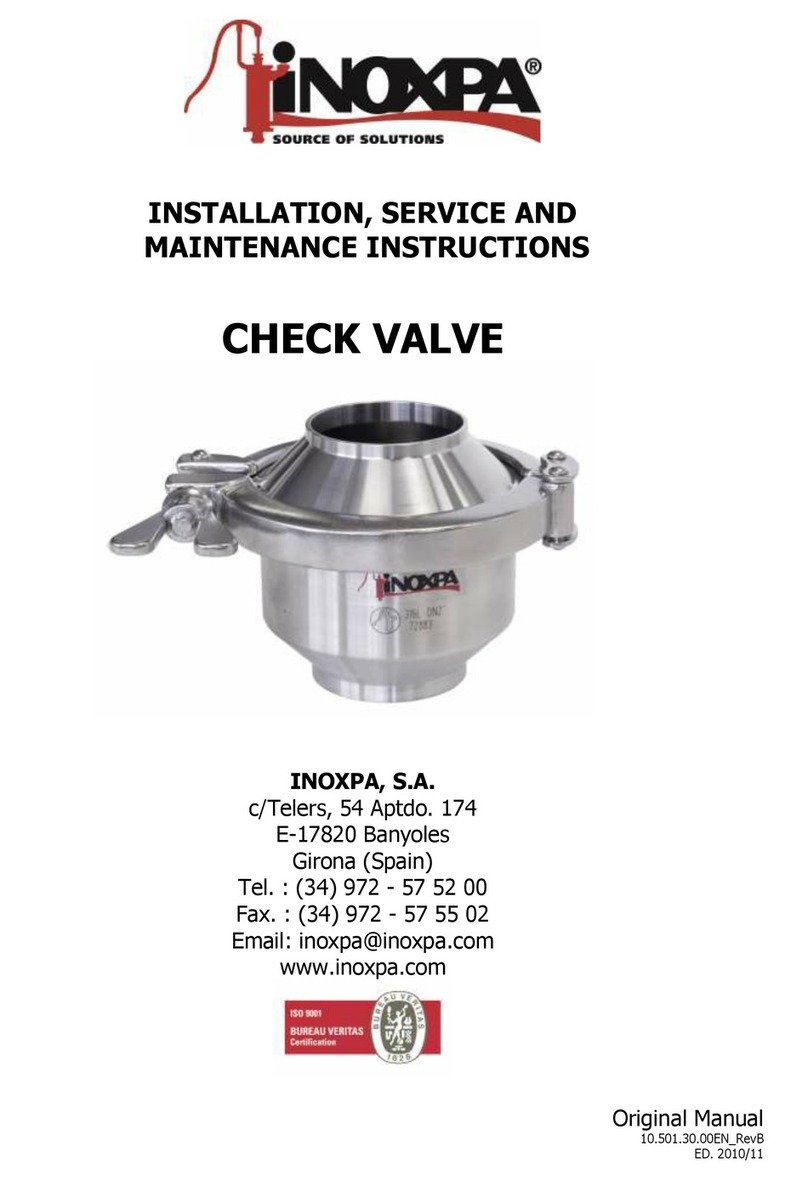

INOXPA 74700 Manual

INSTALLATION, SERVICE AND

MAINTENANCE INSTRUCTIONS

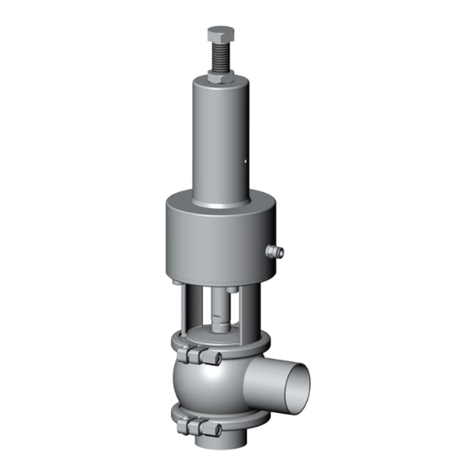

OVERFLOW VALVE

INOXPA, S.A.

c/Telers, 54 Aptdo. 174

E-17820 Banyoles

Girona (Spain)

Tel. : (34) 972 - 57 52 00

Fax. : (34) 972 - 57 55 02

Email: inoxpa@inoxpa.com

www.inoxpa.com

Original Manual

10.207.30.00EN_RevC

ED. 2010/11

Declaration of Incorporation

The manufacturer: INOXPA, S.A.

c/ Telers, 57

17820 Banyoles (Girona), Spain

herewith declares that the machine:

OVERFLOW valve 74700

with the serial number: ________________

conforms to the relevant provisions of the following directives:

Machinery Directive 2006/42/EC (RD 1644/2008)

Pressure equipment Directive 97/23/EC

It also declares that the technical documentation for this partly completed machinery has been developed in

compliance with Appendix VII Section B and it agrees to issue this documentation as and when required by the

national authorities.

In compliance with Regulation (EC) 1935/2004 on materials and articles intended to come into contact with food.

In compliance with Regulation (EC) 2023/2006 on good manufacturing practice for materials and articles intended

to come into contact with food.

The aforementioned partly completed machinery shall NOT be put into service until the final machinery into which

it is to be incorporated has been declared in conformity with the Machinery Directive, as required by Appendix II A.

Identification of the person empowered to draw up the Declaration on behalf of the manufacturer, and qualified to

compile the technical file established by the Community:

Banyoles, 8 January 2014

David Reyero Brunet

Technical Office Manager

ED. 2010/11 1.Safety 3

1.Safety

1.1. INSTRUCTION MANUAL.

This instruction manual contains basic indications which should be fulfilled during the installation, starting and maintenance.

The information published in the instruction manual is based on updated information.

INOXPA reserves the right to modify this instruction manual without prior notice.

1.2. START-UP INSTRUCTIONS.

This instruction manual contains essential useful information to handle and maintain your valve appropriately .

Not only should the safety instructions indicated in this chapter be observed and fulfilled, but so should the special measures

and recommendations included in the other chapters of this manual. These instructions should be kept in a safe location near

the installation.

1.3. SAFETY.

1.3.1. Warning symbols.

General danger of injury

Danger of injuries caused by the rotary

parts of the equipment

Electrical hazard

Danger! Caustic or corrosive agents.

Danger! Suspended loads

Danger for the correct operation of the

equipment.

Compulsory requirement to ensure safety

at work

Use of goggles is compulsory.

1.4. GENERAL SAFETY INSTRUCTIONS.

Read the instruction manual carefully before installing and starting up the valve. Contact INOXPA in

case of doubt

1.4.1. During the installation.

The

Technical Specifications

of Chapter 8 should always be observed.

The installation and use of the valve should always be carried out in accordance with applicable

regulations regarding health and safety.

Before starting up the valve, verify that the assembly is correct and that the shaft is perfectly

aligned. An incorrect alignment and/or excessive force in securing the valve may cause serious

mechanical problems in the valve.

1.4.2. During operation.

The

Technical Specifications

of Chapter 8 should always be observed. Under no circumstances can the

limit values specified be exceeded.

NEVER touch the valve and/or the tubes in contact with the liquid during operation. You risk being

burnt if you work with hot products.

4 1.Safety ED. 2010/11

The valve contains parts operating in linear movement. Do not place your hands or fingers in the

valve-closing area. This may cause serious injury.

1.4.3. During maintenance

The

Technical Specifications

of Chapter 8 should always be observed.

NEVER disassemble the valve until the pipes have been emptied. Bear in mind that the liquid in the

pipe may be dangerous or extremely hot. Consult the regulations in effect in each country for these

cases.

Do not leave parts loose on the floor.

All electrical work should be carried out by authorised personnel.

1.4.4. In compliance with the instructions.

Any non-fulfilment of the instructions may result in a risk for the operators, the environment and the machine, and may result

in the loss of your right to claim damages

This non-fulfilment may result in the following risks:

Failure of important functions of the machines/plant.

Failure of specific maintenance and repair procedures.

Possibility of electric, mechanical and chemical risks.

Will place the environment in danger due to the release of substances.

1.5. GUARANTEE.

Any guarantee will be cancelled immediately and as a matter of law and, in addition, we will require compensation for any

claims of civil liability presented by third parties, if:

The installation and maintenance work has not been carried out according to the instructions of this manual.

The repairs are not carried out by our personnel or have been carried out without our written authorisation.

The parts used are not INOXPA original parts.

Modifications have been carried out on our materials without written authorisation.

The material has been badly used, incorrectly used, or used with negligence or has not been used according to the

indications and intended use specified in this manual.

The general conditions of delivery already in your possession are also applicable.

Please do not hesitate to contact us in case of doubts or more complete explanations are required on specific data

(adjustments, assembly, disassembly, etc.).

ED. 2010/11 2.Table of contents 5

2.Table of contents

1. Safety 3

1.1. Instruction manual.........................................................................................................3

1.2. Start-up instructions.......................................................................................................3

1.3. Safety...........................................................................................................................3

1.4. General safety instructions..............................................................................................3

1.5. Guarantee.....................................................................................................................4

2. Table of contents 5

3. Receiving and Installation 6

3.1. Check the shipment .......................................................................................................6

3.2. Delivery and unpacking ..................................................................................................6

3.3. Identification .................................................................................................................6

3.4. Location........................................................................................................................7

3.5. Flow direction................................................................................................................7

3.6. Overflow valve position. .................................................................................................7

3.7. Assembly. .....................................................................................................................7

3.8. Inspecting and checking.................................................................................................8

3.9. Welding. .......................................................................................................................8

4. Star-up 9

4.1. Valve applications. .........................................................................................................9

4.2. Start-up. .......................................................................................................................9

4.3. Operation......................................................................................................................9

4.4. Valve calibration. ...........................................................................................................9

5. Operating problems Causes and solutions 10

6. Maintenance 11

6.1. General information .....................................................................................................11

6.2. Maintenance................................................................................................................11

6.3. Cleaning......................................................................................................................12

7. Assembly and disassembly 13

7.1. Disassembly / assembly of the overflowvalve fig: 74700..................................................13

7.2. Disassembly / assembly of the overflowvalve fig: 74700m. ..............................................14

8. Technical Specifications 16

8.1. Overflow valve dimensions............................................................................................17

8.2. Section and parts list....................................................................................................18

8.3. Parts lists ....................................................................................................................20

6 3.Receiving and Installation ED. 2010/11

3. Receiving and Installation

3.1. CHECK THE SHIPMENT

The first thing to do on receiving the valve is to verify that it is matches the delivery note.

INOXPA will inspect all the equipment before packing, although it cannot guarantee that the merchandise will arrive intact to

the user. For this reason, the valve received and any other article should be checked and, if it is found not to be in good

condition and/or not all parts are included, the carrier should submit a report as soon as possible.

Each valve has a manufacturing number engraved. Indicate the manufacturing number in all documents and correspondence.

3.2. DELIVERY AND UNPACKING

INOXPA will not be responsible for the inappropriate unpacking of the valve and its components.

3.2.1. Delivery:

Check that all the parts indicated in the delivery slip exist

Complete valve.

Its components (if supplied).

Delivery slip.

Instruction manual.

3.2.2. Unpacking:

Remove all traces of packing materials from the valve or parts.

Inspect the valve or its constituent parts for possible damage caused during transport.

Avoid any possible damage to the valve and its components.

3.3. IDENTIFICATION

ED. 2010/11 3.Receiving and Installation 7

The buyer or user will be responsible for the assembly, installation, starting and operation of the

valve.

3.4. LOCATION.

Place the valve in such a way as to facilitate inspections and checks. Leave sufficient space around the valve for appropriate

inspection, separation and maintenance (See Section 3.7.1).

3.5. FLOW DIRECTION.

The overflow valve is designed to be installed according to the indicated direction of flow.

3.6. OVERFLOW VALVE POSITION.

The overflow valve is designed to be installed in any position, although fitting it upside down is not recommended.

3.7. ASSEMBLY.

Once the location of the valve is established, the pipe can be connected by welding the body or by jeans of accessoriees

(unions). The overflow valve is designed to be installed in any position, although fitting it ápside down is not recommended.

Excessive stress should be avoided during the assembly of

the valves and special attention should be given to the

following:

Vibration which may be produced in the installation.

Expansion of the pipes during circulation of hot liquids.

The weight that the pipes can withstand.

Excessive intensity of welding.

Recommended

Not

recommended

8 3.Receiving and Installation ED. 2010/11

3.8. INSPECTING AND CHECKING

Check the following before use:

Check that the clamp and the adjusting nuts

are well tightened.

If it has a handle, turn it several times to

ensure that it works. (the seat of the valve

must lift and fall)

3.9. WELDING.

The welding work can only be carried out by people qualified, trained and equipped with the

necessary means to carry out this work.

Disassemble the valve before starting the welding work.

3.9.1. Welding ende overflow valve . 74700

Disassemble the valve as indicated in the

Assembly and disassembly

section.

Weld the valve body to the pipes.

When welding the valve body, it is very important to maintain the minimum distance (dimension A) enabling disassembly

of the valve for later checks and replacement of internal valve parts (seals, shafts, springs). This distance is also

important when the valves are supplied with a handle.

DN

A

No

handle

With

handle

25-1”

250

325

32

260

335

40-1 ½”

275

345

50-2”

300

360

65-2 ½”

355

425

80-3”

380

445

ED. 2010/11 4.Star-up 9

4.Star-up

The start-up of the valve can be carried out provided the instructions indicated in Chapter 3 –

Receiving and Installation

are

followed.

4.1. VALVE APPLICATIONS.

This equipment is suitable for his use in food process.

Overflow valves of type 74700 and 74700M are basically used to avoid any excessive pressure in the pipes, particularly in

positive-displacement pumps, in order to prevent any over-pressures that may damage the concerned equipment (bypass

assembly).

4.2. START-UP.

Before start-up, the responsible persons should be duly informed of the operation of the valve and

the safety instructions to be followed. This instruction manual should be available to personnel at all

times.

The following should be taken into consideration before starting up the valve;

Check that the pipe and valve are completely free from any traces of welding or other foreign matter. Carry out the

cleaning of the system if required.

Verify the smooth operation of the valve. If necessary, lubricate moving/rotating parts with special grease or soapy

water.

Check for possible leaks and check that all the pipes and connections are watertight and free from leaks

Actuate the valve (if supplied with a handle)

4.3. OPERATION.

Do not modify the operating parameters for which the valve has been designed without written prior

authorisation from INOXPA.

Danger of burns! Do not touch the valve or pipes when hot liquids are circulating or when cleaning

and/or sterilisation are being carried out.

4.4. VALVE CALIBRATION.

The overflow valve can be shipped pre-calibrated in factory, provided this has been requested in writing on the order.

Overflow valve calibration is carried out using a bypass-type assembly (flow recirculation). To carry out the calibration, it is

necessary to use a pump, a gauge (for pressure measurements), a shut-off valve and the overflow valve.

Operate the pump with the shut-off valve in closed position. The flow will make the bypass (recirculation) by passing through

the overflow valve. Tighten the upper nut (first loosening the lock nut) of the overflow valve until the gauge shows that the

pump is at maximum working pressure. The overflow valve will remain calibrated to the pressure indicated on the gauge; if it

exceeds this pressure, then the overflow valve will open and make the flow recirculate preventing the installation from being

damaged.

10 5.Operating problems. Causes and solutions ED. 2010/11

5.Operating problems. Causes and

solutions

PROBLEM

CAUSE/EFFECT

SOLUTION

VALVE DOES NOT

CLOSE

Dirt / foreign matter between the seal of the shaft and the

seat of the valve body.

The springs are not applying pressure to the stop washer

of the shaft

The check valve seal is worn and defective.

Clean the body and seat.

Increase the tightening torque of

the springs.

Replace the seals.

INTERNAL LEAK OF

THE PRODUCT

(VALVE CLOSED)

Premature wearing of the seals.

Replace the seals.

Premature

wearing of

the seals.

Watertight seal worn or affected by the

product.

Excessive pressure in the line.

Working temperature too high

Loss of watertightness (vibration).

Replace the seals with others of

different material and more

appropriate to the product.

Tighten any loose components.

Clean frequently.

Backpressure

Replace the spring with a stronger

one.

EXTERNAL LEAK OF

THE PRODUCT

Seal of the body defective

Seal of the shaft defective

Replace the seals with new ones

VALVE DOES NOT

OPEN/CLOSE

Deformation of seat seal.

Spring in poor condition and/or jammed (dirtiness)

The valve does not close when the pressure increases.

Replace the seal seat with other of

different quality, if prematurely

deteriorated.

Replace spring and/or shaft

(clean).

Adjust the valve

Recalibrate the valve. See point

4.4 Valve calibration.

ED. 2010/11 6.Maintenance 11

6.Maintenance

6.1. GENERAL INFORMATION

This valve, just like any other machine, requires maintenance. The instructions contained in this manual cover the identification

and replacement of spare parts. The instructions have been prepared for maintenance personnel and for those responsible for

the supply of spare parts.

Carefully read Chapter 8.

Technical Specifications

.

All replaced material should be duly eliminated/recycled according to the directives in effect in the

area.

Assembly and disassembly of the valves must only be carried out by qualified staff.

Before starting on maintenance work, ensure that the tubes are not pressurised.

6.2. MAINTENANCE.

The following is recommended for appropriate maintenance:

Regular inspection of the valve and its components.

Keep a record of the operation of each valve, noting any incidents.

Always have spare seals in stock.

During maintenance, pay particular attention to the danger indications indicated in this manual manual.

The valve and pipes should not be pressurised during maintenance.

The valve should not be hot during maintenance. Danger of burns!.

6.2.1. Maintenance of the seals.

REPLACEMENT OF SEALS

Preventive maintenance

Replace after twelve (12) months.

Maintenance after a leak

Replace at the end of the process.

Scheduled maintenance

Regularly check that there are no leaks and that the valve is operating smoothly.

Keep a record of the valve.

Use statistics to plan inspections.

Lubrication

During assembly, apply lubricants compatible with the seal material. See the

following table.

SEAL COMPONENT

LUBRICANT

Class NLGI DIN

51818

NBR/ FPM/ VMQ

Klübersynth UH 1 64-2403

3

EPDM/ NBR/ FPM

PARALIQ GTE 703

3

The time interval between each preventive maintenance may vary according to the working conditions to which the valve is

submitted: Temperature, pressure, number of operations per day, type of cleaning solutions used, etc.

6.2.2. Storage

Storage of the valves should be carried out in an enclosed area, under the following conditions:

Temperature from 15ºC to 30ºC

Relative humidity <60%

Open-air storage of the equipment is NOT allowed.

12 6.Maintenance ED. 2010/11

6.2.3. Spare parts

To request spare parts, it is necessary to indicate the type of valve, the position and the description of the part which can be

found in chapter 8.

Technical Specifications

.

6.3. CLEANING

The use of aggressive cleaning products such as caustic soda and nitric acid may cause burns to the

skin.

Use rubber gloves during the cleaning process.

Always use protective goggles.

6.3.1. Automatic CIP (cleaning-in-place)

If the valve is installed in a system provided with the CIP process, its disassembly will not be required.

Cleaning solutions for CIP processes.

Only use clear water (chlorine-free) to mix with the cleaning agents:

a) Alkaline solutions: 1% by weight of caustic soda (NaOH) at 70ºC (150ºF)

1 Kg NaOH + 100 l. of water = cleaning solution

o

2,2 l. NaOH al 33% + 100 l. of water = cleaning solution

b) Acid solution: 0,5% by weight of nitric acid (HNO3) at 70ºC (150ºF)

0,7 litres HNO3at 53% + 100 l. of water= cleaning solution

Check the concentration of cleaning solutions; it may cause the deterioration of the watertight seals

of the valve.

To eliminate any remains of cleaning products, ALWAYS perform a final rinse with clean water on completion of the cleaning

process.

Before beginning the disassembly and assembly work, clean the valve inside as well as outside.

6.3.2. Automatic SIP (sterilization-in-place)

The process of sterilization with steam is applied to all the equipment including the pigging.

Do NOT start the equipment during the process of sterilization with steam.

The parts/materials suffer no damage if the indications specified in this manual are observed.

No cold liquid can enter the equipment till the temperature of the equipment is lower than 60°C

(140°F).

Maximum conditions during the SIP process with steam or overheated water

a) Max. temperature: 140°C / 284°F

b) Max. time: 30 min

c) Cooling: Sterile air or inert gas

d) Materials: EPDM / PTFE (recommended)

FPM / NBR / VMQ (not recommended)

ED. 2010/11 7.Assembly and disassembly 13

7.Assembly and disassembly

Proceed with caution. There is danger of personal injury.

Assembly and disassembly of the valves must only be carried out by qualified staff.

Caution! Recoiled springs.

There is danger of injury if the valve clamp is released (pos. 34) while the valve is still at rest. The

recoiled springs may abruptly throw the regulating nut upwards (pos. 26C) .

It is essential to release the tension in the springs before loosening the clamp.

7.1. DISASSEMBLY / ASSEMBLY OF THE OVERFLOWVALVE FIG: 74700

Disassembly

1. Loosen the lock nut (26F).

2. Mark the position in the shaft (08) and

then unscrew and release the valve nut

(26C).

3. Remove the clamp (34).

4. Remove the spring cover (12A). The

shaft stop washer (25) and the spring

(06) will be pulled out.

5. Pull the shaft (08) upwards together

with the body cap (12), shaft seal (05)

and the O-ring (20B).

6. Remove the shaft seal (05) from the

body cap (12).

7. Remove the O-ring (20B) from the body

cap (12).

8. Remove the elastic ring (45) and the

shaft seel (08A).

9. Remove the seat seel (19).

Assembly

1. Place the seat seal (19) on the shaft (08).

2. Place the shaft seal (08A) and attach the

assembly with the elastic ring (45).

3. Place the O-ring (20B) on the body cap

(12).

4. Place the shaft seal (05) in the body cap

(12).

5. Place the shaft assembly through the shaft

seal (05) and onto the body (01).

6. Mount the spring cover (12A) on the valve

body (01).

7. Assemble the spring cover (12A) to the

valve housing (01) with the clamp (34).

Tighten the nut of the clamp.

8. Place the stop washer (25) and the

springs (06) on the spring cover (12A).

9. Screw the lock nut on (26F) passing the mark made before disassembly.

10. Screw the nut on (26C) until reaching the mark.

11. Screw the lock nut (26F) against the nut (26C) to fix it in place.

A spanner is required to disassemble the valve.

14 7.Assembly and disassembly ED. 2010/11

7.2. DISASSEMBLY / ASSEMBLY OF THE OVERFLOWVALVE FIG: 74700M.

Disassembly

1. Remove pin (50A) from the handle (04).

2. Remove the handle (04) from the shaft

(08).

3. Loosen the lock nut (26F).

10. Mark the position in the shaft (08) and

then unscrew and release the valve nut

(26C).

11. Remove the clamp (34).

12. Remove the spring cover (12A). The

shaft stop washer (25) and the spring

(06) will be pulled out.

13. Pull the shaft (08) upwards together

with the body cap (12), seat seal (05)

and the O-ring (20B).

14. Remove the seat seal l (05) from the

body cap (12).

15. Remove the O-ring (20B) from the body

cap (12).

16. Remove the elastic ring (45) and the

shaft sleeve (08A).

17. Remove the seat seal (19).

Assembly

1. Mount the seat seal (19) on the shaft (08).

2. Mount the shaft sleeve (08A) and attach

the assembly with the elastic ring (45).

3. Place the O-ring (20B) on the body cap

(12).

4. Place the seat seal (05) in the body cap

(12).

5. Mount the shaft assembly over the seat

seal (05) and place onto the body (01).

6. Mount the spring cover (12A) on the valve

body (01).

7. Assemble the spring cover (12A) to the

valve housing (01) with the clamp (34).

Tighten the nut of the clamp.

8. Place the spring washer (25) and the

springs (06) on the body cap (12A).

9. Screw the lock nut on (26F) passing the

mark made before disassembly.

10. Screw the nut on (26C) until reaching the

mark.

11. Screw the lock nut (26F) against the nut

(26C) to fix it in place.

12. Place the handle (04) on the shaft (08) ensuring that the holes are lined up.

13. Insert the pin (50A) into the hole of the handle (04) and the shaft (08).

A spanner is required to disassemble the valve.

ED. 2010/11 7.Assembly and disassembly 15

7.3. DISASSEMBLY / ASSEMBLY OF THE OVERFLOWVALVE WITH PTFE SEAT.

Disassembly

1. Loosen the lock nut (26F).

2. Mark the position in the shaft (08) and then unscrew

and release the valve nut (26C).

3. Remove the clamp (34).

4. Remove the spring cover (12A). The shaft stop

washer (25) and the spring (06) will be pulled out.

5. Pull the shaft (08) upwards together with the body

cap (12), shaft seal (05) and the O-ring (20B).

6. Remove the shaft seal (05) from the body cap (12).

7. Remove the O-ring (20B) from the body cap (12).

8. Remove the elastic ring (45) and the shaft seel

(08A).

9. Remove the O-ring (20C) to the shaft seel (08A).

10. Remove the seat seel (19).

Assembly

1. Place the seat seal (19) on the shaft (08) and the O-

ring (20C) in the shaft seel (08A).

2. Place the shaft seal (08A) and attach the assembly with

the elastic ring (45).

3. Place the O-ring (20B) on the body cap (12).

4. Place the shaft seal (05) in the body cap (12).

5. Place the shaft assembly through the shaft seal (05)

and onto the body (01).

6. Mount the spring cover (12A) on the valve body (01).

7. Assemble the spring cover (12A) to the valve housing

(01) with the clamp (34). Tighten the nut of the clamp.

8. Place the stop washer (25) and the springs (06) on the

spring cover (12A).

9. Screw the lock nut on (26F) passing the mark made

before disassembly.

10. Screw the nut on (26C) until reaching the mark.

11. Screw the lock nut (26F) against the nut (26C) to fix it

in place.

A spanner is required to disassemble the valve.

16 8.Technical Specifications ED. 2010/11

8.Technical Specifications

VALVE GENERAL DATA

Maximum working pressure

DN-25/80

DN-1"/3"

10 bar

Maximum working temperature

121ºC (250ºF) EPDM standard seals

(Other qualities of seals will be adapted for higher temperatures)

Opening pressure

Spring-adjustable.

Surface finish

In contact with the product: Ra 0,8 μm

External surfaces: Machined finish (turned on lathe)

Maximum output

DN-25/1”

DN-32

DN-40/1½”

DN-50/2”

DN-65/2½”

DN-80/3”

10000lts/h

12000lts/h

15000lts/h

20000lts/h

35000lts/h

55000lts/h

VALVE MATERIALS

Parts in contact with the product

AISI 316L (1.4404)

Other steel parts

AISI 304L (1.4306)

Seals in contact with the product

EPDM (Estándar) –VITON - PTFE

Acabado superficial

Parts in contact with the product Ra. 0,8m

Tipo de conexiones

DIN 11851 (Standard)

Connections: Weld, FIL-IDF, BS-RJT, SMS, Clamp, Flanges, Macon

Resistance of the materials / seals depends on the type of pumped product and processing

conditions. Please contact INOXPA for help in making the right choice.

ED. 2010/11 8.Technical Specifications 17

8.1. OVERFLOW VALVE DIMENSIONS

DN

d1

I

H

AISI 316L

DN

d1

I

H

AISI 316L

1”

22,1

50

220

274700101EB

25

26

50

220

274700025EB

1 ½”

34,8

60

240

274700112EB

32

32

55

230

274700032EB

2”

47,5

70

255

274700200EB

40

38

60

240

274700040EB

2 ½”

60,2

80

290

274700212EB

50

50

70

255

274700050EB

3”

72,9

90

310

274700300EB

65

66

80

290

274700065EB

80

81

90

310

274700080EB

DN

d1

I

H1

AISI 316L

DN

d1

I

H1

AISI 316L

1”

22,1

50

230

274700101EAM

25

26

50

230

274700025EAM

1 ½”

34,8

60

250

274700112EAM

32

32

55

240

274700032EAM

2”

47,5

70

265

274700200EAM

40

38

60

250

274700040EAM

2 ½”

60,2

80

305

274700212EAM

50

50

70

265

274700050EAM

3”

72,9

90

325

274700300EAM

65

66

80

305

274700065EAM

80

81

90

325

274700080EBAM

S/S Fig 74700

S/S Fig 74700M

18 8.Technical Specifications ED. 2010/11

8.2. SECTION AND PARTS LIST

FIG:74700

POSITION

DESIGNATION

MATERIAL

QUANTITY

01

Housing

AISI 316L

1

05*

Shaft seal

EPDM

1

06

Spring

AISI 302

1

08

Shaft

AISI 316L

1

08A

Shaft sleeve

AISI 316L

1

11*

Guide bushing

Iglidur G

1

12

Body cap

AISI 316L

1

12A

Spring cover

AISI 304L

1

19*

Gasket

EPDM

1

20B*

O’ring

EPDM

1

25

Spring washer

AISI 304L

1

26C

Nut

AISI 304L

1

26F

Lock nut

AISI 304L

1

34

Clamp

AISI 304

1

45

Elastic ring

AISI 304

1

* Recommended spare parts.

FIG:74700M

POSITION

DESIGNATION

MATERIAL

QUANTITY

01

Housing

AISI 316L

1

04

Handle

AISI 304L

1

05*

Shaft seal

EPDM

1

06

Spring

AISI 302

1

08

Shaft

AISI 316L

1

08A

Shaft sleeve

AISI 316L

1

12

Body cap

AISI 316L

1

12A

Spring cover

AISI 304L

1

19*

Gasket

EPDM

1

20B*

O-ring

EPDM

1

22D

Upper screw

BRONCE

1

25

Spring washer

AISI 304L

1

26C

Nut

AISI 304L

1

26F

Lock nut

AISI 304L

1

34

Clamp

AISI 304

1

45

Elastic ring

AISI 304

1

50A

Pin

AISI 304

1

* Recommended spare parts.

ED. 2010/11 8.Technical Specifications 19

FIG:74700 PTFE SEAT

POSITION

DESIGNATION

MATERIAL

QUANTITY

01

Housing

AISI 316L

1

05*

Shaft seal

FPM

1

06

Spring

AISI 302

1

08

Shaft

AISI 316L

1

08A

Shaft sleeve

AISI 316L

1

11*

Guide bushing

Iglidur G

1

12

Body cap

AISI 316L

1

12A

Spring cover

AISI 304L

1

19*

Gasket

PTFE

1

20B*

O’ring

FPM

1

20C*

O’ring

FPM

1

25

Spring washer

AISI 304L

1

26C

Nut

AISI 304L

1

26F

Lock nut

AISI 304L

1

34

Clamp

AISI 304

1

45

Elastic ring

AISI 304

1

* Recommended spare parts

20 8.Technical Specifications ED. 2010/11

8.3. PARTS LIST

FIG:74700

* Recommended spare parts.

DN

01

05*

06

08

08A

11*

12A

12

25

351249.6

450811.E

1-MU-452447

2-MU-452448

3-MU-452599

452301A.6

452123A.6

GSM1012-10

452210.4

450890.6

1”

351256.6

452618A.6

452617A.6

32

351250.6

1-MU-452449

2-MU-452450

3-MU-452600

452301B.6

452123B.6

40

351251.6

1-MU-452451

2-MU-452452

3-MU-452601

452301C.6

452123C.6

452211.4

450891.6

1 ½”

351257.6

452618C.6

452617C.6

50

351252.6

1-MU-452453

2-MU-452454

3-MU-452602

452301D.6

452123D.6

452212.4

450892.6

2”

351258.6

452618D.6

452617D.6

65

351253.6

1-MU-452455

2-MU-452456

3-MU-452603

452301E.6

452123E.6

GSM1315-10

452213.4

450893.6

2 ½”

351259.6

452618E.6

452617E.6

3”

351260.6

1-MU-452457

2-MU-452458

3-MU-452637

452618F.6

452617F.6

452214.4

450894.6

80

351254.6

452301F.6

452123F.6

DN

19*

20B*

25

26C

26F

34

45

25

452121A.E

O4040835

452119A

452138.4

452137.4

1703200

AE-09000

1”

452616A.E

32

452123B.E

40

452121C.E

O4053535

452119B

452115.4

452117.4

1703212

1 ½”

452616C.E

50

452121D.E

O4066235

1703300

2”

452616D.E

65

452121E.E

O4091635

452119C

452116.4

452118.4

1703400

2 ½”

452616E.E

3”

452616F.E

O4098035

1703412

80

452121F.E

Table of contents

Other INOXPA Control Unit manuals

INOXPA

INOXPA VEEVALV Manual

INOXPA

INOXPA C-TOP Reed Manual

INOXPA

INOXPA INNOVA T Manual

INOXPA

INOXPA C-TOP+ User manual

INOXPA

INOXPA C-TOP+ User manual

INOXPA

INOXPA OVERFLOW Manual

INOXPA

INOXPA C-TOP Installation and user guide

INOXPA

INOXPA NL Manual

INOXPA

INOXPA BALL Installation and user guide

INOXPA

INOXPA BUTTERFLY Manual

INOXPA

INOXPA BALL Manual

INOXPA

INOXPA 72700 Manual

INOXPA

INOXPA C-TOP+ User manual

INOXPA

INOXPA INNOVA D Manual

INOXPA

INOXPA INNOVA J Installation and user guide

INOXPA

INOXPA OVERFLOW VALVE Manual

INOXPA

INOXPA INNOVA P Manual

INOXPA

INOXPA INNOVA F Ex Manual

INOXPA

INOXPA INNOVA S Manual

INOXPA

INOXPA INNOVA P Series Manual