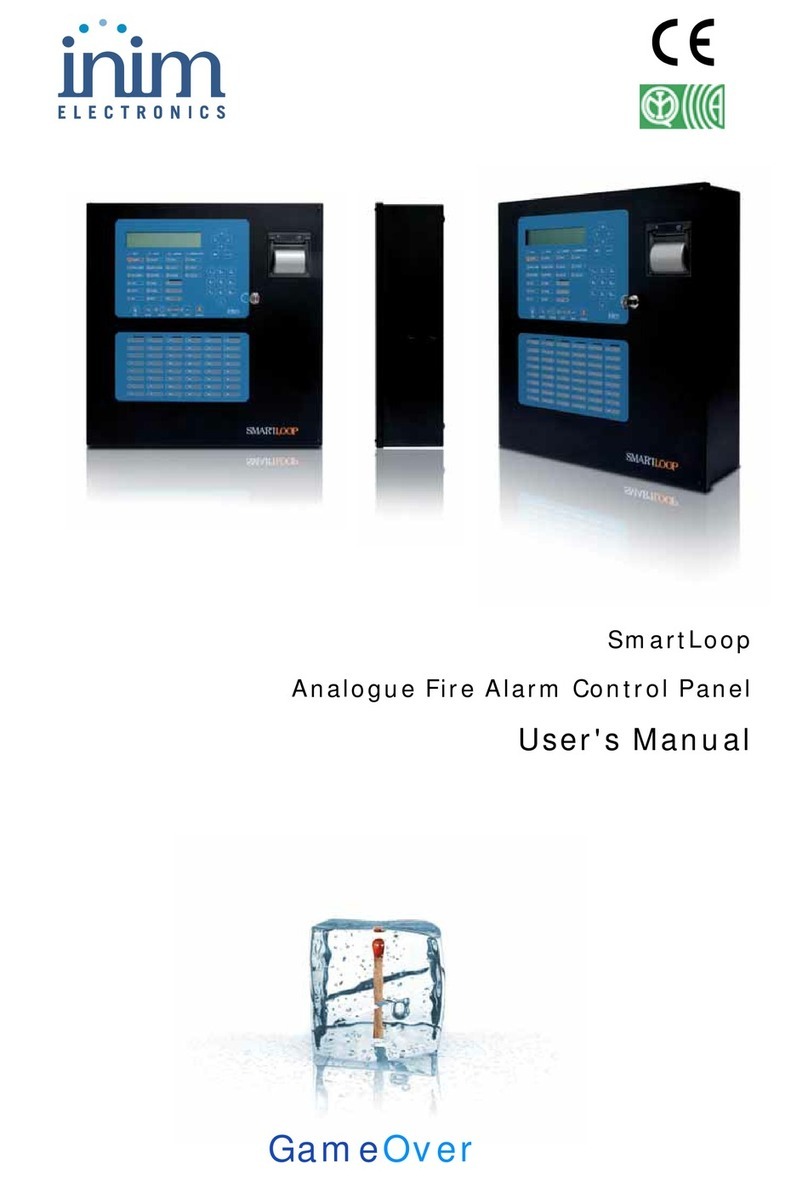

INIM Electronics SmartLoop User manual

SmartLoop

Analogue Fire Alarm Control Panel

Installation manual

GameOver

Installation Manual

2

Copyright

The information contained in this document is the sole property of Inim Electronics s.r.l. No

part may be copied without written authorization from Inim Electronics s.r.l.

All rights reserved.

This Control panel has been designed and developed to the

highest standards of quality and performance implemented by

Inim Electronics.

This control panel must be installed in accordance with the

instructions described in this manual and in compliance with

the laws in force.

All control panels from the SmartLoop series are EN54-2;

EN54-4 compliant.

All control panels from the SmartLoop series, and all

accessory items and special functions have IMQ Sistemi di

Sicurezza certification, unless otherwise stated.

Installation Manual

3

Table of contents

Chapter 1 Overview ............................................................................ 5

1.1 Application and use 5

1.2 In order to validate the IMQ-SISTEMI DI SICUREZZA certification, and in

compliance with EN54-2 regulations, 7

1.3 About the SmartLoop fire alarm panel series 7

1.4 Description of the models 7

1.5 Features 8

Chapter 2 General information.............................................................. 9

2.1 Documentation supplied 9

2.2 Manual details 9

2.3 About the Software 9

2.4 Addressees 9

2.5 Operator authorization—access levels 9

2.6 Intellectual property rights 10

2.7 Disclaimer 10

2.8 Recommendations 10

2.9 Testing the system 10

2.10 Note to the installer 10

2.11 Technical support 10

2.12 Conventions 10

2.13 Manufacturer's name and address 11

2.14 Device identifier 12

2.15 Warranty 12

2.16 Safety laws 12

Chapter 3 Device management............................................................14

3.1 Product handling and storage 14

3.2 Environmental conditions 14

3.3 Unpacking the device 14

Chapter 4 Internal devices ..................................................................16

4.1 The motherboard 16

4.2 About attachment boards 17

4.3 The SmartLoop/2L board 18

4.4 The SmartLoop/NET board 19

4.5 The SmartLAN board 21

4.6 The SmartLoop/PSTN board 22

4.7 The SmartLoop/INOUT board 23

4.8 SmartLetUSee/LED module 23

4.9 The SmartLoop/PRN module (for “/P” models only) 24

4.10 The SmartLetUSee/LCD and SmartLetUSee/LED Repeater panels 26

Chapter 5 Technical specifications........................................................27

Chapter 6 Installation.........................................................................29

6.1 Choosing the mounting location 29

6.2 Installation flow, guidelines and testing 29

6.3 Connecting the SmartLoop/LED module 31

6.4 Connecting the SmartLoop/PRN printer module 32

Chapter 7 Connections .......................................................................33

7.1 Note to the Installer regarding wiring and connection compliancy 33

7.2 About the circuitry 33

7.3 Description of the motherboard terminals 34

7.4 Loop Connections 34

7.5 Loop terminals 35

7.6 Connecting devices to the Loop 35

7.7 NAC Outputs (Notification Application Circuit) 36

7.8 PL terminal (for Shutdown signaling) 37

Installation Manual

4

7.9 AUX output 37

7.10 AUX R output 37

7.11 Alarm relay 37

7.12 Fault relay 37

7.13 Connecting Repeater panels to the RS 485 bus 38

7.14 Connecting the SmartLoopNET module 38

7.15 Connecting the SmartLoop/INOUT Board 38

7.16 Connecting to a PC or serial printer 40

7.17 Connecting a SmartLinkLAN board equipped panel to a PC 40

7.18 Connecting a serial printer 40

7.19 Batteries 40

7.20 Connecting the Thermal Probe 41

7.21 Connecting to the Mains power source (Electrical Switchboard) 42

Chapter 8 Powering up the system....................................................... 44

8.1 Testing wiring integrity 44

Chapter 9 Troubleshooting.................................................................. 47

9.1 NAC, Alarm and Fault output trouble 47

9.2 LOOP Fault 47

9.3 Repeater Fault 48

9.4 Battery Fault 48

9.5 SmartLoopNET Fault 49

9.6 NET Link ALARM-A 49

Appendix A Maintenance ......................................................................50

Appendix B Argus devices supported by the control panel ......................... 51

Apollo devices supported by the control panel......................... 55

Appendix C Order Codes....................................................................... 61

Installer’s notes .................................................................................62

Installation Manual

Overview 5

Chapter 1

Overview

Note: The control panels described in this manual have been designed and developed to the highest

standards of quality, reliability and performance. All product components are capable to

application requirements and able to operate in compliance with the related technical

specifications when the temperature external to their casing complies with Category 3k5 of IEC

721-3-3.

Danger: The GAS control function is not EN54-2 compliant, as this feature is not mentioned in

the aforesaid standard.

Danger: In order to validate the IMQ-SISTEMI DI SICUREZZA certification, and in compliance

with EN54-2 regulations, all the manual alarm buttons and fire detectors employed in

the system must be associated with fire detection and alarm functions.

1.1 Application and use

The SmartLoop analogue-addressable fire alarm panel manages up to eight loops. The SmartLoop is

capable of working in a network environment (maximum configuration 30 nodes arranged in a token

ring). The loops accommodate different types of fire-security devices (detectors, input and output

modules, callpoints, fire bells, etc.). The maximum loop wire length is 2000 m.

The SmartLoop also provides supervised outputs which guarantee full control of peripheal device

functions (e.g. fire bells). The panel identifies and signals alarm, pre-alarm, fault, early warning,

bypassed zone, test and monitoring conditions. The system status is indicated on the display and on

the system status LEDs. The SmartLoop panel supports up to 8 Repeater panels (accessory items)

which replicate system data and allow building occupants with Level 2 authorization to silence and

reset the system. The panel can also be connected to a PC or printer.

The self-addressing feature and reduced-complexity point programming allow fast and easy

installation.

Figure 1 - Example configuration: 5 node token-ring network environment (HorNet)

PSTN

network

INTERNET

Up to 30 panels

Installation Manual

6Overview

Caption

[A] Loop

All the peripheral devices of the system must be connected in parallel to the loop circuit (2 pole STP).

The loop is a closed electrical circuit in which a wide variety of alarm devices can be accommodated.

Opening or closing the circuit at any point will generate a fault signal. The loop circuit communication

path starts on the Loop-Out terminals and ends on the Loop-In terminals. The panel controls and

communicates with the loop devices via digital protocol. The loop utilizes the same two poles for the

power supply to the system devices and the two-way communication channel.

The loop accommodates:

1. Detectors: A smoke detector is an active fire protection device that detects smoke or flames and

issues an alarm thereby alerting building occupants to the danger of fire.

Detectors can be:

- Optical smoke detectors which look for the presence of visible by-products of combustion in the

detection chamber (Tyndall effect).

- Optical/Heat detectors which operate as per optical smoke detectors but also sense for increase in

the environment temperature. The combination of both sensing methods (smoke and heat)

provides faster detection and reduces the false alarm rate.

- Heat detectors: sense for an increase in the temperature in the protected environment. There are

two types of heat detector: Fixed temperature — that signal alarm when the temperature exceeds

the predefined threshold; and Rate-of-rise — that as well as monitoring the predefined fixed

temperature also respond to rapid increase in temperature.

- Ionization smoke detectors: feature a harmless radioactive source within a dual detection

chamber. They operate by sensing for a change in electrical conductivity across the detection

chamber.

- CO detectors: sense the levels of carbon monoxide given off by all carbon-based materials in the

smouldering stages of a fire (often combined with heat detection sensor).

2. Input Module: a device which monitors the status of another device (callpoint, detector, etc.)

and sends the respective information to the panel. The Input module allows the loop to

accommodate any type of device.

3. Output Module: provides a supervised ancillary output. The cause of activation of this output

can be defined during the system configuration phase. The output module interfaces all types of

loop devices (bells, signaling devices, fire door magnets, etc.).

4. Callpoint: a clearly labeled fire button with instructions for use in the event of fire. Usually placed

near building entrances/exits. These push-button alarm-trigger devices allow building occupants

to activate system alarms.

5. Sounder/Flasher: audible/visual alarm signaling devices. The cause of activation (alarm, pre-

alarm, early warning, etc.) can be defined during the system configuration phase.

For the list of the devices the loop accommodates, and for details regarding their wiring and operating

principles, refer to Appendix B and Appendix B.

The loop circuit configuration (as required by the local Fire code in force) is a fault-tolerant circuit

which, in the event of short-circuit or loop interruption, allows the panel to continue to communicate

and drive the elements on either side of the interruption.

[B] Isolator

In order to provide a fault-tolerant loop circuit that is Fire code compliant, isolator modules must be

installed in series with the loop circuit. Isolators modules detect short-circuit conditions and

consequently interrupt the loop circuit. If a short-circuit occurs, the two isolators adjacent to the

shorted section will open and split the loop in such way as to allow the panel to drive the elements on

either side of the interruption. No more than 32 detectors/devices should be installed between two

isolator modules.

Note: Many detectors/devices have built-in isolators and therefore do not require isolator modules.

Refer to Appendix B and Appendix B for further details.

Installation Manual

Overview 7

1.2 In order to validate the IMQ-SISTEMI DI SICUREZZA certification, and

in compliance with EN54-2 regulations,

1. All the manual alarm buttons and fire detectors employed in the system must be associated with

fire detection and alarm functions.

2. The functions associated with the programmable LEDs on the control panel frontplate (Keypad/

Display board and LED board), and on SmartLetUSee/LCD and Smart letUSee/LED Repeaters must

be set up in accordance with the colour of the LEDs:

•RED: FIRE ALARM Status

•YELLOW: FAULT, TEST and DISABLED Status

Note: The GAS control function is not EN54-2 compliant, as this feature is not mentioned in the

aforesaid standard.

1.3 About the SmartLoop fire alarm panel series

There are 3 expandable models (expandable to 8 loops by means of 3 SmartLoop/2L expansion

boards). All have 2 loops and common components housed in the same sized cabinet. Each

expandable model has a technically-downsized version (in same-sized cabinet) with 1 loop for reduced

complexity applications.

All models manage the same functions and support a full spectrum of hardwired and wireless devices.

The SmartLoop fire alarm panel series provides the following models:

• SmartLoop1010/P Advanced model with 1 loop

• SmartLoop2080/P Advanced model with 2 loops expandable to 8 loops

• SmartLoop1010/G Keypad and display model with 1 Loop

• SmartLoop2080/G Keypad and display model with 2 loops expandable to 8 loops

• SmartLoop1010/S Flush front (unequipped) model with 1 loop

• SmartLoop2080/S Flush front (unequipped) model with 2 loops expandable to 8 loops

Figure 2 - SmartLoop Series - Advanced, Keypad and display, and Flush Front

1.4 Description of the models

The “/P” model is equipped with a keypad, display, fault LEDs, fast buttons and a Zone status LED

pad. This model is suitable for locations where extended visual signals and manual control are

necessary. This model can be enhanced with the SmartLoop/PRN thermal printer (accessory item).

SmartLoop1010/P

SmartLoop2080/P

SmartLoop1010/G

SmartLoop2080/G

SmartLoop1010/S

SmartLoop2080/S

Installation Manual

8Overview

The “/G” model is equipped with a keypad, display, fault LEDs and fast buttons and is suitable for

installation in locations where visual signals and manual control are necessary. This model can be

upgraded at any time after installation (for example, if moved to a location where extended visual

signals and manual control are necessary) by replacing its door with a “/P” model door that is

enhanced with a Zone status LED pad and thermal printer option.

The “/S” model has an unequipped door (no keypad, display or LEDs), and is suitable for installation

in locations where visual indications and manual control are not required (e.g. basements). This

model can be upgraded at any time after installation (for example, if moved to a location where visual

signals and manual control are necessary) by replacing its door with a /P model door or /G model door

(refer to respective paragraph for ‘on-door’ equipment details).

1.5 Features

- Manages up to 240 zones

- Network environment capable (maximum configuration 30 panels)

- Group and Zone sharing among panels in the network environment

- Switching power supply 27.6 V @ 4 A with battery charger function

- 2 on-board loops (on expandable 2080 models); 1 on-board loop (on non-expandable 1010

models)

- 3 programmable NAC outputs

- 1 NAC Alarm output

- 1 NAC Fault output

- 1 dry contact Alarm relay

- 1 dry contact Fault relay

- RS485 Bus — accommodates up to 8 SmartLetUSee Repeaters

- 1 power supply output @ 24 V for external devices.

- 1 power supply output @ 24 V for external devices with "power Cutoff" during reset.

- RS232 and USB connectors for uploading/downloading programming data

- 2000 event buffer

The motherboard provides locations for:

- 3 SmartLoop/2L loop expansion boards with 2 loops per board (for 2080 expandable models only)

- 1 SmartLoop/NET network board

- 1 SmartLAN board

- 1 SmartLoop/PSTN board

- 1 SmartLoop/INOUT Input/Output expansion board

- 1 SmartLoop/LED zone-status LED module (for “/P” models only)

- 1 SmartLoop/PRN thermal printer module (for “/P” models only)

Note: The 1010 non-expandable models with 1-loop have exactly the same features and components as

the 2080 expandable models with 2-loops.

Installation Manual

General information 9

Chapter 2

General information

2.1 Documentation supplied

• Installation manual (this manual)

• Programming Manual

• User's Manual

The manuals are supplied with the device. For further copies of the Installation Manual, please contact

INIM ELECTRONICS offices quoting the order number shown in Appendix C .

2.2 Manual details

Title: SmartLoop Installation Manual

• Edition, Issue: 1.01

• Month and Year of printing: April 2007

• Installation Manual Code: DCMIINE0SLOOP

2.3 About the Software

• SmartLeague software version: 2.0.x

• SmartLoop Firmware Version: FWINI0SL0PAA00 1.00

• SmartLoop Loop Driver Firmware Version: FW0000LOOPDRV 1.00

• SmartLoop Frontplate Firmware Version: FW0000SLEDKBD 1.00

• SmartLAN Firmware Version: FWIN00SLAN 1.00

• SmartLoop/PSTN Firmware Version: FW0000SLPSTN 1.00

• SmartLoop/INOUTFirmware Version: FW0000SLIO 1.00

• SmartLetUSee/LCD Repeater Firmware Version: FW0000SLEDKBD 1.00

• SmartLetUSee/LED Repeater LED Expansion Firmware Version: FW0000SLLED 1.00

2.4 Addressees

• Installer

• Technical assistance

2.5 Operator authorization—access levels

Level 1

All building occupants can view the system status (active events) and events log and silence the panel

beeper.

Level 2

ONLY authorized keyswitch users and PIN users (5 digit codes) can Enable/Disable loop devices, bell

outputs, software zones and network devices, and SILENCE or RESET the system.

Level 3

ONLY authorized technicians, appointed by the Installer company can, by means of a screw driver,

remove the screws and open the fire control panel cabinet to insert the J2 Jumper and then, after

entering a 5 digit PIN (5 digit code) access the parameter programming phase and/or carry out

maintenance work (for example, change the battery, replace fuses, etc.).

Installation Manual

10 General information

Level 4

ONLY authorized technicians, appointed by the Manufacturer can, by means of special tools, carry out

repair work on the motherboard (for example, repair or replace SM components).

2.6 Intellectual property rights

The information contained in this document is private property. All rights reserved.

No part of this document may be copied or reproduced unless expressly authorized in writing by INIM

Electronics, in particular the parts regarding the device specified in paragraph 2.14 Device identifier.

2.7 Disclaimer

INIM Electronics s.r.l. shall not be responsible for damage arising from improper application or use.

This control panel should be handled by qualified personnel only. Installation must be carried out

strictly in accordance with the instructions described in this manual, and in compliance with the local

fire code in force.

2.8 Recommendations

INIM Electronics recommends that the entire system be tested on a regular basis (refer to paragraph

2.9 Testing the system).

2.9 Testing the system

This system has been designed to the highest standards of quality and performance. The system may

fail to function as intended due to the failure of a component. Most problems that prevent a fire

control system from operating as intended can be found by regular testing and maintenance (refer to

Appendix A - Maintenance).

Testing should include all detectors, signaling devices and any other operational devices that are part

of the system.

2.10 Note to the installer

In order to provide adequate protection and instructions for proper use, you (the installer) must be

familiar with the operating procedure of this device. As the only individual in contact with system

users, it is your responsibility to instruct them on how to use this system properly and to bring to their

attention that every fire is different in the amount of smoke and rate of burning. Therefore, smoke

and heat detectors may not provide timely warning of fires caused by violent explosions, escaping gas

or improper storage of inflammable materials.

Regardless of its capabilities, a fire alarm system is not a substitute for the necessary precautions

building occupants must take to prevent or minimize the harmful effects of fire.

2.11 Technical support

Our professional engineers are readily available to assist you. Call our phone number and you will be

connected right away to a person who will answer all your questions and provide you with full

technical support.

2.12 Conventions

2.12.1 Glossary and terminology

Panel; device; system: refer to the devices defined in 2.14 Device identifier.

Left, right, behind, above, below: refer to the directions as seen by the operator in front of the

mounted device.

Communicator (telephone, SMS, digital): synonym of dialer.

STP: Shielded twisted pair cable.

Qualified personnel: those persons whose training, expertise and knowledge of the laws and bylaws

regarding service conditions and the prevention of accidents, are able to identify and avoid all possible

situations of danger.

Installation Manual

General information 11

Select: click on and select a specific item (from drop-down menu, options box, graphic object, etc.).

Press: click on a video button, or press a key on the panel keypad.

2.12.2 Graphic conventions

Following are the graphic conventions used in the text.

Note: The detached notes contain important information about the text.

Attention: The attention prompts indicate that total or partial disregard of the procedure could

damage the connected devices.

Danger: The danger warnings indicate that total or partial disregard of the procedure could

injure the operator or persons in the vicinity.

2.13 Manufacturer's name and address

INIM Electronics s.r.l.

Via Ischia Prima, 34

63013 Grottammare (AP) - Italy

Tel: +39 0735 730924

Fax: +39 0735 736134

Conventions Example Description

Text in Italics Refer to paragraph

1.1 Application

and use

Text in italics: indicates the title of a chapter, section, paragraph,

table or figure in this manual or other published reference.

<text> #<CustomerCode> Variable data.

[lowercase

letter]

or [number]

[A] or [1] Representation of a part of the system or video object.

BUTTON CANC, ESC, RESET Computer or control panel keys.

Installation Manual

12 General information

2.14 Device identifier

Figure 3 - Overview

Product category: Fire Alarm Control Panel

Model: SmartLoop

Year of Manufacture: 2007

2.15 Warranty

INIM Electronics s.r.l. warrants the original purchaser that for a period of 24 months from the date of

final acceptance, the product shall be free of defects in materials and workmanship. The warranty

applies only to defects in parts and workmanship relating to normal use. It does not cover:

• Improper use or negligence

• Damage caused by fire, flood, wind or lightning

•Vandalism

• Fair wear and tear

Inim Electronics s.r.l. shall, at its option, repair or replace any defective products. Improper use, that

is, use for purposes other than those mentioned in this manual will void the warranty. For the full

details and conditions regarding the warranty, refer to the purchase order.

2.16 Safety laws

The aim of the instructions in this section is to ensure that the device is installed and handled

properly. This chapter contains vital information. The installer should be familiar with this section and

bring each item to the attention of the system users.

2.16.1 Compliancy

The design and manufacture of the SmartLoop panel comply with EN 54-2 Fire detection and signaling

systems - Control and signaling panels.

The design and manufacture of the power supply comply with EN 54-2 Fire detection and signaling

systems - Power supply devices.

2.16.2 Managing electronic devices

The normal motions of any person may generate electrostatic potential of thousands of volts.

Discharge of this current through semiconductor devices during handling may cause serious damage

which although may not be immediately evident may reduce the reliability of the circuits.

If located in their housings, the electronic circuits of INIM Electronics products are highly immune to

electrostatic discharge.

Installation Manual

General information 13

Do not expose the circuits to damage by removing the modules unnecessarily from their housings.

3. When removing or handling the boards, hold the board edges only.

4. Do not touch the electronic components, the printed circuits or the metal parts of the connectors.

5. Do not hand the module to another person without first ensuring that you both have the same

electrostatic potential. This can be achieved by simply shaking hands.

6. Place the board on an anti-static surface or a conductor surface with the same potential.

Further information regarding procedures relating to safety when working with electronic devices can

be found in Directive IEC 60147-0F.

2.16.3 Setting up the system

In order to provide adequate protection and instructions for proper use, security professionals

(Installers and maintenance technicians) must be familiar with the operating procedure of this device.

Please read the instructions carefully before installing and/or servicing the system.

Before first power-up, be sure that the earth connection has been completed properly on the

respective terminal.

The recommended minimum wire cross section for the earth connection is 2.5 mm2, that is, unless

otherwise stated in accessory documentation.

2.16.4 Replacement and disposal of used devices

Replacement

When replacing used devices, disconnect the devices concerned then complete the connections of the

new devices in compliance with the instructions printed on the respective leaflets.

Contact your local municipal offices for information regarding the disposal of used electronic devices.

Disposal

Do not burn used electronic devices, or allow them to pollute the environment (countryside, rivers,

etc.). Electronic devices must be disposed of in a safe environment-friendly way. In order to avoid

short-circuits, take all the necessary precautions when removing used batteries. Contact your local

municipal offices for information regarding the disposal of batteries.

Installation Manual

14 Device management

Chapter 3

Device management

3.1 Product handling and storage

This device has been properly packed inside a cardboard box, however, care must be taken to avoid

accidental damage during handling. Cartons/boxes should be placed in such a way as to avoid knocks

and falls, and special care must be taken to protect the devices from extreme heat and/or cold.

3.2 Environmental conditions

Temperature limits:

-10° / +55°C for transport and storage

-5° / +40°C operating temperature

3.3 Unpacking the device

Take due care when unpacking the product, and dispose of all waste packaging in accordance with the

local method of disposal.

The cardboard box contains the SmartLoop control panel (cabinet in metal).

Note: All waste packaging must be disposed of in full respect of the local laws in force.

3.3.1 Inside the box

Figure 4 - Box contents

Inside the box you will find

1. Metal cabinet containing the motherboard

2. Installation Manual

3. Plastic bag containing: resistors, + diodes, 2032 lithium battery, keys, battery connection wires

Installation Manual

Device management 15

Attention: The 2032 lithium battery guarantees data retention. You must insert this battery into

its holder (with “+” sign facing you) before connecting the SmartLoopLAN board.

The package does not include:

Thermal probe, batteries (2 x 12 V), programming software CD. These items must be purchased

separately. Be sure you have these items on hand before starting the installation procedure.

Attention: In order to validate the IMQ-SISTEMI DI SICUREZZA certification and comply with EN

54-4 requirements, installation of a thermal probe is essential.

Be sure you have this item on hand before starting the installation procedure.

Installation Manual

16 Internal devices

Chapter 4

Internal devices

4.1 The motherboard

The SmartLoop motherboard has a 32 bit microprocessor that controls all the control panel functions,

and 2 peripheral microprocessors (one per loop) that manage communications with the system

peripherals. INIM’s R & D professionals have developed and designed the SmartLoop motherboard

using ground-breaking new generation fire technologies that ensure maximum precision and

performance. Deployment of the most advanced reflow technology ensures high-noise immunity and

extreme accuracy. Each connection terminal is protected against electrical surges and is high-noise

immune capable. All terminals on the motherboard are clearly marked and easily identifiable (see

Figure below). The motherboard has been especially designed to accommodate with ease the various

SmartLoop attachment boards.

Figure 5 - About the motherboard

4.1.1 The motherboard components

1. Keypad/Display wire to board connector

2. Loop 1 status LEDs (1 green - 2 red)

3. Loop 2 status LEDs (1 green - 2 red)

4. SmartLoop/2L board connector (2-loop expansion board)

5. SmartLAN board connector

6. Microprocessor Hard Reset button

7. Memory jumper (if removed and the panel is switched Off, the system will restore to factory

default settings)

8. Memory battery (3 V lithium battery)

9. COM RS232 connector (DB9 male)

10.USB connector (type B)

11.SmartLoop/PSTN plug-in module connector

12.Clear ground-fault jumper (removal of this jumper clears ground faults)

13.On-panel thermal printer connector

Installation Manual

Internal devices 17

14.Programming jumper (removal of this jumper blocks access to programming)

15.Ancillary power supply connector (not operational with this model)

16.ProbeTH Thermal probe board connector (Thermal probe not included)

17.Switching power-supply module connector

18.SmartLoop/NET plug-in module connector

19.Resettable fuses

20.Connector for external batteries (not operational with this model)

21.Connector for internal batteries (connection wire included)

22.PL terminals (signal battery disconnected conditions) PL closes to GND in the event of shutdown

(primary and secondary power failure) Under normal operating circumstances, PL is open

23.AUX Terminals: 24 V output for external loads

24.AUX-R Terminals: 24 V output for external loads (with "power Cutoff" during reset) Suitable for

powering devices that require power loss in order to reset (e.g.: beam detectors)

25.RS485 Bus for Repeater connections (accommodates up to 8 Repeaters)

26.ALARM relay (dry contact)

27.FAULT relay (dry contact)

28.Supervised FAULT output protected by 1 A fuse

29.SmartLoop/INOUT plug-in module connector

30.Supervised ALARM output protected by resettable 1 A fuse

31.Programmable NAC outputs protected by resettable 1 A fuse

32.Loop 2 In/Out terminals

33.Loop 1 In/Out terminals

4.2 About attachment boards

The motherboards accommodates the following attachment boards:

- Up to 3 SmartLoop/2L loop expansion boards (2 loops per board) - for Expandable models only

(2080)

- 1 SmartLoop/NET Network board - allows to create a control panel network environment (Hornet

technology)

- 1 SmartLAN LAN board for Ethernet connection (Janus Technology)

- 1 Smartloop/PSTN telephone board for PSTN land line connection

- 1 Smartloop/INOUT expansion board (provides 6 Inputs/Outputs)

“/P” models (Advanced models) also support:

- 1 Smartloop/PRN Thermal printer module (fitted to the frontplate) for printout of events in real-

time or on request Refer to the respective paragraphs for the board descriptions.

Figure 6 - The motherboard accessorized with attachment boards

Installation Manual

18 Internal devices

4.3 The SmartLoop/2L board

All the SmartLoop 2080 series (expandable models) have 2 on-board loops expandable to 8 by means

of 3 SmartLoop/2L expansion boards. The models SmartLoop 1010 series (non-expandable) have 1

loop only.

Each loop accommodates up to 240 or 126 (depending on the selected protocol) fire detection/

signaling devices (refer to Appendix B).

Due to electrical incompatibility (refer to Appendix B), different brand devices (i.e. devices using

different protocols) cannot co-exist on the same loop. However, the loops can be programmed

separately thus allowing the system to manage different brand devices on different loops.

Figure 7 - The SmartLoop/2L board

Figure 8 - The SmartLoop/2L board location on the motherboard

4.3.1 The SmartLoop/EXP board components

1. Loop 1 status LED

2. Loop 2 status LED

3. Flat cable SmartLoop/2L board to board connector (up to 3 boards)

4. Flat cable motherboard to SmartLoop/2L board connector

5. Loop 2 In/Out terminals

6. Loop 1 In/Out terminals

Installation Manual

Internal devices 19

7. Board screws (5)

4.4 The SmartLoop/NET board

The SmartLoop/NET board will allow you to create a token-ring network (see “Example configuration:

6 node token-ring network layout”) of up to 30 control panels by means of a 3-pole cable with a

locking ring. The maximum cable length of 2000 meters (allowed between each control panel)

provides a highly fault-tolerant network. Using a supplementary 2-pole cable (5 poles in all), you can

create a protection ring which can pass alarm conditions, coming from a fire control panel with

microprocessor fault, through the ring.

Danger: In order to allow the ring to operate properly, the Port-B and Alarm-B terminals must

be connected to the successive Port-B and Alarm-B terminals.

4.4.1 The SmartLoop/NET board components

1. Aterminals: for the protection-ring connection (to be connected to Alarm-B of the successive

control panel)

2. Communication Port A (to be connected to Port-B of the successive control panel)

3. In-ring LED (indicates the In Service/Out of Service status of the SmartLoop/NET board. If this

LED is Off, the panel is isolated from the HorNet environment.

4. Port A status LEDs (2)

5. Port B status LEDs (2)

6. Bterminals: for the protection-ring connection (to be connected to Alarm-A of the previous control

panel)

7. Communication Port B (to be connected to the Port-A terminals of the previous control panel)

8. Board screws (4)

Figure 9 - The SmartLoop/NET board

8

8

2

1

7

6

8

8

5 4 3

Installation Manual

20 Internal devices

Figure 10 - The SmartLoop/NET board location on the motherboard

Other manuals for SmartLoop

2

Table of contents

Other INIM Electronics Control Panel manuals

INIM Electronics

INIM Electronics Previdia Compact User manual

INIM Electronics

INIM Electronics SmartLiving 505 Assembly instructions

INIM Electronics

INIM Electronics Previdia Compact Quick guide

INIM Electronics

INIM Electronics Prime Series User manual

INIM Electronics

INIM Electronics Prime Series User manual

INIM Electronics

INIM Electronics Prime060S User manual

INIM Electronics

INIM Electronics PREVIDIA MAX Parts list manual

INIM Electronics

INIM Electronics SmartLoop Owner's manual

INIM Electronics

INIM Electronics PREVIDIA MAX User manual

INIM Electronics

INIM Electronics SmartLight User manual