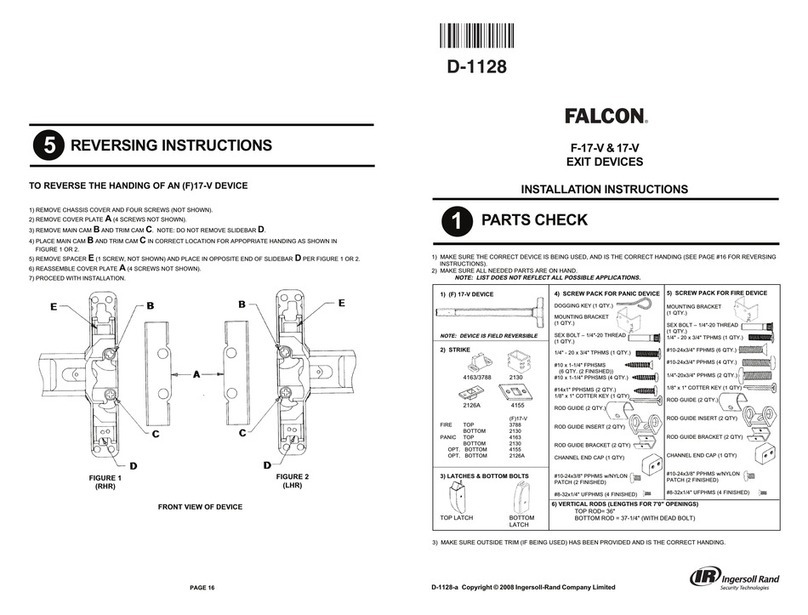

INSTALLATION

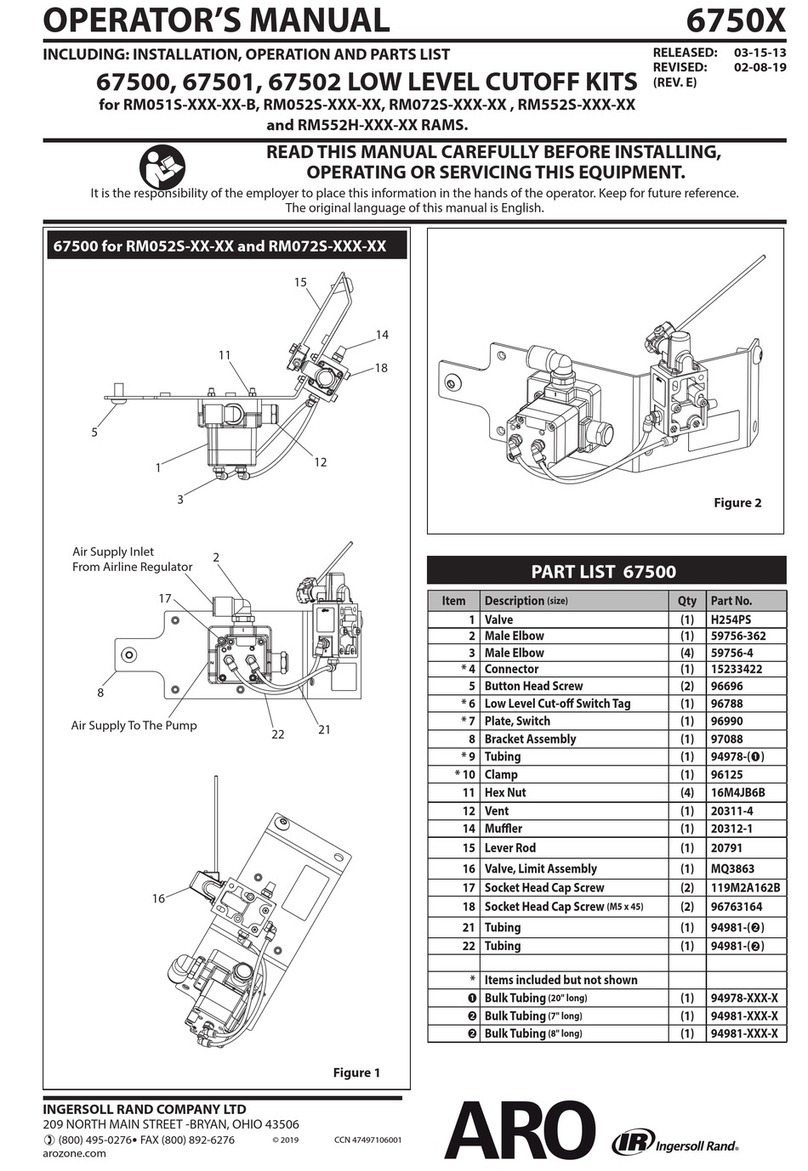

Assemble the components included in the package as

shown in Figure 2 (page 3). NOTE: In rigid plumbing applica-

tions, use exible material and air supply hoses when attach-

ing the pump to prevent damage by vibration.

Insert the pump into the adapter and tight at the proper

height with screws. Thread the bung adapter into the

cover. Insert the pump into the bung and then secure

with the thumb screws provided.

NOTE: Ensure the foot of pump have closed to the bot-

tom of the used drum.

1.

Install the outlet adapter, material hose, hose adapter

and gun with swivel.

Lay the follower on top of a full bucket of grease. Feed

the lower pump end into the follower and secure the

cover with the thumb screws.

Attach a connector to the pump and a coupler to the air

supply hose.

Connect the material hose to the pump outlet. Tighten all

ttings. Use caution not to damage threads.

OPERATION

START-UP

Turn the air regulator to "0" pressure setting. Connect the

air hose.

Prime the pump by cycling slowly, raising the pressure to

20 - 30 psig (1.4 - 2.1 bar). Cycle the pump until the test

grease and any trapped air has been purged from the

system.

Close the dispensing device. Allow the pump to build

line pressure and stall. Check for any leaks and re-torque

ttings if needed. Adjust the air pressure upward as

required for the application.

If the pump does not prime soon after initial

start-up, establish what the problem is to prevent unneces-

sary damage to the pump plunger.

SHUTDOWN

Disconnect the air supply from the pump if it is to be

inactive for a few hours. Open the dispensing device to

relieve line pressure.

SERVICE

Refer to the basic pump manual for service instructions which also

cover disassembly and reassembly for installation of the rebuild kit.

TROUBLESHOOTING

If the pump will not cycle or will not deliver material.

Be certain to check for non-pump problems including

kinked, restrictive or plugged inlet / outlet hose or dis-

pensing device. Depressurize the pump system and clean

out any obstructions in the inlet / outlet material lines.

Check all seals, including track gaskets.

Check direction of "U" cup lips.

2.

3.

4.

5.

1.

2.

3.