INOXPA OVERFLOW VALVE Manual

OVERFLOW VALVE

74700

Original Instructions

10.207.30.07EN

(0) 2023/11

INSTALLATION, SERVICE AND MAINTENANCE INSTRUCTIONS

10.207.32.0012

E C D e c l a r a t i o n o f C o n f o r m i t y

Model:

INOXPA S.A.U.

Telers, 60

17820 - Banyoles (Spain)

hereby declare under our sole responsibility that the

Type:

Serial number:

OVERFLOW VALVE

74700

Technical Oce Manager

15th April 2023

10.207.30.04EN

(A) 2023/04

Document:

Revision:

Machine: VALVE

David Reyero Brunet

fullls all the relevant provisions of the following directive:

Machinery Directive 2006/42/EC

Pressure Equipment Directive 2014/68/EU1

Regulation (EC) nº 1935/2004

Regulation (EC) nº 2023/2006

and with the following harmonized standards and/or regulations:

The technical le has been prepared by the signer of this document.

Size: DN 25 - DN 80 / OD 1’’ - OD 3’’

IXXXXXXXXX to IXXXXXXXXX

XXXXXXXXXIINXXX to XXXXXXXXXIINXXX

1

DN≤25 Designed and manufactured in accordance with the sound engineering practice

DN>25 Class I equipment. Conformity assessment procedure used: Module A

EN ISO 12100:2010, EN ISO 14159:2008, EN 1672-2:2005+A1:2009,

EN 13732-1:2008, EN 12266-1:2012, EN 19:2016.

D e c l a r a t i o n o f C o n f o r m i t y

INOXPA S.A.U.

Telers, 60

17820 - Banyoles (Spain)

hereby declare under our sole responsibility that the

Model: OVERFLOW VALVE

Type: 74700

Technical Oce Manager

15th April 2023

10.207.30.05EN

(A) 2023/04

Document:

Revision:

Machine: VALVE

David Reyero Brunet

Size: DN 25 - DN 80 / OD 1’’ - OD 3’’

Serial number: IXXXXXXXXX to IXXXXXXXXX

XXXXXXXXXIINXXX to XXXXXXXXXIINXXX

fulls all the relevant provisions of these regulations:

and with the following designated standards:

The technical le has been prepared by the signer of this document.

Supply of Machinery (Safety) Regulations 2008

Pressure Equipment (Safety) Regulations 20161

1

DN≤25 Designed and manufactured in accordance with the sound engineering practice

DN>25 Class I equipment. Conformity assessment procedure used: Module A

EN ISO 12100:2010, EN ISO 14159:2008, EN 1672-2:2005+A1:2009,

EN 13732-1:2008, EN 12266-1:2012, EN 19:2016.

1. Table of Contents

1. Table of Contents

2. Generalities

2.1. Instructions manual........................................................................................................................................... 5

2.2. Compliance with the instructions.................................................................................................................. 5

2.3. Warranty ............................................................................................................................................................... 5

3. Safety

3.1. Warning symbols................................................................................................................................................ 6

3.2. General safety instructions............................................................................................................................. 6

4. General Information

4.1. Description ........................................................................................................................................................... 7

4.2.Application............................................................................................................................................................ 7

5. Installation

5.1. Reception of the valve...................................................................................................................................... 8

5.2.Transport and storage...................................................................................................................................... 8

5.3. Identication of the valve................................................................................................................................. 8

5.4. Location .............................................................................................................................................................. 10

5.5. Direction of ow................................................................................................................................................ 10

5.6. General installation ......................................................................................................................................... 10

5.7. Checking and review .......................................................................................................................................11

5.8. Welding ................................................................................................................................................................11

6. Start-up

6.1. Calibration of the valve .................................................................................................................................. 12

7. Operating problems

8. Maintenance

8.1. General considerations.................................................................................................................................. 14

8.2. Maintenance...................................................................................................................................................... 14

8.3. Cleaning.............................................................................................................................................................. 15

8.4. Disassembly and assembly the valve ....................................................................................................... 17

8.5. Disassembly and assembly of the overow valve 74700................................................................... 17

8.6. Disassembly and assembly of the overow valve 74700 with handle............................................ 19

8.7. Disassembly and assembly of the overow valve 74700 with PTFE seat seal........................... 21

9. Technical Specications

9.1. Valve .................................................................................................................................................................... 22

9.2. Materials ............................................................................................................................................................. 22

9.3. Sizes available.................................................................................................................................................. 22

9.4. Weights of overow valve 74700................................................................................................................ 22

9.5. Dimensions of the overow valve 74700 ................................................................................................. 23

9.6. Dimensions of the overow valve 74700 with handle.......................................................................... 23

9.7. Exploded drawing and parts list of the overow valve 74700 ........................................................... 24

9.8. Exploded drawing and parts list of the overow valve 74700 with handle.................................... 25

9.9. Exploded drawing and parts list of the overow valve 74700 PTFE seat seal............................ 26

9.10. Exploded drawing and parts list of the overow valve 74700 PTFE with handle and PTFE

seat seal ..................................................................................................................................................................... 27

INOXPA S.A.U. 10.207.30.07EN · (0) 2023/11

4

2. Generalities

2.1. INSTRUCTIONS MANUAL

This manual contains information about the reception, installation, operation, assembly and mainte-

nance of overow valve 74700.

Carefully read the instruction prior to starting the valve, familiarize yourself with the installation, ope-

ration and correct use of the valve and strictly follow the instructions. These instructions should be

kept in a safe location near the installation area.

The information published in the instruction manual is based on updated data.

INOXPA reserves the right to modify this instruction manual without prior notice.

2.2. COMPLIANCE WITH THE INSTRUCTIONS

Not following the instructions may impose a risk for the operators, the environment and the machine,

and may cause the loss of the right to claim damages.

This non-compliance may cause the following risks:

- failure of important machine/plant functions,

- failure of specic maintenance and repair procedures,

- possible electrical, mechanical and chemical hazards,

- risk to the environment due to the type of substances released.

2.3. WARRANTY

The conditions of the warranty are specied in the General Sales Condition that has been delivered

at the time of placing your order.

The machine may not undergo any modication without prior approval from the manu-

facturer.

For your safety, only use original spare parts and accessories. The usage of other parts

will relieve the manufacturer of any liability.

Changing the service conditions can only be carried out with prior written authorization

from INOXPA.

Please do not hesitate to contact us in case of doubts or if further explanations are required regar-

ding specic data (adjustments, assembly, disassembly, etc.).

The non-compliance of the prescribed indications in this manual means misuse of this gear on the

technical side and the personal safety and this, exempt INOXPA of all responsibility in case of ac-

cidents and personal injuries and/or property damage. Also, excluded from the warranty all break-

downs caused by improper use of the gear.

Generalities

5

INOXPA S.A.U. 10.207.30.07EN · (0) 2023/11

3.1. WARNING SYMBOLS

3. Safety

Safety hazard for people in general and/or equipment

ATTENTION Important instruction to prevent damage to the equipment and/or its function

3.2. GENERAL SAFETY INSTRUCTIONS

Read the instruction manual carefully before installing and starting the valve. Contact

INOXPA in case of doubt.

3.2.1. During installation

Always take into account the Technical Specications of chapter 9.

The installation and use of the valve should always be in accordance with applicable

regulations regarding health and safety.

Before starting up the valve, check that it is assembled correctly and its shaft is perfectly

aligned. Incorrect alignment and/or excessive stress during coupling can cause serious

mechanical problems in the valve.

3.2.2. During operation

Always take into account the Technical Specications of chapter 9.

NEVER exceed the specied limit values.

NEVER touch the valve and/or piping that is in contact with the uid during operation. If

the process involves hot products there is a risk of burns.

The valve contains parts that move in a linear fashion. Do not place hands or ngers in

the valve closing area. This can cause serious injury.

3.2.3. During maintenance

Always take into account the Technical Specications of chapter 9.

NEVER disassemble or remove the valve until the pipes have been emptied. Bear in

mind that the uid in the pipe may be hazardous or extremely hot. Consult the regula-

tions in eect in each country for these cases.

Release the spring tension before starting the disassembly of the valve.

Do not leave loose parts on the oor.

Safety

INOXPA S.A.U. 10.207.30.07EN · (0) 2023/11

6

4. General Information

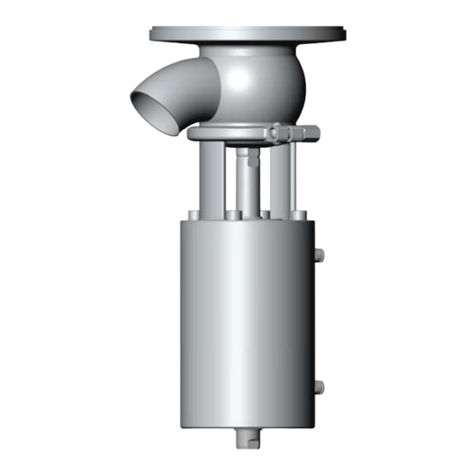

The overow valve 74700 is a valve with a sanitary design operated by springs. It protects the facili-

ties from possible overpressures.

The valve is calibrated to a specic pressure by the pressure nut. This pressure is the safety maxi-

mum pressure to avoid damage to the facility. Under working standard conditions, the valve remains

closed. If the circuit pressure exceeds the calibrated pressure, the valve is opened, allowing the ow

to pass and reducing the pressure facility.

The valve can incorporate a handle designed to allow the valve remains partially open. Thus, during

the CIP process, the cleaning products can pass through the valve.

4.1. DESCRIPTION

4.2. APPLICATION

The overow valve 74700 is a valve used to perform bypass as a relief measure to protect lines,

pumps, accessories, tanks, etc. of the dairies, food, beverage, pharmaceutical or chemical indus-

tries.

General Information

7

INOXPA S.A.U. 10.207.30.07EN · (0) 2023/11

5.1. RECEPTION OF THE VALVE

5. Installation

INOXPA is not liable for any deterioration of the material caused by its transport or unpac-

king.

When receipt the valve, check to see whether all the parts listed on the delivery slip are present:

- complete valve

- its components if any are supplied,

- quick installation guide or instruction manual.

INOXPA inspects all its equipment before packaging. However, it cannot guarantee that the mer-

chandise arrives at the user intact.

When unpacking the valve:

- take all possible precautions against damage to the valve and its components,

- remove any possible traces of packaging from the valve or its parts,

- inspect the valve or the parts that comprise it for possible damage incurred during shipping.

5.2. TRANSPORT AND STORAGE

The buyer or user shall be liable for assembly, installation, start-up and operation of the

valve.

Take all possible precautions when transport and storage the valve to avoid damage it and its com-

ponents.

5.3. IDENTIFICATION OF THE VALVE

Each valve is inscribed with its fabrication number. Indicate de fabrication number on all documents

to refer to the valve.

Installation

INOXPA S.A.U. 10.207.30.07EN · (0) 2023/11

8

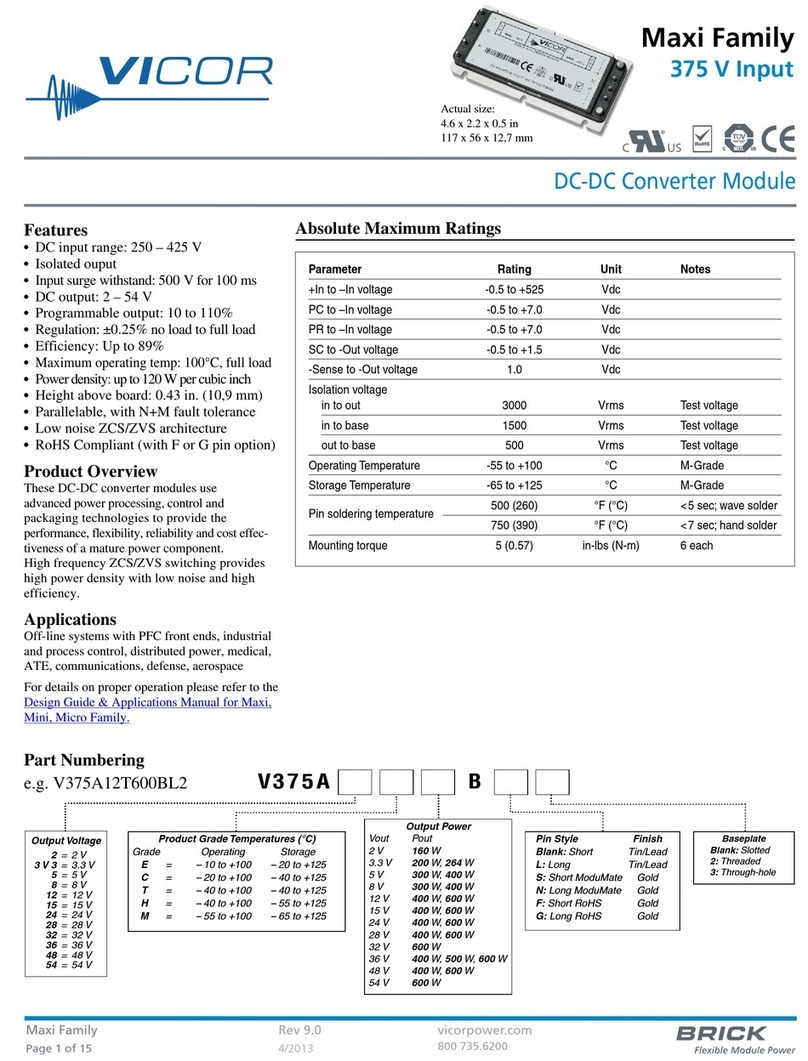

V74 0 0 - 00 06 52 050 06

Tared

03 0 - 300 kPa (0 - 3 bar)

06 0 - 600 kPa (0 - 6 bar)

10 0 - 1000 kPa (0 - 10 bar)

Size

025 DN 25, OD 1’’

032 DN 32

040 DN 40

045 OD 1½’’

050 DN 50, OD 2’’

063 OD 2½’’

065 DN 65

076 OD 3’’

080 DN 80

Seals

52 EPDM

70 PTFE/FPM

78 FPM

Material

06 1.4404 (AISI 316L)

Connection

00 welded/welded

10 male/welded

11 male/male

77 clamp/clamp

Standard pipe

0 DIN

1 OD

Type

0 standard

1 manual

Product family

V74 Overow valve 74700

Installation

9

INOXPA S.A.U. 10.207.30.07EN · (0) 2023/11

5.4. LOCATION

Place the valve leaving enough space around it to realise easily the disassembly, inspection and

review of the valve even when the valve is operating. Consult in chapter 5.8. Welding the required

minimum distances. The installation should allow that the removable parts are could remove easily.

5.6. GENERAL INSTALLATION

The overow valve 74700 is designed to be installed according to the ow direction indicated in the

following gure:

5.5. DIRECTION OF FLOW

After the location of the valve is dened, the valve can be joined to the pipe by welding the valve

housing or using ttings.

In case of joining the valve to the pipe by ttings do not forget the seals and tighten the unions pro-

perly.

The overow valve can be installed in any position although tting it upside down is not recommen-

ded.

10.207.32.0016

10.207.32.0017

Recommended Not recommended

10.207.32.0018

During installation, the valve avoids using excessive force and pay

special attention to:

- vibrations that may be produced on the facility,

- thermal dilation that the pipe may undergo when hot uids are

circulating,

- the weight that the pipe can support,

- excessive welding current.

10.207.32.0019

Installation

INOXPA S.A.U. 10.207.30.07EN · (0) 2023/11

10

5.7. CHECKING AND REVIEW

Perform the following checks before using the valve:

- check that the clamp and the regulation nut are tighted enough,

- if the valve has a handle, turn it several times to check the correct opening of the valve seat.

5.8. WELDING

Welding work should only be done by qualied persons who are trained and equipped

with the necessary equipment to perform this kind of work.

To perform the welding works:

- disassemble the valve as indicated in chapter 8.5. Disassembly and assembly of the overow

valve 74700,8.6. Disassembly and assembly of the overow valve 74700 with handle and 8.7.

Disassembly and assembly of the overow valve 74700 with PTFE seat seal.

- weld the valve body to the pipes maintaining the distance indicated in the following table,

dimension A. This will allow for disassembly of the valve, doing the subsequent reviews and

changing the necessary valve pieces like seals, bushings, etc.

10.207.32.0020

10.207.32.0021

DN A (mm)

Standard Manual

25 - 1’’ 250 325

32 260 335

40 - 1½’’ 275 345

50 - 2’’ 300 360

65 - 2½’’ 355 425

80 - 3’’ 380 445

A

A

10.207.32.0022

10.207.32.0023

- Mount the valve following the instructions indicated in chapter 8.5. Disassembly and assembly

of the overow valve 74700,8.6. Disassembly and assembly of the overow valve 74700 with

handle and 8.7. Disassembly and assembly of the overow valve 74700 with PTFE seat seal.

Installation

11

INOXPA S.A.U. 10.207.30.07EN · (0) 2023/11

6. Start-up

Read carefully the instructions in chapter 5. Installation before start-up the valve.

Before putting the valve into service the following must be taken into consideration:

- check that the piping and valve are completely free of possible traces of welding slag or other

foreign particles. Clean the system if necessary,

- check that the valve moves smoothly. If necessary, lubricate it with special grease or soapy

water,

- check for possible leaks, and make sure the pipes and their connections are sealed and do not

have any leaks,

- in the case of the manual valve, actuate the valve.

Before start-up, the persons in charge must be duly informed about how the valve works

and the safety instructions to follow. This instruction manual will be available to person-

nel at all times.

ATTENTION

Do not modify the operating parameters for which the valve has been designed without

prior written authorisation from INOXPA.

¡Burn hazard! Do not touch the valve or the pipes when hot uids are circulating or when

cleaning and/or sterilization are being carried out.

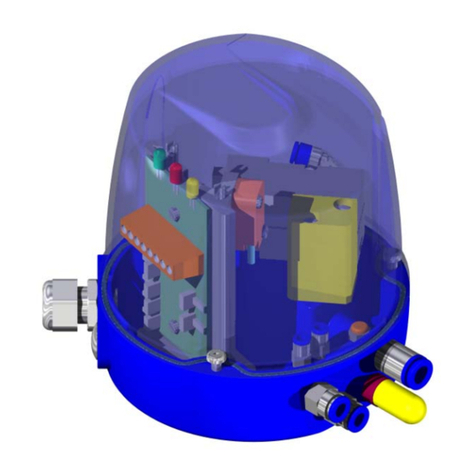

6.1. CALIBRATION OF THE VALVE

Upon request, the overow valve is shipped calibrated from the factory.

The valve calibration is performed with a ow recirculation through a bypass-type mounting. To per-

form it, it is necessary to have a pump, a gauge, a shut-o valve and the overow valve to tare and

follow the next steps:

- operate the pump with the shut-o valve in closed position. Thus, the ow will do the recircula-

tion going through the overow valve,

- loosen the lock nut and tighten the top nut of the overow valve until the gauge indicates the

whished pressure in the overow valve.

Once the valve is calibrated, it will open when the installation pressure exceeds the calibrated pres-

sure. So, the ow will recirculate to prevent the installation damage.

10.207.32.0007

Start-up

INOXPA S.A.U. 10.207.30.07EN · (0) 2023/11

12

7. Operating problems

Valve does not close

Internal leak of product (valve closed)

External leak of product

Valve does not open/close

PROBABLE CAUSES SOLUTIONS

•Dirt and/or foreign body between the shaft sleeve

and the valve body seat. - Clean the body and the seat

•The springs are not applying pressure on the

shaft stop washer. - Increase the tightening torque of the springs

•The shaft sleeve seal is worn or defective - Replace the seals

• Normal wear of the seals - Replace the seals

•

Premature

wear of the

seals

Sealing gasket worn or aected by

the product - Replace the seals with others of dierent mate-

rial and more adequate for the product

- Tighten the loosening pieces

- Clean frequently

Excessive pressure in the line

Working temperature too high

Loss of tightness (vibrations)

• Back pressure - Change the spring with a stronger one

• Body seal defective

- Replace the seals with new ones

• Shaft seal defective

• Deformation of seat seal - Replace the seat seal with another of dierent

quality if it has deteriorated prematurely

•Spring in poor condition and/or jam for the dirt - Replace or clean the spring and the shaft

•The valve does not open when the pressure

increases - Calibrated the valve

Operating problems

13

INOXPA S.A.U. 10.207.30.07EN · (0) 2023/11

8. Maintenance

This valve, just like any other machine, requires maintenance. The instructions in this chapter cover

the maintenance of the valve, the identication and replacement of the spare parts and the disas-

sembly and assembly of the valve. The instructions are aimed at maintenance personnel and those

responsible for the supply of spare parts.

Read carefully the chapter 9. Technical Specications.

Maintenance work should only be done by qualied persons who are trained and equi-

pped with the necessary equipment to perform this kind of work.

All replaced material should be duly disposed or recycled according to the directives in

eect in each area.

Make sure that the pipes are not under pressure before starting maintenance work.

8.1. GENERAL CONSIDERATIONS

8.2. MAINTENANCE

To perform maintenance properly is recommended:

- periodic inspection of the valve and its components,

- keeping an operational record of each valve writing down any problems,

- always having spare replacement seals in stock.

Pay special attention to the hazard warnings indicated in this manual during the performance of the

maintenance work.

The valve and the pipes must never be under pressure during maintenance.

¡Burn hazard! Do not touch the valve or the pipes when hot uids are circulating or when

cleaning and/or sterilization are being carried out.

8.2.1. Maintenance of the seals

REPLACING SEAL

Preventive maintenance Replace after 12 months

Maintenance after a leak Replace at the end of the process

Planned maintenance

Regularly check the absence of leaks and the smooth ope-

ration of the valve.

Keep a record of the valve’s maintenance.

Use statistics for planning inspections.

Lubrication

During assembly, apply lubricants that are suitable with the

material of which the seat seal is made. See the following

table.

The time interval between each preventive maintenance may vary in accordance with the work con-

ditions to which the valve is subject: temperature, pressure, number of operations per day, type of

cleaning solutions used, etc.

SEAL COMPONENT LUBRICANT NLGI DIN

51818 Class

FPM klübersynth UH 1 64-2403 3

EPDM / FPM PARALIQ GTE 703 3

Maintenance

INOXPA S.A.U. 10.207.30.07EN · (0) 2023/11

14

8.2.2. Storage

The valves should be stored in a closed area under the following conditions:

- temperature between 15ºC y 30ºC,

- air humidity < 60%

Storage of the equipment in the open air is NOT allowed.

8.2.3. Spare parts

To request spare parts is necessary to indicate the type of valve, the size, the fabrication number,

the position and the description of the part which can be found in chapter 9. Technical Specications.

8.3. CLEANING

The use of aggressive cleaning products such as caustic soda and nitric acid may burn

the skin.

Wear rubber gloves during all cleaning procedures.

Always wear protective goggles.

ATTENTION

Check the concentration of the cleaning solutions. An incorrect concentrations may lead

to the deterioration of the valve seals.

To remove any traces of cleaning products, ALWAYS perform a nal rinse with clean water at the end

of the cleaning process.

Clean the entire interior and exterior of the valve before starting disassembly and assem-

bly tasks.

If the valve is installed in a system with a CIP process its disassembly will not be required. EPDM is

the standard seal material that will be used for CIP cleaning, both in alkaline mediums and in acid

mediums. The material of the seal FPM is not recommended.

Two types of solutions can be used for CIP processes:

a. alkaline solution: 1% by weight of caustic soda (NaOH) a 70ºC (150ºF). To make this solution:

1 kg NaOH + 100 l H2O1= cleaning solution

2,2 l NaOH al 33% + 100 l H2O = cleaning solution

b. acid solution: 0,5% by weight of nitric acid (HNO3) a 70ºC (150ºF). To make this solution:

0,7 l HNO3 al 53% + 100 l H2O = cleaning solution

1) only use chlorine-free water to mix with the cleaning agents

8.3.1. CIP (clean-in-place) cleaning

ATTENTION

Do NOT start the equipment during the sterilization with steam.

The parts and the materials will not be damaged if the indications specied in this manual

are observed.

No cold uid can enter the equipment until the temperature of the equipment is lower

than 60°C (140°F).

Sterilization with steam is applied to all equipment including the pigging.

8.3.2. Automatic SIP (sterilization-in-place)

Maintenance

15

INOXPA S.A.U. 10.207.30.07EN · (0) 2023/11

Maximum conditions during the SIP process with steam or superheated water:

a. maximum temperature: 140ºC / 284ºF

b. maximum time: 30 min

c. cooling: sterile air or inter gas

d. materials: EPDM (the material FPM is not recommended)

Maintenance

INOXPA S.A.U. 10.207.30.07EN · (0) 2023/11

16

8.4. DISASSEMBLY AND ASSEMBLY THE VALVE

Proceed with caution. Personal injury can occur.

¡Spring with an applied load! Although the valve is at rest, there is a danger of injury in

case of loosening the clamp since the springs are tensioned, and they could throw parts

of the valve abruptly.

Release the tension of the springs before loosening the clamp.

Valve assembly and disassembly should only be done by qualied persons.

The following tools are needed in order to disassembly and assembly the valve and the drives:

- an spanner wrench to lose the locknut.

8.5. DISASSEMBLY AND ASSEMBLY OF THE OVERFLOW VALVE 74700

8.5.1. Disassembly

Release the tension of the springs before loosening the clamp.

1. If you want the same set value when you mount the valve, mark the part of the shaft (08) that pro-

jects the top nut (26C) to sign its position.

2. Lose the lock nut (26F).

3. Unscrew and disassemble the top nut of the valve (26C).

4. Remove the guide bushing (11) from the inside of the top nut (26C).

5. Unscrew and disassemble the lock nut (26F) of the valve.

6. Remove the clamp (34).

7. Remove the spring cover (12A). This will drag the spring washer (25) and the internal and external

springs.

8. Remove the springs (06) and the spring washer (25) from the spring cover (12A).

9. Pull the shaft (08) upwards to separate from the valve body (01).

10. Remove the body cover (12) from the shaft (08).

11. Remove the shaft seal (05) and the O-ring (20B) from the body cover (12).

12. Remove the elastic ring (45) from the shaft sleeve (08A).

13. Remove the shaft sleeve (08A).

14. Remove the at seal (19).

8.5.2. Assembly

1. Place the at seal (19) on the shaft (08).

2. Place the shaft sleeve (08A) on the shaft (08) situating it on top of the at seal (19) and x the

assembly with the elastic ring (45).

3. Place the shaft (08) in the valve body (01).

4. Place the O-ring (20B) in the body cover (12).

5. Place the body cover (12) on the valve body (01) passing it over the shaft (08).

6. Place the shaft seal (05) in the body cover (12).

7. Place the spring cover (12A) on the body (01) and x it with the clamp (34).

8. Place the spring washer (25) and the springs (06) in the spring cover (12A).

9. Thread the lock nut (26F) of the valve in the spring cover (12A).

10. Place the guide bushing (11) inside the top nut (26C).

11. Thread the top nut (26C) until the mark that you do on the disassembly process of the valve.

12. Thread the lock nut (26F) against the top nut (26C) to x it.

Maintenance

17

INOXPA S.A.U. 10.207.30.07EN · (0) 2023/11

3

08 34

12A

06

25

06

2

26F

26C

10.207.32.0024

4

1

11

26F

26C

01

08A

08

19

20B

05

12

10.207.32.0025

10.207.32.0026

10.207.32.0027

Maintenance

INOXPA S.A.U. 10.207.30.07EN · (0) 2023/11

18

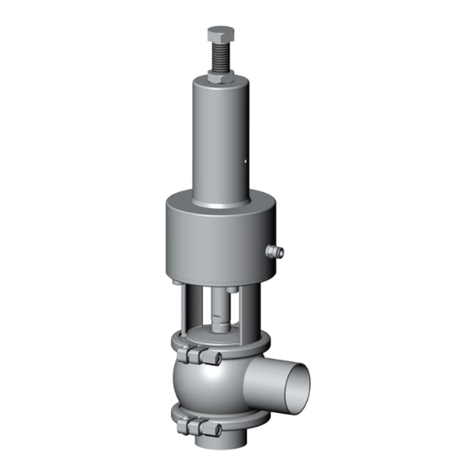

8.6. DISASSEMBLY AND ASSEMBLY OF THE OVERFLOW VALVE 74700 WITH HANDLE

8.6.1. Disassembly

Release the tension of the springs before loosening the clamp.

1. Remove the pin (50A) from the handle (04).

2. Disassemble the handle (04) from the shaft (08).

3. If you want the same set value when you mount the valve, mark the part of the shaft (08) that pro-

jects the top nut (26C) to sign its position.

4. Disassemble the top screw (22D).

5. Lose the lock nut (26F).

6. Unscrew and disassemble the top nut (26C) of the valve.

7. Unscrew and disassemble the lock nut (26F) of the valve.

8. Remove the clamp (34).

9. Remove the spring cover (12A). This will drag the spring washer (25) and the spring (06).

10. Remove the springs (06) and the spring washer (25) from the spring cover (12A).

11. Pull the shaft (08) upwards to separate from the valve body (01).

12. Remove the body cover (12) from the shaft (08).

13. Remove the shaft seal (05) and the O-ring (20B) from the body cover (12).

14. Remove the elastic ring (45) from the shaft sleeve (08A).

15. Remove the shaft sleeve (08A).

16. Remove the at seal (19).

8.6.2. Assembly

1. Place the at seal (19) on the shaft (08).

2. Place the shaft sleeve (08A) on the shaft (08) situating it on top of the at seal (19) and x the

assembly with the elastic ring (45).

3. Place the shaft (08) in the valve body (01).

4. Place the O-ring (20B) in the body cover (12).

5. Place the body cover (12) on the valve body (01) passing it over the shaft (08).

6. Place the shaft seal (05) in the body cover (12).

7. Place the spring cover (12A) on the body (01) and x it with the clamp (34).

8. Place the spring washer (25) and the springs (06) in the spring cover (12A).

9. Thread the lock nut of the valve (26F) in the spring cover (12A).

10. Thread the top nut (26C) until the mark that you do on the disassembly process of the valve.

11. Thread the lock nut (26F) against the top nut (26C) to x it.

12. Thread and adjust the top screw (22D) to ensure the opening of the valve by the handle.

13. Place the handle (04) on the shaft (08).

14. Place the pin (50A) to x the handle (04) on the shaft (08).

Maintenance

19

INOXPA S.A.U. 10.207.30.07EN · (0) 2023/11

2

26C

26F

22D

50A

04

26C

26F

4

34

08

06

12A

25

19

45

08A

01

05

08

12

20B

1

10.207.32.0028

10.207.32.0029

10.207.32.0030

10.207.32.0031

3

Maintenance

INOXPA S.A.U. 10.207.30.07EN · (0) 2023/11

20

This manual suits for next models

1

Table of contents

Other INOXPA Control Unit manuals

INOXPA

INOXPA INNOVA F Installation and user guide

INOXPA

INOXPA BALL Installation and user guide

INOXPA

INOXPA C-TOP Reed Manual

INOXPA

INOXPA INNOVA T Manual

INOXPA

INOXPA INNOVA J Installation and user guide

INOXPA

INOXPA BUTTERFLY Manual

INOXPA

INOXPA C-TOP+ User manual

INOXPA

INOXPA C-TOP Installation and user guide

INOXPA

INOXPA INNOVA F Manual

INOXPA

INOXPA NL Manual