INOXPA INNOVA J Installation and user guide

INSTALLATION, SERVICE AND MAINTENANCE

INSTRUCTIONS

SINGLE SEAT RELIEF VALVE

INNOVA J

INOXPA S.A.U.

Telers, 60 Aptdo. 174

17820 –Banyoles

Tel.: +34 972 57 52 00

Fax.: +34 972 57 55 02

www.inoxpa.com

Original Manual

10.245.30.01EN

(0) 2018/05

10.245.32.0001

10.245.30.02EN

(0) 2018/05

(1) The serial number may be preceded by a slash and by one or two alphanumeric characters

EC Declaration of Conformity

We,

INOXPA, S.A.U.

Telers, 60

17820 –Banyoles (Girona)

Hereby declare under our sole responsibility that the machine

Relief Valve

Designation

INNOVA

Type

INNOVA J

From serial number I282400 to I500000 (1) / 000061900IIN to 000100000IIN (1)

Fulfills all the relevant provisions of the following directive:

Machinery Directive 2006/42/CE

Pressure Equipment Directive 2014/68/EU

Identification of the person empowered to draw up the Declaration on behalf of the manufacturer and

qualified to compile the technical file established by the community

David Reyero Brunet

Technical Office Manager

Banyoles, May 17, 2018

(0) 2018/05 1. Safety 3

1. Safety

1.1. INSTRUCTION MANUAL

This instruction manual contains basic guidelines, which must be followed during installations, start-up,

and maintenance.

The information published in this instruction manual is based on updated data.

INOXPA reserves the right to modify this instruction manual without prior notice.

1.2. INSTRUCTIONS FOR START-UP

This instruction manual contains essential and useful information for the correct handling and maintenance

of your valve.

The safety instructions detailed in this section as well as all the special measures and recommendations

included in the other sections of this manual must be observed and fulfilled. These instructions must be

kept in a safe location near the installation area.

1.3. SAFETY

1.3.1. Warning symbols

Danger for people in general

Danger of injury caused by moving

equipment parts.

Electrical hazard

Danger caustic or corrosive agents

Danger to the correct operation of

the equipment

Mandatory to ensure safety at the

workplace

Mandatory use of safety goggles

1.4. GENERAL SAFETY INSTRUCTIONS

Read the instruction manual carefully before installing and using the valve. If in doubt,

please contact INOXPA

1.4.1. Durante la instalación

The Technical specifications in chapter 8 should always be observed.

The installation and use of the valve must always be carried out in accordance with

applicable safety and health regulations.

Before putting the valve into service, check to make sure it is assembled correctly and that

the shaft is perfectly aligned. Misalignment and/or excessive forces when securing the valve

can cause serious mechanical problems with the valve.

4 1. Safety (0) 2018/05

1.4.2. During operation

Always take the Technical specifications in chapter 8 into consideration. The specified limit values shall

NEVER be exceeded under any circumstance.

NEVER touch the valve and/or piping that is in contact with the fluid during operation. If the

process involves hot products, there is a risk of burns.

The valve contains parts that move in a linear fashion. Do not place hands or fingers in the

valve closing area. This can cause serious injury.

1.4.3. During maintenance

The Technical specifications in chapter 8 should always be observed.

NEVER disassemble or remove the valve until the pipes have been emptied. Bear in mind that

the fluid in the pipe may be hazardous or extremely hot. Consult the regulations in effect in

each country for these cases.

Inside the actuator, there is a spring with an applied load, and the steps specified in this

manual must be followed when performing maintenance operations to avoid injury.

Do not leave loose parts on the floor.

All electrical work must be carried out by authorised personnel.

1.4.4. Compliance with the instructions

Any failure to comply with the instructions may impose a risk to the operators, the environment and the

machine, and may ultimately result in the loss of any right to claim damages.

Failure to comply may entail the following risks:

Failure of important machine/plant functions.

Failure of specific maintenance and repair procedures.

Threat of electrical, mechanical and chemical hazards.

Placing the environment at risk due to the substances released.

1.4.5. Warranty

Any warranty will be void immediately and lawfully; additionally, INOXPA shall be compensated for any

civil liability claims submitted by third parties, in the following cases:

The installation and maintenance work has not been carried out following the instructions in this

manual.

The repairs have not been made by our personnel or have been made without our written

authorisation.

The parts used are not INOXPA genuine parts.

Modifications have been carried out on our material or equipment without written authorisation.

The material or equipment has been improperly used, has been used carelessly, or has not been

used according to the instructions and their intended purpose, specified in this manual.

The general terms of delivery already in your possession are also applicable

The machine may not undergo any modification without prior approval from the

manufacturer. For your safety, only use original spare parts and accessories.

The usage of other parts will relieve the manufacturer of any liability

Please do not hesitate to contact us in case of doubts or if further explanations are required regarding specific

data (adjustments, assembly, disassembly, etc.)

(0) 2018/05 2. Table of contents 5

2. Table of contents

1. Safety .................................................................................................................................... 3

1.1. Instruction manual.................................................................................................................... 3

1.2. Instructions for start-up ............................................................................................................ 3

1.3. Safety ...................................................................................................................................... 3

1.4. General safety instructions ........................................................................................................ 3

2. Table of contents................................................................................................................... 5

3. General information .............................................................................................................. 6

3.1. Description ............................................................................................................................... 6

3.2. Application ............................................................................................................................... 6

3.3. Innova J................................................................................................................................... 6

4. Installation............................................................................................................................ 7

4.1. Reception of the valve............................................................................................................... 7

4.2. Transportation and storage ....................................................................................................... 7

4.3. Identification ............................................................................................................................ 8

4.4. Positioning................................................................................................................................ 9

4.5. Direction of flow ....................................................................................................................... 9

4.6. General installation ................................................................................................................... 9

4.7. Checking and review ................................................................................................................10

4.8. Welding...................................................................................................................................10

4.9. Actuator air connection ............................................................................................................11

5. Start-up............................................................................................................................... 12

5.1. Uses of the valve .....................................................................................................................12

5.2. Start-up...................................................................................................................................12

5.3. Operation ................................................................................................................................12

5.4. Valve setting............................................................................................................................13

6. Operating problems ............................................................................................................ 14

7. Maintenance........................................................................................................................ 15

7.1. General considerations .............................................................................................................15

7.2. Maintenance............................................................................................................................15

7.3. Cleaning..................................................................................................................................16

7.4. Assembly and disassembly........................................................................................................17

7.5. Disassembly/assembly of the Innova J ......................................................................................18

7.6. Replacing the seat seal.............................................................................................................19

7.7. Actuator assembly / disassembly...............................................................................................20

8. Technical specifications ...................................................................................................... 22

8.1. Technical specifications ............................................................................................................22

8.2. Exploded drawing and parts list Innova J...................................................................................23

6 3. General information (0) 2018/05

3. General information

3.1. DESCRIPTION

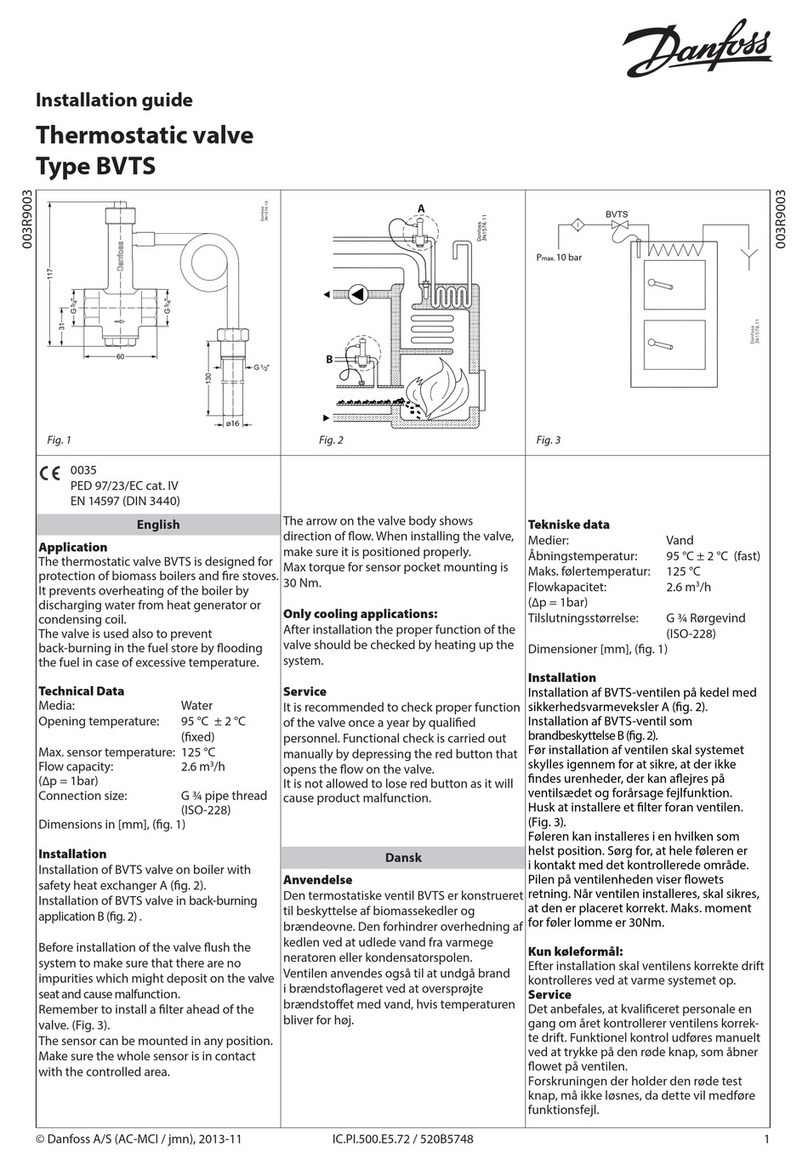

INNOVA J (relief) valve is pneumatically actuated single-seat valve .Closing pressure of the valve is set by

the spring pressure, which can be regulated by means of the screw located on the top of the valve. When

the set pressure exceeds, valve opens.

The valve is provided with a pneumatic seat lift, it allows the CIP liquid to pass through during CIP

process.

3.2. APPLICATION

The INNOVA J valve is designed for dairy and food-processing industries, beverage production, and

pharmaceutical and fine chemicals industries.

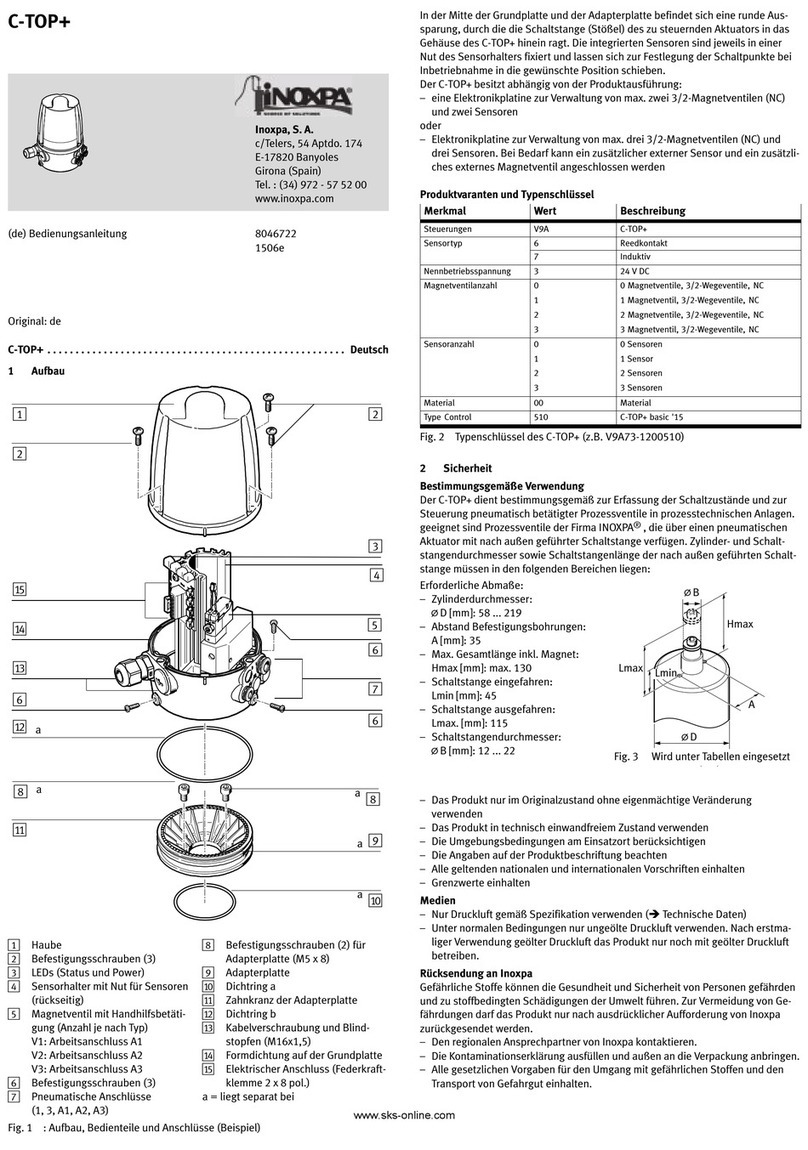

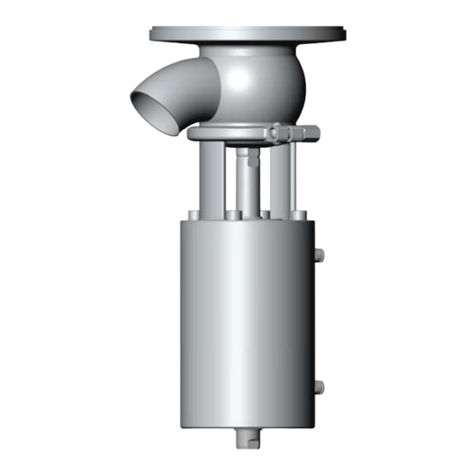

3.3. INNOVA J

The INNOVA J valve is a pneumatically actuated single seat valve designed for use as relief valve.

Actuator

Lantern

Housing

(0) 2018/05 4. Installation 7

4. Installation

4.1. RECEPTION OF THE VALVE

INOXPA will not be liable for any deterioration of the material occurred during shipping or

unpacking. Visually check that the packaging has not been damaged.

The first thing to do upon receipt of the valve is to check it and make sure that it matches the packing list.

INOXPA inspects all its equipment before packaging; however, it cannot guarantee that the merchandise

arrives to the user intact. Therefore, when receiving valves or any other item, they must be checked; if it

is found that they are not in good condition or not all the parts are present, the carrier will fill out a report

as soon as possible.

Each valve is inscribed with its fabrication number. Indicate the fabrication number on all documents and

correspondence.

4.2. TRANSPORTATION AND STORAGE

INOXPA shall in no case be liable for improper unpacking of the valve and its components.

4.2.1. Delivery

Check to see whether all the parts listed on the delivery slip are present:

Complete valve.

Its components (if any are supplied).

Delivery slip.

Instruction manual.

4.2.2. Unpacking

Remove any possible traces of packaging from the valve or its parts

Inspect the valve or the parts that comprise it for possible damage incurred during shipping.

Take all possible precautions against damage to the valve and its components.

The buyer or user shall be liable for assembly, installation, start-up and operation of the

valve

Fabrication number

8 4. Installation (0) 2018/05

4.3. IDENTIFICATION

WA

J

L

0

-

0

06

52

050

12

0

Options

0

---

1

ID Ra<0,5

Actuator

11

T1 S/E NC

12

T2 S/E NC

13

T3 S/E NC

14

T4 S/E NC

Size

025

DN 25, OD 1"

040

DN 40, OD 1 1/2"

050

DN 50, OD 2"

063

OD 2 1/2"

065

DN 65

076

OD 3"

080

DN 80

100

DN 100, OD 4"

Unions

43

HNBR

52

EPDM

78

FPM

Material

06

AISI 316L

Connection

0

Welded

Standard Pipe

0

DIN

1

OD

Housing configuration

L,T

1 housing

A,B,C,D

2 housings

Types

J

Relief valve

Product family

WA

Válvula INNOVA

(0) 2018/05 4. Installation 9

4.4. POSITIONING

Position the valve in a way that facilitates inspections and reviews. Allow sufficient space around the valve

for adequate review, dismantling and maintenance (see table in section 4.8.1. Single seat relief valve,

weld/weld).

4.5. DIRECTION OF FLOW

The following image indicates the recommended direction for product flow, as well as the direction of

closing, depending on the type of valve. Following these indications will prevent water hammer and its

consequences to the extent possible, which can occur when single-seat valves close.

The recommended direction will always be contrary to the movement of valve closing; that is, when the

valve is closing, the valve will always work against the pressure of the fluid.

4.6. GENERAL INSTALLATION

After the location of the valve is defined, the pipe can be joined by welding the valve housing or using

fittings. In this case, do not forget the seals, and tighten the unions

properly.

Before starting to weld the valve housings to the pipe, disassemble the

valve to prevent damage to the joints, following the instructions in

section 7.4. Assembly and disassembly.

Avoid using excessive force when assembling the valves, and pay special

attention to:

Vibrations that may be produced on the facility.

Thermal dilation that the pipe may undergo when hot fluids are

circulating.

The weight that the pipe can support.

Excessive welding current.

10 4. Installation (0) 2018/05

4.7. CHECKING AND REVIEW

Perform the following checks before using:

Check that the clamps and nuts are well secured.

Open and close the valve (applying compressed air to the actuator) several times to make sure it

operates correctly and to make sure that the shaft joint is coupled smoothly to the valve housing.

4.8. WELDING

Welding work should only be done by qualified persons who are trained and equipped with

the necessary equipment to perform this kind of work.

Before starting welding, disassemble the valve as explained in section 7.4. Assembly and disassembly.

4.8.1. Single seat relief valve, weld/weld

Disassemble the valves as indicated in section 7.4. Assembly and disassembly.

Weld the valve housing to the pipes.

When welding the valve housing, it is very important to keep the minimum distance (height A) to

allow the valve to be disassembled for subsequent reviews and to change valve parts (seals,

bushings, etc.)

Valve size

A [mm]

DN25/OD1”

370

DN40/OD1½”

380

DN50/OD2”

430

DN65/OD2½”

480

DN80/OD3”

500

DN100/OD4”

540

(0) 2018/05 4. Installation 11

4.9. ACTUATOR AIR CONNECTION

Connect and check the compressed air connections.

INOXPA valves are supplied with connections for Ø6 pipe, and with a silencer on S/E actuators.

Consider the quality of the compressed air, according to the specifications described in 8.

Technical specifications.

Conexiones neumáticas

roscaR1/8’’

12 5. Start-up (0) 2018/05

5. Start-up

Valve start-up can be done if the instructions detailed in chapter 4. Installation have been followed first.

5.1. USES OF THE VALVE

It is widely used as a bypass valve for the positive displacement pumps. It is also used to protect the

equipment in case of excessive pressure.

5.2. START-UP

Prior to start-up, the persons in charge must be duly informed about how the valve works

and the safety instructions to follow. This instruction manual will be available to personnel

at all times.

Before putting the valve/actuator into service, the following must be taken into consideration:

Check that the piping and valve are completely free of possible traces of welding slag or other

foreign particles. Clean the system if necessary.

Check to make sure the valve moves smoothly. If necessary, lubricate it with special grease or

soapy water.

Check for possible leaks, and make sure the pipes and their connections are sealed and do not

have any leaks.

If the valve has been supplied with an actuator, make sure that the alignment of the valve shaft

and the actuator shaft enables smooth movement.

Check that the compressed air pressure at the inlet to the actuator matches what is indicated in

the Technical specifications.

Consider the quality of the compressed air, according to the specifications described in chapter 8.

Technical specifications.

Actuate the valve.

5.3. OPERATION

Do not modify the operating parameters for which the valve has been designed without

prior written authorisations from INOXPA.

Do not touch the moving parts of the coupling between the actuator and the valve when the

actuator is connected to the compressed air supply.

Burn hazard! Do not touch the valve or the pipes when hot fluids are circulating or when

cleaning and/or sterilization are being carried out.

(0) 2018/05 5. Start-up 13

5.4. VALVE SETTING

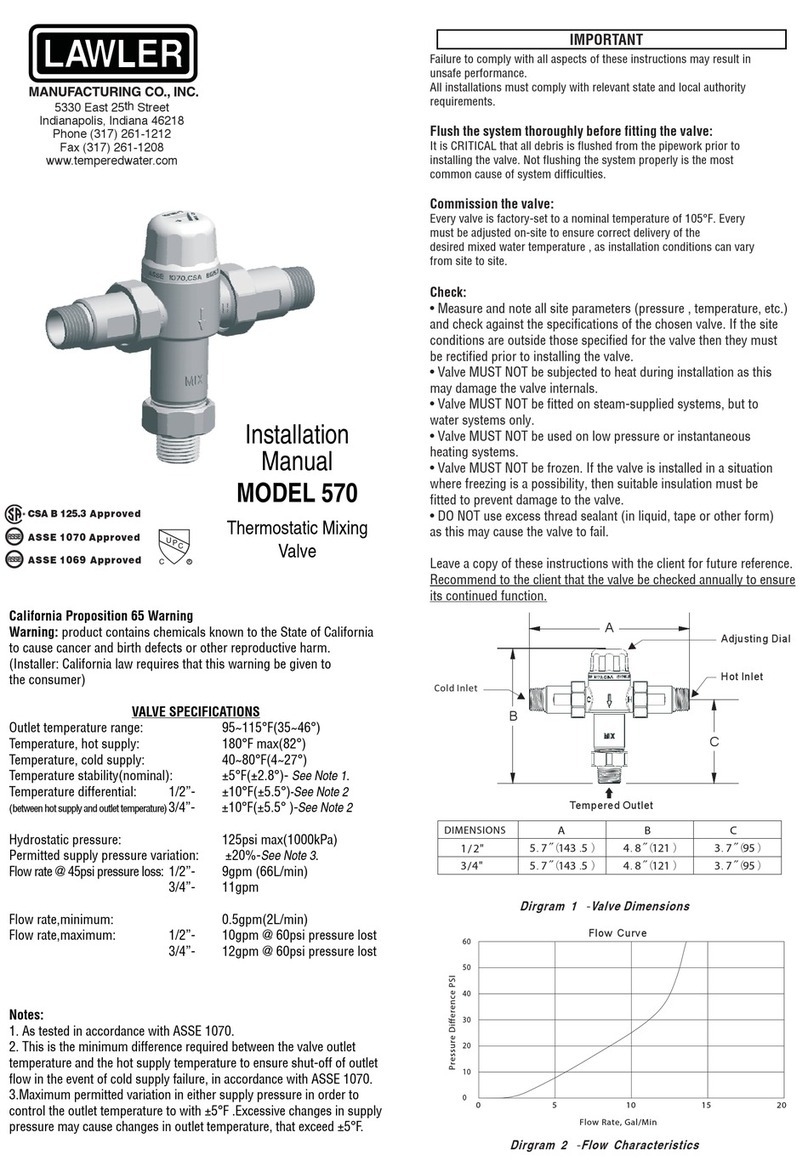

Type J valve can be set by client. Calibration requires a pump, a pressure gauge (to measure the

pressure), a shut-off valve and Type J valve.

Start up the pump with the shut-off valve in the closed position. The liquid will pass through the Type J

valve, which will act as a bypass (recirculation). Tighten the top screw (previously loosening the lock nut)

on the TypeJvalveuntilthepressuregaugeindicatesthepump’smaximumworkingpressure.Thevalve

will then be set to the pressure indicated on the pressure gauge; if this pressure is exceeded, the valve

will close and the flow will be recirculated, thus preventing any damage to the system.

10.210.32.0013

14 6. Operating problems (0) 2018/05

6. Operating problems

Water hammer

Valve does not open/close

Internal leak of product (valve closed)

The valve plug is sticking

PROBABLE CAUSES

SOLUTIONS

•

The seal or guide bushing is worn, deteriorated

or has gotten stuck

Replace the seals

Replace the seals with ones made of a different

material or grade that is more appropriate for

the product

Lubricate with soapy water or a lubricant that is

compatible with the seal material and the

product

•

Insufficient air pressure

Replace the actuator with a larger one

Increase the compressed air pressure

•

Normal wear of seals

Replace the seals

•

Premature wear of the seal / affected by the

product

Replace the seals with ones made of a different

material or grade that is more appropriate for

the product

Reduce the pressure in the line

Reduce the working temperature

•

Product residue has been deposited on the valve

seat and/or plug

Clean frequently

•

Excess product pressure

Replace the actuator with a larger one

Connect an auxiliary compressed air nipple on

the side of the spring (to offset the excess

pressure) without exceeding (4 bar)

Reduce the product pressure

•

Loss of seal (vibrations)

Tighten loose parts

•

Product pressure exceeds the actuator

specifications

Replace the actuator with a larger one

Reduce the product pressure

Use auxiliary air on the spring side

•

Warping of seals

Replace the seals with ones of a different

quality, if they have deteriorated prematurely

•

Actuator spring in poor condition and/or stuck

(dirty)

Replace spring (clean)

•

The direction of flow is the same as the direction

of closing

The direction of flow should go against the

direction of closing

Choke the air discharge to reduce the pressure

(0) 2018/05 7. Maintenance 15

7. Maintenance

7.1. GENERAL CONSIDERATIONS

This valve, just like any other machine, requires maintenance. The instructions in this manual cover the

identification and replacement of spare parts. The instructions are aimed at maintenance personnel and

those responsible for the supply of spare parts.

Carefully read chapter 8. Technical specifications.

All replaced material should be duly disposed of/recycled according to the directives in effect

in each area.

Valve and/or actuator assembly and disassembly should only be done by qualified persons.

Before starting maintenance work, make sure that the pipes are not under pressure.

7.2. MAINTENANCE

To perform maintenance properly, the following are recommended:

Periodic inspection of the valve and its components.

Keeping an operational record of each valve, nothing any problems.

Always having spare replacement seals in stock.

During maintenance, pay special attention to the hazard warnings indicated in this manual.

The valve and the pipes must never be under pressure during maintenance.

During maintenance, the valve must never be hot. Burn hazard!

7.2.1. Seal maintenance

CHANGING SEALS

Preventive maintenance

Replace every 12 months

Maintenance after a leak

Replace at the end of the process

Planned maintenance

Regularly check for the absence of leaks and smooth operation of the

valve

Keep a valve log

Use statistics to plan inspections

Lubrication

During assembly, apply lubricants that are compatible with the seal

material. See the table below

SEAL COMPONENT

LUBRICANT

Clase NLGI DIN

51818

HNBR/ FPM

Klübersynth UH 1 64-2403

3

EPDM/ HNBR/ FPM

PARALIQ GTE 703

3

The period between each preventive maintenance service will vary depending on the working conditions to

which the valve is subject: temperature, pressure, number of operations per day, type of cleaning

solutions used, etc.

16 7. Maintenance (0) 2018/05

7.2.2. Storage

Valves should be stored in an enclosed location under the following conditions:

Temperature from 15ºC to 30ºC

Ambient humidity < 60%

Equipment MAY NOT be stored outside.

7.2.3. Spare parts

To order spare parts, you must indicate the valve type and the position and description of the part, as

found in chapter 8. Technical specifications.

7.3. CLEANING

The use of aggressive cleaning products such as caustic soda and nitric acid may burn the

skin.

Wear rubber gloves during all cleaning procedures.

Always wear protective goggles.

7.3.1. CIP (Clean-in-Place) cleaning

If the valve is installed in a system with a CIP process, its disassembly will not be required. EPDM is the

standard seal material that will be used for CIP cleaning, both in alkaline mediums and in acid mediums.

The other two options (HNBR, FPM) are not recommended.

Cleaning solutions for CIP processes.

Only use clear water (chlorine-free) to mix with the cleaning agents:

a) Alkaline solution: 1% by weight of caustic soda (NaOH) at 70ºC (150ºF)

1 kg NaOH + 100 l of H2O = cleaning solution

or

2,2 l of 33% NaOH + 100 l of H2O = cleaning solution

b) Acid solution: 0,5% by weight of nitric acid (HNO3) at 70ºC (150ºF)

0,7 l of 53% HNO3+ 100 l of H2O = cleaning solution

Check the concentration of the cleaning solutions; incorrect concentrations may lead to the

deterioration of the valve seals.

To remove any traces of cleaning products, ALWAYS perform a final rinse with clean water at the end of

the cleaning process.

Before starting disassembly and assembly tasks, clean the entire interior and exterior of the

valve.

(0) 2018/05 7. Maintenance 17

7.3.2. Automatic SIP (Sterilization-in-Place)

Sterilization with steam is applied to all equipment including the pigging.

Do NOT start the equipment during the sterilization with steam.

The parts/Materials will not be damaged if the indications specified in this manual are

observed.

No cold fluid can enter the equipment until the temperature of the equipment is lower than

60°C (140°F).

Maximum conditions during the SIP process with steam or superheated water:

a) Max. temperature: 140°C / 284°F

b) Max. time: 30 min

c) Cooling: Sterile air or inert gas

d) Materials: EPDM (HNBR and FPM materials are not recommended)

7.4. ASSEMBLY AND DISASSEMBLY

Proceed with caution. Personal injury can occur.

Always disconnect the compressed air before starting to disassemble the valve.

Never disassemble the valve clamps directly without reading the instructions carefully, since

the actuator contains a spring inside it with an applied load.

Valve and/or actuator assembly and disassembly should only be done by qualified persons.

18 7. Maintenance (0) 2018/05

7.5. DISASSEMBLY/ASSEMBLY OF THE INNOVA J

7.5.1. Disassembly

1. Loosen nut (26) and unscrew screw (22).

2. Apply compressed air to the actuator (10A) so that the plug

shaft (08) passes the open position.

3. Loosen and separate the clamps (34).

4. Separate the actuator (10) and bottom port (02) from the

valve housing (01).

5. Remove seal (20B) from bottom port (02).

6. Release the compressed air in the actuator.

7. Unscrew the Allen bolts (23) from the lantern (21).

8. Unscrew the plug shaft (08) from the actuator shaft two 17

mm crescent spanners.

9. Finish unscrewing the plug shaft by hand.

10. Once the plug shaft is out, remove the housing cap (12) and

the seals inside it (20B and 05).

11. Remove the guide bushing (17).

12. Remove the seat seal (05C) as explained in section

7.6. Replacing the seat seal.

7.5.2. Assembly

1. Insert the lantern (21) underneath the actuator.

2. Fit the guide bushing (17) on the lantern (21).

3. Lubricate the seals with soapy water if necessary.

4. Install the seals (20B and 05) in the housing cap (12) and put

this assembly in the lantern.

5. Install the seat seal (05D) as explained in section

7.6. Replacing the seat seal.

6. After the seat seal is installed (05D), then screw in the plug

shaft (08) with the actuator shaft (10A).

7. Tighten the four Allen bolts (23) that secure the lantern (21)

to the actuator (10A).

8. Apply compressed air to the actuator so that the plug shaft

(08) is in the open position.

9. Install the seal (20B) in bottom port (02).

10. Assemble bottom port (02) and intermediate housing (01)

and secure it using clamps (34).

11. Mount the actuator (10) - lantern (21) - plug shaft (08) -

housing cap (12) assembly to the valve housing (01) (can be

turned 360º according to the user’s needs) and secure it

using the clamp (34).

12. Release the compressed air in the actuator.

13. Set the screw (22) and lock the nut (26).

See section 8.2.1. Exploded drawing For a reference to the parts

described.

Note! To replace the seat seal, see section 7.6. Replacing the seat

seal.

(0) 2018/05 7. Maintenance 19

7.6. REPLACING THE SEAT SEAL

1. Put the plug shaft in a vertical position—for example,

with a bench clamp—so that the shaft is kept stable and

no damage is caused to the mating surface of the conical

seal. Do not press the shaft too much if using a bench

clamp.

2. Remove the used seal using a screwdriver or a sharp

hook-shaped tool. Make sure not to damage the mating

surface of the seal.

3. Lubricate the new seat seal with soapy water if necessary

to facilitate installation.

4. Insert the seal in the plug shaft seat accommodation so

that its edges are inside the accommodation. Preferably,

the seal should fit within the part of the section that has

the greatest diameter, as shown in the figure.

5. Then, with the help of an appropriate tool (not piercing),

press the edge of the seal that has not yet fit into the

accommodation, as shown in the figure.

6. This operation should be done around the entire

diameter, applying the tool in the sequence 1-2-3-4-5-

6-7-8 as shown in the bottom figure. Always press on

opposite sides. Once you get to the last step of this

sequence, repeat the process until the seal is completely

inside the accommodation.

7. Press the seal with your fingers to make sure it is well

seated. Make sure there are no parts projecting due to

poor positioning of the seal.

The following tools are needed to assemble/disassemble the

valve:

1 crescent spanners 15 mm and 1 crescent spanners 17 mm –To remove the plug shaft DN 25.

2 crescent spanners 17 mm –To remove the plug shaft DN 40 to DN 100.

Crescent spanner 13 mm –For the clamps.

Appropriate tool (not piercing) to mount the seat seals.

Allen key per the table:

Proceed with caution. Personal injury can occur.

Never directly disassemble the clamps from the valve Reading the instructions carefully.

Valve/actuator assembly and disassembly should only be done by qualified persons.

Zone

DN 25/40

DN 50/65/80

DN 100

Lantern

5 mm

6 mm

10 mm

Cap

4 mm

5 mm

8 mm

20 7. Maintenance (0) 2018/05

7.7. ACTUATOR ASSEMBLY / DISASSEMBLY

Do not apply compressed air until the disassembly/assembly process is completed. The figure is a

schematic representation of some of the steps in the actuator disassembly process.

7.7.1. Disassembly

1. Fully loosen regulating screw (22) to remove nut (26) and

regulating screw (22).

2. Remove air-fitting (18).

3. Position the actuator in the base of the clamp or in the lathe

collet. A thick tube (102) and a shim (101) must be used on

actuator base cover (12).

4. Apply force to the shim (101). Once the cover (12) has

dropped some distance, remove the snap ring (45), this

should have sufficient free space to be able to remove it.

5. Reduce the force on the shim (101) slowly until the top cover

is free (you will note that the spring no longer exerts

pressure).

6. Remove the actuator base cover (12).

7. Remove lock ring (45B) to separate piston (30) from shaft

(08).

8. Remove spring (06).

9. Take out the seals (20A and 20B), the scraper (60) and the

guide (11) from the cover (12).

10. Take out the seals (20 and 20C) from the piston (30).

11. Remove actuator stop (43) from actuator body (01).

7.7.2. Montaje

1. Insert actuator stop (43) inside the actuator body (01).

2. Fix regulating screw (22) in actuator stop (43) and tighten it

with actuator nut (26).

3. Insert spring inside the body (06).

4. Mount the scraper (60), seals (20A & 20B) and guide (11) on

actuator base cover (12).

5. Mount seals (20 and 20C) on the piston (30).

6. Fix piston (30) on actuator shaft (08) with the help of lock

ring (45B).

7. Locate actuator shaft (08) inside actuator base cover (12).

8. Slide the assembly of piston (30), actuator shaft (08) and

actuator base cover (12) inside the actuator body (01).

9. Hold the actuator assembly into clamp and place a thick tube

(102) and a shim (101) as shown in figure beside.

10. Apply force on the shim (101) so it lowers by some distance.

Insert the snap ring (45).

11. Reduce the force applied slowly until the tool no longer

touches the cover.

12. Install air-fitting (18).

13. Apply compressed air to check the proper functioning of the

actuator.

Table of contents

Other INOXPA Control Unit manuals

INOXPA

INOXPA BUTTERFLY Manual

INOXPA

INOXPA INNOVA F Installation and user guide

INOXPA

INOXPA OVERFLOW Manual

INOXPA

INOXPA INNOVA F Ex Manual

INOXPA

INOXPA C-TOP+ User manual

INOXPA

INOXPA PHARMAVALVE Installation and user guide

INOXPA

INOXPA INNOVA T Manual

INOXPA

INOXPA INNOVA F Manual

INOXPA

INOXPA INNOVA G Manual

INOXPA

INOXPA BALL Installation and user guide