Single chain fall hoists.

8. Remove retainer wire (130), hook ring (129) and hook

anchor pin (128). Position the last link of the chain in the

hook slot. Replace hook anchor pin (128), hook ring (129)

and retainer wire (130).

9. Install buffer (133) with buffer ring (134) on opposite

chain end so offset shoulder of buffer is facing the

bottom of the hoist motor. Place buffer 6 in. (15 cm)

from the chain end. This buffer activates the bottom limit

switch.

10. Secure buffer (133) in position with capscrew (137) and

nut (136).

11. Attach the last chain link to the hoist with capscrew (78)

and washer (114).

.

Check that the chain is not twisted.

Double chain fail hoists

12. Feed the chain end with a nylon string into the hook block

(127). Take care that the “standing" links on the new

chain are facing away from the hook block sheave.

13. Secure the last link on the chain to the hoist body with

capscrew (117) and washer (116).

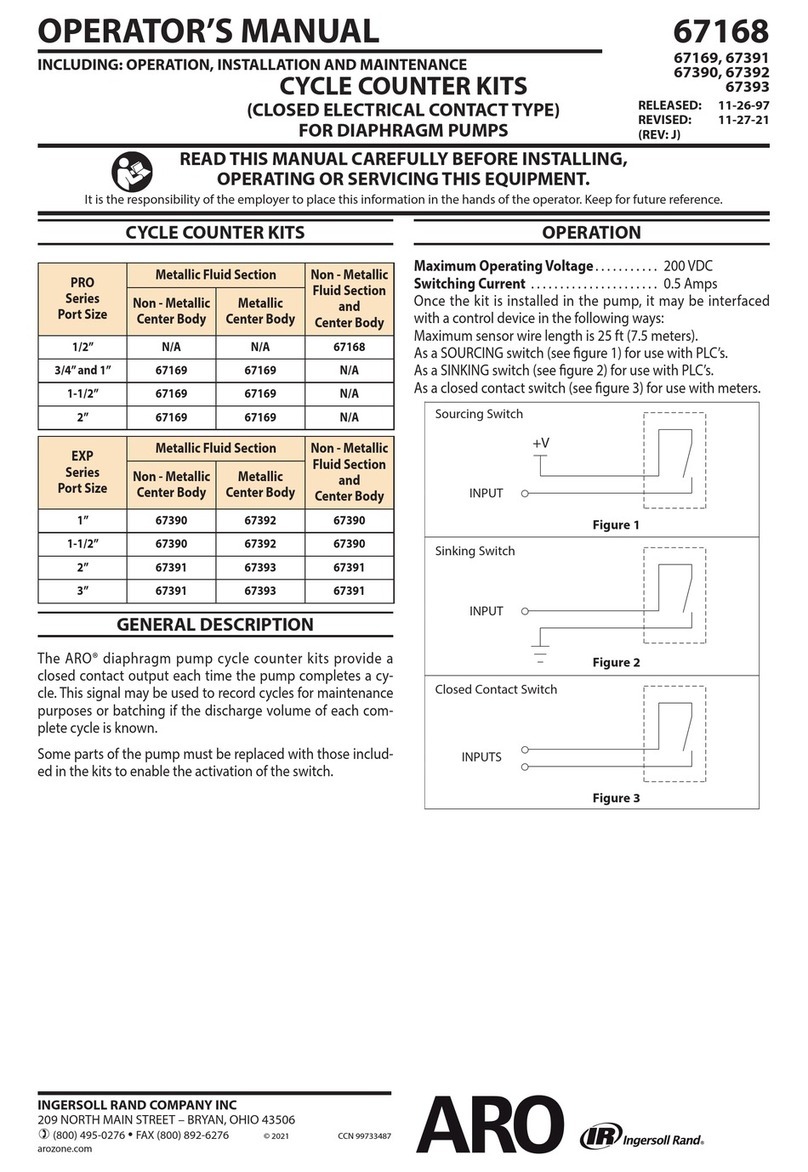

(Dwg. D6090010)

14. Secure the opposite end of the chain as previously

described for the single chain fall hoists.

In the event that the chain has been completely removed from

the hoist it will be necessary to remove the hoist brake. Refer

to the instructions for “Brake Disc Replacement” (Ref. Dwg.

D6090010).

Insert the first link in “D” so link is parallel to pinion (112).

Ensure welded side of second chain link faces away from

sprocket (107).

Rotate pinion (112) by hand to install chain until it appears at

“C”

. Do not attempt to install the chain by powering the hoist.

Attach the chain at “A” after installing buffer (133).

Reinstall the brake and complete chain installation as

previously described.

General Disassembly

The following instructions provide the necessary information

to disassemble, inspect, repair, and assemble the hoist. Parts

drawings of the hoist assembly are provided in the Parts

section

If a hoist is being completely disassembled for any reason,

follow the order of the topics as they are presented.

It is recommended that all maintenance work on the hoist be

performed on a bench in a clean dust free work area. In the

process of disassembling the hoist, observe the following :

1.

2.

3.

4.

5.

6.

7.

Never disassemble the hoist any further than is necessary

to accomplish the needed repair. A good part can be

damaged during the course of disassembly.

Never use excessive force when removing parts. Tapping

gently around the perimeter of a cover or housing with a

soft hammer, for example, is sufficient to break the seal.

Do not heat a part with a flame to free it for removal,

unless the part being heated is already worn or damaged

beyond repair and no additional damage will occur to

other parts.

In general, the hoist is designed to permit easy

disassembly and assembly. The use of heat or excessive

force should not be required

Keep the work area as clean as practical, to prevent dirt

and other foreign matter from getting into bearings or

other moving parts.

All seals and ‘O’rings should be discarded once they have

been removed. New seals and ‘O’rings should be used

when assembling the hoist.

When grasping a part in a vise, always use leather-

covered or copper-covered vise jaws to protect the surface

of the part and help prevent distortion, This is particularly

true of threaded members, machined surfaces and

housings.

Do not remove any part which is press fit in or on a

subassembly unless the removal of that part is necessary

for repairs or replacement.

Disassembly Instructions

(Ref. Dwg. D6090001)

1.

2.

6.

7.

8.

9.

Disconnect all hoses from hoist motor. Position hoist

vertically so brake end is down Remove the four

capscrews and pry motor assembly from gear casing (61).

Set motor assembly to one side for later disassembly. Pull

coupling (110) from pinion (ll2).

Remove capscrews (6), pull out tubes (57) and screen

(58) from gear casing (61). Reposition hoist in a vertical

position so motor end is down

Progressively loosen capscrews (78) in cover (77) one

turn at a time each, until the brake spring load is relaxed.

Remove spring washers (80). Lift off brake disc (79) and

brake friction disc (83).

Remove capscrews (115) and pry brake cover (73) and

gasket (90) from gear casing (61). Lift off spring washer

(88).

Pull piston (76) with ‘O’rings (74) and (75) from brake

cover (73).

Pry bearing (89) from planet support (64).

Set hoist in a horizontal position and from the motor end

of the gear casing (61) carefully tap on the end of pinion

(112) to remove planet assembly.

Remove retainer ring (85) and tap out pinion (112).

4