INIM Electronics Previdia Compact Quick guide

Configuration manual

1

MANUAL FOR

SYSTEM CONFIGURATION,

COMMISSIONING AND

MAINTENANCE

EN 54-2

EN 54-4

EN 54-21

EN 12094-1

ANALOG-ADDRESSABLE FIRE ALARM CONTROL PANEL,

EXTINGUISHANT SYSTEM CONTROL PANEL,

ALARM TRANSMISSION AND FAULT WARNING ROUTING EQUIPMENT

0051

0051-CPR-1498

0051-CPR-1499

2Warranty

Fire detection and extinguishant system

Warranty

INIM Electronics s.r.l. (Seller, Our, Us) warrants the original purchaser that this product shall be free from defects in

materials and workmanship under normal use for a period of 24 months. As INIM Electronics s.r.l. does not install this

product directly, and due to the possibility that it may be used with other equipment not approved by Us; INIM

Electronics s.r.l. does not warrant against loss of quality, degradation of performance of this product or actual damage

that results from the use of products, parts or other replaceable items (such as consumables) that are neither made nor

recommended by INIM Electronics. Seller obligation and liability under this warranty is expressly limited to repairing or

replacing, at Seller's option, any product not meeting the specifications. In no event shall INIM Electronics s.r.l. be liable

to the purchaser or any other person for any loss or damage whether direct of indirect or consequential or incidental,

including without limitation, any damages for lost profits, stolen goods, or claims by any other party caused by defective

products or otherwise arising from the incorrect or otherwise improper installation or use of this product.

This warranty applies only to defects in parts and workmanship relating to normal use. It does not cover:

• damage arising from improper maintenance or negligence

• damage caused by fire, flood, wind or lightning

• vandalism

• fair wear and tear

IINIM Electronics s.r.l. shall, at its option, repair or replace any defective products. Improper use, that is, use for purposes

other than those mentioned in this manual will void the warranty. Contact Our authorized dealer, or visit our website for

further information regarding this warranty.

Limited warranty

INIM Electronics s.r.l. shall not be liable to the purchaser or any other person for damage arising from improper storage,

handling or use of this product.

Installation of this Product must be carried out by qualified persons appointed by INIM Electronics. Installation of this

Product must be carried out in accordance with Our instructions in the product manual.

Copyright

The information contained in this document is the sole property of INIM Electronics s.r.l.

No part may be copied without written authorization from INIM Electronics s.r.l.

All rights reserved.

Configuration manual

Table of contents 3

Table of contents

Warranty.......................................................................................................................... 2

Limited warranty........................................................................................................... 2

Copyright........................................................................................................................ 2

Table of contents ......................................................................................................... 3

Chapter 1 General information ....................................................................................................5

1.1 Manufacturer's details .....................................................................................................................5

1.2 About this manual ............................................................................................................................5

1.3 Description of the configuration and programming procedures .......................................6

1.4 Operator classification - Access Levels ......................................................................................6

Chapter 2 Configuration ................................................................................................................ 7

2.1 First startup.........................................................................................................................................7

2.2 Access to programming.................................................................................................................8

2.3 Accessing the configuration menu .............................................................................................8

2.4 Access to the device modification menu..................................................................................9

2.5 Resetting factory default data .....................................................................................................10

Chapter 3 System Parameters .....................................................................................................11

3.1 General parameters of the control panel ................................................................................ 11

3.2 Configuring the Ethernet network.............................................................................................11

3.3 Configuring the Hornet+ network............................................................................................. 12

3.4 Configuring the loops ...................................................................................................................12

3.5 SD card functions........................................................................................................................... 15

3.6 Configuring the terminals ............................................................................................................15

3.7 Configuring the users....................................................................................................................15

3.8 Configuring the communicator .................................................................................................16

3.9 Configuring the extinction channel .......................................................................................... 17

3.10 Setting the date and time............................................................................................................ 20

3.11 Firmware revision ...........................................................................................................................21

Chapter 4 Parameters of devices and their groupings.........................................................22

4.1 Loop point parameters ................................................................................................................ 22

4.2 Parameters of control panel terminals .................................................................................... 23

4.3 Zone parameters ........................................................................................................................... 24

4.4 Output group parameters........................................................................................................... 24

4.5 Replicate programming procedure.......................................................................................... 25

Chapter 5 Commissioning...........................................................................................................26

5.1 Testing the Control panel ........................................................................................................... 26

5.2 Testing to detectors and manual activations..........................................................................27

5.3 Testing signalling and activations ..............................................................................................27

5.4 Extinction system test ...................................................................................................................27

Chapter 6 Maintenance................................................................................................................28

6.1 Testing the control panel............................................................................................................ 28

6.2 Testing the detectors ................................................................................................................... 28

6.3 Manual activation test .................................................................................................................. 28

6.4 Testing signalling and activations ............................................................................................. 28

6.5 Testing the extinction system .................................................................................................... 28

4Table of contents

Fire detection and extinguishant system

Configuration manual

General information 5

Chapter 1

General information

1.1 Manufacturer's details

Manufacturer: INIM ELECTRONICS s.r.l

Production plant: Centobuchi, via Dei Lavoratori 10

Comune: 63076, Monteprandone (AP), Italy

Tel.: +39 0735 705007

Fax: +39 0735 704912

E-mail: [email protected]iz

Web: www.inim.biz

The persons authorized by the manufacturer to repair or replace the parts of this system, hold authorization to work on

INIM Electronics brand devices only.

1.2 About this manual

Manual code: DCMCINE0PREVIDIAC

Version: 1.00

This manual describes the procedures for the configuration, commissioning and maintenance of the Previdia Compact

fire-detection system.

1.2.1 Graphic conventions

Following are the graphic conventions used in this manual.

Note: The notes contain important information relating to the text.

Attention: The “Attention” prompts indicate that total or partial disregard of the procedure could damage the

device or its peripherals.

Conventions Example Description

Text in italics

Refer to paragraph

1.2.1 Graphic

conventions

Indicates the title of a chapter, section,

paragraph, table or figure in this manual or

other published reference

[Uppercase letter] or

[number] [A] or [1] Reference relating to a part of the system

or video object.

6General information

Fire detection and extinguishant system

1.3 Description of the configuration and programming procedures

Following is a flow chart which summarizes the operations to be carried out during the installation and commissioning

phases of the Previdia Compact system and indications regarding the manuals to refer to for each operation.

1. Installation and cabling (refer to the Installation Manual)

2. Addressing devices

3. Initializing (refer to the Installation Manual)

4. Configuration from the front plate (operations described in this manual)

5. Troubleshooting (operations described in this manual)

6. Connection to PC and reading (optional)

7. Configuration of parameters (editing data, optional)

8. Writing on control panel and testing (optional)

9. Commissioning (operations described in this manual)

10. System handover

11. Maintenance (operations described in this manual)

1.4 Operator classification - Access Levels

The control panel has 4 distinct access levels:

Level 1: Public level - this is the normal access level of the control panel and is the access level for building inhabitants

who are neither authorized to use the system nor instructed in its use.

This level allows building inhabitants to view information on the screen and signalling LEDs, interact with the system (in

accordance with Level 1) and scroll through the information by means of the buttons and touchscreen. Level 1 allows the

following operations only:

• mute buzzer

• test signalling LEDs

• activate alarm signalling when an early-warning process is running

Level 2: Authorized users - this access level is for the system supervisors and is for authorized personnel who are

adequately instructed in the use of the system and its functions.

Access requires the use of a key or entry of a valid access code with sufficient access rights. In addition to the operations

described for level 1 it is also possible to carry out the following operations:

• mute alarm signalling devices

• rearm the control panel

• activate alarm signalling devices manually

• disable control panel elements

• place in test status one or more of the system elements

Level 3: Programming - this access level is for specialized technical operators who carry out system configuration,

commissioning and maintenance.

Access requires entry of a valid access code with sufficient access rights after inserting a jumper which enables

programming. Refer to the manual for system configuration, commissioning and maintenance.

ONLY authorized technicians, appointed by the Manufacturer can, by means of special tools, carry out repair work on

the motherboard.

Level 4: ONLY authorized technicians, appointed by the Manufacturer can, by means of special tools, carry out repair

work on the motherboard.

Configuration manual

Configuration 7

Chapter 2

Configuration

2.1 First startup

Once the installation and cabling procedures have been completed (refer to the Installation Manual of the Previdia

Compact system) the system is ready for first startup.

In the case of first startup and after having performed the procedure to set the factory data, it is necessary to enter the

unlock code:

This is a code printed on a special label, affixed to the cardboard box containing the control panel. Alternatively, it can be

found at the following Internet address (the serial number of the control panel will be requested, once provided the

unlock code will be provided):

https://service-previdia.inimcloud.com

Once the unlock code has been entered, you will be asked to select the required the language.

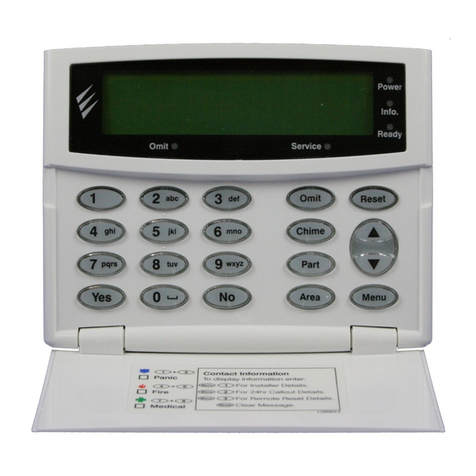

The control panel screen will be as follows:

In the case of faults or other types of events, the latter will be shown on the display. You can retrieve the home

screen at any time by tapping on the respective icon on the status bar [C].

In order to configure the Previdia control panel it is necessary to work through the following procedure:

1. Access programming (paragraph 2.2)

2. Access the configuration menu (paragraph 2.3)

[A]

Buttons to access the

events logs, system

status and

programming.

[B]

Status bar (always

present) shows

essential information

regarding the system.

[C]

“Home” button

Please enter the code

printed on the control panel box SHOW

(also on https://service-previdia.inimcloud.com)

12345 12345 12345 12345

OK

ESC

Log

System status

Programming

01/01/2018 18:23

Access level:1 C

A

B

8 Configuration

Fire detection and extinguishant system

3. Enroll the loop devices, after the respective fault search (paragraph 3.4.2)

4. Set up the control panel parameters (Chapter 3, System Parameters)

5. Configure the connected devices and their groups (Chapter 4, Parameters of devices and their groupings)

6. Check eventual signalling and search for faults (paragraph 5.3)

7. Set the date and time (paragraph 3.10)

Note: Once the configuration operations have been completed correctly, the control panel will be ready to

operate.

The control panel is configured to consider each input point (detector, module, terminal) as a fire-alarm

point. Therefore, in the event of a fire alarm it will activate all the outputs available on its loops or

terminals.

At this point it is necessary to proceed with eventual changes to the configuration data for the

distribution of points in zones, edit descriptions of the various system elements, define specific

activation sequences, etc.

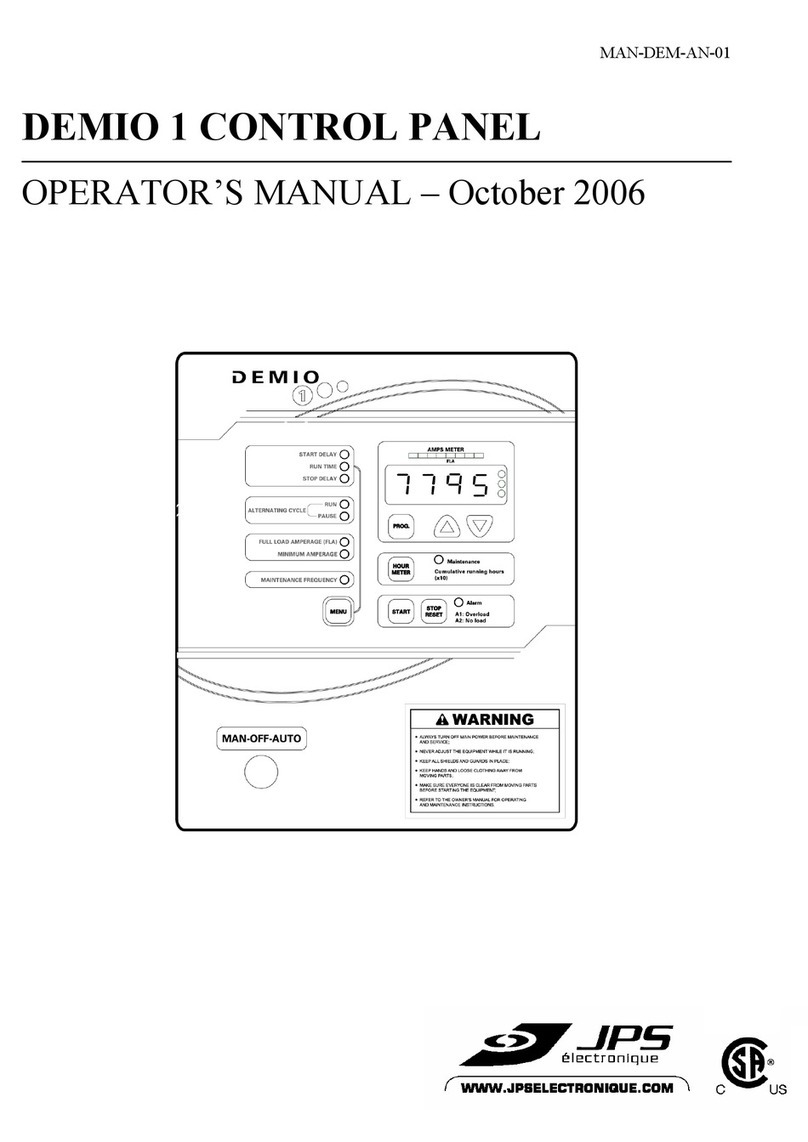

2.2 Access to programming

To access the programming phase of the Previdia control panel, it is

necessary to work through the following procedure:

1. Insert the programming jumper (see opposite, [D]).

2. Press the Programming button on the stand-by screen (see above,

[A]).

3. A keypad will appear (see opposite, [E]) for the entry of a code with

installation privileges.

Note: The default access code to level 3 is “00004”.

4. The accessed programming menu will provide the following options:

- Configuration (refer to paragraph 2.3)

- Modify (refer to paragraph 2.4)

- Factory default settings (refer to paragraph 2.5)

2.3 Accessing the configuration menu

The configuration menu allows the programmer to put all the parts of the Previdia Compact System in the configuration

(control panel, connections and connected devices) after the initial installation phase.

To access the configuration menu it is necessary to first access the programming phase of the control panel (paragraph

2.2) and then tap on the Configuration button which appears on the screen. Once inside the Configuration menu, the

control panel screen will show an image of the control panel frontplate highlighting the access buttons to the

configuration sections.

D

00004

1 2 3

4 5 6

7 8 9

C 0 OK

E

Configuration manual

Configuration 9

2.4 Access to the device modification menu

Once the Previdia Compact system has been configured it is necessary to set the parameters, or change the default

programming of the devices connected to the control panel (single or in group).

The Previdia Compact control panel provides a direct programming option on the control panel for its connected

devices and their logical groups (zones and output groups) without need of accessing the “Configuration” section

(paragraph 2.3). To access it, you must access the programming phase of the control panel (paragraph 2.2) and then

press the Modify button on the menu on the screen.

The section you access will show Ia list containing the access buttons to the programming subsections::

• Zones (refer to paragraph 4.3)

• Output groups (refer to paragraph 4.4)

• I/O Lines (refer to paragraph 4.2)

• Loop points (refer to paragraph 4.1)

Pressing one of these buttons will allow you to view the list of the respective elements. The list shows the index,

description, and status of each element, and by tapping on one of the lines, you will be able to program the parameters

of the individual element.

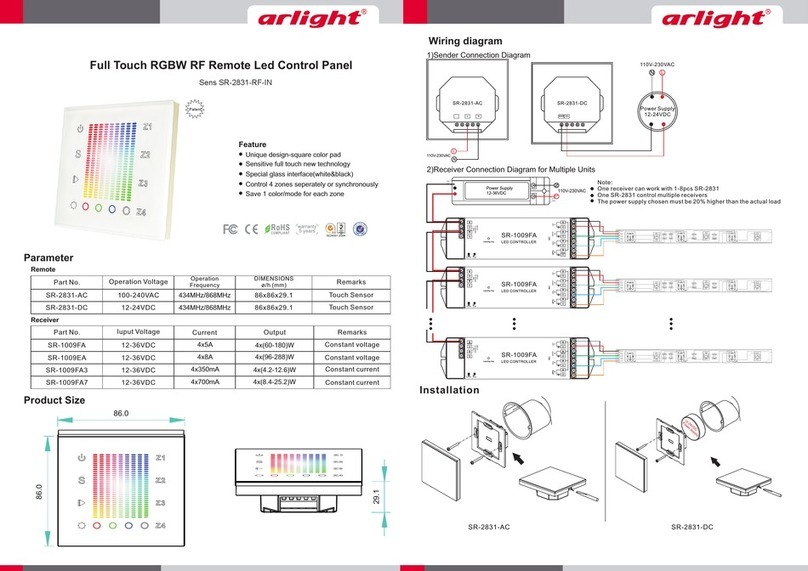

Icon Function buttons Display

Access to the configuration of the

general parameters of the control

panel.

Refer to paragraph 3.1

Access to the configuration of the

extinction channel.

Refer to paragraph 3.9

Access to the configuration of the

Ethernet network.

Refer to paragraph 3.2

Access to the configuration of the

Hornet+ network.

Refer to paragraph 3.3

Access to the configuration of the

loops (loop 1 and loop 2).

Refer to paragraph 3.4

Access to the functions provided by

the SD card.

Refer to paragraph 3.5

Access to the configuration of the

inputs and outputs provided by the

control panel terminals.

Refer to paragraph 4.2

Access to the configuration of the

control panel access codes.

Refer to paragraph 3.7

Access to the configuration of the

general parameters of the remote

communicator.

Refer to paragraph 3.8

Access to the configuration of the

power supply.

Refer to paragraph 5.1

Access level:3

10 Configuration

Fire detection and extinguishant system

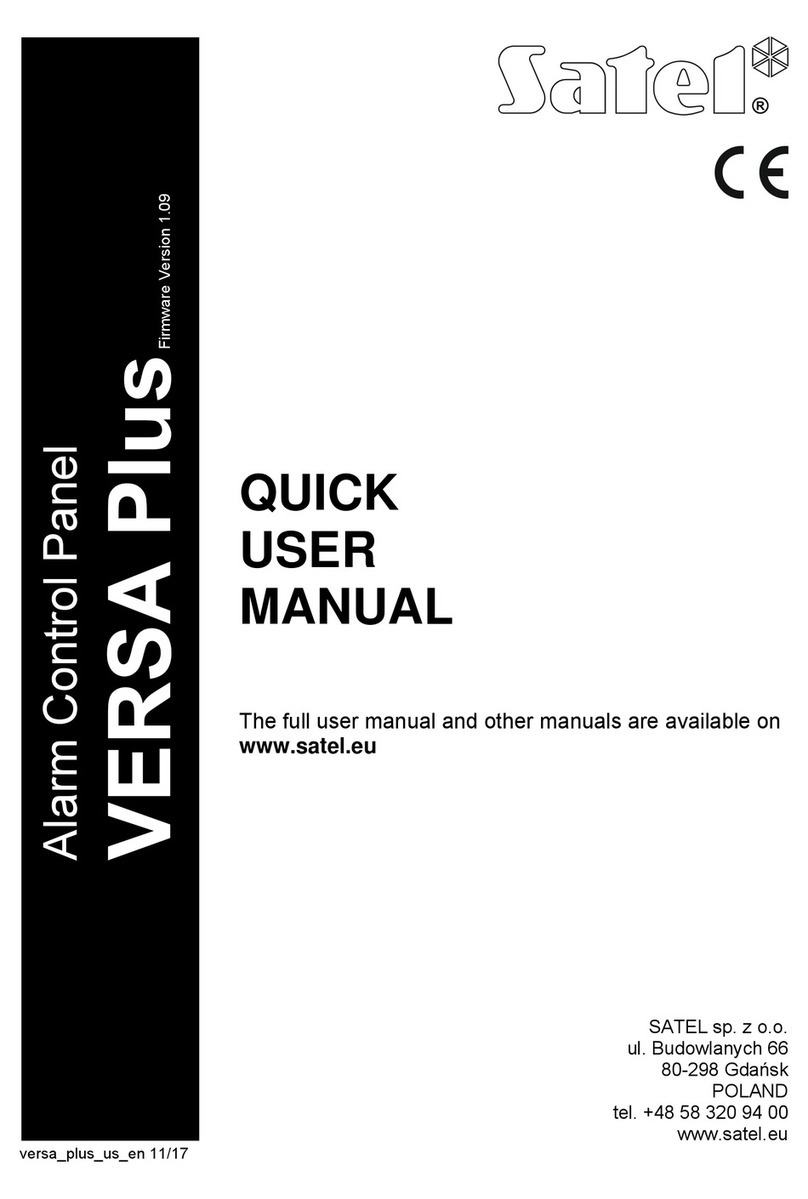

2.5 Resetting factory default data

The resetting of the factory default data and consequent deletion of the

configuration data on the Previdia Compact control panel can be done in

two ways:

• Selecting the Factory data option from the programming menu (refer

to paragraph 2.2).

• Using the buttons available on the plastic support of the electronic

boards, as shown in the figure [A]:

1. Press the FACTORY button.

2. While holding down the FACTORY, button, press the RESET button

then release it.

After confirmation of the request for reset to factory default data, the control panel will carry out the same operations as

at first startup, described at the beginning of this manual.

A progress bar will confirm factory data resetting in course.

A

Configuration manual

System Parameters 11

Chapter 3

System Parameters

The configuration of the Previdia Compact control panel, its interfaces and external connections provides for the settings

of a series of parameters reachable from the control panel by accessing control panel programming (paragraph 2.2) and

then pressing the Configuration button on the menu shown on the screen.

Once inside the Configuration menu (paragraph 2.3), the control panel screen will show an image of the control panel

frontplate highlighting the access buttons to the configuration sections.

3.1 General parameters of the control panel

Tapping on the appropriate icon inside the control panel configuration screen accesses the configuration

section of some of the control panel parameters.

The available parameters are:

•Panel name, editable field for the description of the

control panel

•Mains failure delay, field for the delay (expressed in

minutes) which must pass between detection of mains

failure by the control panel and mains failure signalling

•Disable buzzer, option that, if activated, disables the

control panel buzzer

•Direct alarm on second prealarm, option that, if

activated, generates an alarm signal as soon as two

detectors go into prealarm status, regardless of the zone

they belong to. Otherwise the alarm condition will

activate at the end of the first prealarm time.

The Esc and Set buttons will allow you to exit the section

without changing the programming or saving it.

3.2 Configuring the Ethernet network

If an Ethernet network connection is used, it will be necessary to set up the IP address and parameters of the network.

This operation must be carried out for each of the Previdia control panels and repeaters connected to the Ethernet

network via LAN cable.

To set the network parameters you must enter the programming phase of the control panel (paragraph 2.2)

and then tap on the appropriate icon inside the control panel configuration screen.

The available parameters are:

• IP address

•Netmask

•Gateway

•Port

The Esc and Set buttons will allow you to exit the section

without changing the programming or saving it.

Previdia Compact Panel name

060 Mains failure delay (min)

Disable buzzer Esc

Direct alarm on second prealarm

Set

Access level:3

IP 192 168 1121

Net mask 255 255 255 0

Gateway 192 168 1 1

Port 6001 Esc Set

Access level:3

12 System Parameters

Fire detection and extinguishant system

3.3 Configuring the Hornet+ network

If the installation has control panels connected in a Hornet+ network, it will be necessary to assign the network address

to each control panel.

To set the network parameters you must enter the programming phase of the control panel (paragraph 2.2)

and then tap on the appropriate icon inside the control panel configuration screen.

The available parameters are:

• Bit rate (bps)

• Network Address

•Hornet gateway, option that, if activated, will set the

control panel as the gateway to the network

Note: Only one point can be set as the gateway to

a Hornet+ network.

Each control panel in the same Hornet+

network must be set with the same bit rate

and univocal address.

The Esc and Set buttons will allow you to exit the section without changing the programming or saving it.

3.4 Configuring the loops

The operations for the configuration of the loops and the devices connected to them can be reached by first

accessing the control panel programming section (paragraph 2.2) and then by tapping on the icon of the loop

you wish to configure.

The section reached in this way provides the following buttons:

•Auto-configure, button to access the automatic loop-configuration procedure (refer to paragraph 3.4.1).

•Diagnostics, button to access the section for loop diagnostics (refer to paragraph 3.4.2).

•Parameters, button to access the section for the selection of the type of devices installed on the loop (refer to

paragraph 3.4.3).

•Esc, button to step back.

Note: For the first configuration of the system, it is recommended that you run the loop configuration after

appropriate addressing of the devices as per the following order of access to the sections:

• Parameters

• Auto-configure

• Diagnostics

.

3.4.1 Auto-configuration of the loop

Pressing the Auto-configure button provides you with the following buttons for access to the relative subsections:

•Enroll

• Readdress

•Update

•Add/Change

Hornet Configuration

57600 bps Hornet gateway

000 Address Esc

Set

Access level:3

Configuration manual

System Parameters 13

Enroll: This button performs a loop scan (after command

confirmation) which searches for all the connected devices

and puts those found into the configuration [A].

A report of the devices will be shown when the scan ends.

The Diagnostics button [B] allows you to step to the

technical report which can also be accessed from the Loop

configuration menu (refer to paragraph 3.4.2).

Note: It is possible to use this procedure only

when you have already performed an

addressing operation, automatic or manual, on the devices connected to the loop.

Readdress: This button performs a loop scan (after command confirmation) which searches for the serial numbers of all

the devices. The control panel automatically assigns an address to each device in consecutive order, following the

connection order on the loop.

This operation may take some minutes depending on the size and composition of the loop.

A summarized report is shown containing the devices found, as described in the “Enroll” section ([A]).

Update: This button starts the procedure (after command

confirmation) which is to be performed after changes have

been carried out on a previously configured loop (add,

remove or replace devices).

The control panel provides a table showing the previously

enrolled configuration in the columns on the left [A], and

the newly detected configuration in the columns on the

right [B]. Positions in which changes have not been

detected will be outlined in green. Changes will be

indicated in white.

This operation may take some minutes depending on the

size and composition of the loop.

It is possible to select a device from the column on the right and move it up or down by means of the arrow keys [C].

In this way you can select which addresses will be assigned when, after pressing the Set button [D], the process that re-

addresses the loop devices starts.

Add/Change: This button accesses a section where you

can select a specific address and change, remove or add a

device manually.

At the side of the loop device list are a series of buttons

which will allow you to work on the device selected by a

screen tap gesture, as follows:

-Delete: button to delete the selected device.

-Add/Change: button to change or add a device

manually.

After completing the connection of a new device or

replacing an old device, it is necessary to select the address

involved then tap on the Add/Change button. When using Inim protocol, it is necessary to enter the serial number of the

new device.

-Program: button to access a section where it is possible to change some of the device options (refer to paragraph

4.1 Loop point parameters).

Once this operation has been completed the control panel will communicate with the new device. The appearance of

the type of device detected is the confirmation of its acquisition.

Procedure completed - Found: 73

1 Generic

44 Detectors

12 IN modules

5 OUT modules

0 IN/OUT modules

3 Sounders

8 Call points

Diagnostics

Esc

Access level:3

AB

Found: 6

N. SN Type SN Type

2010EE4D4 Conv. zone module 010EE4D4 Conv. zone module

3010EE4E0 Call point 010EE4E0 Call point

4010EE0AB Input module 010EE0AB Input module

5 010C7CAC Optical heat det. 010C7C11 Optical heat det.

6010E1CE0 Optical heat det. 010E1CE0 Optical heat det.

Esc Set

Access

level:3

AB

CD

N. SN Type Description

1010BE432 Optical heat det. Room 1

2010EE4D4 Conv. zone module Stairway module

3010EE4E0 Call point Button 1

4010EE0AB Input module Corridor module

5010C7CAC Optical heat det. Room 2

6010E1CE0 Optical heat det. Room 3

Delete Add/Change Program Esc

Access

level:3

14 System Parameters

Fire detection and extinguishant system

3.4.2 Loop diagnostics

The Diagnostics button in the Loop configuration menu accesses the section for the loop diagnosis.

The upper left side of the template [A] shows some of the

electrical data of the loop.

•Loop status: indicates whether the loop is a closed ring

circuit or open

•Loop O Terminal: indicates eventual short-circuits or

anomalies immediately on the loop output terminals

•Loop I Terminal: indicates eventual short-circuits or

anomalies immediately on the loop input terminals

•Loop Consumption: indicates the voltage draw of the

loop

•Cable resistance: indicates the resistance value of the

cable

The upper right side of the template [B] shows the number

and type of devices currently in configuration.

The lower part [C] provides the following buttons:

•Loop reset, button to reset the loop and reassess its status.

In the event of a “Loop open” fault, it will be necessary to tap on this button in order to check whether or not the

interruption has been cleared.

•Scan, button to start a scan on an already enrolled loop.

The procedure verifies whether there are any connected devices which are not in the configuration, if devices have

been lost or if there are any other anomalies. The results of the scan can be viewed in the section on the top right of

the display.

•Show topology, button which steps to the layout screen

of the devices in the configuration of the already enrolled

loop.

The layout shows all the devices which are connected to

the loop and how they are connected to one another.

Any devices in alarm or fault status will be outlined in red or

yellow [D].

The selection of a device accesses the management page

of the device itself

The Update button [E] refreshes the screen by updating any

alarms and faults signalled by the devices shown (restored

fault events will not be shown).

3.4.3 Loop Parameters

The Parameters button on the loop configuration menu allows you to

set:

• Device protocol

• Wiring type (2 or 4 wires)

Note: If you are making a two-wire connection, you can install

a maximum of 32 fire-alarm devices on the loop

(detectors or call points).

Loopx: loop yyy

Loop status: closed

Loop O terminal: OK

Loop I terminal:

Loop consumption (mA): 15

Cable resistance (Ohm): 0

Generic: 1

Detectors: 44

IN Modules: 12

OUT Modules: 5

IN/OUT Modules: 0

Sounder/flashers: 3

Call points: 8

Rearm Scan Show layout Esc

Access

level:3

AB

C

Update Esc

Access

level:3

001

002

003

004

005

006

007

008

D

013

014

015

016

017

E

023

024

025

D

Inim

4 wires Esc

Set

Configuration manual

System Parameters 15

3.5 SD card functions

Tapping on the appropriate icon inside the control panel configuration template accesses some of the

functions available on the SD card.

A list with the following buttons will appear:

•Save Program Data, saves the control panel programming data to the SD card in a .dat file, the name of which

coincides with the serial number of the control panel.

•Save Log, saves the contents of the events log to the SD card in a file named “xxxx_log. txt”, where “xxxx” is the serial

number of the control panel.

It is possible to import the data contained in the file into a spreadsheet (the character used as the delimiter of the

various fields is the full stop and comma “;”).

•Read Program Data, if there is a .dat file on the SD card whose name coincides with the serial number of the control

panel, the programming data contained in it will overwrite that currently used.

•Read Display Config. if the “Desktop.Bin” file is on the SD card, the data contained in it (images, buttons and labels to

be displayed in the stand-by screen) will overwrite that currently used. If the previously-mentioned file is not present

on the SD card, and there is the file “Logo. bmp” file is, the image contained in it (260x222 pixel) will be shown on the

stand-by screen.

The Esc and Set buttons will allow you to exit the section without changing the programming or saving it.

3.6 Configuring the terminals

The configuration of the motherboard terminals includes both the configuration of the devices connected to the control

panel motherboard terminals, the “I/O” terminals and relay output terminals.

Tapping on the appropriate icon inside the control panel configuration screen accesses the configuration

section of the input/output terminals.

The configuration of the “I/O” [A] terminals requires firstly

specification of the type of device connected to them, then

the programming of the parameters, which vary according

to the specified choice. Each of the 4 “I/O” terminals can be

configured as:

•Output

•Input

•Notused

For control panel models that provide extinction functions,

the previous screen appears as shown in the figure.

In this case, terminals “I/O3” and “I/O4” are not

programmable, and are dedicated to signalling the pre-

extinction condition and the activation of the Electrovalve

output.

The “relay” output is also available on the list of “I/O” terminals [B].

For each terminal, regardless of whether it is an input or an output, the Program button allows access to the

programming menu of the connected device (refer to paragraph 4.2).

3.7 Configuring the users

Tapping on the appropriate icon inside the control panel configuration screen accesses the configuration

section of the control panel access codes.

I/O 1 Output Program

I/O 2 Input Program

I/O 3 Pre-extinction Program

I/O 4 Gas release Program

Relay Program Esc Set

Access level:3

A

B

16 System Parameters

Fire detection and extinguishant system

This section provides the list of available codes.

Once a code is selected, you can remove it from the

system by pressing the Delete button.

Instead the Program button will allow you to set its

parameters:

•Description, label that identifies the user and that is

shown in the events it is involved in.

•PIN, 5-figure number that identifies the user, thus

allowing access to the system.

•Type, determines the set of operations the user can

control. The following values are possible (refer to

paragraph 1.4 Operator classification - Access Levels and

the User manual):

-No code, code not enabled to access the system.

-User level, coincides with “Level 2” (authorized user)

-Superuser level, same as the previous level, with the

added possibility of loop-device replacement.

-Maintenance operator level, same as the previous level

with the added possibility of stopping the valve pulse

for those models that support extinction functions

-User level, coincides with “Level 3” (authorized user)

Previdia Compact control panels are supplied at default with

the first 4 codes already pre-set:

3.8 Configuring the communicator

To set the network parameters you must first enter the control panel programming phase (paragraph 2.2) and

then tap on the appropriate icon inside the control panel configuration screen.

The boxes marked [A] will allow you to select the

communication channels you want to use:

•Ethernet, for transmission of events with the SIA-IP

protocol over Ethernet cable

•PREVIDIA-C-DIAL, for transmission through the optional

communicator of the Previdia Compact.

If selected, the following channels will also become

available:

•SIM (SIA-IP), for transmission of events with the SIA-IP

protocol over 3G

•SIM (Voice/SMS), for transmission of events with

Contact-ID protocol, of voice messages or SMS texts

over 3G

•PSTN, transmission of events with Contact-ID protocol or

voice messages over the landline

The APN button [B] provides access to a section for the parameters required for the connection to the mobile network.

The Contacts button [C] accesses the phone book programming phase.

After selecting a contact, you will be able to configure it by pressing the Program button.

Code number Code type Default PIN

1 User level 00001

2 Superuser level 00002

3 Maintenance level 00003

4 Installer level 00004

5 ... No code /

N. Type Description

1User level Code 1

2Superuser level Code 2

3Maintenance level Code 3

4Installer level Code 4

5No code Code 5

6No code Code 6

Delete Program Esc

Access

level:3

Code parameters

Code 2 Description

PIN Esc

User level Type Set

Access

level:3

PREVIDIA-C-DIAL Ethernet

SIM (SIA-IP) APN

SIM (voice/SMS) Contacts Esc

PSTN Actions Set

Access

level:3

A

B

C

D

Configuration manual

System Parameters 17

If you are configuring an “SMS” or “PSTN” type channel, the communication protocol will be requested:

•SIA-IP

•ContactID

• Voice call

•SMS

The parameters made available in the contact programming section that follows vary according to the selected protocol.

Pressing the Actions button [D] on the communicator configuration screen will access the list of communication

operations set on the control panel. Selecting one of them and then pressing the Program button accesses the

configuration screen.

The “Type” parameter allows you to specify which events will trigger the action (alarm, fault, etc.).

Note: For the first two actions (alarm and system failure), the “Description” and “Type” fields are not editable.

The Associated contacts button accesses a screen that allows you to specify to which contacts the event

communication will be sent.

If the presence of the Previdia-C-DIAL communicator, set by means of the previously-mentioned option, is

different from the one the control panel detects, the appropriate icon inside the control panel configuration

screen will change status and appear in yellow

.

3.9 Configuring the extinction channel

The parameters of the extinction channel, for control- panels that provide one, can be accessed through the

control-panel programming section (paragraph 2.2), by simply tapping on the relevant icon on the

configuration screen.

The successive sections provide the various programmable parameters (refer to the extinction flowchart and the table of

extinction-terminal functions in the installation manual).

3.9.1 Extinction times

The following parameters can be set on the extinction-

channel configuration page:

•Automatic pre-extinction time: duration of pre-

extinction time, in seconds, when triggered by fire-

fighting devices connected to the control panel.

•Manual pre-extinction time: duration of pre-extinction

time, in seconds, when triggered by input devices

programmed for manual-extinction (refer to following

sections).

•Valve Pulse (option 4.21 “Control of flooding time” of EN

12094-1): duration of release time, in seconds.

Leaving the respective box [A] empty removes all time

limitations.

000

Pre-ext. Automatic

(sec)

Zones

000 Pre-ext. Manual

(sec) Inputs

Valve Pulse

300 (sec) Esc Set

Access

level:3

A

B

C

18 System Parameters

Fire detection and extinguishant system

3.9.2 Trigger zones

The Zones button [B] accesses a screen that permits up to

three zones to activate the extinction phase when, within

one of the indicated zones, a certain number of alarms is

reached.

In order to select the zones, you must first activate one of

the three available options via the [D] check box, then tap

on the respective field at the side [E] to access the list of

configured zones. The arrow buttons [F] will allow you to

specify the number of alarms (maximum 3).

The image at the side shows how the system can be

configured so that the extinction channel is activated when

there are at least two alarms in zone 2.

3.9.3 Extinction input

The Inputs button [C] will allow you to configure the control-panel input points to activate the extinction functions.

EN12094-1: To ensure compliance with EN 12094-1, the inputs in use must be on-board I/O or supervised inputs on

loop modules (such as the EM312SR module).

It is not possible to connect more than 32 devices to each of the selected input terminals.

It is necessary to specify the input associated with the “Manual Extinction” function (the others are

optional).

These functions are grouped into the following categories:

•Activate

This section provides the extinction-activation parameters.

The parameters of the “Manual extinction” command allow

for the selection of an associated group (loop 1, loop 2 or

one of the “I/O” terminals [G]), and the point [H] that

activates the release of the fire extinguishing agent in

accordance with the programmed pre-extinction time.

Selecting “--” for the group disables manual extinction on

the control panel.

•Deactivate

This section provides the parameters for stopping the

extinction procedure. There are 4 different modes available

for stopping the extinction procedure, each one attributable

to a different input:

-Stop Extinct. ABORT (Option 4.27 “Emergency

interruption device” of EN 12094-1): stops the

extinction procedure definitively

-Stop Extinct. HOLD (Option 4.20 “Emergency hold

device” of EN 12094-1): stops the extinction procedure

until reset (which restarts the pre-extinction time)

-Stop Extinct. ADD (Option 4.20 “Emergency hold

device” of EN 12094-1): stop the extinction procedure

until reset (the pre-extinction time-counter will not be

altered)

-Stop Extinct. EXTERN (Option 4.19 "Monitoring the status of components" of EN 12094-1): same as “Stop Extinc.

Hold”, but activated without human intervention (for example by a door contact that inhibits the release of gas)

The parameters of the 4 commands allow for the assignment of a group (loop 1, loop 2 or one of the terminals “I/O” [G]))

and the point [H] which activates the relative stop-extinction mode.

Selecting “--” for the assigned group disables the related stop-extinction mode.

EN12094-1: If the “Stop Extinction ABORT” function is utilized with a Previdia Compact control panel, the “Stop

Extinction HOLD” and “Stop Extinction ADD” functions cannot be associated with inputs, and vice versa.

Trigger zones Requested Alarms

Zone 2 2

1

1

Esc Set

Access

level:3

D E F

Manual extinction

L 1 Button 1

Esc Set

Access

level:3

G H

Stop Extinct. ABORT

L 1 Input module 1

Stop Extinct. HOLD

L 1 Button 2

Stop Extinct. ADD

L 2 Input module 2

Stop Extinct. EXTERN

--

Esc Set

Access

level:3

G H

Configuration manual

System Parameters 19

•Disable

This section provides the parameters of disabling the

extinction procedure. There are 3 different modes available

for disabling the extinction procedure, each one attributable

to a different input:

-Disab. Extinguishing: disables all the extinction

functions

-Disab. Man. Exting.: disables the programmed inputs

for manual activation of the extinction procedure

-Disab. Aut. Exting. (option 4.23 “Manual only mode” of

EN 12094-1): disables the automatic-activation of the

extinction procedure

The parameters of the 3 different disablement modes allow for the assignment of a group (loop 1, loop 2 or one of the

terminals “I/O” [G])) and the point [H] which activates the related extinction-disablement mode.

Selecting “--” for the assigned group disables the related extinction-disablement mode.

•Flow/Pressure

This section provides the parameters for the functions of

the “Pressure switch”, “Pressure switch confirm” and “Flow

switch” that can be associated with three different inputs:

-Pressure switch (option 4.19 “Monitoring of the status

of components” of EN 12094-1): input for the

connection of a pressure valve that activates in the

event of low pressure in the cylinders

-Flow switch (option 4.18 “Signal representing the flow

of the extinguishing agent” EN 12094-1): input for the

connection of a flow sensor, the activation of which

signals the release of the fire-extinguishing gas

-Press. switch Confirm: input for the connection of a

device used to verify the release condition of the fire-extinguishing gas by means of the pressure switch

The parameters of the 3 different functions allow for the assignment of a group (loop 1, loop 2 or one of the terminals “I/

O” [G])) and the point [H] associated with the extinction function.

Selecting “--” for the assigned group disables the related function type.

3.9.4Extinction outputs

In order to configure an output for the extinction function, you must associate it with one of the default groups prepared

for this purpose, and described below.

EN12094-1: You must use on-board I/O or supervised outputs on the loop (such as the EM312SR module or sounder/

flashers on the loop).

You must provide outputs associated with the following functions (the others are optional):

-Electrovalve

-Pre-extinction

-Release

The “Electrovalve” function can only be associated with the output corresponding to the “I/O 4” terminal on the

motherboard of the control panel.

The default “Pre-Extinction” function is associated with the output corresponding to the “I/O 3” terminal on the

motherboard of the control panel.

Disab. Extinguishing

L 1 Input module 4

Disab. Man. Exting.

L 2 Button 3

Disab. Aut. Exting.

--

Esc Set

Access

level:3

G H

Pressure switch

L 1 Button 4

Flow switch

L 2 Button 5

Press. switch Confirm

--

Esc Set

Access

level:3

G H

20 System Parameters

Fire detection and extinguishant system

The Previdia Compact control panel has pre-configured default output groups with specific extinction functions:

EN12094-1: The previous groups can be associated with supervised outputs connected to other devices, internal or

external to the fire extinguishing system, thus creating options 4.24 “Triggering signals to equipment

within the system” and 4.26 “Triggering of the equipment outside the system” of standard EN 12094-1.

3.10 Setting the date and time

Proceed with the time and date setting by selecting the time

and date pane in the lower-right corner of the start page [B]

and, after entering an access code, set the individual fields

using the scroll arrows.

Outputs group Activation EN 12094-1

Associated

extinction

function

3

Extinguishing

Group that activates the release of the gas. Release

4

Pre-

Extinguishing

Group that goes into prealarm status during the

pre-extinction time and into alarm status during

the release phase.

By programming a different

tone pattern (or sound) for the

prealarm and alarm conditions

of an output associated with

this group, this output will

implement option 4.30

(“Activation of alarm devices

with different signals ”).

Pre-Extinguishing

5

Automatic

Exting.

Group that activates during pre-extinction and

release conditions, if they are triggered by

automatic activations (e.g. two alarms in a

specific zone).

6

Manual Exting.

Group that activates during pre-extinction and

release conditions, if they are triggered by

inputs programmed for manual extinction

activation.

7

Manual Stop

Group that follows the activation of inputs

programmed as “Stop extinction Abort”, “Stop

extinction Hold” or “Stop extinction Add”.

Options 4.27 “Emergency

abort device" and 4.20

"Emergency hold device”

8

Stop By Device

Group that follows the activation of the inputs

programmed as “Stop extinction External”.

4.19 “Monitoring of the status

of components”

9

Disab. Aut.

Exting.

Group that activates in the event of the

disabling of automatic activation (e.g. two

alarms in a specific zone) of extinction

4.19 “Monitoring of the status

of components”

10

Exting. Fault

Group that is activated in the event of a fault on

any component of the system with extinction

functions (an extinction input or an output set

as “Fire Protection System”).

11

Activate Exting.

Group whose activation starts the automatic

pre-extinction time count.

Log

System status

Programming

01/01/2018 18:23

Access

level:1

B

C

Other manuals for Previdia Compact

2

Table of contents

Other INIM Electronics Control Panel manuals

INIM Electronics

INIM Electronics SmartLoop User manual

INIM Electronics

INIM Electronics Previdia Compact User manual

INIM Electronics

INIM Electronics PREVIDIA MAX User manual

INIM Electronics

INIM Electronics SmartLoop User manual

INIM Electronics

INIM Electronics SmartLight User manual

INIM Electronics

INIM Electronics Previdia 216 User manual

INIM Electronics

INIM Electronics Prime Series User manual

INIM Electronics

INIM Electronics Prime Series User manual

INIM Electronics

INIM Electronics SmartLoop Owner's manual

INIM Electronics

INIM Electronics Prime060S User manual