TE Connectivity OCEAN 2.0 User manual

Other TE Connectivity Power Tools manuals

TE Connectivity

TE Connectivity MATE-AX 2335290-1 User manual

TE Connectivity

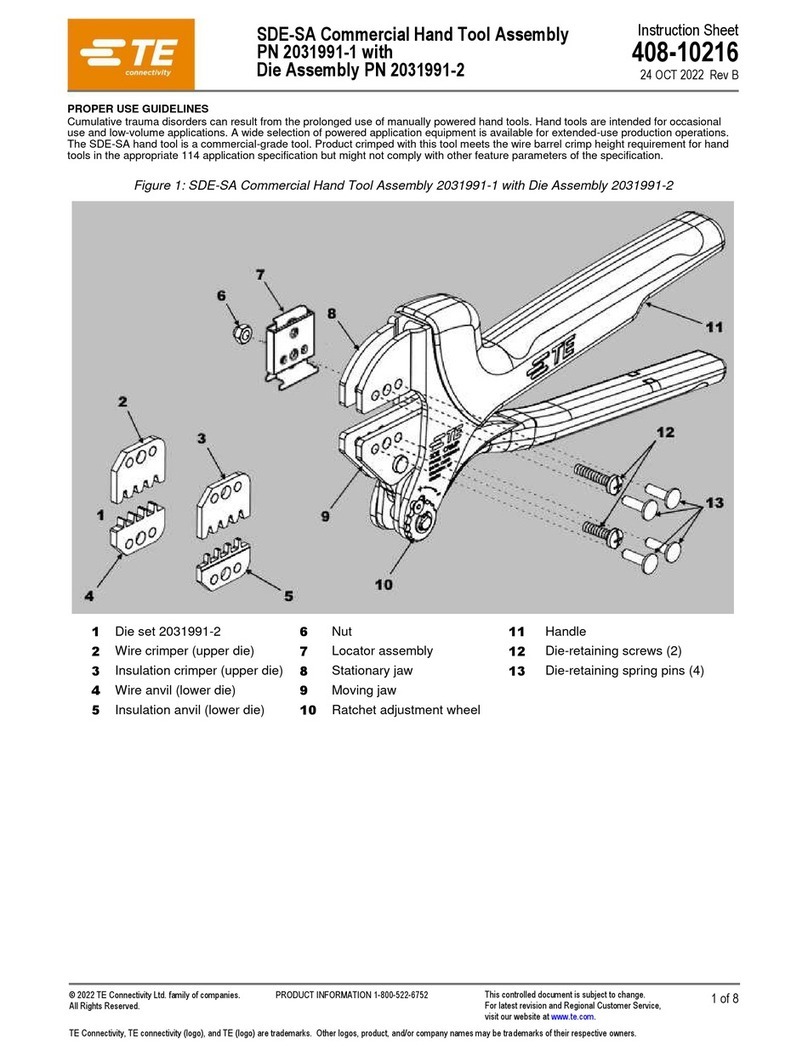

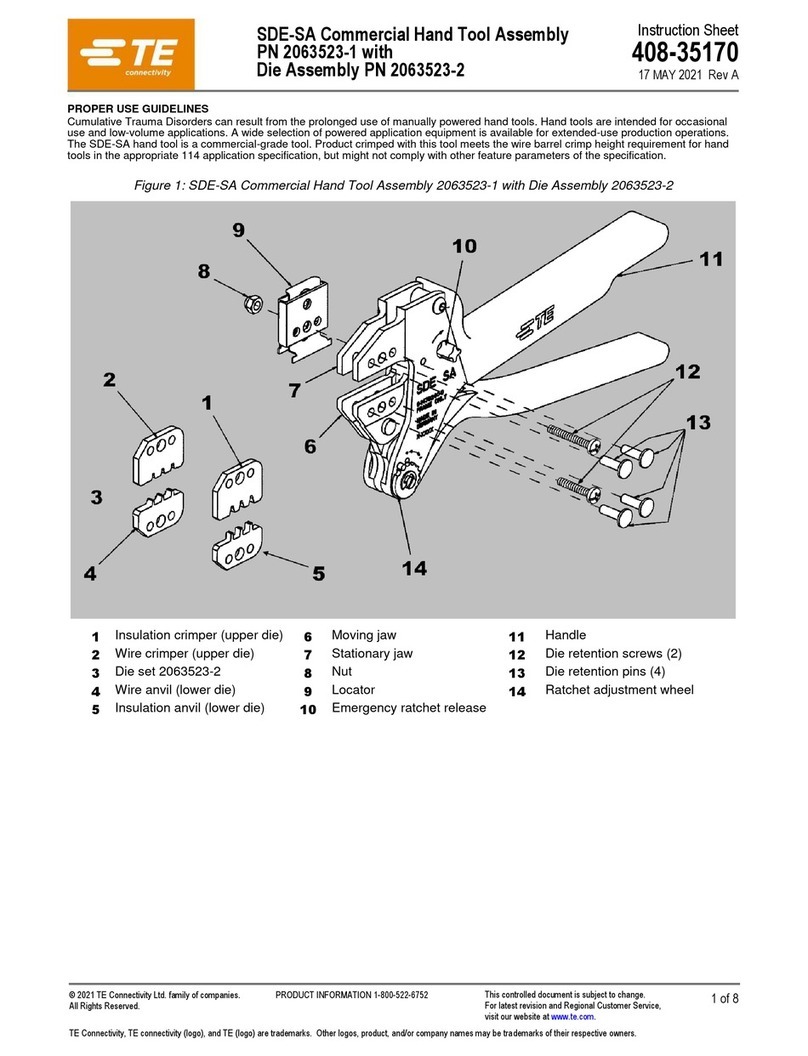

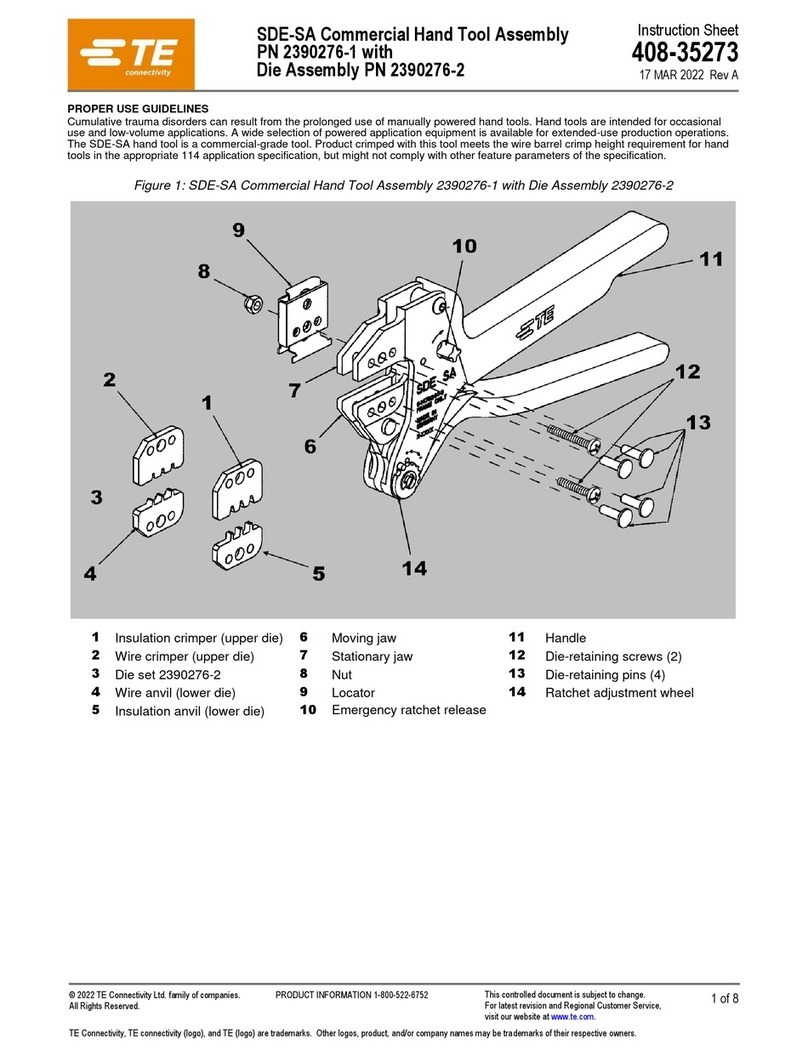

TE Connectivity SDE-SA User manual

TE Connectivity

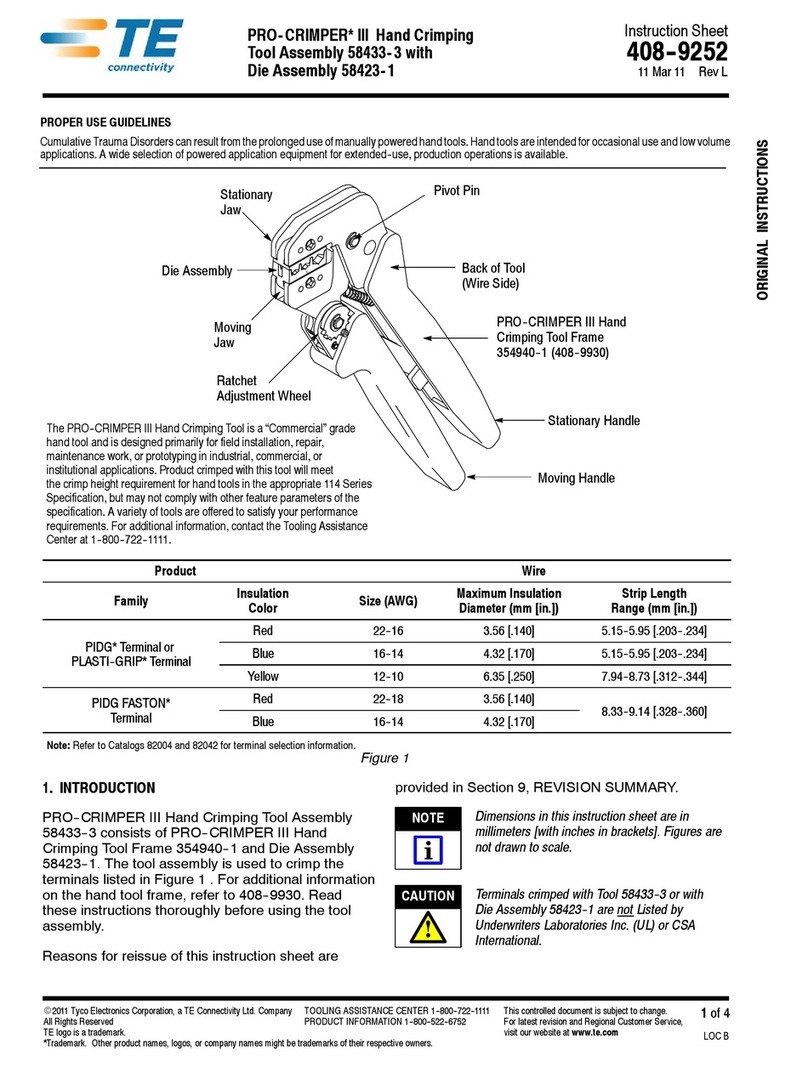

TE Connectivity PRO- CRIMPER III User manual

TE Connectivity

TE Connectivity PRO- CRIMPER III User manual

TE Connectivity

TE Connectivity 2389783-1 User manual

TE Connectivity

TE Connectivity Hand tool for AMP DUOPLUG 2.5 User manual

TE Connectivity

TE Connectivity 1976330-1 User manual

TE Connectivity

TE Connectivity 539 666-2 User manual

TE Connectivity

TE Connectivity 91904 Series User manual

TE Connectivity

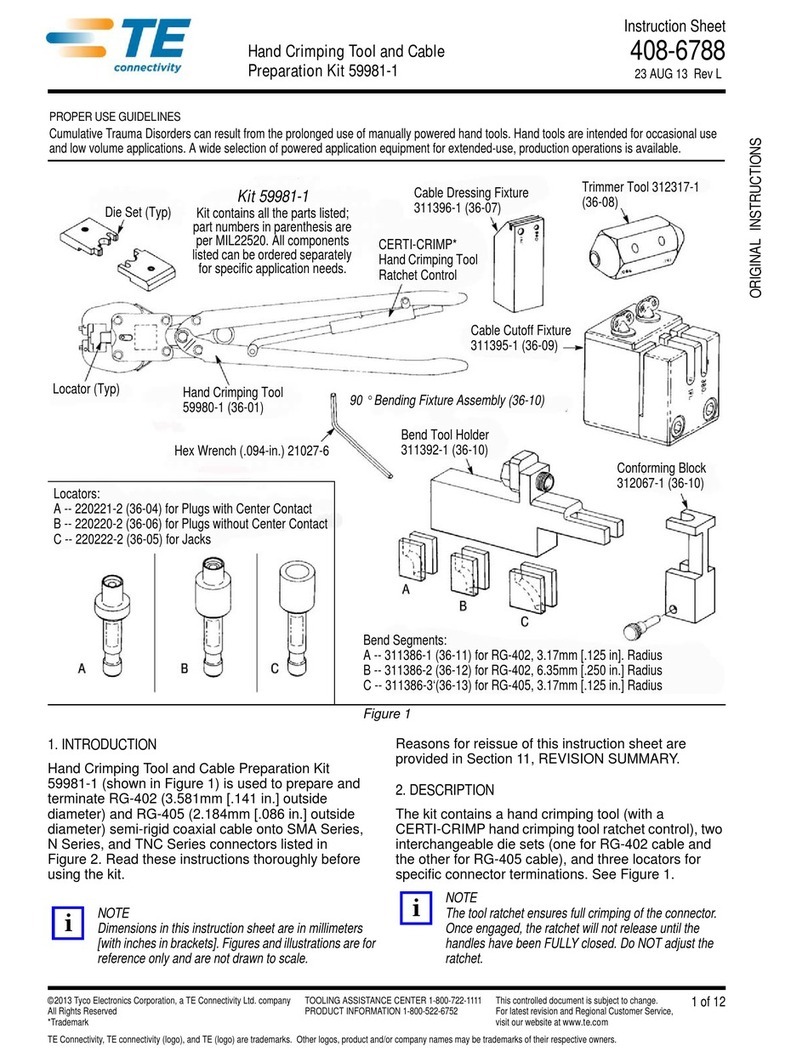

TE Connectivity 59981-1 User manual

TE Connectivity

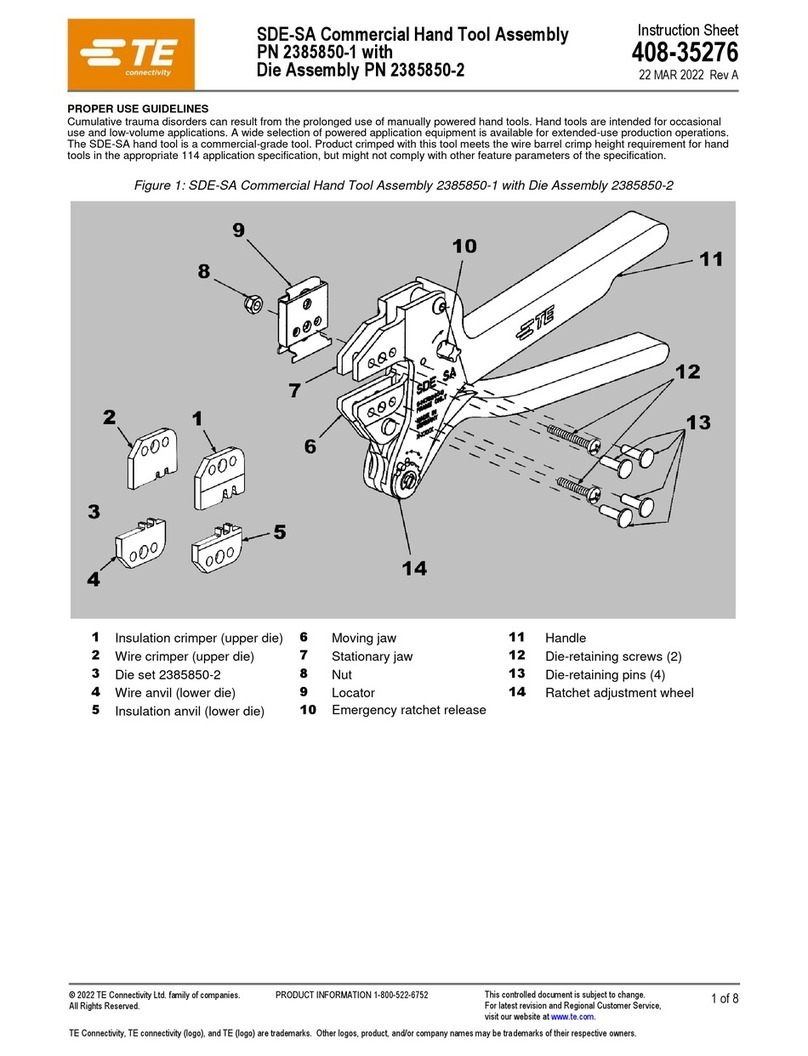

TE Connectivity 2385850-1 User manual

TE Connectivity

TE Connectivity SDE-SA User manual

TE Connectivity

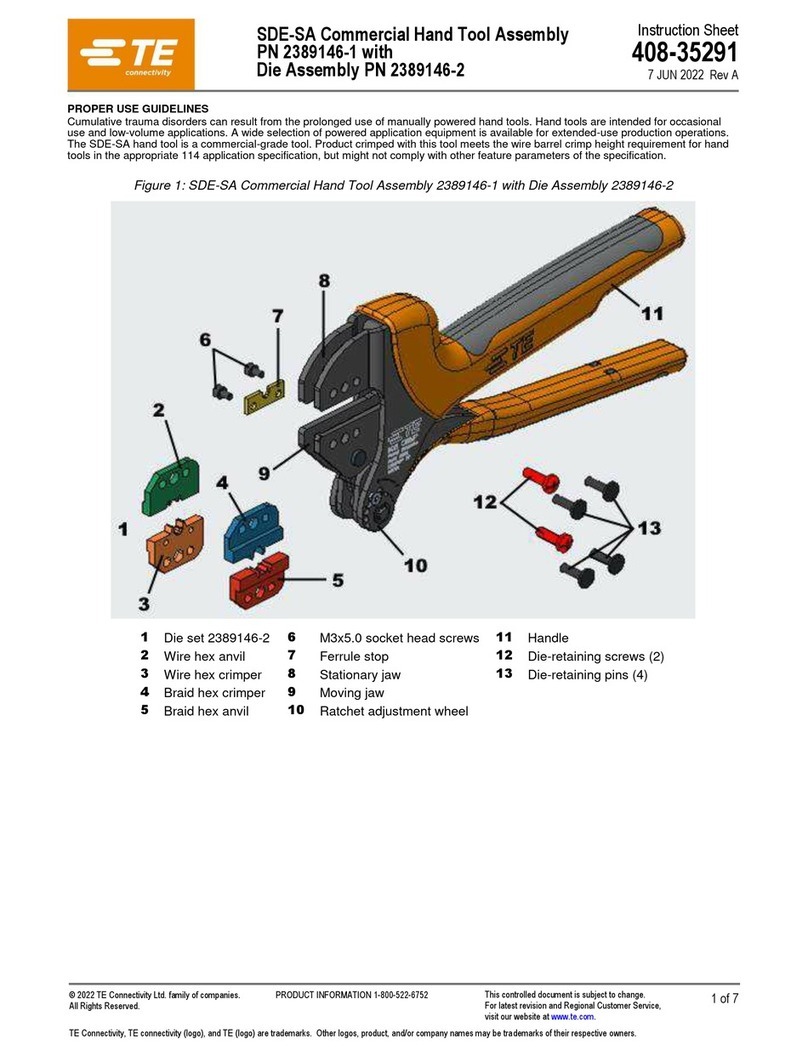

TE Connectivity SDE-SA User manual

TE Connectivity

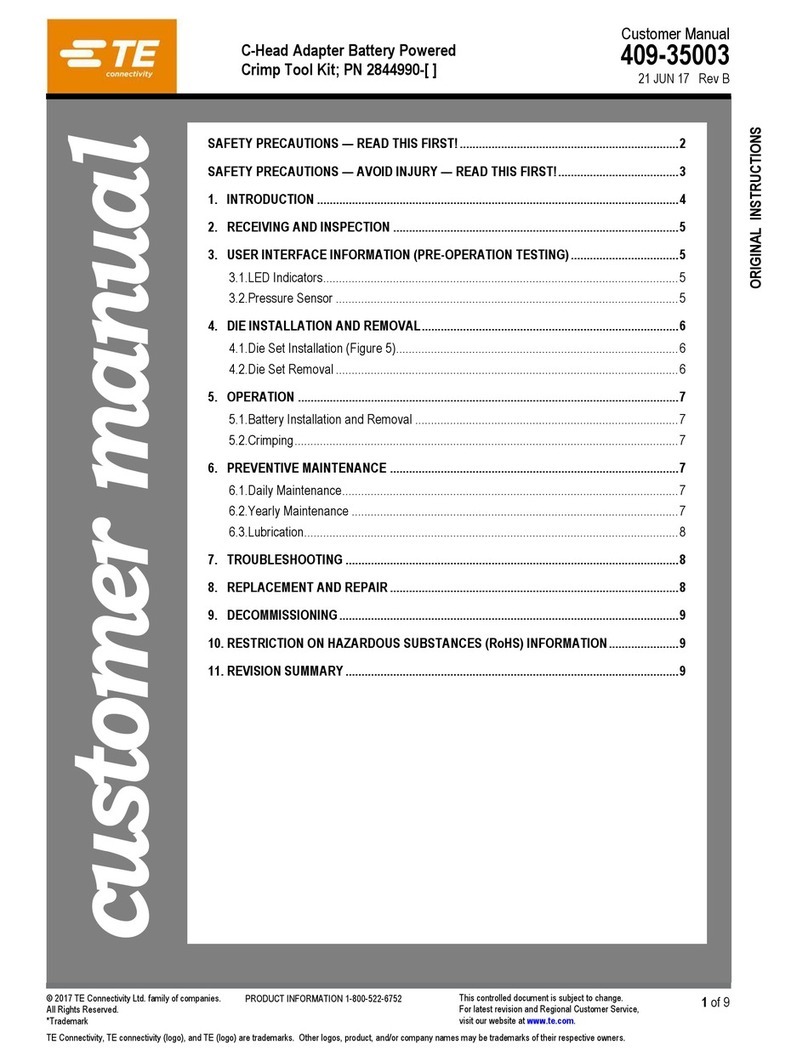

TE Connectivity 2844990-1 Reference guide

TE Connectivity

TE Connectivity 408-160034 User manual

TE Connectivity

TE Connectivity PRO-CRIMPER III User manual

TE Connectivity

TE Connectivity 59275 User manual

TE Connectivity

TE Connectivity 2405856-1 User manual

TE Connectivity

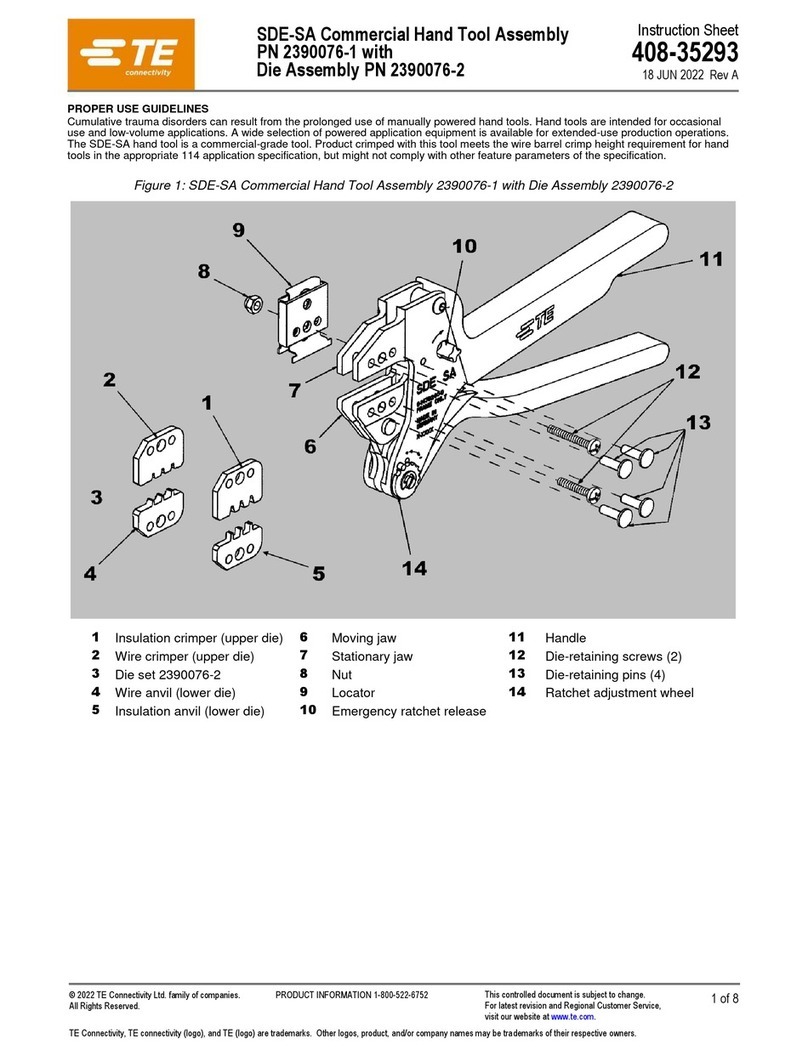

TE Connectivity 2390076-1 User manual

TE Connectivity

TE Connectivity 354940-1 User manual