- 4 -

Range:

DT-640STC 12 m x 12 m

(40' x 40')

DT-660STC 18 m x 18 m

(60' x 60')

DT-6100STC 30.5 m x 6 m

(100' x 20')

Alarm relay:

Energized Form C (NC)

125 mA, 25 VDC

22 o m series protection resistor

PRODUCT SPECIFICATIONS

PIR fields-of-view:

standard (wide angle) lens

44 long range

12 intermediate

6 lower

4 down

IMPORTANT: T e DT-600 series sensors s ould be tested at least once

each year to ensure proper operation.

Power requirements:

10 - 12.9 VDC

35 mA max., 12 VDC

PIR white light immunity:

10,000 Lux

RFI immunity:

10 MHz - 1000 MHz (30 V/m)

Trouble output:

Open collector

Voltage between collector and

emitter (Vce) is .3V max at 50 mA

1K series protection resistor

(for future use)

Command input:

Self-test initiate

Active low 0 to 1.5V

Inactive ig 6 to V+

Input impedance 110 Ko ms

(min.)

Sensitivity:

2 - 4 steps wit in field of view

Copyrig t 2001 IntelliSense.

All Rig ts Reserved.

5-051-512-00 Rev B

IntelliSense, DUAL TEC, and INFORMER are

registered trademarks of Honeywell, Inc.

Frequencies:

Varies per country

Tamper:

NC, 25 mA, 30 VDC

Operating temperature:

0o to 49o C (32o to 120o F)

Dimensions:

13 cm x 7 cm x 6 cm

5" H x 2-7/8" W x 2-5/16" D

Weight:

340.2 g (12 oz )

Accessories:

SMB-10 swivel mount bracket

Lens Kit P/N 0-000-400-05

*NOTE: T e ULC label or listed marking on a product is t e only

evidence provided by Underwriters Laboratories of Canada to identify

products t at ave been produced under t e Listing and Follow-up

Service.

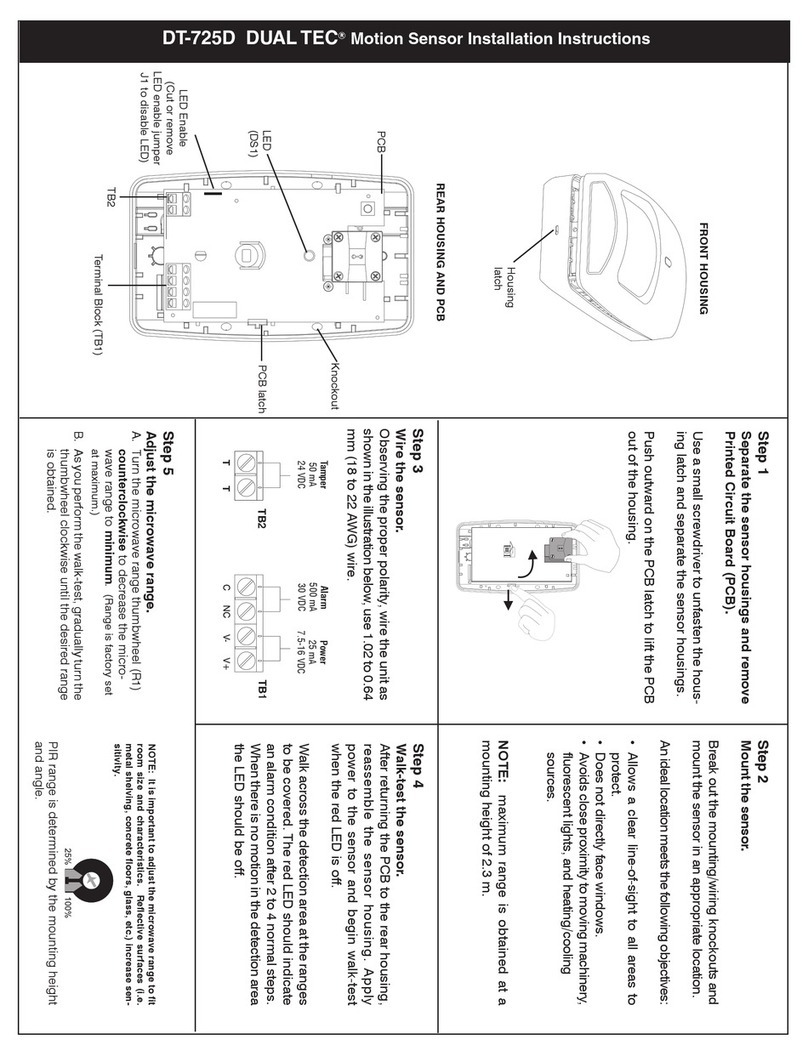

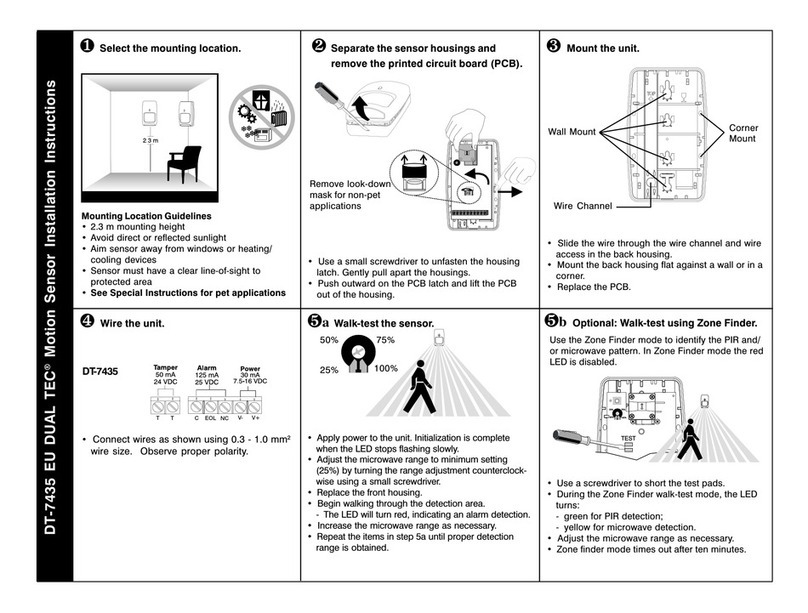

2.3 m

(7'6")

12 m (40' )

Down Long Range

Intermediate

Zones

floor

Lower

SIDE VIE

ide Angle Lens

SIDE VIE

Barrier Lens

floor

2.3 m

(7'6")

30.5 m (100' )

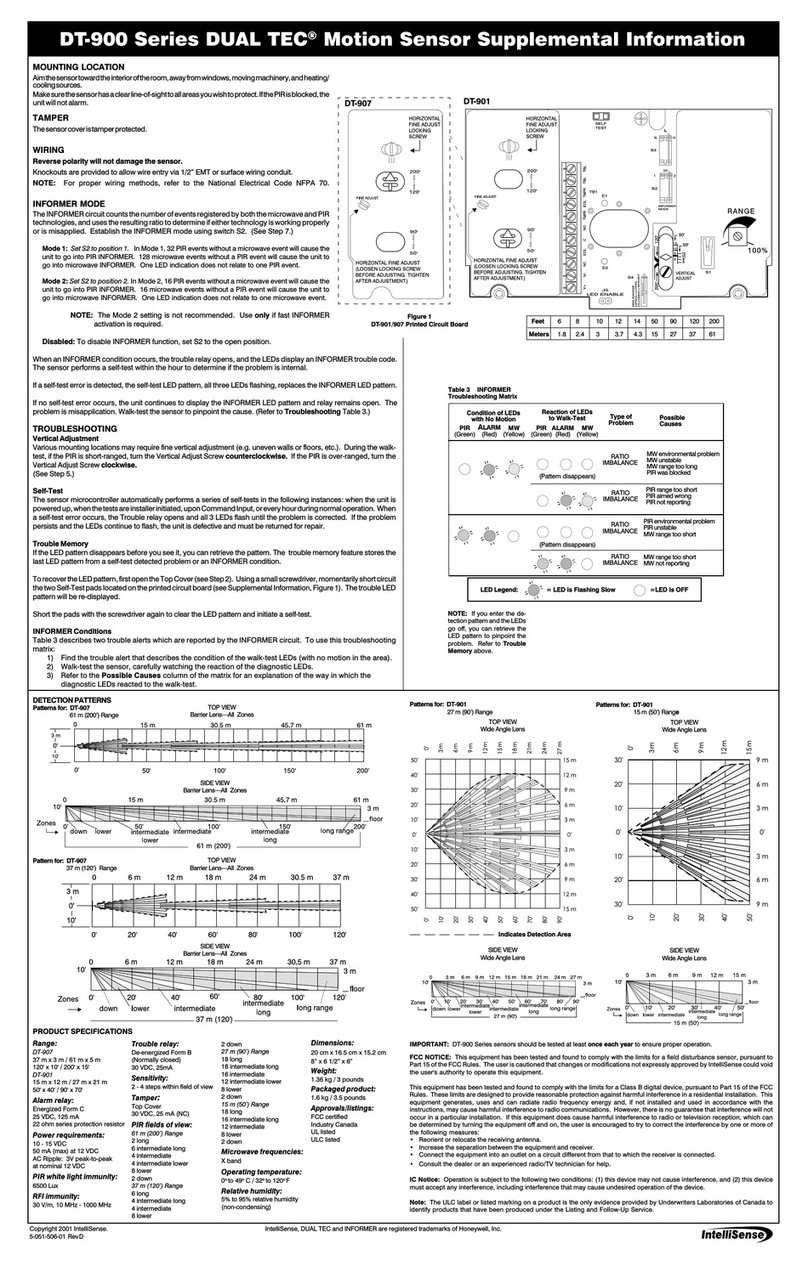

DETECTION PATTERNS Patterns for: DT-640STC

(Use as reference for DT-660STC)

DT-6100STC Pattern

12 m (40')

TOP VIE

ide Angle Lens/Pet-Alley

SIDE VIE

Barrier Lens

floor

2.3 m

(7'6")

12 m (40' )

TOP VIE

Barrier Lens

DETECTION PATTERNS FOR OPTIONAL LENSES

SIDE VIE

Pet-Alley Lens

1.2 m (4')

IMPORTANT: For UL certificated installation, t e DT-600 series sensors

must be connected to a UL listed power supply or UL listed control unit

capable of providing a minimum of four hours of standby power.

Approvals/listings:

FCC certified

UL listed

ULC* listed

IC certified

T is Class B digital apparatus meets all requirements of t e Canadian Interference-

Causing Equipment Regulations.

Cet appareil numérique de la classe B respecte toutes les exigences du Règlement sur

le matériel brouilleur du Canada.

12 m (40' )

12 m (40' )

Relative humidity:

5% to 95% relative umidity

(non-condensing)

NOTE: Pet-Alley lenses are not to be used in ULC-certified installations.

FCC Notice: T is equipment as been tested and found to comply wit t e limits for a field

disturbance sensor, pursuant to Part 15 of t e FCC Rules. T e user is cautioned t at c anges or

modifications not expressly approved by IntelliSense could void t e user's aut ority to operate

t is equipment.

T is equipment as been tested and found to comply wit t e limits for a Class B digital device,

pursuant to Part 15 of t e FCC Rules. T ese limits are designed to provide reasonable protection

against armful interference in a residential installation. T is equipment generates, uses and can

radiate radio frequency energy and, if not installed and used in accordance wit t e instructions,

may cause armful interference to radio communications. However, t ere is no guarantee t at

interference will not occur in a particular installation. If t is equipment does cause armful

interference to radio or television reception, w ic can be determined by turning t e equipment

off and on, t e user is encouraged to try to correct t e interference by one or more of t e following

measures:

Reorient or relocate t e receiving antenna.

Increase t e separation between t e equipment and receiver.

Connect t e equipment into an outlet on a circuit different from t at to w ic t e receiver is

connected.

Consult t e dealer or an experienced radio/TV tec nician for elp.