INTENSEcycles Sniper Trail User manual

user manual Sniper XC

Sniper Trail

AT INTENSE, WE HAVE ONE GOAL - TO PROVIDE THE RIDE OF YOUR LIFE //

Our team of designers, engineers and product experts are focused on one thing every

day: your experience on the bike. We build bikes that are as thrilling to look at as they

are to ride, and we build them for the select few of you who understand the difference

and refuse to settle for anything else.

From the early days of Intense, when founder Jeff Steber worked alone in his garage to

today, where a crew of talented people work in a Temecula, CA factory, Intense has been

a brand built on passion by forward thinkers who, even today, love nothing more than

to throw a leg over a sweet bike and head out for a rip. We’re so glad you’ve joined us.

Welcome to Intense, enjoy your experience.

THE SNIPER XC, SNIPER TRAIL //

The Sniper is a ground-up, dedicated, pedaling machine with two different travel

versions, XC 100mm and Trail 120mm. Short travel rigs should descend like their long

travel siblings and that’s what we’ve done. This is no “Twitchy XC bike”. With the 29”

wheel size and progressive XC/Trail geometry, you get a stable ride that goes where you

point it. Offered with a standard hardware package as well as a light weight SL package

to shave some grams, the Sniper takes XC Race and Trail riding to the next level.

registration

WWW.INTENSECYCLES.COM/WARRANTY-CARD/

contact customer service

cs@intensecycles.com

951-296-9596

Welcome to

the family

2// SNIPER user manual

introduction / registration 2

Sniper xc frame features / component spec 4

sniper xc Geometry 5

sniper trail frame features / Component spec 6

sniper trail geometry 7

exploded view and b.o.m. 8

Assembly 10

torque chart 17

setup 18

maintenance 22

INTENSE CYCLES // 3

4// SNIPER user manual

sNIPer xc

frame

features /

spec

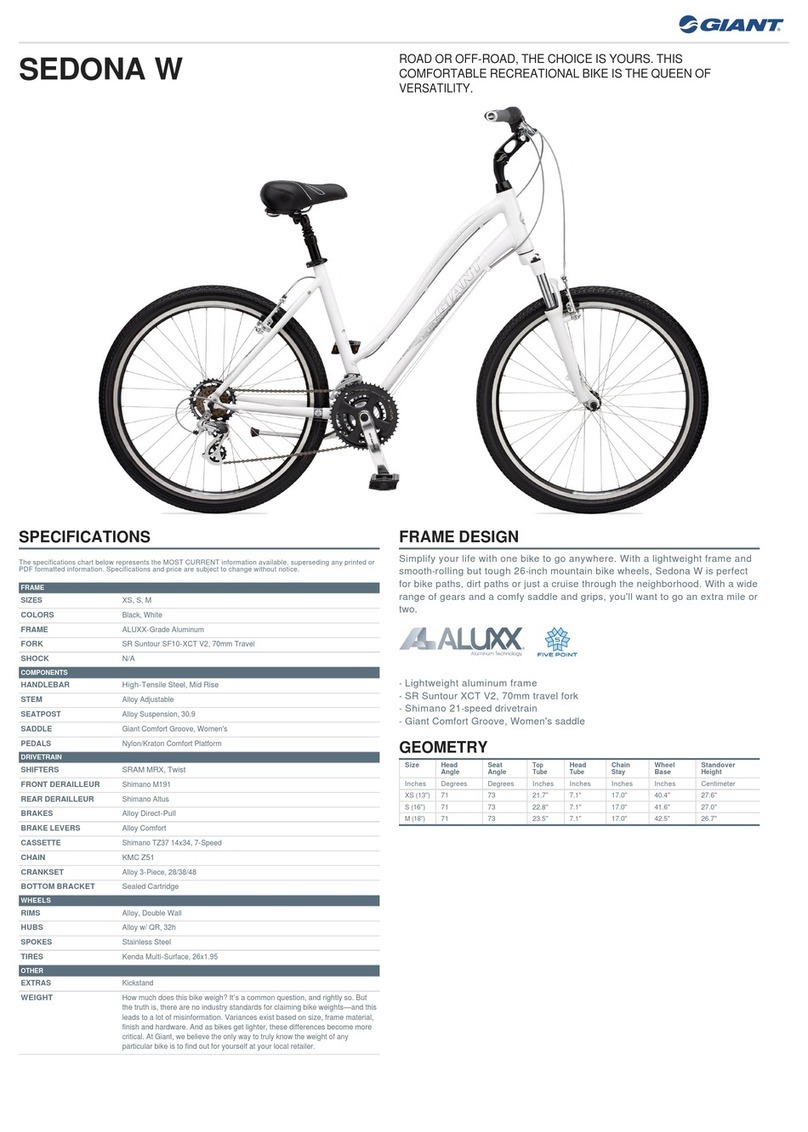

Frame Features //

•Rear Travel: 3.94 inches (100mm) with 165 x 40 stroke shock

•29” Wheel size

•Integrated BOOST 148 x 12 dropouts

•4.76 lbs / 2158 grams = Standard frame w/ alloy lower link & shock

•4.73 lbs / 2144 grams = SL Super Light frame w/ magnesium lower link & shock

•Injection molded top link

•INTERNAL CABLE ROUTING

•Internal Seat Tube Cable Routing for dropper posts

•Monocoque front triangle

•H20 Bottle Fitment

•FLacK GuaRD Downtube, Chainstay, and Seatstay protection

•Tapered Head Tube

•Max Bearings and Dedicated Frame Hardware

Component Spec //

•Fork: FOX 32 Step Cast 100mm with 44 mm Offset, 503.7mm Axle to crown length

•Rear Shock: FOX Float DPS 165 x 40, trunnion mount, 20mm x 8mm reducers

•Seat post – 31.6mm

•Headset – Cane Creek, 40, Alloy Cartridge (www.canecreek.com) IS 41 Top, IS

52 Lower. IS=Integrated Top and Lower Headset

•Bottom bracket - PF92

•Rear Axle – BOOST 148 x 12 with hidden lever

•Brake Mount – Post Mount for 160mm rotor

•Crank set - BOOST 148 Compatible - single ring only

•Rear Wheel - BOOST 148 Compatible

INTENSE CYCLES // 5

sNiPer xc

Geometry

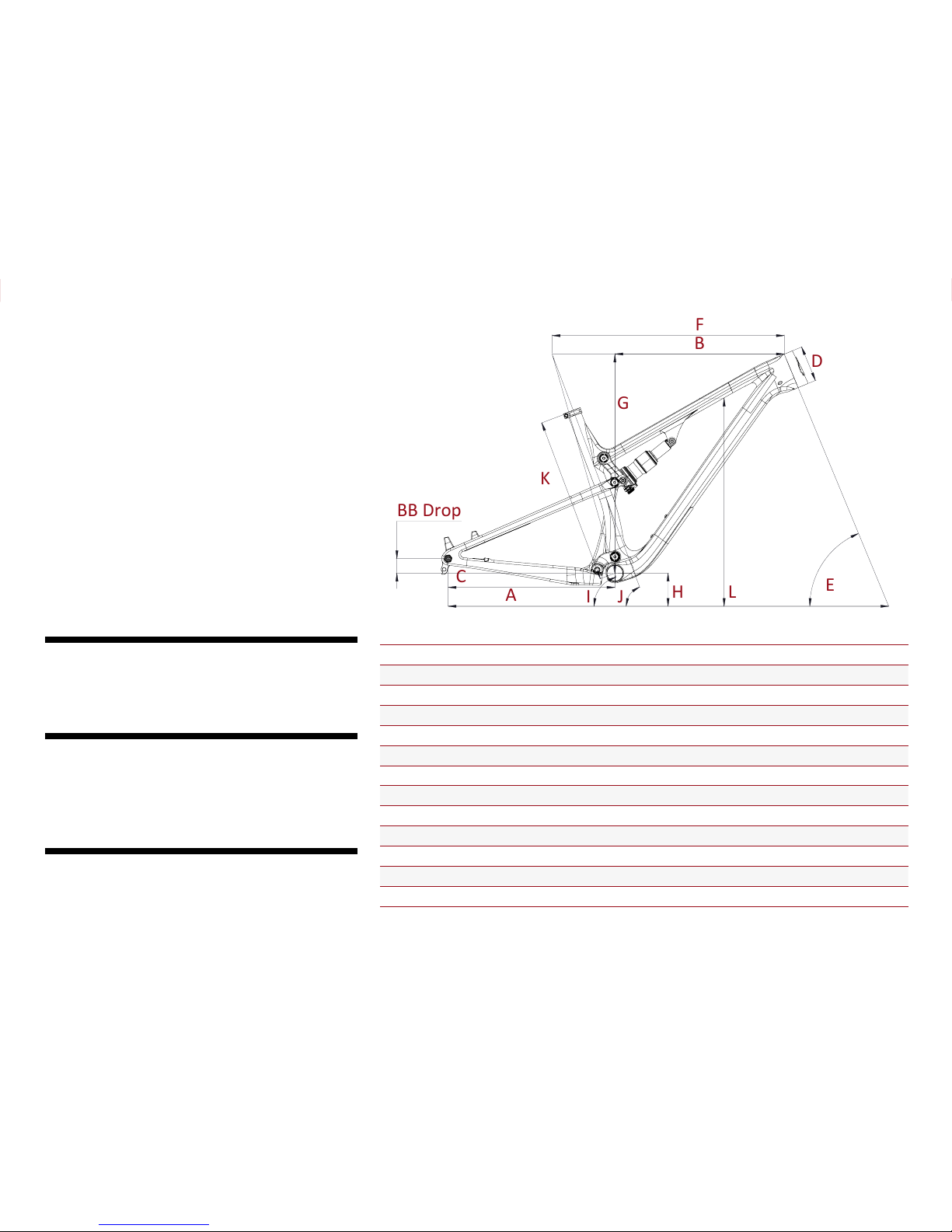

BB Drop

C

F

A

B

E

D

G

H

L

K

I

J

GEOMETRY NOTEs

GEOMETRY TAKEN AT TOP OUT WITH 503.7MM axle to crown length

AND 44mm FORK OFFSET.

Component spec NOTE

the sniper xc is designed around the use of a single chain ring

only. Use of a double or triple ring set will not allow proper

clearance with the frame.

Warning

NOT INTENDED FOR USE WITH FORKS LARGER THAN 120MM OF TRAVEL.

SMALL MEDIUM LARGE XLARGE

AWheel Base: 1127 mm / 44.4” 1152 mm / 45.37” 1179 mm / 46.4” 1206 mm / 47.5”

BTop Tube Length: 584 mm / 23.0” 609 mm / 24.0” 635 mm / 25” 660 mm / 26”

CChain Stay Length: 439 mm / 17.3” 439 mm / 17.3” 439 mm / 17.3” 439 mm / 17.3”

DHead Tube Length: 90 mm / 3.54” 95 mm / 3.7” 105 mm / 4.13” 115 mm / 4.5”

EHead Tube Angle: 67.5˚ 67.5˚ 67.5˚ 67.5˚

F Reach: 421 mm / 16.6” 444.5 mm / 17.5” 468 mm / 18.4” 490 mm / 19.3”

G Stack: 570 mm / 22.45” 575 mm / 22.6” 584 mm / 23” 593 mm / 23.4”

HBB Height: 330 mm / 13.0” 330 mm / 13.0” 330 mm / 13.0” 330 mm / 13.0”

BB Drop: 38 mm / 1.50” 38 mm / 1.50” 38 mm / 1.50” 38 mm / 1.50”

ISeat Tube Angle (Effective): 74˚ 74˚ 74˚ 74˚

JSeat Tube Angle (Actual): 69.4˚ 69.4˚ 69.4˚ 69.4˚

KSeat Tube Length: 406 mm / 16” 437 mm / 17.2” 488 mm / 19.2” 538 mm / 21.2”

LStandover Height: 769 mm / 30.3” 771 mm / 30.4” 776 mm / 30.5” 781 mm / 30.75”

6// SNIPER user manual

Frame Features //

•Trail Rear Travel: 4.7 inches (120mm) with 165 x 45 stroke shock

•29” Wheel size

•Integrated BOOST 148 x 12 dropouts

•4.76 lbs / 2158 grams = Standard frame w/ alloy lower link and shock

•4.73 lbs / 2144 grams = SL Super Light frame w/ magnesium lower link & shock

•Injection molded top link

•INTERNAL CABLE ROUTING

•Internal Seat Tube Cable Routing for dropper posts

•Monocoque front triangle

•H20 Bottle Fitment

•FLacK GuarD Downtube, Chainstay, and Seatstay protection

•Tapered Head Tube

•Max Bearings and Dedicated Frame Hardware

Component Spec //

•Fork: FOX 34 120 mm with 51 mm Offset, 527.1mm axle to crown length

•Rear Shock: FOX Float DPS 165 x 45, trunnion mount, 20mm x 8mm reducers

•Seat post – 31.6mm

•Headset – Cane Creek, 40, Alloy Cartridge (www.canecreek.com) IS 41 Top, IS

52 Lower. Is = Integrated Top and Lower Headset

•Bottom bracket - PF92

•Rear Axle – BOOST 148 x 12 with hidden lever

•Brake Mount – Post Mount for 160mm rotor

•Crank set - BOOST 148 Compatible - single ring only

•Rear Wheel - BOOST 148 Compatible

sNIPer trail

frame

features /

spec

INTENSE CYCLES // 7

GEOMETRY NOTEs

GEOMETRY TAKEN AT TOP OUT WITH 527.1MM axle to crown LENGTH

AND 51MM FORK OFFSET.

Component spec NOTE

the sniper trail is designed around the use of a single chain

ring only. Use of a double or triple ring set will not allow

proper clearance with the frame.

Warning

NOT INTENDED FOR USE WITH FORKS LARGER THAN 120MM OF TRAVEL.

sNIPer trail

Geometry

BB Drop

C

F

A

B

E

D

G

H

L

K

I

J

SMALL MEDIUM LARGE XLARGE

AWheel Base: 1142 mm / 45” 1168 mm / 46” 1195 mm / 47” 1221 mm / 48”

BTop Tube Length: 584 mm / 23.0” 609 mm / 24.0” 635 mm / 25” 660 mm / 26”

CChain Stay Length: 439 mm / 17.3” 439 mm / 17.3” 439 mm / 17.3” 439 mm / 17.3”

DHead Tube Length: 90 mm / 3.54” 95 mm / 3.7” 105 mm / 4.13” 115 mm / 4.5”

EHead Tube Angle: 66.5˚ 66.5˚ 66.5˚ 66.5˚

F Reach: 421 mm / 16.6” 444.5 mm / 17.5” 468 mm / 18.4” 490 mm / 19.3”

G Stack: 570 mm / 22.45” 575 mm / 22.6” 584 mm / 23” 593 mm / 23.4”

HBB Height: 338 mm / 13.3” 338 mm / 13.3” 338 mm / 13.3” 330 mm / 13.0”

BB Drop 38 mm / 1.50” 38 mm / 1.50” 38 mm / 1.50” 38 mm / 1.50”

ISeat Tube Angle (Effective): 73˚ 73˚ 73˚ 73˚

JSeat Tube Angle (Actual): 68.4˚ 68.4˚ 68.4˚ 68.4˚

KSeat Tube Length: 406 mm / 16” 437 mm / 17.2” 488 mm / 19.2” 538 mm / 21.2”

LStandover Height: 779 mm / 30.7” 781 mm / 30.76” 786 mm / 31” 791 mm / 31.2”

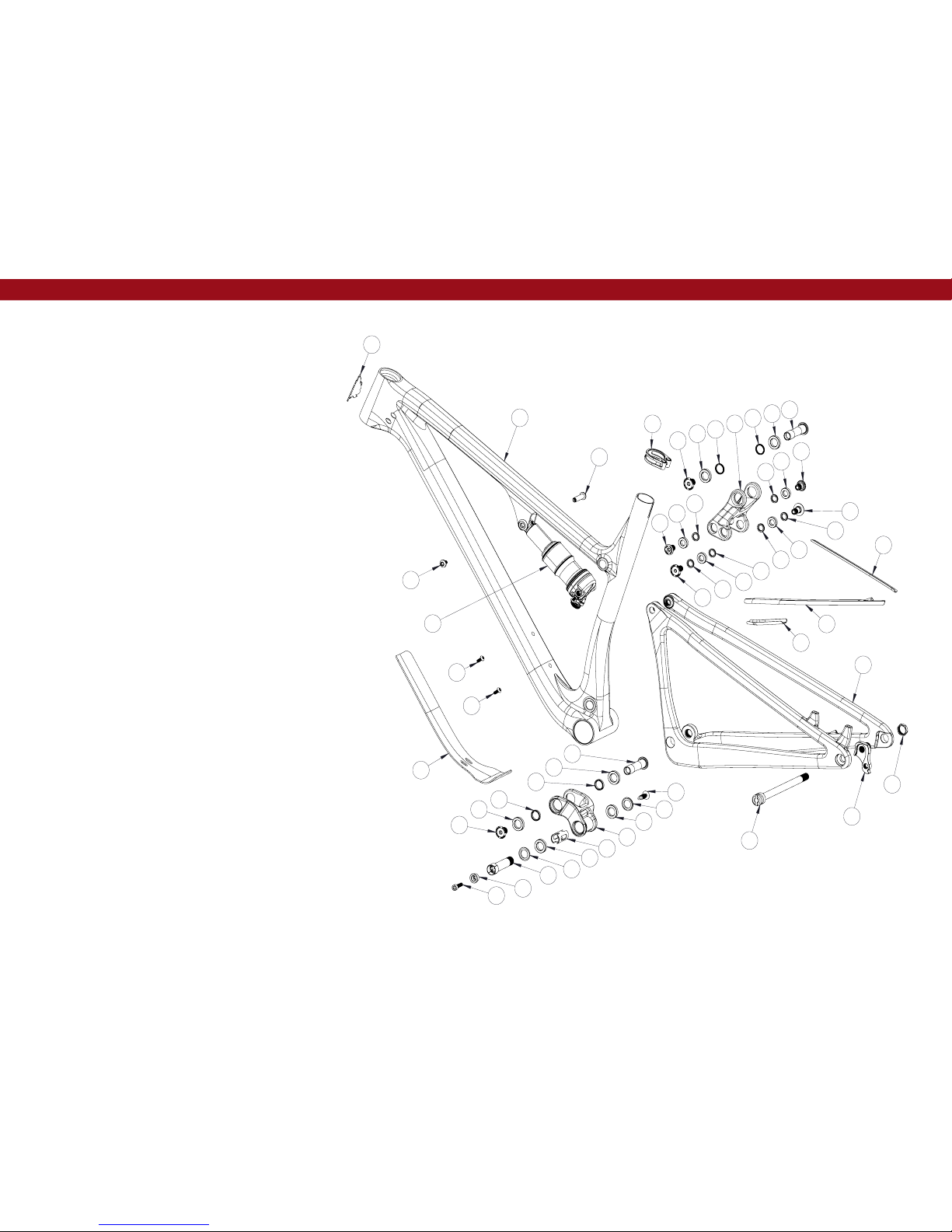

8// SNIPER user manual

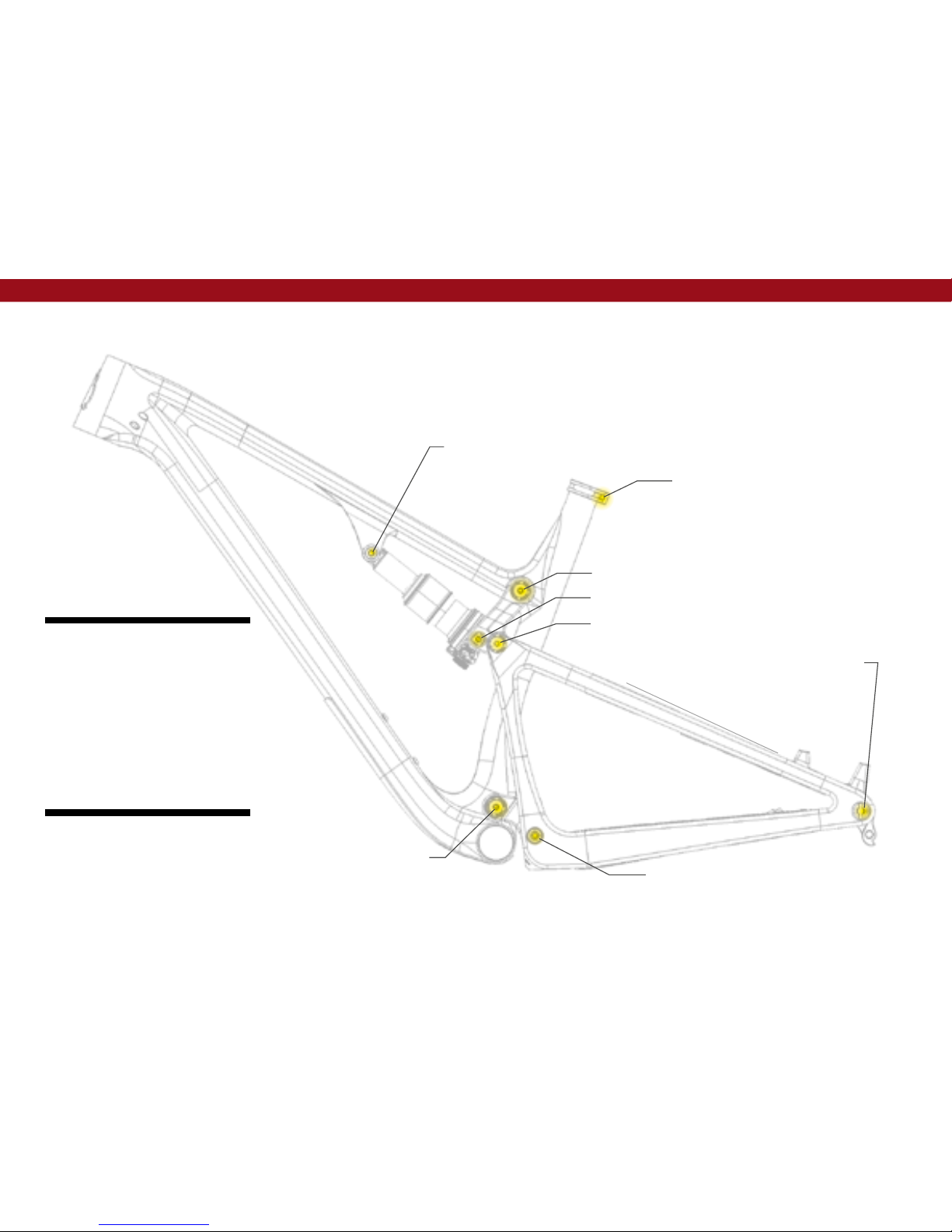

exploded

view and

b.o.m.

29

30

22

12

7

11

94

24

8

6

5

15

32

17

1

10

16

23

2

3

19

20

21

1

23

23

7

10

8

11

13

11

13

11

24

11

923

11

24

12

24

23

19

23

31

14

26

25

27

18

28

INTENSE CYCLES // 9

ITEM

NO. ITEM PART

NUMBER DESCRIPTION QTY. TORQUE SPEC.

1Bearing Cap 130765 Top Link Bearing Cap 2N/A

2Bolt Main Pivot 130791 Bolt Main Pivot

1.5t Expander Blk 17 Nm /

60 in-lbs

3Cone Adjuster 130807 Main Pivot Expander Cone 1N/A

4Top Link 130823 Injection Molded Top Link 1N/A

5Hanger 130826 Forged Derailleur Hanger 1N/A

6Hanger Nut 130827 Rear Derailleur Hanger Nut 111 Nm /

100 in-lbs

7Axle Upper 130828 Top Link Pivot Axle 212 Nm /

106 in-lbs

8Bolt Shoulder 130829 Top Link Upper Pivot Bolt 212 Nm /

106 in-lbs

9Spacer 130830 Top Link Upper Spacer,

19mm OD 15mm ID 2.5mm 2N/A

10 Spacer 130831 Lower Link Spacer

19mm OD x 15mm ID x 4mm 2N/A

11 Spacer 130832 Top Link Lower Spacer

15mm OD x 10mm ID x 2.5mm 6N/A

12 Shock Bolt 130833 Trunnion Shock Bolt 216 Nm /

140 in-lbs

13 Bolt Shoulder 130834 Top Link Lower Pivot Bolt 216 Nm /

140 in-lbs

14 Bearing Spacer 130845 Lower Link Bearing Spacer 1N/A

15 Rear Axle 130846 148 x 12mm Boost

with Hidden Lever 111 Nm /

100 in-lbs

16 Lower Link 130825 Forged Aluminum Lower Link 1N/A

16 Lower Link 130854 Forged Magnesium Lower Link 1N/A

17 Plug 140038 Lower Link Pivot Plug 1N/A

ITEM

NO. ITEM PART

NUMBER DESCRIPTION QTY. TORQUE SPEC.

18 Seat Collar 340343 Bolt-On Seat Clamp 14 Nm /

35.5 in-lbs

19 BHCS

M5 X 12 410010 Bottle Mount Bolt,

Button Head, M5 X 12 26 Nm /

54 in-lbs

20 SHCS

M6 x 22 410009 Cone Adjuster Bolt,

Socket Head, M6 x 22 114 Nm /

125 in-lbs

20 SHCS

M6 x 22 410032 Cone Adjuster Bolt,

Socket Head, M6 x 22 Titanium 114 Nm /

125 in-lbs

21 Shock Bolt,

Male 410056 M6 Thread, Steel 110 Nm /

88 in-lbs

21 Shock Bolt,

Male 410066 M6 Thread, 7075-T6 110 Nm /

88 in-lbs

22 Shock Bolt,

Female 410060 8mm OD x 31mm

Long Female Steel 110 Nm /

88 in-lbs

22 Shock Bolt,

Female 410067 8mm OD x 31mm

Long Female 7075-T6 110 Nm /

88 in-lbs

23 Bearing 6802 430008 15 x 24 x 5 2RS,

MAX Radial Bearing 6N/A

24 Bearing 6800 430011 10 x 19 x 5 2RS,

MAX Radial Bearing 4N/A

25 Guard Flack CS 500294 Flack Guard Sniper Chainstay Top 1N/A

26 Guard Flack Ststy 500295 Flack Guard Sniper Seatstay 1N/A

27 Guard Flack CS 500296 Flack Guard Sniper

Chainstay Bottom 1N/A

28 Guard Flack DT 500297 Flack Guard Sniper Downtube 1N/A

29 Head Badge 500335 Head Badge Flame Logo 1N/A

30 Rear Shock Shock 165 x 40 XC, 165 x 45 Trail 1N/A

31 Front Triangle Carbon, 4 Sizes 1N/A

32 Rear Triangle Carbon, 1 Size 1N/A

(ST)

(ST)

(ST)

(ST)

(SL)

(SL)

(SL)

(SL)

10 // SNIPER user manual

Assembly

Tools needed

•HIGH GRADE WATERPROOF GREASE

•5MM HEX WRENCH

•6MM HEX WRENCH

•8MM HEX WRENCH

•TORQUE WRENCH

•5MM HEX BIT

•8MM HEX BIT

•19MM SOCKET

pro tips

•BE SURE TO APPLY A THIN COAT OF GREASE TO ALL PIVOT AXLES AND REAR AXLE.

THIS WILL REDUCE THE CHANCES OF CORROSION DUE TO MOISTURE AND PREVENT ANY

POSSIBLE CREAKS.

•AFTER THE FIRST FEW RIDES AND ALL THE COMPONENTS ARE BROKEN IN AND SETTLED

INTO PLACE, GO THROUGH AND RE TORQUE ALL PIVOT AXLES AND FASTENERS. AFTER

THIS FIRST ADJUSTMENT, YOU WILL BE READY TO RIP FOR THE LONG HAUL.

•USE GREASE ON ANY METAL TO CARBON INTERFACE, INCLUDING BB AND HEADSET.

PREFACE //

Service and maintenance on an Intense bicycle requires special tools, abilities and

knowledge of working on bicycles. It is always recommended to use an authorized

Intense dealer for service and maintenance. Always wear eye protection. It is critical

to use the proper tools, loctite, grease and torque specs during assembly. Failure to

follow these instructions may result in serious bodily injury or death.

INTENSE CYCLES // 1 1

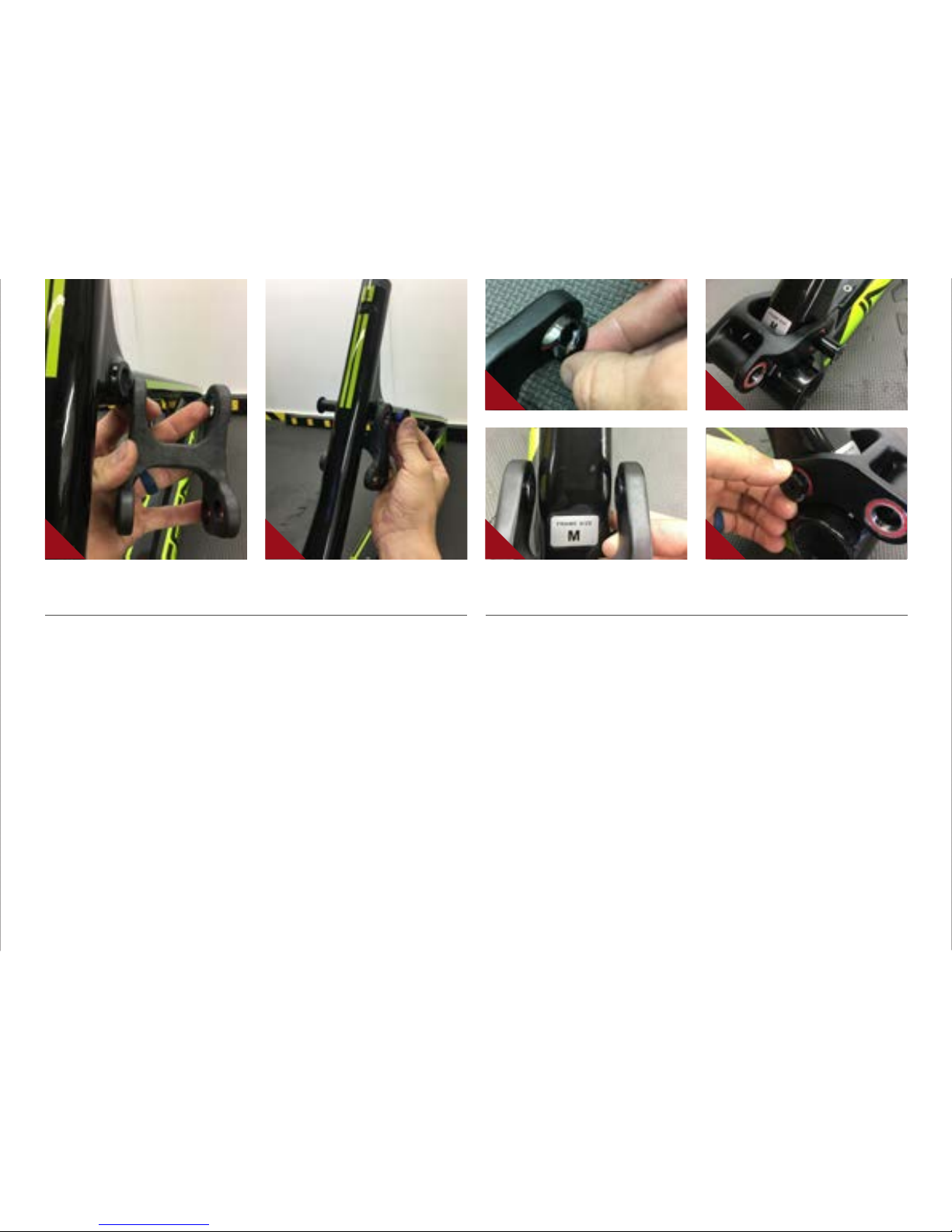

1

53

642

CONNECTING TOP LINK TO FRONT TRIANGLE //

AHolding top link (#130823) as oriented

in the above picture; hold upper link

pivot bolt spacers (#130830) with your

fingertips against the inside of the bearing

races (IMAGE #1).

BMatch upper link to pivot point on top

tube making sure the spacers don’t fall out.

CUsing upper pivot axle (#130828), insert

through non-drive side of top link bearing

and push through to drive side bearing

(IMAGE #2).

DThread shoulder bolt (#130829) by

hand until snug. We will return with a

6mm hex key and a 5mm hex key bit on

a torque wrench after completed frame

assembly.

CONNECTING THE LOWER LINK TO FRONT TRIANGLE //

AHolding the lower link (#130854), use

a small dab of grease on the lower link

spacers (#130831) to help keep them

against the inside of the bearing races

for easier installation (IMAGE #3).

BFrom the back of the seat tube, slide

the lower link over and match lower link

to pivot point on front triangle, making

sure the spacers don’t fall out (IMAGE #4).

CUsing the pivot axle (#130828), insert

through drive side of lower link bearing

and push through to drive side bearing

(IMAGE #5).

DThread shoulder bolt (#130829) by

hand until snug. We will return with a

6mm hex key and 5mm hex bit on a

torque wrench after completed frame

assembly (IMAGE #6).

12 // SNIPER user manual

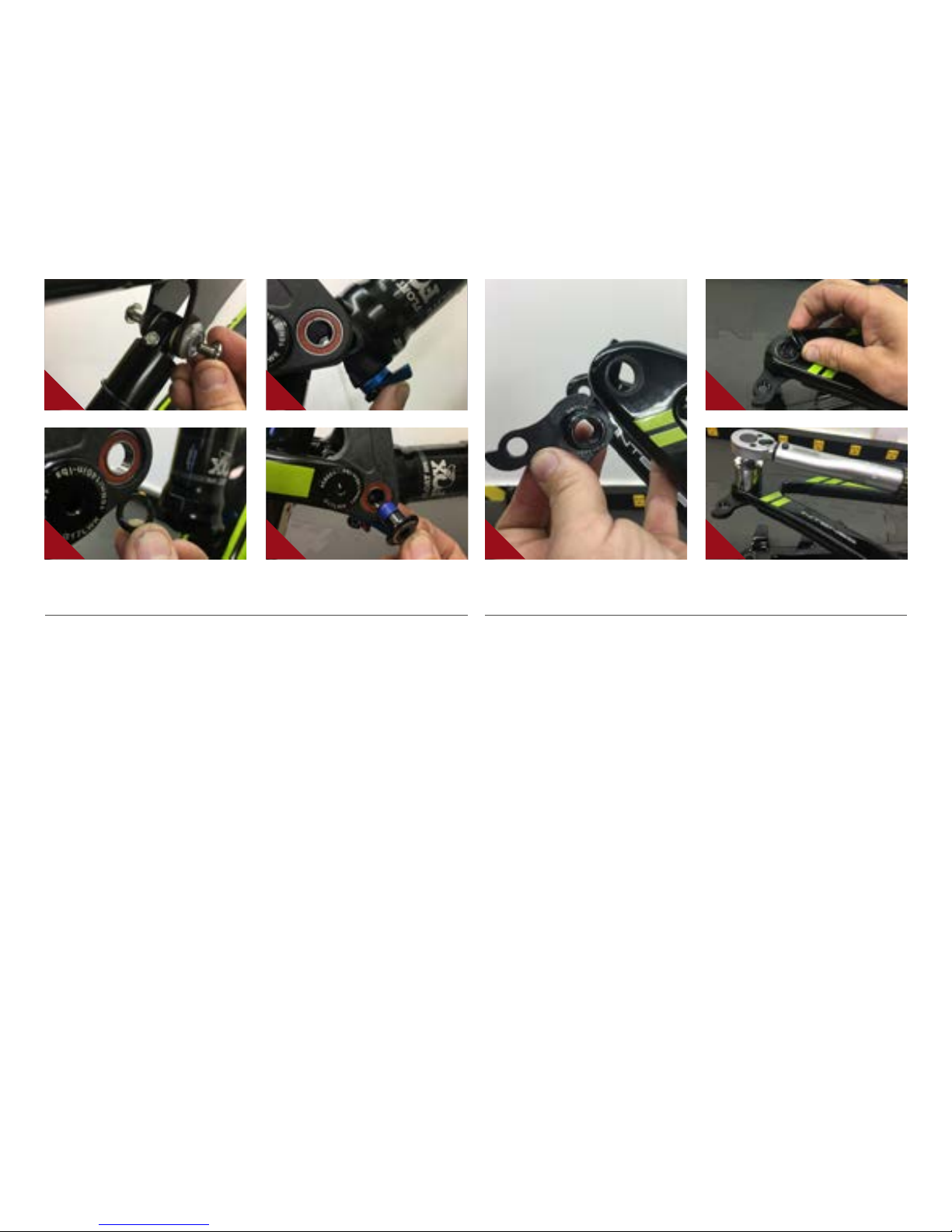

8

711 139

12 1410

CONNECTING REAR TRIANGLE TO LOWER LINK //

APut a small dab of grease on the

outside bearing race as well as on

the contacting surface of the bearing

cap (#130765). This will help hold the

bearing caps in place during installation

(IMAGE #7).

BSlide rear triangle over the lower link

and line up the pivot point over the

bearing caps (IMAGE #8).

CInsert greased main pivot bolt

(#130791) into non-drive side of lower

link. Insert 8mm hex wrench and tighten

till lightly snug. We will return with a

torque wrench after completed frame

assembly (IMAGE #9).

DInsert push rivet (#140038) on the

drive side in the pivot axle (IMAGE #10).

CONNECTING REAR TRIANGLE TO TOP LINK //

APut a small dab of grease on the

outside/inside bearing races as well as

on the contacting surface of the bearing

spacers (#130832). Be sure to place a

greased bearing spacer on both the

outside and inside bearing faces. You

will use a total of 4 spacers for this

step (IMAGE #11 and #12).

BSwing the rear triangle up to line up

pivot point with upper link bearing cap

(IMAGE #13).

CInsert clevis bolts (#130834) into

drive side and non-drive side seat stays.

Tighten by hand until snug. We will come

back with 5mm hex torque wrench after

complete frame assembly (IMAGE #14).

INTENSE CYCLES // 1 3

INSTALLING REAR SHOCK //

AHolding the shock with the shaft and

eyelet pointing towards the front of the

bike, align shock eyelet with shock tab.

Insert shock shoulder bolt (#410067) from

non-drive side and thread in shock shoulder

bolt (#410066) on drive side (IMAGE #15).

Tighten until snug by hand and we will

return with a 5mm hex key and torque

wrench after completed frame assembly.

BPut a small dab of grease on the bearing

spacer (#130832) and place on inside

facing bearing race. You will be using 2

bearing spacers for this step. Then gently

pivot shock trunnion mount tabs into place

and align (IMAGE #16 and #17).

CInsert and thread in trunnion bolt

(#130833) on drive side and non-drive

side and tighten by hand until snug. We

will return with a 5mm hex key torque

wrench after completed frame assembly

(IMAGE #18).

17 2015

19

18 2116

INSTALLING DERAILLEUR HANGER //

AApply a thin layer of grease to the

derailleur hanger (#130826) shank and

install into the keyed insert on the drive

side of the rear triangle (IMAGE #19).

BInstall derailleur hanger nut (#130827)

using a 19mm socket, torque to 11 nm /

100 in-lbs (IMAGE #20 and #21).

14 // SNIPER user manual

TOP LINK TORQUE PROCEDURE //

A First step here is to tighten the top link

pivot axle (#130828 & #130829). Using

a 6mm hex wrench and a 5mm hex bit

on a torque wrench, tighten to 12 nm /

106 in-lbs (IMAGE #24).

BNext we will tighten the clevis bolt

(#130834). Using a 5mm hex bit on a

torque wrench, tighten to 16 nm / 140

in-lbs (IMAGE #25).

22 2423 25

SHOCK TORQUE PROCEDURE //

AUsing a 5mm hex key and a 5mm hex

bit on a torque wrench, tighten shock

bolt (#410066 &410067) to 10 nm /

88 in-lbs (IMAGE #22).

BUsing a 5mm hex bit on a torque

wrench, tighten trunnion bolts (#130833)

to 16 nm / 140 in-lbs (IMAGE #23).

INTENSE CYCLES // 1 5

27

26 29

28

LOWER LINK TORQUE PROCEDURE PT.1 //

A Using a 8mm hex bit on a torque

wrench, tighten main pivot bolt (#130791)

to 7 nm / 60 in-lbs (IMAGE #26).

BNext install the cone spacer (#130807)

with the M6x22mm bolt (#410032) and

tighten until snug by hand (IMAGE #27).

CUsing a 5mm hex bit on a torque

wrench, tighten to 14 nm / 125 in-lbs

(IMAGE #28).

LOWER LINK TORQUE PROCEDURE PT.2 //

A Using a 6mm hex wrench and a 5mm hex bit on a torque wrench, tighten the pivot axle

& shoulder bolt (#130828 & #130829) to 12 nm / 106 in-lbs (IMAGE #29).

16 // SNIPER user manual

31

30 33 34

32

REAR AXLE ASSEMBLY //

AInsert QR 148x12mm rear axle

(#130846) into axle opening on non-drive

side (IMAGE #30).

BAlign and start the axle thread. (IMAGE

#31) then, grab the tips of the silver bar

going through the rear axle, pull out and

push over to one side (IMAGE #32).

CTighten axle using the integrated lever

to approximately 10 nm.

DTip lever back over until parallel with axle and push back in until flush (IMAGE #33

an d #34).

INTENSE CYCLES // 1 7

torque

Achieving proper torque is vital to

ensuring the safe performance and

function of the SNIPER frame. Failure

to do so could result in sub-optimal

performance of your frame as well as

premature wear and tear of individual

parts.

additional reference

In addition to this chart, all torque

values are laser etched onto

corresponding hardware for your

reference.

torque chart

12 Nm / 106 in/lbs

4 Nm / 35.5 in/lbs

16 Nm / 140 in/lbs

16 Nm / 140 in/lbs

12 Nm / 106 in/lbs

10 Nm / 88 in/lbs

M8 HEX 7 Nm / 60 in/lbs

M5 HEX 14 Nm / 125 in/lbs

Derailleur Cap: 11 Nm / 100 in/lbs

Axle (non-drive side): 10 Nm / 88 in/lbs

seatpost

Before insertion, liberally coat the seat post with carbon paste and gently slide

into the seat tube. With a minimum seat post insertion of 4", tighten seat post

clamp to 4nm. (Over tightening the seat post clamp will inhibit the movement of

the seat post and potentially damage seat post and/or seat tube.

18 // SNIPER user manual

set up

4”

seatpost

PREFACE //

We are almost ready to rip. Just a few

more checkpoints and adjustments

to ensure the performance and ride

characteristics of the Sniper is optimised

for you.

Tools needed

•shock pump

•small ruler or measuring device

•Intense Carbon Paste

•TORQUE WRENCH

recommendation

When setting up the suspension sag, ask a fellow ripper to help. but if alone,

using a wall to lean your shoulder against will do just fine.

INTENSE CYCLES // 1 9

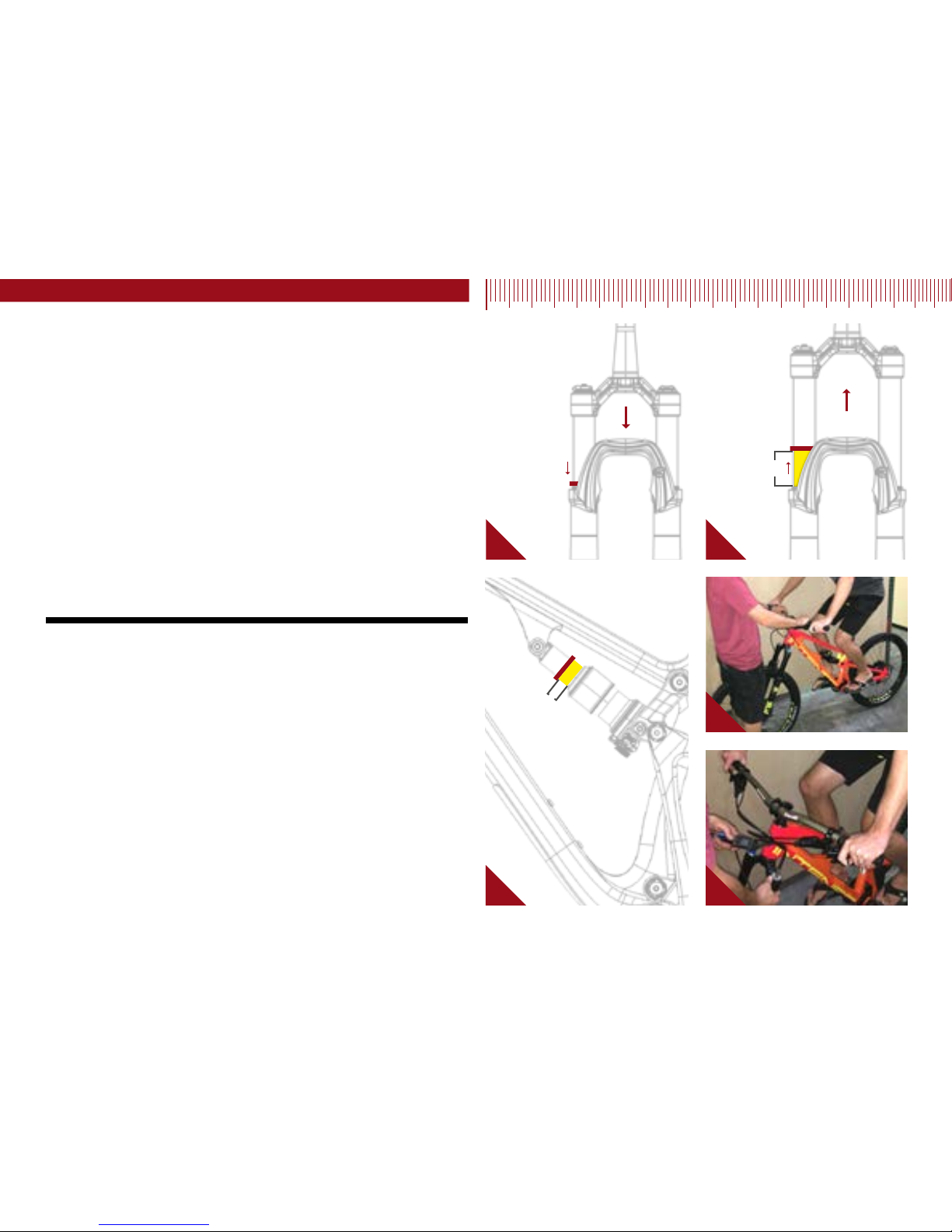

setting the sag

1. Remove fork and shock air caps and be sure you have a shock

pump and a small ruler or measuring device handy.

2. Go ahead and hop on the bike. Be sure to place all your weight on the

seat with the dropper in the up position and both hands on the grips.

3. Give the bike 5-6 moderate bounces and sit back down on the saddle.

4. Now have your friend slide both the rear shock and the front fork

o-rings down against the seal lip of the damper bodys (IMAGE #1).

5. Step off the bike nice and easy. Be sure to not compress the suspension

after the o-rings have been set.

Pro Tip

Here is where having a friend helps. Have them straddle the front wheel and pull

the handle bars in a upward direction as to not allow the suspension to compress

as you get off (image #4).

6. Using your measuring device, measure the gap between the suspension

seal lip and the o-ring. Using the chart on the following page will tell you

if you need more air pressure or less air pressure (IMAGES #2, #3).

7. Adjust air pressure with your shock pump accordingly (IMAGE #5).

8. Re-visit steps 2-6 until your desired sag measurement have been reached.

9. Install valve caps.

10. Go ride your bike!

15% - 25%

While suspension

is compressed on

fork or rear shock,

slide o-ring down

against the seal lip

of damper body.

Release compression.

Measure gap from

o-ring to seal lip.

Sniper XC = 12mm

Sniper Trail = 13.5mm

4

21

3 5

cm 1 2 3 4 5 6 7 8 9 10

Sniper XC

Travel 100mm

Shock StRoke 40mm

Shock Sag 30% when sitting on the bike

Fork Sag 15-25% when sitting on the bike

SHOCK: Float DPS Performance Elite

SHOCK: Float DPS Factory

RIDER WEIGHT(LBS/KGS) SPRING (PSI) Rebound (Clicks Out)

100 lbs/ 45 kgs 100 11

110 lbs/ 50 kgs 110 10

120 lbs/ 54 kgs 120 9

130 lbs/ 59 kgs 130 9

140 lbs/ 63.5 kgs 140 9

150 LBS / 68 KGS 150 8

160 LBS / 73 KGS 160 8

170 LBS / 77 KGS 170 8

180 LBS / 82 KGS 180 7

190 LBS / 86 KGS 190 7

200 LBS / 91 KGS 200 7

210 LBS / 95 KGS 210 6

220 LBS / 100 KGS 220 6

230 LBS / 104 KGS 230 5

240 LBS / 109 KGS 240 5

250 LBS / 113 KGS 250 4

260 LBS / 118 KGS 260 4

270 LBS / 122 KGS 270 3

280 LBS / 127 KGS 280 3

290 LBS / 131.5 KGS 290 2

300 LBS / 136 KGS 300 2

20 // SNIPER user manual

set up and tune

proper set up and tuning can vary

from shock to shock. Please

consult the Fox manual included

with your bike for complete

information about set up, tuning

and general maintenance or visit

www.foxracingshox.com

The PSI settings in the following

chart are suggestions to quickly set

baseline sag. be sure the end of your

sag set up results in 30% of rear

suspension sag.

shock setup

fox float dps

XC 165 x 40mm

trail 165 x 45mm

This manual suits for next models

1

Table of contents

Other INTENSEcycles Bicycle manuals

INTENSEcycles

INTENSEcycles M9 PRO User manual

INTENSEcycles

INTENSEcycles Spider 275 User manual

INTENSEcycles

INTENSEcycles 951 Series User manual

INTENSEcycles

INTENSEcycles TAZER User manual

INTENSEcycles

INTENSEcycles carbine 275 User manual

INTENSEcycles

INTENSEcycles PRIMER 29 User manual

INTENSEcycles

INTENSEcycles Recluse User manual

INTENSEcycles

INTENSEcycles PRIMER 29 User manual

INTENSEcycles

INTENSEcycles ACV User manual

INTENSEcycles

INTENSEcycles ACV User manual