6 47143300_ed1

NOTICE

This following installation can be accomplished more easily by

aligning the compressed Blades with the webs at the narrowest

portion of the opening. Keeping the Blades on the web allows

them to slide the length of the Liner without interference.

9. Using nger pressure, compress the Springs with the Blades

until the outer edges of the Blades are ush with the drive shaft

surface. Capture the Blades in this position by installing the Liner

Assembly, guide spring end trailing, over the Drive Shaft and

against the Rear Liner Cover. Make certain the Liner Pins (43) in

the Liner enter the holes in the Cover.

10. Insert the hub end of the Rear Liner Cover into the Disassembly

Arbor from the Tool Kit and stand it on a workbench with the

Drive Shaft upward.

11. Install the Seal Back-Up Ring (53) followed by the Drive Shaft

O-ring (52) in the central opening in the face of the Front liner

Cover.

12. Install the Front Liner Cover Assembly over the Drive Shaft and

against the Liner.

For Model 500A, make certain the Oil Stop Cap Assembly aligns

with the Spring Guide assembly.

For Model 700A, make certain the Torque Adjustment Screw (57)

aligns with the proper spring guide opening that was marked

during assembly.

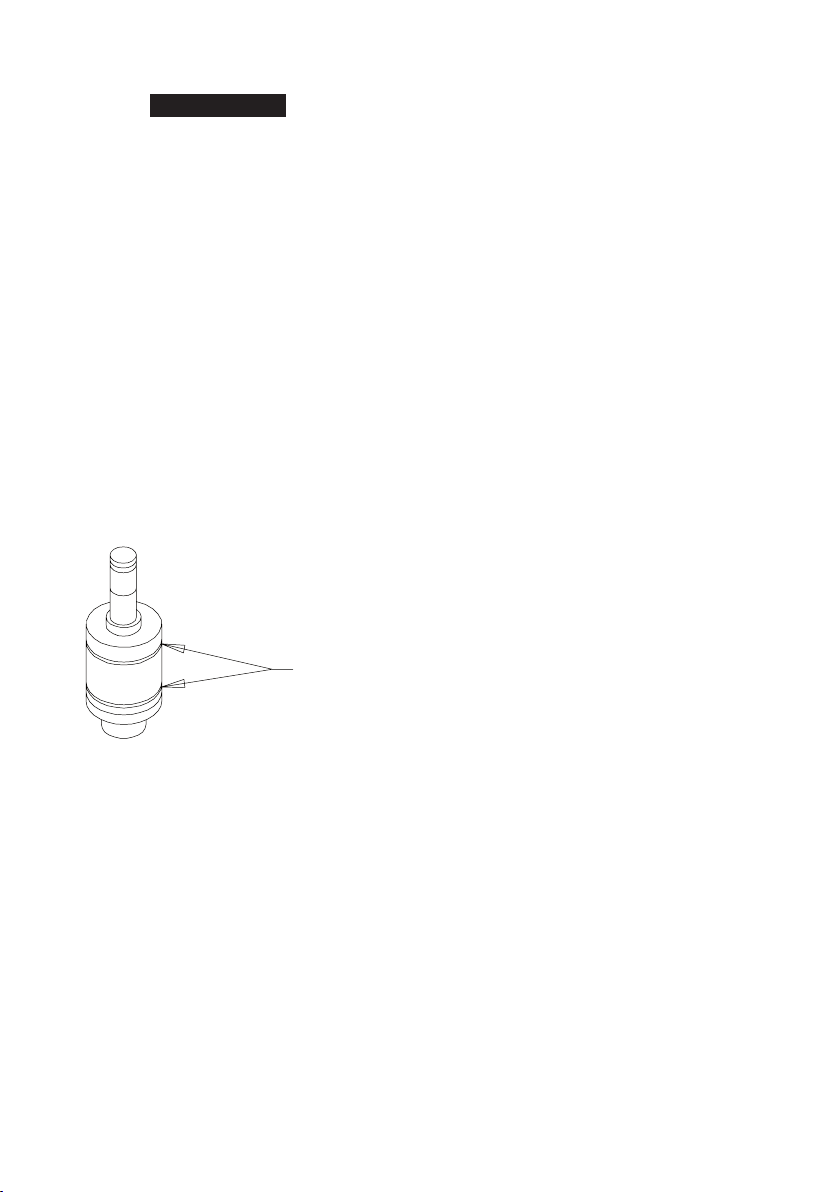

13. For Model 500A, install the Liner Cover O-ring (41) in the groove

that was formed where the Rear Liner Cover contacts the Liner

and install the Liner O-ring (37) in the groove formed where the

Front Liner Cover contacts the Liner. Lubricate the Seals with

O-ring lubricant. (Refer to Dwg. TPD1312).

Liner Seals

(Dwg. TPD1312)

14. For Model 500A, apply some grease to the Liner Cover Seal (68)

and install it in the grooves inside the Liner Housing (32) near the

end with the external wrench ats.

For Model 700A, apply some grease to the two Liner Cover Seals

(68) and install them in the grooves inside the Liner Housing (31)

near the end with the external wrench ats.

15. For Model 500A, orient the Liner Housing so the Liner Cover Pin

(55) will enter the hole in the Housing and install the Housing

over the Liner.

For Model 700A, place the Liner Housing Seal end trailing, over

the assembled Liner. Make certain the notch in the trailing end

face of the Housing aligns with the Oil Plug (59) in the Front Liner

Cover. Use the Pressing Sleeve from theTool Kit to oppress the

Housing over the Seals during installation.

16. Grasp the ats of the Liner Housing in the vise jaws with the

output spindle downward. Remove the Rear Liner Cover and ll

the recess in the Cover with grease. Reinstall the Cover and push

it downward below the threads at the rear of the Housing.

17. Using Spanner Plug furnished with the Tool Kit and a torque

wrench, install the Housing Cap, (castellated end leading for

Model 700A). Tighten the Cap between 101 and 116 ft-lb (137

and 157 Nm) torque.

18. Make certain the Drive Shaft rotates freely and then ll the

mechanism with uid as instructed in the section, CHANGING

THE MEVHANISM FLUID.

Assembly of the Angle Head

1. If the Spindle Shaft Busing was removed, press a new Bushing

into the Angle Housing (69), large end trailing, until it seats.

2. Lubricate and install the two pinion Bearings (75) on the shaft of

the Bevel Pinion (77) and insert the assembly, gear end leading,

into the motor end of the Angle Housing.

3. Install the Pinion Bearing Cap (73) and tighten it snug.

4. Insert the Spindle Shaft (79) into the gear end of the Spindle (81).

5. Chalk the gear teeth of the Spindle and carefully insert the

assembly into the Angle Housing. Make certain the Shaft enters

the Bushing. Install the Spindle Cap (85) and lightly tighten it.

6. Using a wrench on the square drive, rotate the Spindle to

suciently mark the chalked gear teeth. Carefully remove the

Spindle Cap and examine the gear teeth.

7. If the gearing runs smoothly and gear tooth engagement is

good, reinstall the Cap and tighten it and the Pinion Bearing Cap

securely.

If the gearing does not run smoothly or gear tooth engagement

is poor, proceed as follows:

Determine which way the Spindle or Pinion must move to

improve engagement.

Insert the correct thickness Pinion Bearing Shim (76), Spindle

Upper Shim (80) or Spindle Lower Shim (84) separately or in

combination to achieve the desired engagement.

Chalk the gear teeth and test the tooth engagement again.

When satised that the proper bevel gear engagement has

been achieved, tighten the Spindle Cap and Pinion Bearing

Cap securely.

8. Remove the Grease Plug (71) and ll the cavity with gear grease.

9. Install the Bearing Cap Retaining Screw (74) and Spindle Cap

Retaining Screw (86) and tighten them securely.

10. Install the assembled Impulse Unit Drive Assembly on the rotor

shaft in the Motor Housing (1).

11. Install the Angle Housing Space (72), small opening leading, into

the Drive Shaft (48) against the impulse mechanism.

12. Place a new Gasket (78) on the Angle Housing and install the

assembled Angle Housing over the Drive Shaft against the

Housing. Install the four Angle Housing Mounting Screws (89)

and Lock Washers (90). Tighten each Screw between 45 and 50

in-lb (5.1 and 5.6 Nm) torque.

a.

b.

c.

d.