INOXPA C-TOP S Manual

CONTROL HEAD

Original Instructions

10.426.30.03EN

(0) 2022/01

INSTALLATION, SERVICE AND MAINTENANCE INSTRUCTIONS

10.426.32.0013

E C D e c l a r a t i o n o f C o n f o r m i t y

INOXPA S.A.U.

Telers, 60

17820 - Banyoles (Spain)

hereby declare under our sole responsibility that the

Model: C-TOP S

Type: C-TOP S 24V DC 0E, C-TOP S 24V DC 1E, C-TOP

S 24V DC 2E, C-TOP S 24V DC 3E, C-TOP S AS-I

1E, C-TOP S AS-I 2E, C-TOP S AS-I 3E

Technical Oce Manager

15th December 2021

10.246.30.05EN

(0) 2021/12

Document:

Revision:

Machine: CONTROL HEAD

David Reyero Brunet

fullls all the relevant provisions of the following directive:

Electromagnetic Compatibility Directive 2014/30/EU

and with the following harmonized standards and/or regulations:

EN 61326-1:2013

The technical le has been prepared by the signer of this document.

Serial number: IXXXXXXXXX to IXXXXXXXXX

XXXXXXXXXIINXXX to XXXXXXXXXIINXXX

D e c l a r a t i o n o f C o n f o r m i t y

INOXPA S.A.U.

Telers, 60

17820 - Banyoles (Spain)

hereby declare under our sole responsibility that the

Model: C-TOP S

Type: C-TOP S 24V DC 0E, C-TOP S 24V DC 1E, C-TOP

S 24V DC 2E, C-TOP S 24V DC 3E, C-TOP S AS-I

1E, C-TOP S AS-I 2E, C-TOP S AS-I 3E

Technical Oce Manager

15th December 2021

10.426.30.06EN

(0) 2021/12

Document:

Revision:

Machine: CONTROL HEAD

David Reyero Brunet

fullls all the relevant provisions of these regulations:

Electromagnetic Compatibility Regulations 2016

and with the following designated standards:

EN 61326-1:2013

The technical le has been prepared by the signer of this document.

Serial number: IXXXXXXXXX to IXXXXXXXXX

XXXXXXXXXIINXXX to XXXXXXXXXIINXXX

1. Table of Contents

1. Table of Contents

2. Generalities

2.1. Instructions manual.................................................................................................................................6

2.2.Compliance with the instructions ............................................................................................................ 6

2.3. Warranty..................................................................................................................................................6

3. Security

3.1. Warning symbols.....................................................................................................................................7

3.2. General safety instructions ..................................................................................................................... 7

4. General Information

4.1. Description ..............................................................................................................................................9

4.2.Application...............................................................................................................................................9

5. Installation

5.1.Reception of the control head ............................................................................................................... 10

5.2.Transport and storage...........................................................................................................................10

5.3.Identicationofthecontrolhead ........................................................................................................... 10

5.4. Location ................................................................................................................................................10

5.5.Mechanical installation of the control head ...........................................................................................10

5.6.Pneumatic installation of the control head ............................................................................................12

5.7.Electrical installation of the control head............................................................................................... 13

6. Setup

6.1.Autotune................................................................................................................................................15

6.2. Manualtune ...........................................................................................................................................16

6.3. Auxiliary modes....................................................................................................................................16

6.4. Reset.....................................................................................................................................................17

6.5. Colour coding.......................................................................................................................................17

7. Operating problems

8. Technical Specications

8.1. Materials ...............................................................................................................................................19

8.2. Environment..........................................................................................................................................19

8.3. Control head ......................................................................................................................................... 19

8.4. Solenoid valves.....................................................................................................................................19

8.5. Comunication ........................................................................................................................................19

8.6.Dimensions of the C-TOP S.................................................................................................................. 20

8.7.Exploded drawing and parts list ............................................................................................................ 20

2. Generalities

2.1. INSTRUCTIONS MANUAL

This manual contains information about the reception, installation, operation, assembly and mainte-

nance of the control head C-TOP S.

Carefully read the instruction before starting the control head, familiarize yourself with the installation,

operation and correct use of the control head and strictly follow the instructions. These instructions

should be kept in a safe location near the installation area.

The information published in the instruction manual is based on updated data.

INOXPA reserves the right to modify this instruction manual without prior notice.

2.2. COMPLIANCE WITH THE INSTRUCTIONS

Not following the instructions may impose a risk for the operators, the environment and the machine,

and may cause the loss of the right to claim damages.

This non-compliance may cause the following risks:

- failure of important machine/plant functions,

- failureofspecicmaintenanceandrepairprocedures,

- possible electrical, mechanical and chemical hazards,

- the risk to the environment due to the type of substances released.

2.3. WARRANTY

TheconditionsofthewarrantyarespeciedintheGeneralSalesConditionthathasbeendelivered

at the time of placing your order.

The machine may not undergo any modication without prior approval from the

manufacturer.

For your safety, only use original spare parts and accessories. The usage of other parts

will relieve the manufacturer of any liability.

Changing the service conditions can only be carried out with prior written authorization

from INOXPA.

Please do not hesitate to contact us in case of doubts or if further explanations are required regarding

specicdata(adjustments,assembly,disassembly,etc.).

Generalidades

5

INOXPA S.A.U. 10.426.30.03EN · (0) 2022/01

3.1. WARNING SYMBOLS

3. Security

Safety hazard for people in general and/or for the control head

Electrical hazard

ATTENTION Important instruction to prevent damage to the equipment and/or its function

3.2. GENERAL SAFETY INSTRUCTIONS

Read the instruction manual carefully before installing and starting the control head.

Contact INOXPA in case of doubt.

For a reliable and without problems function follow the instructions of this manual.

This control head cannot be used in atmospheres where exist explosion hazards.

The installation and the use of the control head always must be following the health and

safety applicable regulations.

3.2.1. During installation

Always take into account the TechnicalSpecicationsinchapter8.

Use the device only for its intended use and only with the recommended equipment by

INOXPA.

Before performing the installation ensure that the compressed air and the power supplies

areswitchedoandthattheactuatoroftheprocessvalveispressureless.

Ensure that the power supply does not restart.

All the electrical work should be carried out by specialised personnel.

Only use power supplies that guarantee reliable electrical isolation of the operating

voltage as per IEC/DIN EN 60204-1.

Observe the general requirements for PELV circuits in accordance with IEC/DIN EN

60204-1.

Installation errors can damage the electronics or cause malfunctions.

The C-TOP S contains electrostatically sensitive components. Electrostatic discharge

caused by improper handling or incorrect earthing can damage the internal electronics.

3.2.2. During operation

Always take into account the TechnicalSpecicationsinchapter8.

Only use the product if it is in perfect technical condition.

NEVERexceedthespeciedlimitvalues.

Do not touch the inside of the control head when it is in operation.

Seguridad

INOXPA S.A.U. 10.426.30.03EN · (0) 2022/01

6

3.2.3. During maintenance

Always take into account the TechnicalSpecicationsinchapter8.

Before starting the maintenance work, make sure that the compressed air supply is

switchedoandthattheairsupplyhosesarepressureless.Securethesystemagainst

accidental restarting.

All the electrical work should be carried out by specialised personnel.

Before starting the maintenance work, make sure that the power supplies are switched

o.Securethesystemagainstaccidentalrestarting.

All the electrical work should be carried out by specialised personnel.

The C-TOP S contains electrostatically sensitive components. Electrostatic discharge

caused by improper handling or incorrect earthing can damage the internal electronics.

Seguridad

7

INOXPA S.A.U. 10.426.30.03EN · (0) 2022/01

4. General Information

The C-TOP S is a control head that adapts to all of the INOXPA actuators to automate pneumatic

drive process valves. To automate the process valves, the control head can have up to three solenoid

valves.

The control head contains a linear detection electronic module comprised of several hall-eect

sensors. A PLC system sends signals to the solenoid valves of the control head through the unit’s

electronic module to control and operate the main valve. At the same time, the electronic module

sends feedback signals to the PLC to indicate the current position valve. A particular colour for each

valve position lights up to indicate its current status at all times.

The control head is set using the electronic module.

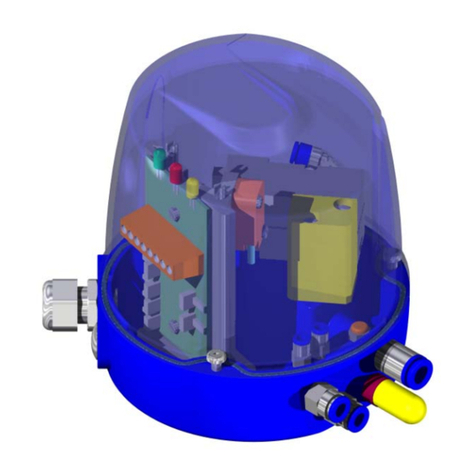

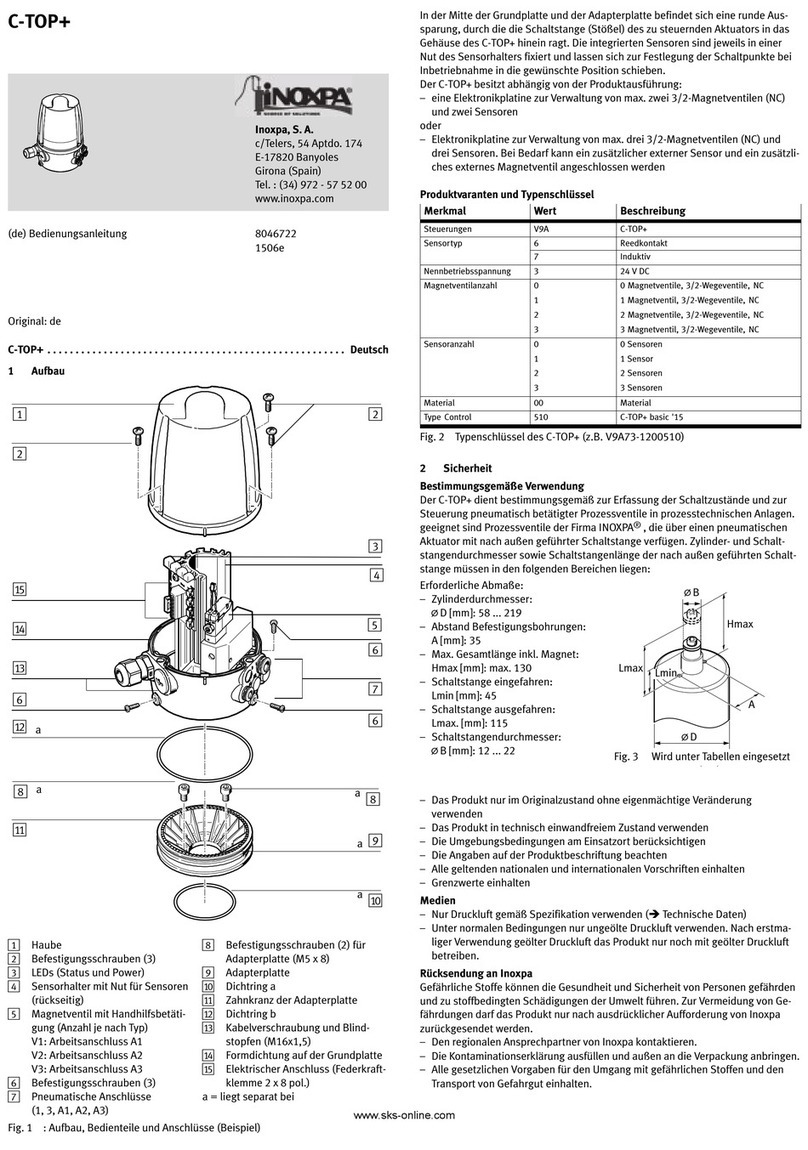

The control head main parts are:

4.1. DESCRIPTION

4.2. APPLICATION

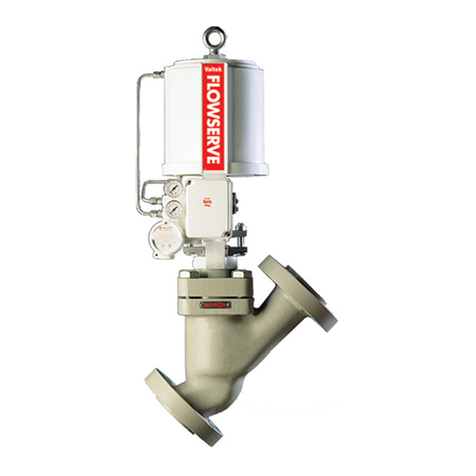

TheC-TOPScaninstallonanyprocessvalve(buttery,ball,diaphragmandsingleordoubleseat

valves)ofthefood,beverage,chemicalorpharmaceuticalindustry.

Cover screws

Cover seal

Cover

Base screws

Solenoid valves Electronic module

Cable gland

Base

Target

Base seal

Pneumatic ports

10.426.32.0014

Información General

INOXPA S.A.U. 10.426.30.03EN · (0) 2022/01

8

INOXPA is not liable for any deterioration of the material caused by its transport or

unpacking.

When receipt the control head, check to see whether all the parts listed on the delivery slip are

present:

- control head,

- instruction manual.

INOXPA inspects all control heads before packaging. However, it cannot guarantee that the

merchandise arrives at the user intact.

When unpacking the valve:

- take all possible precautions against damage to the control head and its components,

- inspect the valve or the parts that comprise it for possible damage incurred during shipping.

5.1. RECEPTION OF THE CONTROL HEAD

5. Installation

5.2. TRANSPORT AND STORAGE

The buyer or user shall be liable for assembly, installation, start-up and operation of the

control head.

Take all possible precautions when transporting and storing the control head to avoid damaging it

and its components.

5.3. IDENTIFICATION OF THE CONTROL HEAD

Each control head is inscribed a fabrication number for its identication. indicate the fabrication

number on all documents to refer to the control head.

5.4. LOCATION

Place the control head leaving enough space around it to realize easily the dismantling, the inspec-

tion and the review of the control head. The installation should allow that the removable parts are

could remove easily.

5.5. MECHANICAL INSTALLATION OF THE CONTROL HEAD

All the installation work of the control head should be carried out by specialised personnel.

Always follow the instructions of the present manual.

Checkthatthecompressedairandpowersupplyareswitchedoandtheactuatoris

pressureless before starting the assembly or disassembly works.

Instalación

9

INOXPA S.A.U. 10.426.30.03EN · (0) 2022/01

To mount the control head on the actuator of the valve follow the next process:

1. Ifnecessary,ttheshaftadapterontheactuatorshaft.

2. Placethetarget(10)ontheshaftadapter.

3. Removethecoverscrews(01).

4. Position the C-TOP S on the actuator.

5. Tightenthebasescrews(04)whichjointheheadwiththeactuator.

6. Placethecover(02)andtightenthecoverscrews(01).

10.426.32.0001

Instalación

INOXPA S.A.U. 10.426.30.03EN · (0) 2022/01

10

5.6. PNEUMATIC INSTALLATION OF THE CONTROL HEAD

All the installation work of the control head should be carried out by specialised personnel.

Always follow the instructions of the present manual.

Checkthatthecompressedairandpowersupplyareswitchedoandtheactuatoris

pressureless before starting the assembly or disassembly works.

Cut the air hoses at the needed length before starting the pneumatic installation.

To perform the pneumatic installation follow the next process:

1. Connect the air hoses between the necessary air connections A1, A2 and/or A3 of the C-TOP

S and the valve’s air connections.

2. Connect the air supply hose to the air intake 1 of the control head.

3. Connect the compressed air supply.

Use only approved air supply’s connections and suitable quality for the installation.

Cut the air connections with a suitable cutter to avoid damage to them.

Use the air supply’s connections with sufficient length to avoid tensions on them and to

avoid its disassemble if separate the control head of the valve is needed.

solenoid valve connection

V1, V2 y V3

air leak

air supply’s connection

10.426.32.0001

Theidenticationoftheconnectionsisonthecontrolhead.

Connection Description tube outer ØThread

1 supply port for operating pressure 8 mm

G 1/8’’

3 exhaust air connection -

A1 working port of solenoid valve V1

6 mmA2 working port of solenoid valve V2

A3 working port of solenoid valve V3

Instalación

11

INOXPA S.A.U. 10.426.30.03EN · (0) 2022/01

Printing Description

O

4 output position 4

3 output position 3

2 output position 2

1 output position 1

Ext

-0V(GND)externalsensor

+ 24V DC external sensor

S input external sensor

I

3input3(solenoidvalve3)

2input2(solenoidvalve2)

1input1(solenoidvalve1)

-0V(GND)

+ 24V DC

5.7. ELECTRICAL INSTALLATION OF THE CONTROL HEAD

All the electrical work should be carried out by specialised personnel.

Check that the power supplies are switched off.

Secure the installation to prevent unintentional activation.

The C-TOP contains electrostatically sensitive components. The electrostatic discharge

caused by improper handling or incorrect earthing can damage the internal electronics.

The control head C-TOP S is available in three versions of the electronic module with three systems

of communication:

1. Digital 24V DC communication for 2 or 3 solenoid valves.

2. Digital 24 V DC communication for 0 or 1 solenoid valves.

3. AS-interface communication.

5.7.1. Electrical installations with digital communication 24V DC

To perform the electrical installation of the control head with digital 24V DC communications follow

the next steps:

1. Removethecoverscrews(01).

2. Liftandremovethecover(02).

3. Route the electrical cable through the cable gland.

4. Connect the cables to the terminal according to the wiring diagram.

5. Tightenthecablegland(08).

6. Placethecover(01)andxitwiththecoverscrews(01).

Wiring diagram digital 24 V DC communication for 2/3 solenoid valves and 4 outputs:

Wiring diagram digital 24 V DC communication for 1 solenoid valve and 3 outputs:

Printing Description

O

3 output position 3

2 output position 2

1 output position 1

I 1 input1(solenoidvalve1)

-0V(GND)

+ 24V DC

10.426.32.0004

10.426.32.0005

Instalación

INOXPA S.A.U. 10.426.30.03EN · (0) 2022/01

12

5.7.2. Electrical installation with AS-interface communication

The C-TOP S with AS-interface communication includes a cable with a multipole connector so it is

not needed to perform any internal wiring.

Wiring diagram AS-interface communication:

Printing Description

Ext

-0V(GND)externalsensor

+ 24V DC external sensor

S input external sensor

--AS-i(M12,pin3)

++AS-i(M12,pin1)

M12 male multi-pole connector:

10.426.32.0006

10.426.32.0007

Instalación

13

INOXPA S.A.U. 10.426.30.03EN · (0) 2022/01

6. Setup

Thecontrolheadleavesthefactorywithoutconguration.Performaprevioussettingthatconsistsof

memorizingdierentpositionsoftheshaftofthevalveactuatorisneededtobeabletouseit.Once

itisinstalledandisswitchedonforthersttime,theC-TOPSasheswithawhiteandpinklightto

indicate that it has not any position memorized.

The control head C-TOP S has two setting modes:

- autotune

- manualtune

Thedierentsettingmodesofthecontrolheadareperformedthroughtheofpulsationsthe“I” and

“II”buttonswhichareinthetoppartoftheelectronicmoduleofthecontrolhead,sotocongureit

will be necessary to lift its cover.

The“I”y“II” buttons of the electronic module answer to three types of pulsations according to the

following table:

Pulsation short pulsation long pulsation

Time(s) < 1 1 - 3 > 3

Signalling light green continuous light lightgreenashinglight

6.1. AUTOTUNE

Theautotunecongurationallowsanautomaticcongurationanditworkswellformostapplications.

Thiscongurationmodeisrecommendedwheneverpossible.

Withthisconguration,thecontrolheadactivatesthesolenoidvalvessequentiallyandmemorizethe

dierentpositionsofthevalve.

Theautotunecongurationcanbecarriedoutintwoways:

- by external signals

- by the internal signals generated by the control head itself

In the autotune conguration by the external way, when the control head receives a signal, the

corresponding solenoid valve will be activated and memorize the new position. The control head will

be pending to receive new signals for 10 minutes maximum. When the control head receives the

external signal, the new position will activate the corresponding digital output and will light the control

headaccordingtotheconguredcolourforthisposition.Thecontrolheadcongurationwillnishif,

during these 10 minutes, all the possible input signals have been received. Otherwise, is possible to

congurethecontrolheadbyinternalsignalsgeneratedbythecontrolheaditself.

Toperformtheautotunecongurationbyinternalsignalsfollowthenextsteps:

1. Doalongpressonthe“I” button. The end of the long press will be indicated by a light green

ashingilluminationandthestartofthecongurationbyawhiteashinglightfor2seconds.

2. Thecontrolhead’scongurationwillstartautomaticallyactivatingandmemorisingthedierent

positionsofthevalve.Thetransitionsbetweendierentpositionswillbeindicatedbyapink

ashing light. When memorizing each position, the control head will be illuminated by the

conguredcolourforsuchposition,itwillactivatethecorrespondingoutletanditwillstartthe

transition to the next position.

3. Toindicatetheendoftheautotunecongurationthecontrolheadwillbeilluminatedbyawhite

continuous light for 5 seconds.

Doashortpressonthe“II”buttontocanceltheprocessoftheautotuneconguration.

Consult chapter 7. Operating problemsifanerroroccursduringtheautotuneconguration.

Puesta en marcha

INOXPA S.A.U. 10.426.30.03EN · (0) 2022/01

14

6.3. AUXILIARY MODES

To perform the test mode follow the next steps:

1. Doashort presson the“I” button. The start of the test mode will be indicated by a white

ashinglight.

2. A test sequence is executed for each solenoid valve. If the target’s position is the memorized

position is checked for each solenoid valve. If the target’s position is correct, the control head

willbeilluminatedbythecorrespondingconguredcolourforeachsolenoidvalve.

3. The control head’s light is closed during the change of the solenoid valve.

4. Toindicatetheendofthetestmodethecontrolheadwillbeilluminatedbyawhiteashing

light for 2 seconds.

6.2. MANUALTUNE

Toperformthemanualtunecongurationfollowthenextsteps:

1. Doalongpressonthe“II” button. The end of the long press will be indicated by a light green

ashingilluminationandthestartofthecongurationbyawhiteashinglightfor2seconds.

2. Perform the following steps for each possible valve’s position that have to be memorized:

- place the valve on the position to be memorized. To do this you can use the manual locking

of the solenoid valves.

- thecontrolheadwillbeilluminatedbythecorrespondingconguredcolour.

- doalongpressonthe“II”buttontomemorizethepositionorpress“I” to discard it.

• If the position is memorized, the control head will be illuminated continuously light

bythecorrespondingconguredcolourfor5seconds.Oncethepositionissavedthe

controlheadwillbeilluminatedbyaashinglightofthecolourofthenextpositionwhich

has to memorize.

• Ifthepositionisdiscardedthecontrolheadilluminatesbyaashinglightofthecolour

of the next position which has to memorize.

The maximum time to memorize the valve’s position or discard it is 120 seconds. After this

time,thecongurationprocesswillbecancelled.

- toindicatetheendofthemanualtunecongurationthecontrolheadwillbeilluminatedby

a white continuous light for 5 seconds.

Themanualtune programmingallows themanualconguration ofthe controlhead.Thismode is

used in cases where the autotune mode is not possible. For example, it is recommended in case

ofdoubleeectactuatorsorifyouwanttoactivate,simultaneously,morethanonesolenoidvalve.

Inthiscongurationmode,thepositionsassociatedwitheachoutputmustbememorizedoneby

one.

Doashortpressonthe“I”buttontocanceltheprocessofthemanualtuneconguration.

Consult chapter 7. Operating problemsifanerroroccursduringthemanualtuneconguration.

The control head has two additional modes which can be useful to do check and maintenance tasks:

- test

- maintenance

6.3.1. Test mode

Thetestmodeallowscheckingthecontrolhead’sconguration.Onlyifyoucreateaconguration

previously, manually or automatically, you can access the test mode.

During the performance of the test mode, you can pass from checking one solenoid valve to another

bydoingashortorlongpressonthe“I” button.

Doashortorlongpressonthe“II” button to cancel the test mode.

Puesta en marcha

15

INOXPA S.A.U. 10.426.30.03EN · (0) 2022/01

6.3.2. Maintenance mode

The maintenance mode is used to activate the solenoid valves manually.

To entry to the maintenance mode, situate the DIP switch 4 in the ON position.

Theentrytothemaintenancemodeisindicatedwithawhiteashinglightfor2seconds.

Once inside the maintenance mode, the solenoid valves can be activated manually doing pressing

the“I”and“II” buttons according to the combinations of the following table:

“I” button “II” button Activate

solenoid valve

Pressed Not pressed 1

Not pressed Pressed 2

Pressed Pressed 3

Not pressed Not presseg None

Ifthecontrolheadisconguredforeachsolenoidvalvethatisactivatedmanually,thecontrolhead

willbeilluminatedbythecorrespondingconguredcolour.Ifinstead,thecontrolheadhasnotany

conguration,thecontrolheadwillbeilluminatedbyawhitelight.

To nalize the maintenance mode, situate the DIP switch 4 in the OFF position. The end of the

maintenancemodewillbeindicatedbyaashinglightfor2seconds.

Torestorethedefault settings, reset the controlheadpressing the “I” and “II” buttons until the

control head illuminates by a white continuous light.

6.4. RESET

Thecontrolheadisilluminatedbydierentcolourstoinformthestatusofthevalveandthecontrol

head. There are some default colours and other ones that be chosen to congure the dierent

positions of the valve.

The default colours to operate the C-TOP S are:

- White:togetinandoutofthedierentoperatingmodes.Ifnochangehasoccurredattheexit

ofthesettingmode,thelightofthecontrolheadwillbeashing.Instead,ifanychangeshave

occurred, the light of the control head will be continuous.

- Pink: to indicate transition.

- Red: to indicate an electronic fault.

DIP 1 DIP 2 DIP 3 OUT 1 OUT 2 OUT 3 OUT 4

0 0 0 blue green yellow orange

1 0 0 green blue yellow orange

0 1 0 green yellow blue orange

1 1 0 blue yellow green orange

0 0 1 yellow blue green orange

1 0 1 yellow green blue orange

0 1 1 blue green orange yellow

1 1 1 green blue orange yellow

Othercolourscanbeconguredforeachoutletaccordingtothefollowingtable:

6.5. COLOUR CODING

Puesta en marcha

INOXPA S.A.U. 10.426.30.03EN · (0) 2022/01

16

Before doing a fault diagnosis check that the control head is correctly connected.

7. Operating problems

Fault description Possible causes Action

The electrical signal is NOT sent

or received

The cables are defective or

improperly connected

Check the electric connection and

the power supply

The electronic module is defective Replace the electronic module

The electrical signal is NOT sent

or received and the control head

NOT be illuminated

The control head is in maintenance

mode. The rest position light

savedashes

Movethe“DIPSwitch4”totheright

to exit the maintenance mode.

See chapter 6.3.2. Autotune

The electrical signal is NOT sent

or received and the control head

FLASHES alternatively with

WHITE and PINK light

There is not any saved

congurationinthecontrolhead

Performthecongurationprocess

according to chapter 6.1. Autotune

or 6.2. Manualtune

Themagnet(target)isdefectiveor

is not installed

Check that the magnet is installed.

If yes, check its state

The electrical signal is NOT

sent or received and the control

head be illuminated with a

CONTINUOUSLY LIGHT

The control head has a

conguration that does not

correspond with the valve/s

Performthecongurationprocess

according to chapter 6.1. Autotune

or 6.2. Manualtune

The process valve does NOT act

and the light of the current position

FLASHES

The control head is receiving

a signal to act but it has not

compressed air supply

Check the compressed air supply

arrives at the control head

The external sensor is defective

or is not correctly congured or

installed

Check that the external sensor is

installed and/or is not defective.

Then, perform the conguration

according to chapter 6.1. Autotune

or 6.2. Manualtune

The control head can not act two

internal solenoid valves at a time

The control head has not

compressed air supply

Check that pneumatic pressure

arrives at the control head

The control head does NOT

respond at the autotune

conguration through external

signals. It ashes alternatively

with WHITE and PINK light

10 minutes have passed after

that the control head has been

connected to the power supply

At the end of this time, perform

the autotune conguration by

internal signs or the manualtune

conguration

Wrong operation of the process

valves

The pneumatic connections are

not correctly connected

Check that each pneumatic hose

is connected to the corresponding

output of the control head

Incidentes de funcionamiento

17

INOXPA S.A.U. 10.426.30.03EN · (0) 2022/01

8. Technical Specications

8.1. MATERIALS

Plastic parts PA6

Screws A2

Seals NBR

Airttings nickel-platedbrass

8.2. ENVIRONMENT

Working temperature C1 - protected areas

Storage temperature -20ºC to 50ºC

Environment temperature -5ºC to 50ºC

Degree of protection IP65, IP67

8.3. CONTROL HEAD

Stroke ≤80mm

Maximum shaft diameter 22 mm

Assembly type screws

Fluid lteredcompressedair,ltrationdegree40µmlubricated

or not lubricated

Measuring principle HALL sensor without contact

Measured quantity position

Accuracy ± 0,8 mm

Visual indicators LED

8.4. SOLENOID VALVES

Quantity 0 - 3

Type 3/2 way, normally closed with manual locking

Operating pressure 3 -7 bar

Operating voltage 24 V DC ±10%

Power consumed 0,35 W

8.5. COMUNICATION

Digital 24 V DC AS-interface

Operatin voltage 24 V DC ± 10% by wire AS-i de 29,5 to 31,6 V DC

Outlets PNP normally open -

Terminal

type push-in, nominal cable

section 0,2 a 1,5 mm2 (22AWGa

16AWG)

type push-in, nominal cable sec-

tion 0,2 a 1,5 mm2 (22AWGa16

AWG)

Main input cableglandM16x1,5(4to10mm

diametercable)

cable gland M16 x 1,5 with 2

m cable and M12 4 pole male

connector

External sensor input M16 x 1,5 plug M16 x 1,5 plug

Version - v3.0(A/Baddressingandupto62

nodes)

Slaveprole -7A77

Especicaciones Técnicas

INOXPA S.A.U. 10.426.30.03EN · (0) 2022/01

18

8.6. DIMENSIONS OF THE C-TOP S

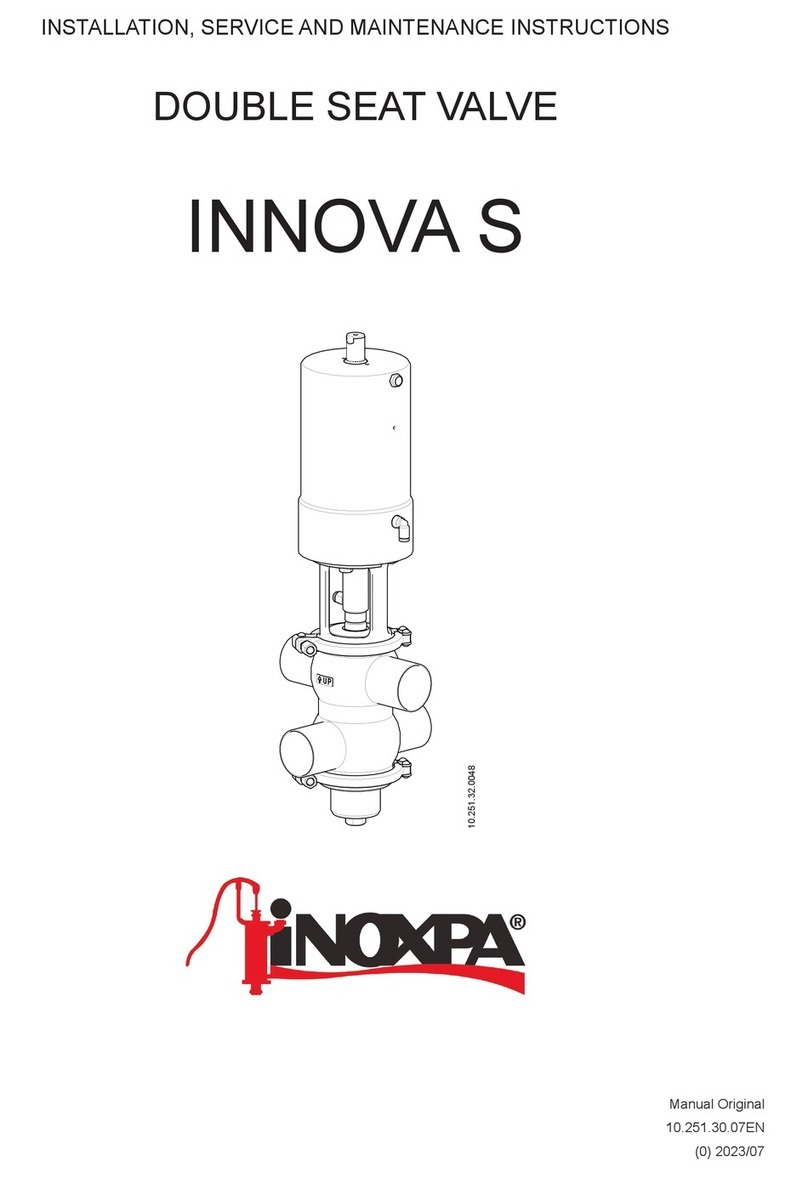

8.7. EXPLODED DRAWING AND PARTS LIST

Position Description

01 cover screws

02 cover

03 cover seal

04 base screws

05 solenoid valves

06 electronic module

07 pneumatic ports

08 cable gland

09 base

10 target

11 base seal

Especicaciones Técnicas

19

INOXPA S.A.U. 10.426.30.03EN · (0) 2022/01

NOTES

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

Table of contents

Other INOXPA Control Unit manuals

INOXPA

INOXPA INNOVA P Series Manual

INOXPA

INOXPA INNOVA S Manual

INOXPA

INOXPA C-TOP+ User manual

INOXPA

INOXPA VEEVALV Manual

INOXPA

INOXPA C-TOP+ User manual

INOXPA

INOXPA INNOVA T Manual

INOXPA

INOXPA INNOVA J Installation and user guide

INOXPA

INOXPA 72700 Manual

INOXPA

INOXPA INNOVA F Installation and user guide

INOXPA

INOXPA INNOVA P Manual

Popular Control Unit manuals by other brands

Patching Panda

Patching Panda BD-Z user manual

EUCHNER

EUCHNER MCM-MLI Series operating instructions

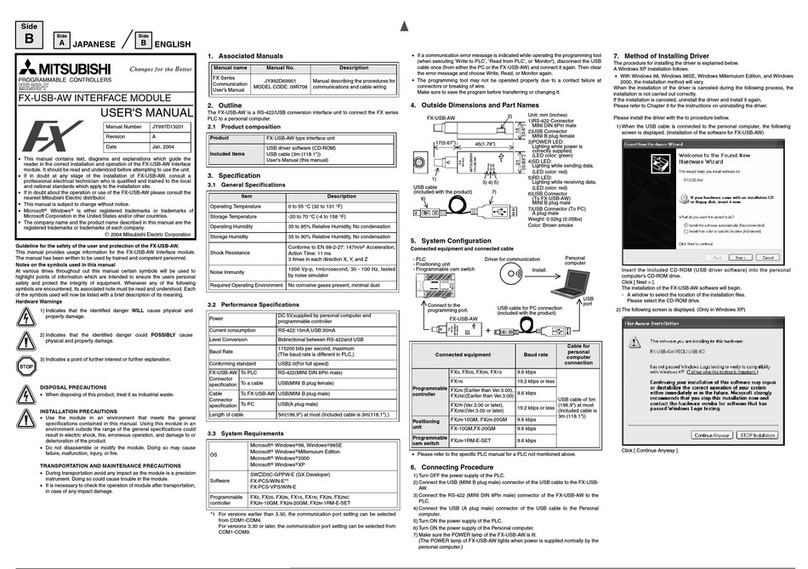

Mitsubishi Electric

Mitsubishi Electric FX-USB-AW user manual

P&B

P&B MR-REF Technical manual

Panasonic

Panasonic EBL512 G3 5000 Planning Instructions

Mitsubishi Electric

Mitsubishi Electric iQ-F Series user manual