1 2

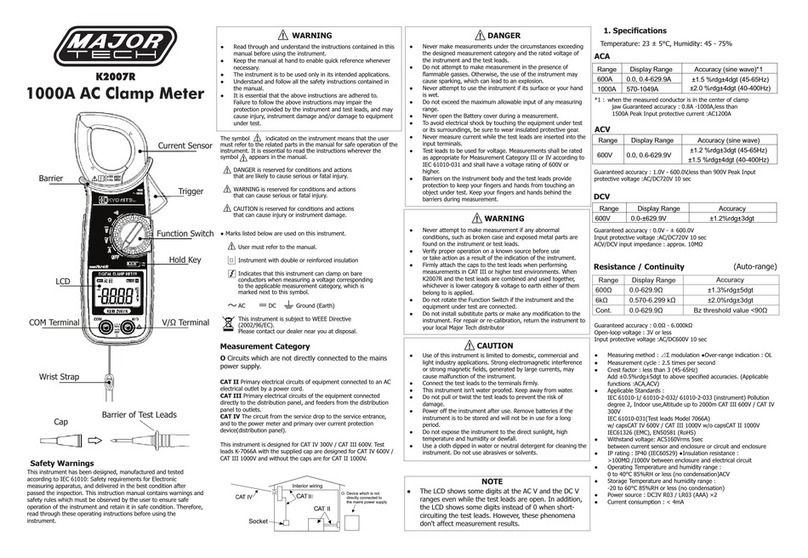

Specification

Tip stroke: 0~2.5mm

Dial Value 0~100HD:

Available test range 10~90HA :

Test error: 1HA

Dimension 115x60x25(mm) :

Net weight 160g :

Function

ISH-SDM shore durometer is an instrument for measuring vulcanized

rubber and plastic products. It carries out standard of ISO868, ISO7619,

ASTMD2240, this durometer can be installed in the same model test

stand and used in the laboratory to test the standard hardness of rubber

and plastic objects. It can also be held in hand to measure the surface

hardness of rubber but plastic sample.

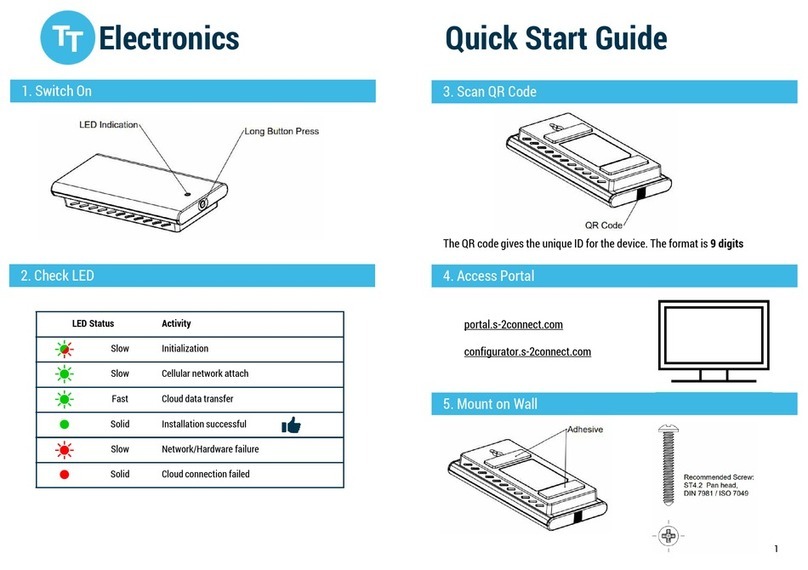

Operation

1

2

3

4

Put the sample on the stable platform, hold the shore durometer, the

tips distance to samples edge at least 12mm, press pressure feet on

the sample, without any vibrancy keep pressure feet parallel to make

the pressure feet and sample contact closely, read the value by the

maximum indicator. After read the value please back the maximum

indicator by turning the knob CCW. For one test, please test hardness 5

times with the different position which distance is 6mm and then

c hoose average value.

Operation Detials

Before test, please check the needle is point to zero. If the needle

is not in zero, please loose the screw on up-right, and turn around

the dial make the needle to zero. Press the meter on glass board,

the needle mast in 100±1HD, if the needle not point to 100±1HD,

please Press the tip slightly for many times. If the needle can not

point to 100±1HD, the durometer can not use. If apply it on the

durometer test stand, move the handle, make the working table up to

lift the weight, make tip surface and feet surface touch to the

working table closely, the needle should point to 100±1HD. If not

in 100±1HD, adjust screw on the working table after adjusting the

needle still not to 100±1HD, it is better to send it to factory to

calibrate.

Thickness of the rubber sample should not be less than 6mm, the

area of sample must be more than 35x15mm. If the thickness is

less than 6mm, please use multilayer sample congruence but not

more than three and the sample must touch totally.

Thickness of the plastic sample should not be less than 6mm, the

a rea of sample must be more than 50x15mm.

The surface of the sample must be smooth, no defect.

After applying the durometer 35000 times, in every apply 10000

times, it is better to check spring pressure and index scale relation

and shape size of tips accordance to the standard.

5After test sample, please place the durometer into box, put it in the

dry environment.

6Please brush clean the up-down shaft and the base of working

table, spread little against--rust oil, prevent rusting.

7When apply the shore durometer, its available test range is 20HD-

90HD, if it is below this range, suggest you to apply model A

durometer.

8Test temperature should in the range of 23±5℃, the relatively humidity

is less than 85%, in the environment of no vibrancy and no erode.

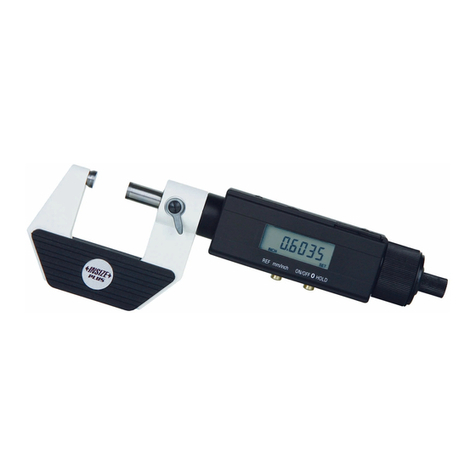

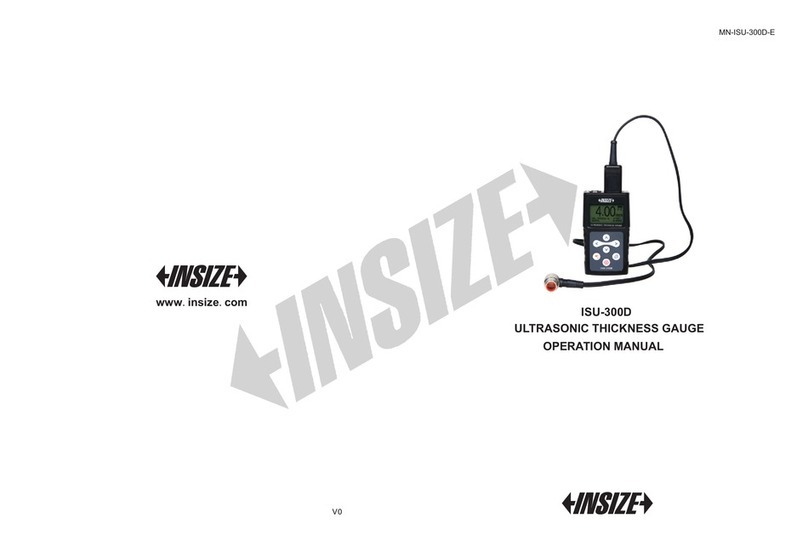

peak value

indicator

Ø3+0.2

-0.5

Ø1.25 0.15±

2.50.04±

30 1° °±

SR0.1±0.012