INIM Electronics SmartLine Series Assembly instructions

SmartLine

Conventional fire detection control panel

Extinguishant system control panel

Alarm transmission and fault warning routing

equipment with integrated power supply equipment

Installation and programming manual

EN 54-2

EN 54-4

EN 54-21

EN 12094-1

0051

0051-CPR-1412

0051-CPR-1413

0051-CPR-1414

2Copyright

Conventional fire detection control panel

Copyright

The information contained in this document is the sole property of INIM Electronics s.r.l.. No part may be

copied without written authorization from IINIM Electronics s.r.l..

All rights reserved.

European directive compliance

This Control panel has been designed and developed to the highest standards of quality and performance

implemented by INIM Electronics s.r.l..

This control panel must be installed in accordance with the instructions described in this manual and in

compliance with the laws in force.

All control panels from the SmartLine series are EN54-2, EN54-4, EN54-21 and EN12094-1 compliant.

All control panels from the SmartLine series, and all accessory items and special functions have IMQ

Security systems certification, unless otherwise stated.

Declarations of performance, declarations of compliance and certificates relating to the products mentioned

in this manual can be downloaded from the following website:

www.inim.biz

Table of contents 3

Installation and programming manual

Table of contents

Copyright ............................................................................ 2

European directive compliance ............................................... 2

Table of contents.................................................................. 3

Chapter 1 Overview............................................................................. 5

1.1 Application and use 5

1.2 Other parts of the system 7

1.3 The SmartLine fire alarm panel models 7

Chapter 2 General information .............................................................. 8

2.1 Supplied documentation 8

2.2 Manual details 8

2.3 Operator qualifications - access levels 8

2.4 Intellectual property rights 8

2.5 Disclaimer 8

2.6 Recommendations 9

2.7 System test 9

2.8 Note to the installer 9

2.9 Technical support 9

2.10 Conventions 9

2.11 Menu paths 10

2.12 CE Mark 10

2.13 Warranty 11

2.14 Safety laws 11

2.15 Replacement and disposal of used devices 12

Chapter 3 Device management ........................................................... 13

3.1 Product handling and storage 13

3.2 Environmental conditions 13

3.3 Unpacking the device 13

Chapter 4 Technical description........................................................... 15

4.1 Control panel 15

4.2 Internal devices 16

4.3 Technical specifications 18

4.4 PCB current draw 18

Chapter 5 User interface .................................................................... 19

5.1 SmartLine panel frontplate 19

5.2 Repeater (add-on panel) 24

Chapter 6 Installation instructions ....................................................... 27

6.1 Mounting the SmartLine/8Z expansion board (accessory item) 27

6.2 Mounting the SmartLAN/485 Ethernet board (accessory item) 28

6.3 Mounting the SmartLetLoose/ONE extinguishant board (accessory item) 29

6.4 Wall mounting 29

6.5 Connecting the lines 30

6.6 Connecting an alarm dialler 34

6.7 Connecting the dialler for fault communications 34

6.8 Connecting the RS485 BUS 35

6.9 Connecting the fault signalling outputs 37

6.10 Connecting the Alarm signalling output 37

6.11 Connecting NAC outputs to the Smart/8Z expansion board 38

6.12 Connecting AUX and AUX-R outputs 38

6.13 Connecting RELAY output 39

6.14 Connecting the Extinguishant module

(optional system enhancement tool) 39

4Table of contents

Conventional fire detection control panel

6.15 Connecting the mains power source 41

6.16 Connecting the batteries 42

6.17 Thermal probe 43

Chapter 7 Powering up and configuring the system................................ 44

7.1 Testing wiring integrity 44

7.2 Connecting the RS232 PC serial link 44

7.3 Powering up the system 45

Chapter 8 Introduction to Programming from the panel .......................... 46

Chapter 9 Programming from panel ..................................................... 47

9.1 Configuring the control panel 47

9.2 Programming the zones 47

9.3 Setting the Timers 53

9.4 Setting holidays 54

9.5 Setting the control panel options 54

9.6 Setting up equations 55

Chapter 10 Detection line threshold-adjustment...................................... 56

Chapter 11 Programming the extinguishant board ................................... 57

11.1 Configuring the extinguishant module 58

11.2 Programming the module 58

11.3 Programming extinguish inputs/outputs 59

Chapter 12 Configuring the devices connected to the RS485 BUS .............. 60

Chapter 13 Closing the programming session ......................................... 61

13.1 Restoring factory settings 61

Chapter 14 SmartLeague software ........................................................ 62

14.1 Overview 62

14.2 The Solutions 62

14.3 Enable programming via PC 62

Chapter 15 Maintenance ...................................................................... 63

15.1 Set Time and date 63

15.2 Viewing events 63

15.3 Day/Night mode 63

15.4 Bypassing a zone 64

15.5 Bypass the DIALER or ALARM NAC output 64

15.6 Testing the zones 64

15.7 Force the status of I/O lines configured as outputs 64

15.8 Set the date for the next maintenance session 65

15.9 Reading the power supply tension 65

Chapter 16 Diagnostics and fault solutions ............................................. 66

16.1 Fault “Open” 66

16.2 Fault “Shorted” 66

16.3 Repeater faults 66

16.4 Battery faults 66

16.5 Other faults 67

Appendix A Iris devices........................................................................ 68

Notes................................................................................ 71

Installation and programming manual

Overview 5

Chapter 1

Overview

Note:

The control panels described in this manual have been designed and manufactured to the highest standards

of quality, reliability and performance adopted by INIM Electronics. The components selected for these

products will operate properly within their specifications when the environmental conditions outside the

product enclosure comply with Class 3k5 (EN60721-3-3.).

Danger:

The GAS control function is not provided for in the aforesaid standard and therefore cannot

be considered EN54-2 compliant.

Danger:

In order to validate the IMQ-SECURITY SYSTEMS certification, and in compliance with EN54-

2, all the manual alarm buttons and fire detectors employed in the system must be

associated with fire detection and alarm functions.

1.1 Application and use

The SmartLine conventional fire control panel manages up to 20 conventional detector lines (zones) for

SmartLine020 models or up to 36 lines for SmartLine036 model. Each line (zone) accepts up to 30 devices

and is provided with an additional I/O line that can be configured as an open-collector output (the

activation principles can be defined during the configuration phase) or as an independent input line

(separate from the zone) for fire detection, gas detection line, etc. The basic model has 4 on-board zones

(2 for the SmartLine020-2 model) expandable to 20 (or 36 for the SmartLine036) by means of 2

SmartLine/8Z optional attachment boards (8 lines per board).

The control panel also provides a series of outputs for the activation of signalling or remote transmission

devices. The graphic display and LEDs provide visual indication of the system status and real-time

signalling of fault conditions. The control panel supports up to 4 repeater panels (SmartLetUSee/LCD-Lite);

these remote consoles replicate all the information provided by the control panel and allow access to level

1 and 2 functions. The control panel can also house and manage the SmartLetLoose/ONE gas extinguishant

boar (optional).

Figure 1 - Example of a typical SmartLine installation

A

D

C

B

F

E

G

6Overview

Conventional fire detection control panel

[A] The zones

Each zone is provided with a pair of terminals (lines) for the connection of the fire-detection devices

deployed in the protected area. Each line (zone) accepts up to 30 devices (conventional detectors or call

points). The control panel can be configured to discriminate between detector and call point triggered

alarms. Each line can be configured to activate various signals (fire alarm, gas alarm, etc.).

The lines accommodate:

•Detectors: A detector is an active fire protection device that detects smoke or flames and issues an

alarm thereby alerting building occupants to the danger of fire. They can be:

- Optical smoke detectors which look for the presence of visible by-products of combustion in the

detection chamber (Tyndall effect).

- Optical/Heat detectors which operate as per optical smoke detectors but also sense for increase in the

environment temperature. The combination of both sensing methods (smoke and heat) provides faster

detection and reduces the false alarm rate.

- Heat detectors which sense for an increase in the temperature in the protected environment. These can

be either fixed temperature detectors (which generate an alarm signal when the ambient temperature

exceeds the pre-set temperature threshold) or rate-of-rise (which respond to a rapid rise in

temperature.

- Ionization smoke detectors: feature a harmless radioactive source within a dual detection chamber.

They operate by sensing for a change in electrical conductivity across the detection chamber.

- CO detectors: sense the levels of carbon monoxide given off by all carbon-based materials in the

smouldering stages of a fire (often combined with heat detection sensor).

•Conventional call point: a clearly indicated fire button with instructions for use in the event of fire.

This device is usually located in strategic positions especially near building entry/exit points. When

activated these devices trigger system alarms.

For further information regarding the list of the detectors the lines accommodate, and for details regarding

their operating principles, refer to Chapter 10 - Detection line threshold-adjustment.

Danger:

In order to comply with EN54-2 requirements, no more than 30 detectors/devices should be

connected to each line.

Each detection line must be terminated with a 3900 ohm resistor (included), in such way as to allow the

control panel to monitor the integrity of the wiring.

[B] SmartLetUSee/LCD-Lite repeater (accessory item)

This optional system enhancement tool (equipped with keypad, LEDs, fast buttons and display) replicates

all the system data. The control panel manages up to 4 repeaters which can be connected at a distance of

up to 1000m from the control panel via RS485 BUS. These devices are usually located near building entry/

exit points in order to allow personnel to obtain information regarding zones affected by alarm conditions

without actually entering the premises.

[C] SmartLevel power supply station (accessory item)

The SmartLevel is the ideal power source for all devices located in the area protected by the fire detection

system. Its internal board meets all EN54 requirements and provides complete supervision of the power

station. The device can be connected to the control panel by means of the RS485 BUS, thus allowing the

complete supervision of the power station and control of the 3 outputs.

[D] Gas extinguishant system (accessory item)

The panel can house and manage a gas extinguishant module (SmartLetLoose/ONE, optional system

enhancement board). The gas extinguishant module is compliant with EN 12094-1.

[E] Sounderflashers

These audible/visual alarm signalling devices connect to the control panel outputs and are capable of

signalling specific conditions. The activation trigger (alarm, pre-alarm, warning, etc.), can be specified

during the system configuration session.

Installation and programming manual

Overview 7

[F] SmartLink Advanced telephone dialler

INIM's SmartLink/G and SmartLink/GP telephone dialers monitor the analogue landline and, in the event of

landline problems (line cutting, etc.) divert incoming and outgoing calls to the GSM network. The

SmartLink/P model operates solely over the PSTN line (landline).

[G] SmartLAN/485 Ethernet connection board (accessory item)

Allows the control panel to connect to an Ethernet network for remote connection. So it is possible to

modify the configuration parameters (up-download programming data) and/or manage the system using

the SmartLook supervision software based on graphical maps.

1.2 Other parts of the system

Zone: a group of points (detectors, etc.) connected to a detection line. The control panel provides an extra

terminal (I/O) for each zone. If the terminal (I/O) is configured as an input, the control panel will be able to

split the detection line of each zone. This feature can be used when zones require a detector line that is

separate from the call point line in order to ensure proper operation of one line in the event of fault on the

other.

Switching power supply: this unit, starting from the mains power supply (230V ) it connects to,

supplies the board with a 24V (27.6V ) stabilized current capable of feeding the control panel and

recharging the batteries. The EN54-4 compliant power-supply module is housed below the motherboard.

the mains power supply (230V ) the primary power source of the system. Refer to paragraph 4.2 -

Internal devices.

Batteries: the secondary power source of the system. The panel enclosure houses two lead batteries @

12V 17Ah (connected in series). The system monitors the battery status (efficiency and charge). In the

event of inefficient or low battery conditions, the system will signal battery fault. In the event of primary

power failure (230V ), the batteries will take over automatically. If the problem persists for a long period

thus causing the battery charge to drop below the minimum value required, they will be shutdown

automatically in order to avoid damage. Refer to paragraph 6.16.

Thermal probe: an accessory tool, to be connected to the panel and attached to the battery pack. This

device monitors the temperature of the external battery pack and regulates the battery charge accordingly.

Refer to paragraph 6.17.

RS485 BUS: 4 wire BUS for the repeater connections. Cabling must done with 4 pole braided shielded

cable. Refer to paragraph 6.8 - Connecting the RS485 BUS.

Timer: a logical entity (the panel provides 8 timers) for automatic time-management of preset intervals (2

intervals per day) on preset days of the week and specific dates. The timers can be used in equations to

manage predefined operations or activate outputs.

Equation: a group of logical conditions defined by the installer. An equation comprises a series of

operators (AND, OR, +, etc.) and a series of operands (Points, Zones, Timers, etc.). An equation can be

associated with an output that will activate when the equation is satisfied.

Holidays: a list of days defined during the system configuration session which are associated with the

control panel timers.

1.3 The SmartLine fire alarm panel models

The available models are:

• SmartLine020-2 - Conventional fire alarm control panel with 2 zones non expandable

• SmartLine020-4 - Conventional fire alarm control panel with 4 zones expandable to 20

• SmartLine036-4 - Conventional fire alarm control panel with 4 zones expandable to 36

8General information

Conventional fire detection control panel

Chapter 2

General information

2.1 Supplied documentation

• Installation and programming manual (this manual)

• User's manual

The Installation manual is inside the device package. For further copies of the Installation Manual, please

contact INIM electronics offices.

2.2 Manual details

• Title: SmartLine installation and programming manual

• Version: 3.60

• Manual code: DCMIINE0SLINE

• Addresses: installer, technicians

2.3 Operator qualifications - access levels

The SmartLine is EN-54 compliant. There are four access levels:

Level 1: The Public

All persons in the building can view the system status (active events) and events log; silence

the panel beeper and, under pre-alarm conditions, override pre-alarm status and activate an

instant alarm.

Level 2: Authorized operators — person/s responsible for the safety of the building and its occupants.

Authorized operators (keyswitch and PIN users) can silence the outputs, reset the panel,

activate the 'Investigation' delay, disable zones, points and outputs, change the operating mode

(Day/Night) and activate the 'Evacuation' alarm.

Level 3: Authorized technicians appointed by the Installer company.

Such technicians possess the tools required for the removal of the control panel frontplate. And,

are allowed to insert the jumper which enables the control panel programming phase (via

control panel or PC), in order to access the programming and maintenance functions. The

control panel is unable to process data or generate fault or alarm signals of any kind during the

programming phase.

Level 4: Technicians employed by the Manufacturer (INIM Electronics s.r.l.).

The manufacturer company technicians can, by means of special tools, repair or replace the

control panel components.

Note:

This manual is for Authorized installer company technicians (Level 3). However, it also provides some

installation information related to level 1 and level 2.

2.4 Intellectual property rights

The information contained in this document is private property. All rights reserved.

This document must not be reproduced, either totally or in part, without the prior written consent of INIM

Electronics, and refers to the devices specified in paragraph 2.12.

2.5 Disclaimer

INIM Electronics s.r.l. shall not be responsible for damage arising from improper application or use.

This control panel should be handled by qualified personnel only. Installation must be carried out strictly in

accordance with the instructions described in this manual, and in compliance with the local fire code in force.

Installation and programming manual

General information 9

2.6 Recommendations

INIM Electronics recommends that the entire system be checked completely at regular intervals (refer to

paragraph 2.7 - System test).

2.7 System test

This system has been designed to provide the highest standards of reliability and performance. Malfunction

of any of the system devices may cause the system to be incapable of reaching the intended levels of

performance. Most problems which prevent the system from operating as intended can be found by regular

testing and maintenance of the system devices (refer to Chapter 15 - Maintenance).

The test must include all the system detectors, signalling devices and all other devices that are part of the

system.

2.8 Note to the installer

In order to provide adequate protection and instructions for correct use of the apparatus, you (the

installer) must be fully aware of the regulations and operating procedures of firefighting. As the only

individual in contact with system users, it is your responsibility to instruct them on how to use this system

properly and to bring to their attention that every fire is different in the amount of smoke and rate of

burning. Therefore, smoke and heat detectors may not provide timely warning of fires caused by violent

explosions, escaping gas or improper storage of inflammable materials.

Regardless of its capabilities, a fire alarm system is not a substitute for the necessary precautions building

occupants must take to prevent or minimize the harmful effects of fire.

2.9 Technical support

Our professional engineers are readily available to assist you. If you require help, call us and you will be

put through to a person capable of answering your questions and providing you with the service you need.

2.10 Conventions

2.10.1 Terminology

Panel; device; system: refer to the devices defined in paragraph 2.12.

Left, right, behind, above, below: refer to the directions as seen by the operator in front of the mounted

device.

Communicator (telephone, SMS, digital):synonym of dialler.

STP: Shielded twisted pair cable.

Qualified personnel: those persons whose training, expertise and knowledge of the laws and bylaws

regarding service conditions and the prevention of accidents, are able to identify and avoid all possible

situations of danger.

Select: click on and select a specific item (from drop-down menu, options box, graphic object, etc.).

Press: click on a video button, or press a key on the panel keypad.

2.10.2 Graphic conventions

Following are the graphic conventions used in the text. For a description of the graphic conventions relating

to the interface, refer to paragraph 5.1 - SmartLine panel frontplate.

Conventions Example description

Text in Italics Refer to paragraph 2.10.2

- Graphic conventions

Text in italics: indicates the title of a chapter, section, paragraph,

table or figure in this manual or other published reference.

<text> #<CustomerCode> Variable data.

[uppercase letter]

or [number]

[A] or [1] Identifies a system component or video object.

BUTTON Esc, RESET Computer or control panel keys.

10 General information

Conventional fire detection control panel

Note:

The detached notes contain important information about the text.

Attention:

The attention prompts indicate that total or partial disregard of the procedure could damage

the connected devices.

Danger:

The danger warnings indicate that total or partial disregard of the procedure could injure the

operator or persons in the vicinity.

2.11 Menu paths

Example

From panel: <key>, Programming, Progr. zone, select a zone, Ok

Via software application: Control panel, Zones

Access to specific functions can be achieved by using the panel keys or PC video objects and the respective path.

Note:

This manual describes the recommended programming flow.

Attention:

For most part this manual describes programming from the control panel.

2.12 CE Mark

Figure 2 - Certifications for SmartLine control panels

Note:

The indications for the CE marking shown in the installation manual of the SmartLetLoose/ONE electronic

board (optional accessory device) are an integral part of the indications shown here on condition that it is

installed in the mentioned control panels.

Declarations of performance, declarations of compliance and certificates relating to the products mentioned

in this manual can be downloaded from the following website:

www.inim.biz

0051

EN 54-2:1997 + A1:2006

EN 54-4:1997 + A1:2002 + A2:2006

EN 54-21:2006

SmartLine020-2

Control and indicating equipment with integrated power supply

equipment and alarm transmission and fault warning routing

equipment for fire detection and fire alarm systems installed in

buildings

INIM ELECTRONICS S.R.L.

via Dei Lavoratori 10 - fraz. Centobuchi

63076 Monteprandone (AP) - Italy

18

0051-CPR-1414

0051

EN 54-2:1997 + A1:2006

EN 54-4:1997 + A1:2002 + A2:2006

EN 54-21:2006

SmartLine036-4

Control and indicating equipment with integrated power supply

equipment and alarm transmission and fault warning routing

equipment for fire detection and fire alarm systems installed in

buildings

INIM ELECTRONICS S.R.L.

via Dei Lavoratori 10 - fraz. Centobuchi

63076 Monteprandone (AP) - Italy

18

0051-CPR-1412

0051

EN 54-2:1997 + A1:2006

EN 54-4:1997 + A1:2002 + A2:2006

EN 54-21:2006

SmartLine020-4

Control and indicating equipment with integrated power supply

equipment and alarm transmission and fault warning routing

equipment for fire detection and fire alarm systems installed in

buildings

INIM ELECTRONICS S.R.L.

via Dei Lavoratori 10 - fraz. Centobuchi

63076 Monteprandone (AP) - Italy

18

0051-CPR-1413

Essential characteristics Performance

SSAPPerformance under fire conditions

SSAPPerformance of power supply

Response delay (response time to fire) PASS

SSAPPerformance of transmission

SSAPOperational reliability

Durability of operational

reliability:

temperature resistance PASS

vibration resistance PASS

SSAPelectrical stability

humidity resistance PASS

Options provided according to EN 54-2 Performance

7.8 Output to the fire alarm device PASS

7.9 Control of fire alarm routing equipment PASS

SSAPeticsuelledodratiR11.7

7.12 Dependencies on more than one signal (Type A and B) PASS

SSAPTest condition01

Essential characteristics Performance

SSAPPerformance under fire conditions

SSAPPerformance of power supply

Response delay (response time to fire) PASS

SSAPPerformance of transmission

SSAPOperational reliability

Durability of operational

reliability:

temperature resistance PASS

vibration resistance PASS

SSAPelectrical stability

humidity resistance PASS

Options provided according to EN 54-2 Performance

7.8 Output to the fire alarm device PASS

7.9 Control of fire alarm routing equipment PASS

SSAPeticsuelledodratiR11.7

7.12 Dependencies on more than one signal (Type A and B) PASS

SSAPTest condition01

Essential characteristics Performance

SSAPPerformance under fire conditions

SSAPPerformance of power supply

Response delay (response time to fire) PASS

SSAPPerformance of transmission

SSAPOperational reliability

Durability of operational

reliability:

temperature resistance PASS

vibration resistance PASS

SSAPelectrical stability

humidity resistance PASS

Options provided according to EN 54-2 Performance

7.8 Output to the fire alarm device PASS

7.9 Control of fire alarm routing equipment PASS

SSAPeticsuelledodratiR11.7

7.12 Dependencies on more than one signal (Type A and B) PASS

SSAPTest condition01

Installation and programming manual

General information 11

2.13 Warranty

INIM Electronics s.r.l. warrants that for a period of 24 months from the date of commissioning, the product

shall be free of defects in materials and workmanship. The warranty applies only to defects in parts and

workmanship relating to normal use. It does not cover:

• Improper use or negligence

• Damage caused by fire, flood, wind or lightning

• Vandalism

• Fair wear and tear

INIM Electronics s.r.l. shall, at its option, repair or replace any defective products. Improper use, that is,

use for purposes other than those mentioned in this manual will void the warranty. For the full details and

conditions regarding the warranty, refer to the purchase order.

2.14 Safety laws

The aim of the instructions in this section is to ensure that the device is installed and handled properly. It is

assumed that anyone who handles this apparatus is familiar with the contents of this chapter.

2.14.1 Compliancy

The design and manufacture of the SmartLine panel conform with EN 54-2 Fire detection and signalling

systems - Control and signalling panels.

The power supply unit has been especially designed and manufactured in full compliance with EN 54 part 4

Fire detection and fire alarm systems - Power supply equipment.

The SmartLetLoose/ONE extinguishant board enhanced SmartLine control panel has been developed and

designed in compliance with EN 12094-01 Fire-fighting Systems - Components of fire-extinguishant

systems - Part 1: Requirements and testing methods for automatic electrical command and fire-extinguish

or delay management devices.

2.14.2 Managing electronic devices

The normal motions of any person may generate electrostatic potential of thousands of volts. Discharge of this

current through semiconductor devices during handling may cause serious damage which although may not be

immediately evident may reduce the reliability of the circuits.

If located in their housings, the electronic circuits of INIM Electronics products are highly immune to

electrostatic discharge.

Do not expose the circuits to damage by removing the modules unnecessarily from their housings.

• When removing or handling the boards, hold the board edges only.

• Do not touch the electronic components, the printed circuits or the metal parts of the connectors.

• Do not hand the board to another person without first ensuring that both of you have the same

electrostatic potential. This can be achieved by simply shaking hands.

• Place the board on an anti-static surface or a conductor surface with the same potential.

Further information regarding procedures relating to safety when working with electronic devices can be

found in EN 61340-5-1 e CLC/TR 61340-5-2.

2.14.3 Setting up the system

In order to provide adequate protection and instructions for proper use, security professionals (Installers

and maintenance technicians) must be familiar with the operating procedure of this device.

Please read the instructions carefully before installing and setting up this product.

Before first power-up, be sure that the earth connection has been completed properly on the respective

terminal. The recommended minimum wire cross section for the earth connection is 2.5 mm

2

, unless

otherwise stated in accessory documentation.

12 General information

Conventional fire detection control panel

2.15 Replacement and disposal of used devices

Replacement

When replacing obsolete devices, disconnect the devices concerned then complete the connections of the

new devices in compliance with the instructions printed on the respective leaflets.

In order to avoid short-circuits, take all the necessary precautions when removing used batteries.

Disposal

Do not burn used electronic devices, or allow them to pollute the environment (countryside, rivers, etc.).

Electronic devices must be disposed of in a safe environment-friendly way. When disposing used devices or

batteries, contact your local municipal offices for information regarding their disposal.

Informative notice regarding the disposal of electrical and electronic equipment

(Applicable in countries with differentiated waste collection systems)

The crossed-out bin symbol on the equipment or on its packaging indicates that the product

must be disposed of correctly at the end of its working life and should never be disposed of

together with general household waste.

The user, therefore, must take the equipment that has reached the end of its working life to the

appropriate civic amenities site designated to the differentiated collection of electrical and

electronic waste.

As an alternative to the autonomous-management of electrical and electronic waste, you can hand over the

equipment you wish to dispose of to a dealer when purchasing new equipment of the same type.

You are also entitled to convey for disposal small electronic-waste products with dimensions of less than

25cm to the premises of electronic retail outlets with sales areas of at least 400m

2

, free of charge and

without any obligation to buy.

Appropriate differentiated waste collection for the subsequent recycling of the discarded equipment, its

treatment and its environmentally compatible disposal helps to avoid possible negative effects on the

environment and on health and favours the re-use and/or recycling of the materials it is made of.

Installation and programming manual

Device management 13

Chapter 3

Device management

3.1 Product handling and storage

This device is safely packed inside a cardboard box, however, care must be taken to avoid accidental

damage during handling. Cartons/boxes should be placed in such a way as to avoid knocks and falls, and

special care must be taken to protect the devices from extreme heat and/or cold.

3.2 Environmental conditions

Temperature limits:

-10° / +55°C for transport and storage

-5° / +40°C operating temperature

3.3 Unpacking the device

On receipt the goods must be unpacked with care. All waste packaging materials must be disposed of in

compliance with the local laws and bylaws in force.

The metal enclosure of the device is packed carefully inside the cardboard box.

Note:

The lead batteries are not included. Be sure you have the batteries on hand before starting.

When you remove the four screws and metal-frontplate, you will find:

• The SmartLine motherboard mounted on a plastic support that bridges the two sides of the metal box.

• Power supply module located under the plastic support. The power supply module is connected to the

SmartLine motherboard.

• A plastic bag containing:

- Battery connection wires

- Eyelet terminal for connection to earth

- Key for access level 2

- Resistors and EOL diodes for supervised circuits

- Expansion board connection cable (SmartLine036 only)

• [A] ProbeTH - thermal probe battery-charge optimizer

The following accessory items must be ordered separately:

• [B] SmartLetUSee/LCD-Lite - repeater panel

• [C] SmartLetLoose/ONE - extinguishant board

• [D] SmartLevel - power-supply station

• [E] SmartLine/8Z - 8 zones expansion board

• [F] SmartLAN/485 - Ethernet interface board

14 Device management

Conventional fire detection control panel

Figure 3 - Thermal probe and accessory devices

A

D

B

F

E

C

Installation and programming manual

Technical description 15

Chapter 4

Technical description

4.1 Control panel

Figure 4 - External and internal parts of the SmartLine020

Figure 5 - Inside the SmartLine036

[A] Frontplate with display, keys

and signalling LEDs

[B] Slot for level 2 access key

[C] Frontplate

[D] Securing screws for the front

cover

[E] Cable entries (located on all

sides of the enclosure)

[F] Data label

[G] Plastic support for front panel

and motherboard mounting

[H] Plastic support anchor screw

[I] About the motherboard

[J] Power supply module

[K] Backup battery housing

[L] Cable entry

[M] Anchor screw hole

A

B

C

D

F

G

E

K

J

I

H

L

L

L

M

M

A

B

D

D

D

H

H

H

C

G

L

K

J

I

H

L L

L

M

M

A

B

H

H

H

K

16 Technical description

Conventional fire detection control panel

4.2 Internal devices

Figure 6 - SmartLine motherboard

Main components:

[A]

ZONE +

/

-

Zone detection-line terminals

[B]

ZONE I/O

Zone I/O terminals

[C]

RS485

RS485 BUS terminals for repeater and power station connections, max. 0.9 A

[D]

FAULT

Fault output, dry contact

[E]

DIALER

Output terminal for dialler connection, supervised

[F]

ALARM NAC

Supervised alarm output

[G]

AUX

24V - 0.8A output for external loads

[H]

AUX R

24V - 0.8A output for external loads - off during reset

[I]

RELAY

Programmable dry contact (Alarm at default)

[J] Power-supply module connector

[K] Connector for the earth wire of the power supply module

[L] Earth-fault-bypass jumper - if this jumper is removed faults will be bypassed

[M] RS232 serial port for PC connection

[N] Jumper for programming from panel (keypad and LCD) J8

[O] Jumper for programming from PC J9

[P] Extinguishant module connector

[Q] Buzzer

[R] Connector for expansion board

[S] Reserved connectors DO NOT USE

A B C D E F G H I

Q

A B A B A B

L

R

M

K

J

O

PN

S

S

Installation and programming manual

Technical description 17

Figure 7 - Switching power supply

The switching power supply is attached to the backplate of the metal enclosure. The power supply type

depends on the control panel model.

Note:

INIM s.r.l. reserves the right to change, replace, in part or entirely, the components not strictly relating to

the installation procedure described in Chapter 6 - Installation instructions.

SmartLine020 SmartLine036

[A]

Mains input terminal board

[B] SmartLine mother board connector

[C] Battery connector

[D] Thermal probe connector

A

A

D

C

B

D

B

C

SmartLine020

Power Supply

SmartLine020

Power Supply

N

L

230V ~ 50/60 Hz

AC I

nput

NL

230V ~ 50/60 Hz

AC I

nput

18 Technical description

Conventional fire detection control panel

4.3 Technical specifications

4.4 PCB current draw

Specification SmartLine020 SmartLine036

AC power 230V (-15% / +10%) 50/60Hz

Maximum current draw 230V 0.5 A 1.1 A

Nominal output voltage 27.6 V

Maximum output current 2.1 A 5.2 A

I

max. a

1.5 A 4 A

I

max. b

1.5 A 4 A

Maximum battery current emission during primary

power failure

1.5 A 4 A

Maximum current for external loads and accessory

devices

1.41 A 3.91 A

Maximum current draw on terminal + AUX 0.8 A

Maximum current draw on terminal + AUX-R 0.8 A

Maximum battery-charge current 0.6 A 1.2 A

Battery specifications 2 x 12 V, 7 Ah 2 x 12 V, 17 Ah

2 x 12 V/7 Ah YUASA NP-12 FR or similar with case flame

class UL94-V2 or higher

Maximum internal resistance of the batteries (R

i max

) 2.7 Ohm 1 Ohm

Output voltage from 18 to 27.6V

Battery shutdown tension 19V

Internal fuse of switching power supply module T 3.15A 250V

Maximum output current ripple 1%

Operating temperature from -5°C to 40°C

Isolation class I

Enclosure protection class (EN 60529) IP30

Dimensions 325 x 325 x 80 mm 497 x 380 x 87 mm

Weight 2.8 Kg 6 Kg

Module Standby current draw Maximum current draw

SmartLine motherboard 90 mA 90 mA

SmartLAN/485 board 50 mA 50 mA

SmartLine/8Z board 50 mA 50 mA

SmartLetLoose/ONE board 10 mA 70 mA

SmartLetUSee/LCD-Lite repeater 40 mA 80 mA

Installation and programming manual

User interface 19

Chapter 5

User interface

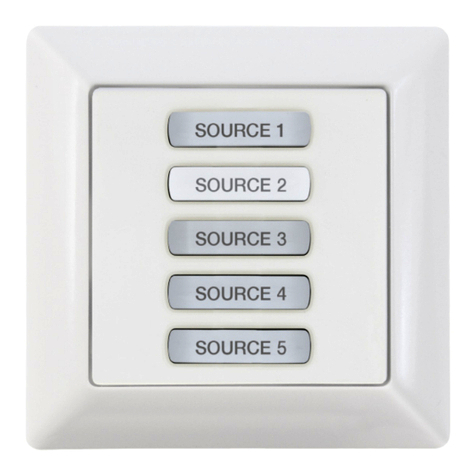

Figure 8 - Frontplate

5.1 SmartLine panel frontplate

5.1.1 Commands

Command Access level 1 Access level 2 Note

[A] Navigation keys To be used to navigate through the

menus on the display. Their effect

varies in accordance with the

context. See Chapter 8 -

Introduction to Programming from

the panel.

[B] Slot for level 2

access key

Key not inserted or

inserted in vertical

position

Key inserted in horizontal

position

When the key is removed or placed

in the vertical position and no key

is pressed, the control panel will

hold access level 2 status for 20

seconds.

[C] SILENCE Pushing this button

silences the panel

beeper.

Silences (switches OFF) active

outputs with the silenceable

attribute. The silenceable

outputs will hold silenced status

until a new event occurs that

releases the outputs

automatically. The SILENCE

button operates as a toggle

switch, therefore, silenced

outputs can be unsilenced by

pushing the button again.

If the system is operating in Night

mode, SILENCE status will be held

for the preset SILENCE time only.

This is a safety precaution

designed to protect building

occupants and persons in charge of

night-security who, after silencing

the system, may be overcome by

smoke or fumes during fire

investigation and unable to restart

the alarm signalling devices

manually.

[D] RESET Push this button to clear any

active events, delete the

memory and restore standby

conditions.

Any alarm/fault conditions which

persist after RESET operations will

generate new alarm/fault signals.

C

D

E

F

G

H

I

A

B

L

M

K

J

T

N

O

S

P

Q

W

R

U

X

V

Y

Z

A1

B1

C1

D1

E1

F1

20 User interface

Conventional fire detection control panel

5.1.2 Signalling

[E] EVACUATE If this button is pressed

during active pre-alarm

conditions, the system

will override the

programmed pre-alarm

time and generate an

instant alarm.

If this button is pressed when

pre-alarm conditions are not

active, the system will generate

a panel alarm.

[F] INVESTIGATE If this button is pressed during

active pre-alarm conditions, the

system will add the preset

investigation time to the

running pre-alarm time (this

operation can be done once

only).

The extended alarm delay will allow

authorized building occupants and/

or security staff to check and verify

the fire hazard.

Extinguishant board commands

[G] DISABLE

EXTINGUISH

If this button is pressed once,

the system will disable fire-

extinction commands. If this

button is pressed again, the

system will re-enable fire-

extinction commands.

This button can be used during

testing and maintenance of the fire

extinction devices.

[H] DISABLE AUTO If this button is pressed once,

the system will disable

automatic fire-extinction

commands generated by the

board. If this button is pressed

again, the system will re-enable

automatic fire-extinction

commands generated by the

board.

[I] DISABLE

MANUAL

If you push this button once,

the system will disable manual

extinguish commands. If you

push this button again, the

system will re-enable manual

extinguish commands. Refer to

paragraph 6.14 - Connecting

the Extinguishant module

(optional system enhancement

tool).

LED If On solid: If Blinking: Note

[J] Display See Chapter 8 - Introduction to

Programming from the panel.

[K] SILENCED

(yellow)

Indicates that the

system has been

silenced.

[L] RESET

INHIBITED

(yellow)

In the event of pre-

alarm/alarm, indicates

that reset commands are

not allowed. Reset will

be allowed when all

outputs have been

silenced and this LED

goes Off.

This feature ensures that persons

responsible for the safety of the building

and its occupants do not reset the system

without first silencing the outputs, and

evaluating the alarm. The silence operation

will stop the signalling devices and restore

quiet thus allowing the operator to consider

the best way to proceed. The operator will

then be able to reset the system and

restore standby status.

Command Access level 1 Access level 2 Note

This manual suits for next models

3

Table of contents

Other INIM Electronics Control Panel manuals

INIM Electronics

INIM Electronics Prime Series User manual

INIM Electronics

INIM Electronics Prime Series User manual

INIM Electronics

INIM Electronics Prime060S User manual

INIM Electronics

INIM Electronics SmartLoop Owner's manual

INIM Electronics

INIM Electronics PREVIDIA MAX User manual

INIM Electronics

INIM Electronics Previdia Compact User manual

INIM Electronics

INIM Electronics SmartLoop User manual

INIM Electronics

INIM Electronics Previdia Compact User manual

INIM Electronics

INIM Electronics SmartLight User manual

INIM Electronics

INIM Electronics Previdia Compact Quick guide