651533ĆX

PAG 2OF8

MAINTENANCE

W th proper care, th s un t w ll g ve long rel able serv ce. To ma nta n th s

performance t should be flushed out w th solvent mmed ately follow ng

each spray per od.

CAUTION Always disconnect pump power source and reĆ

lease all pressure before disassembly or removal of any part.

FOR CL ANING: Use solvent with highest possible flash point,

that is compatible to material being used.

1. ShutĆoff a r pressure to pump and rel eve l qu d pressure n system

through manual rel ef valve at outlet f lter on those models

equ pped, or tr gger gun mak ng sure pressure s rel eved. Never

attempt to force pa nt backward from gun through hose to pump

and pa nt conta ner.

2. Place gun safety lock n closed pos t on and remove spray t p from

gun. Place t p n small conta ner of solvent for soak ng and f nal

clean ng. Use soft br stle brush to remove any pa nt collect on on

t p. If t p or f ce s clogged, remove obstruct on by us ng a r blow gun

appl ed to outlet of or f ce at front of t p and blow ng back through

rear of t p, f obstruct on w ll not blow out, use clean ng w re, toothĆ

p ck or brush br stle to d slodge. N V R ATT MPT TO CL AN

TIP WHIL IT IS ATTACH D TO SPRAY GUN.

3. Remove gun from hose and clean exter or w th su table solvent and

brush. Allow gun to soak n solvent for a short t me f necessary to

soften accumulat on. After clean ng, w pe exter or of gun w th dry

cloth. (NOTE: Inter or of gun has not yet been cleaned).

4. Remove pump from pa nt conta ner and place pump nlet nto conĆ

ta ner of su table clean solvent.

5. D rect open end of hose nto pa nt conta ner and start pump by apĆ

ply ng only suff c ent a r pressure to cycle pump slowly and to force

pa nt from pump and hose nto grounded pa nt conta ner. When solĆ

vent beg ns to flow from hose, sw tch hose to grounded solvent conĆ

ta ner, ncrease a r pressure to pump allow ng solvent to c rculate

through pump, hose and back to conta ner for approx mately one

m nute or unt l exam nat on nd cates hose and system are clean.

6. Whenever 60530 nl ne sw vel f lter s be ng used, remove from

hose and gun, d sassemble and clean.

7. ShutĆoff a r pressure to pump and assemble gun to end of hose.

8. D rect end gun (w thout t p) nto top of grounded (bond ng recomĆ

mended) solvent conta ner and release safety lock on gun so tr gĆ

ger can be retracted.

9. Start pump w th gun tr gger retracted, ncrease a r pressure unt l

suff c ent pressure s obta ned to cause pump to cycle approx mateĆ

ly 25 cycles per m nute. Purge gun approx mately one m nute wh le

nterm ttently operat ng tr gger. Adjust pack ng gland f necessary to

prevent leakage.

10. ShutĆoff a r pressure to pump and pull gun tr gger to rel eve presĆ

sure n system wh le gun s st ll d rected nto grounded solvent conĆ

ta ner.

11. Place safety lock on gun n closed pos t on and reassemble cleaned

spray t p to gun, w pe all exter or surfaces clean.

12. D sconnect pump from power source.

SERVICE

If mater al leakage occurs around the (12) reta n ng screw, the (10)

pack ng and the (11) flat pack ng have perhaps become worn. T ghten

the (12) reta n ng screw and f th s doesn't stop the leakage replace the

pack ng.

If mater al leakage occurs at the spray t p of the gun, check for d rt or

fore gn matter wh ch may prevent the (7) ball and stem assembly from

seat ng properly.

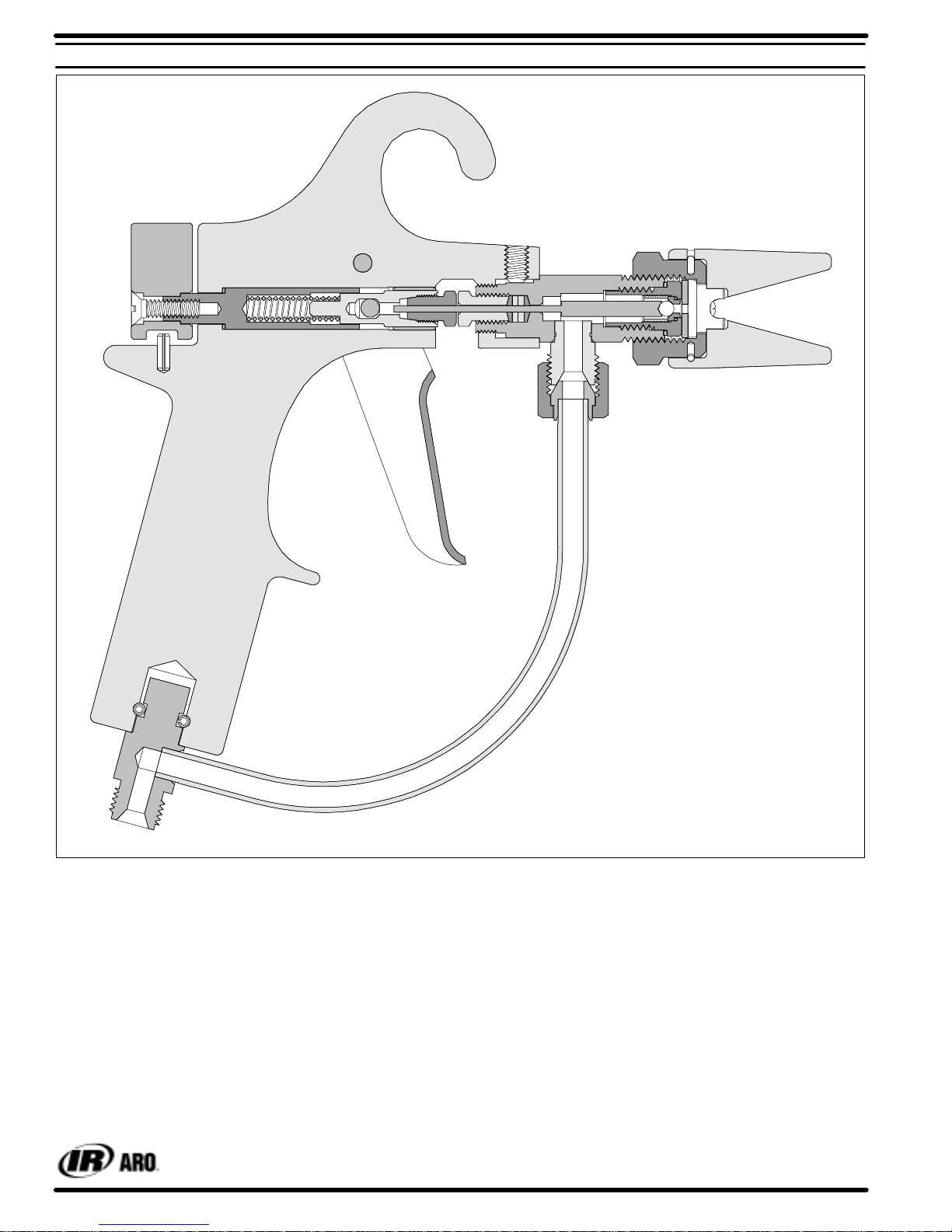

DISASSEMBLY

1. D sconnect a r l ne from pump and rel eve mater al l ne pressure by

pull ng (22) tr gger.

2. D sconnect mater al l ne from gun.

3. Unscrew the (1) cap and guard assembly and remove the (2) washĆ

er and spray t p.

4. Loosen the (13) collet nut.

5. Loosen the (19) set screw. D sconnect and remove the (21) nlet

tube braz ng assembly by loosen ng the tube nut and rotat ng the

tube assembly 90_to e ther s de of the (20) handle.

6. Unscrew the (9) spray gun body and adapter assembly from the

(20) handle.

7. Remove the (3) screw, (8) washer and (12) reta n ng screw from (9)

spray gun body and adapter assembly.

8. Remove the (7) ball and stem assembly and the (10) pack ng and

(11) flat pack ng from the (9) spray gun body and adapter assembly.

For normal cleaning or service, parts (14), (15), (16), (17), (18), (22),

(23), (24), (25), (26), (27) and (28) need not be removed.

REASSEMBLY

1. Insert the (7) ball and stem assembly nto the (9) spray gun body

and adapter assembly.

2. Carefully sl p the two (10) pack ngs and two (11) flat pack ngs n the

order shown n the d agram over the w re of the (7) ball and stem

assembly.

3. Sl de the (12) reta n ng screw onto the (7) ball and stem assembly

and push the pack ngs nto the (9) spray gun body and adapter asĆ

sembly. T ghten (12) reta n ng screw hand t ght.

4. Install the (8) washer on the (3) screw and screw the assembly nto

(9) spray gun body and adapter assembly hand t ght. Then back off

screw 3/4 turn.

5. Push the (7) ball and stem assembly forward unt l t seats on the ball

seat of the (3) screw and t ghten (12) reta n ng screw.

6. Screw the (9) spray gun body and adapter assembly nto the (20)

handle. Be sure the w re of the (7) ball and stem assembly enters

the hole n the (13) collet nut. Back off the (9) spray gun body and

adapter assembly unt l mater al nlet faces down. T ghten (19) set

screw.

7. Be ng sure the ball s st ll seated n the ball seat, ret ghten the (13)

collet nut.

8. T ghten the (3) screw.

9. Replace the (21) nlet tube braz ng assembly nto the (20) handle

and (9) spray gun body and adapter assembly.

10. Check safety operat on by rotat ng the (25) knob to the safe pos t on

and pull the (22) tr gger. If movement of the (7) ball and stem asĆ

sembly s noted, adjust the gun as follows. W th the safety off and

the ball seated on the ball seat, hold the tr gger and loosen the (13)

collet nut. Pull the tr gger back sl ghtly and ret ghten the (13) collet

nut. Recheck safety operat on and readjust f necessary.

11. Insert the spray t p and (2) washer n the (1) cap and guard assemĆ

bly and screw cap on (9) spray gun body and adapter assembly.