© Intatec Ltd 2023 3

Preparation for installation

Access: Ensure safe access to allow the transportation of the buffer vessel to it's intended

location and adequate lighting is available.

Tools: Ensure the correct tools and consumables are available for the installation before

commencing.

Handling and Lifting: Manual handling of large or heavy equipment may present a risk of

injury. A full risk assessment should be carried out detailing the appropriate equipment to be

used and the method of handling.

Weight: Ensure that the wall or floor is structurally sound to support the filled weight of he

buffer vessel and associated fittings and pipework.

Freezing: Provision must be made to protect the buffer vessel against freezing conditions

including when not in use and not fully drained.

Storage: The buffer vessel should remain in it's packaging until you are about to commence

installation. The buffer vessel should be stored vertically in a dry area.

Installation

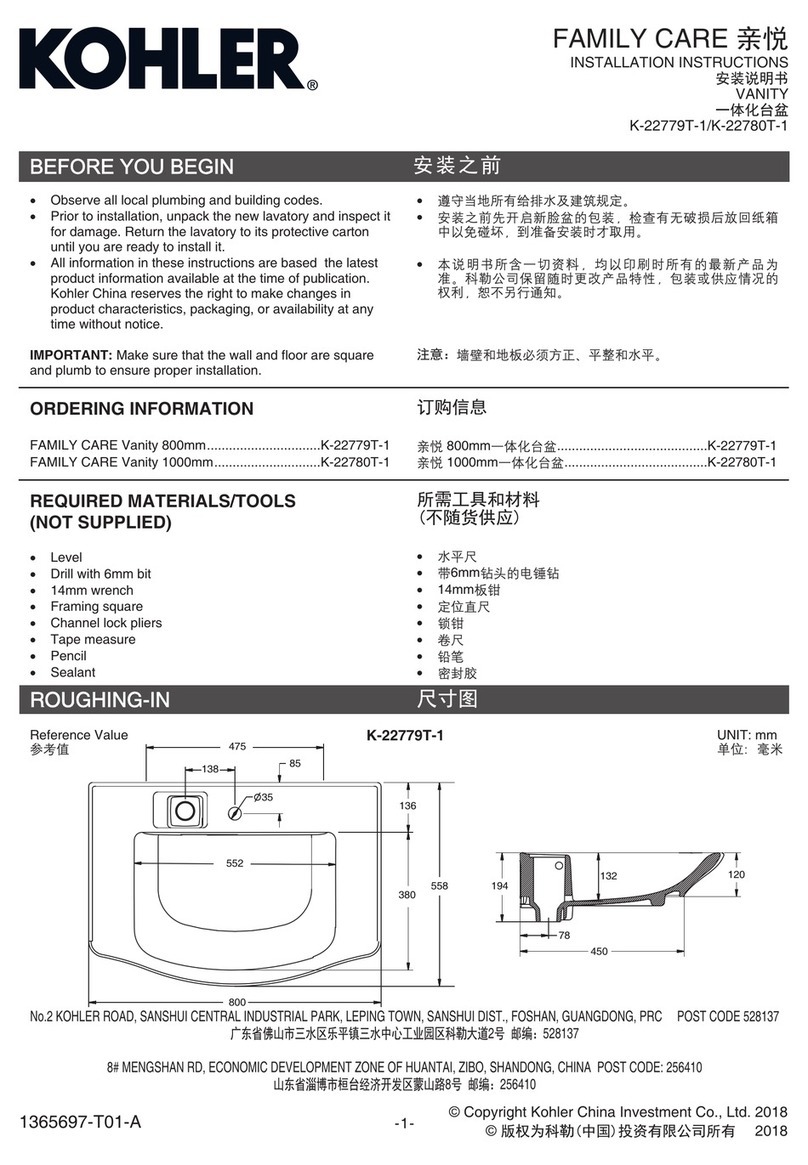

Ensure that there is sufficient space around the buffer vessel to fit and access the pipe fittings

in the 4 side connections.

If wall mounting the 25 litre buffer vessel ensure that the 4 fixing screws are of sufficient size and

length to hold the buffer secure.

Stand the buffer vessel vertically on a level floor and connect to 2 flow pipes and 2 return pipes

as shown.

The connection where is it shown in the top of the vessel can be used to vent air when filling the

system and can be fitted with a manual valve to act as an air vent (not supplied).

Tighten the joints and ensure they are water tight.

When floor standing it is advisable to provide additional support to prevent excessive movement

of the buffer vessel.

Commissioning

Before filling check that the expansion vessel in the system is charged to the designated pressure.

Open the main water supply to the buffer vessel.

Flush the system until all the air is expelled, air vents should be fitted at the highest points in the

system for this purpose.

The connection at the top of the vessel can be used to aid filling and air venting.

The system should now be full of liquid, check all joints for signs of leakage.

Inhibitor should be added as specified.

The system is now ready for use.