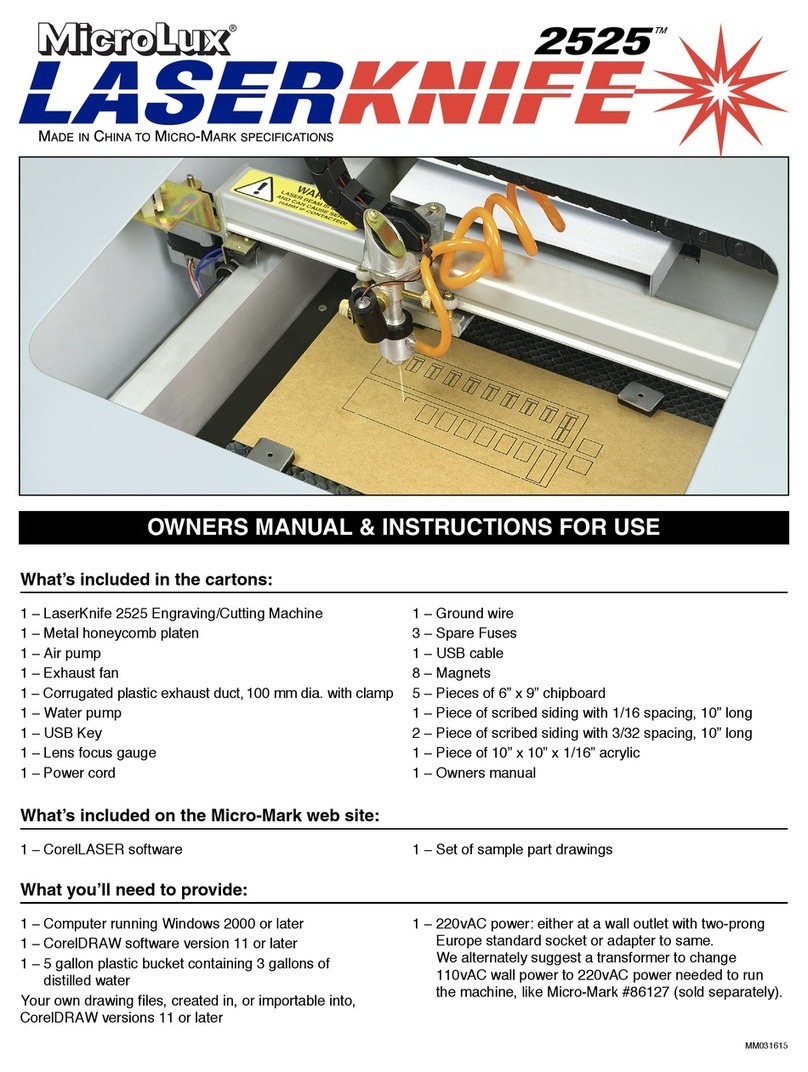

insize ISU-200D User manual

www.insize.com

ISU-200D

ULTRASONIC THICKNESS GAUGE

OPERATION MANUAL

MN-ISU-200D-E

1

Attention

In order to obtain good measurement precision, you need to clear

away the rusty, sundry, grease, etc. on the working surface.

Please use the couplant on the working surface, measure

repeatedly around the target area and take average value.

Please clean the couplant on the transducer and working surface

after measure.

Please don’t pull the transducer cable when use the instrument.

2

Overview

The Thickness Gauge is a digital ultrasonic thickness gauge. Base on the

same operating principles as SONAR is capable of measuring the

thickness of various materials with accuracy as high as 0.01mm or

0.001inch. It is suitable for a variety of metallic and non-metallic

materials.

1

3

2

Specification:

Resolution: 0.01mm (range<100mm), 0.1mm (range 100mm)

Accuracy: ±0.05mm (range < 10mm), ±(0.01+0.5%H)mm (range

10mm). H is the thickness to be measured.

Velocity: 1000~9999m/s

Structure:

Measuring principle:

The digital ultrasonic thickness gauge determines the thickness of a

part or structure by accurately measuring the time required for a short

ultrasonic pulse generated by a transducer to travel through the

thickness of the material, reflect from the back or inside surface, and

be returned to the transducer. The measured two-way transit time is

divided by two to account for the down and back travel path, and then

multiplied by the velocity of sound in the material. The result is

expressed in the wall-known relationship:

H is the thickness, v is the velocity, t is the time.

: Sign of difference mode.

: Sign of scan mode.

3

Key Functions

4

Key Function

--Turn on/off the instrument (long press)

--Turn on/off the backlight (short press)

Data save: after get a new reading, press this key once and the

screen appear “*”, then long press this key to save the reading.

Function key: continue to press this key and select the functions

then press enter key to set.

Velocity key: continue to press this key and select the velocity

and you can press the up or down keys to adjust the value.

Up key and quickly enter scan mode

Down key and quickly enter alarm mode

Enter key

Calibration key

Basic operations

1

3

2

Power on and off:

Long press the key until screen show the picture as below:

Insert the plus of the probe into the socket on the instrument.

FILE1: File selection(5 files in total).

5M: Probe selection(4 kinds of probe: 2M, 5M, 7M, H2M).

MENU: Menu selection.

20:30: System time.

: Sign of coupling.

: Battery information(When it is , the battery should

be charged).

: Sign of alarm mode.

Transducer setting:frequency

The frequency of the transducer should be preset to the instrument

before measuring operation. This enables the user to select the

transducer type among supported transducers according to frequency

and diameter depending on application requirements.

Use the following steps to select your transducer frequency:

Press the key to select the desired frequency of the probe.

On the measurement screen, press the key twice to activate the

transducer frequency tab.

Press the key back to the measurement screen.twice

Sound velocity setting:

In order for the gage to make accurate measurements, it must be

set to the correct sound velocity for the material be measured.

Use the following steps to select your transducer frequency:

On the measurement screen, press the key to preset commonly

using velocity.

Use the and to adjust the value until it matches the sound

velocity of the material to be measured.

56

4

Zero setting:

Plug the transducer into the instrument, make sure that the

connector are fully engaged. Check that the wearface of the

transducer and surface of the zero disc is clean.

Select the frequency(5M) and sound velocity(5920m/s).

Apply a single droplet of couplant to the face of the zero disc.

Press the transducer against the probe disc, makeing sure that

transducer sits flat against the surface.

While the transducer is firmly coupled to the zero disc, the

thickness value is shown on the screen.

Press the key to set the value to 4.00mm.

5

Thickness measurement:

When the screen is displaying thickness measurements, the

display will hold the last value measured, until a new

measurement is made.

Plug the transducer into the instrument, make sure that the

connector are fully engaged. Check that the wearface of the

transducer and surface of the workpiece is clean.

Select the frequency and sound velocity according to material

of the workpiece.

Apply a single droplet of couplant to the face of the workpiece.

Press the transducer against the , makeing sure that

transducer sits flat against the surface.

workpiece

While the transducer is firmly coupled to the , the

thickness value is shown on the screen.

workpiece

6Calibration to a known velocity:

Make measurement of the test block whose thickness is

known(for example: 10mm) according to chapter “Thickness

measurement” correctly.

After the thickness value shows on the screen, press key

and remove the transducer from the surface, the display will

hold the last measurement made. At the same time, sign *

shows on the right of the screen as below.

Press key or to change the value to the exact value

10.00mm.

Press key , the sound velocity of the material measured will

show and it is saved as one of the commonly using velocities

at the same time.

System setup

1Scan mode setting:

While the gauge excels at making single point measurements, it

is sometimes desirable to examine a larger region, searching for

the thinnest point. The gauge includes a feature, called Scan

Mode, which allows it to do just that.

On the measurement screen, press the key multiple times to

activate the【MENU】tab.

78

Press key to enter the main menu interface.

Press key or to move the cursor to “System setup” and

then press to enter it.

Press key or to move the cursor to “Scan Mode” and then

press to switch on or off scan mode as below.

Press key to confirm setting and return to main menu

interface.

2

Alarm mode setting(Limit Setting):

The Thickness Gauge will alarm when the measured value is

beyond measurement range. The buzzer will ring if the measured

value reaches pre-set lows or pre-set highs.

Enter alarm mode setting according to “ scan mode setting”.

Press to turn on the alarm mode and enter menu ”LOW

LIMIT” as below.

Press key or to change lower limit.

Press key to enter menu ”HIGH LIMIT” to set high limit.

Press key to confirm setting and return to main interface.

3Difference mode setting:

Enter difference mode setting according to “ scan mode

setting”.

Press to turn on the difference mode and enter menu

“TARGET MENU” as below:

Press key or to change the target value and press key

to go back.

Press key to confirm setting and return to main interface.

When making measurement, if the measurement value is larger

than target value, mark is replaced by + and if the measurement

value is larger than target value, mark is replaced by -. The value

showing on the screen is absolute of measurement value minus

target value.

4Two-point CAL setting:

This procedure requires that the operator has two known

thickness points on the test piece that are representative of the

range to be measured.

Enter two-point CAL setting according to “ scan mode setting”.

Press to turn on the two-point CAL then press key return

to main interface.

When thickness value shows on the screen, press key to

make 2-Point CAL, the tester remind you to make thin

calibration as below:

910

Press key to “froze” the reading, then press key or to

change the value to standard value and then press key to

confirm. At the same time the tester remind you to make thick

calibration as below:

Make thick calibration just as thin calibration.

Press key to confirm and return to main interface.

Send data to PC

1

There are 5 files (FILE1-FILE5) that can be used to store the

measurement values inside the gauge. At most 100 records can be

stored to each file. On measurement screen, press the key multiple

times to activate the【FILE name】tab as below:

Storing a reading:

Use the key to select the desired file to save the data.

After get a n ew rea ding, press key once and the

screen appear “*”. Then long press this key to save the

reading.

Long press key to save the reading.

2

Viewing stored readings:

Press key to activate the【FILE name】tab and press key

to select the desired file to view the data.

Press key to view the data saved as below:

Press key or to view all data saved.

Press key to exit.

3

Delete data

Press key when you are viewing data saved to delete that data

and the next data will show on the screen.

You can also enter the function menu to delete single file or all

files.

:

Connect instrument to the computer by using USB cable.

Memory management

1

Put the software CD into the CD-ROM, double click the “USB

Driver” to install the USB cable drive. After installation you need

enter into Device Manager to ensure the interface code. Like the

following picture it is COM4.

2

11 12

Double click the “hypertrm” and input a name for the connection

as following picture, then click “OK”.

3

Select the interface code of the USB cable.

4

Set the parameters as following picture then click “OK”.

5

Enter the function menu and select the tab “Send data to PC”,then

press key.

6

The screen will display the data saved before, now you can edit,

save, print the data.

7

Standard delivery

1pc

1pc

1pc

1bottle

1pc of each

Main unit

Transducer ISU-PT12

AC/DC adapter

Couplant

USB cable and software disc

ISU-PT08

Transducer

Optional Accessory

13 14

Sound velocity

Material Sound Velocity

Inch/µS M/s

Air

Aluminum

Beryllium

Boron Carbide

Brass

Cadmium

Copper

Glass(crown)

0.013

0.250

330

6300

0.390 9900

0.510 12900

0.430 11000

4300

2800

4700

5300

Alumina Oxide

0.170

0.110

0.180

0.210

Glycerin

Gold

Ice

Inconel

Iron

Iron (cast)

Lead

Magnesium

Mercury

Molybdenum

Monel

Neoprene

Nickel

Nylon, 6.6

Oil (SAE 30)

Platinum

Plexiglass

Polythylene

Polystyrene

Polyurethane

Quartz

Rubber, Buty

Silver

Steel, Mild

Steel, Stainless

Teflon

Tin

Titanium 0.240

0.130

0.060

0.228

0.233

0.140

0.070

0.230

0.0700

0.093

0.070

0.110

Tungsten

Uranium

Water

Zinc

0.200

0.130

0.584

0.170 4200

1480

3400

5200

6100

3300

1400

5800

5920

3600

1800

5800

1900

2400

1900

1700

3300

1700

2600

5600

1600

5400

6300

1400

5800

2200

4600

5900

5700

4000

3200

19000.075

0.130

0.160

0.220

0.230

0.180

0.085

0.230

0.057

0.250

0.210

0.063

0.220

0.100

0.067

0.130

Table of contents

Other insize Measuring Instrument manuals

insize

insize PLUS 3631 Series User manual

insize

insize ISQ-TS120K User manual

insize

insize ISH-DSD User manual

insize

insize ISN-L70 User manual

insize

insize ISU-250C User manual

insize

insize ISU-300D User manual

insize

insize 1149 Series Technical manual

insize

insize 1113INS Technical manual

insize

insize ISF-DF Series User manual

insize

insize ISF-1DF Series User manual