INTENSEcycles TRACER CARBON User manual

user manual TRACER CARBON

introduction / registration 2

frame features / component spec 4

Geometry 5

exploded view and b.o.m. 6

Assembly 8

torque chart 13

setup 14

maintenance 18

AT INTENSE, WE HAVE ONE GOAL - TO PROVIDE THE RIDE OF YOUR LIFE //

Our team of designers, engineers and product experts are focused on one thing every

day: your experience on the bike. We build bikes that are as thrilling to look at as they

are to ride, and we build them for the select few of you who understand the difference

and refuse to settle for anything else.

From the early days of Intense, when founder Jeff Steber worked alone in his garage to

today, where a crew of talented people work in a Temecula, CA factory, Intense has been

a brand built on passion by forward thinkers who, even today, love nothing more than

to throw a leg over a sweet bike and head out for a rip. We’re so glad you’ve joined us.

Welcome to Intense, enjoy your experience.

THE TRACER CARBON //

For the hardcore Enduro rider, the Tracer Carbon is built with a short rear end for

quick maneuvers and a long front end with a slack, 65.5 degree head angle to keep

things stable. 165mm of rear wheel travel on a stable pedaling platform gets you up

the hills easily and still allows for big hits on the way down. No corners were cut in

designing the easily serviceable pivots and lightweight carbon chassis but who needs

to cut corners when you’re on the fastest rig on the trail.

registration

WWW.INTENSECYCLES.COM/WARRANTY-CARD/

contact customer service

cs@intensecycles.com

951-296-9596

Welcome to

the family

2// tracer carbon user manual INTENSE CYCLES // 3

4// tracer carbon user manual INTENSE CYCLES // 5

frame

features /

spec

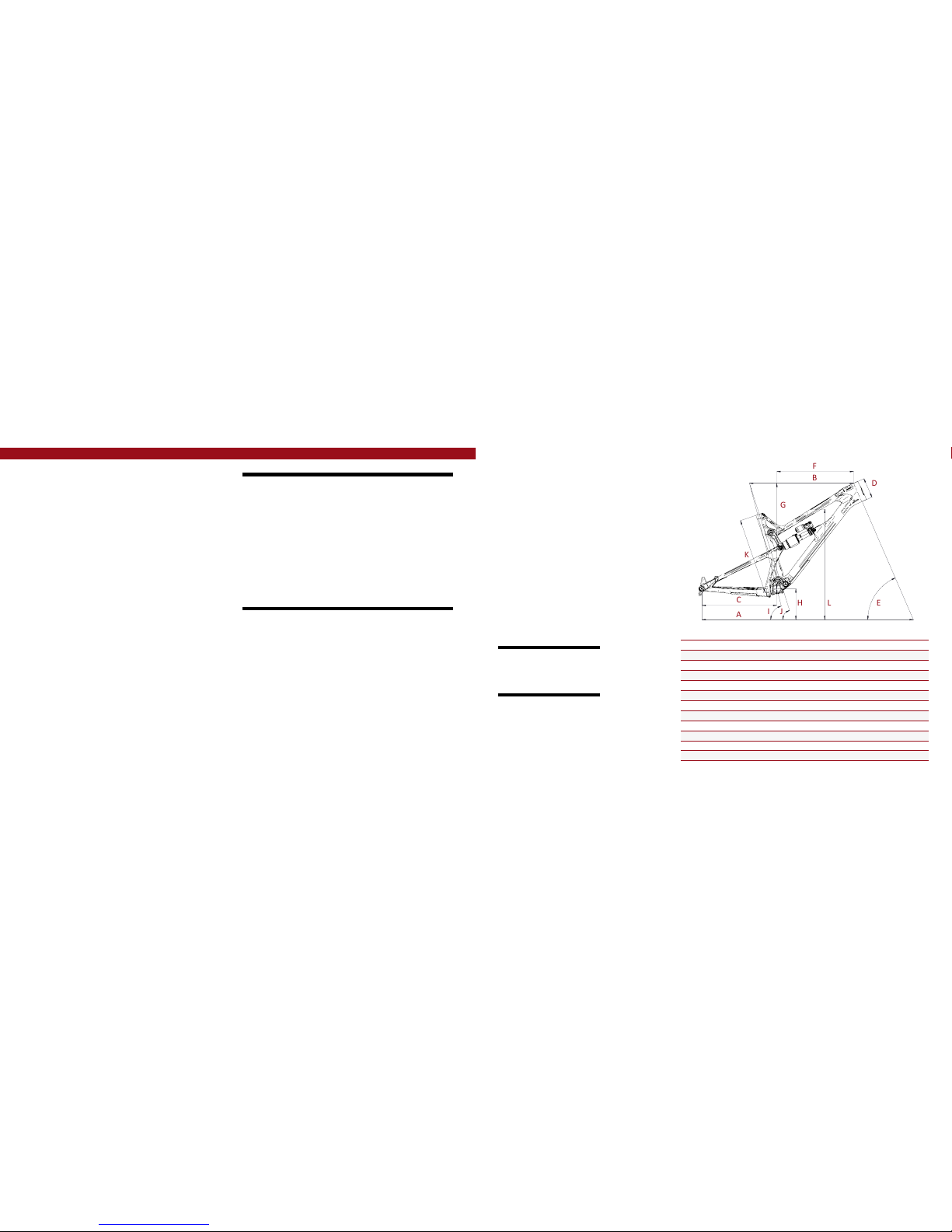

Geometry

A

B

C

F

E

D

G

H

L

K

I

J

GEOMETRY NOTEs

GEOMETRY TAKEN AT TOP OUT WITH 552MM

FORK LENGTH AND 42MM FORK OFFSET.

Component spec NOTE

the Tracer carbon is designed around

the use of a single chain ring. Use of a

double or triple ring set will not allow

proper clearance with the frame.

Frame Features //

•Travel: 6.5" (165mm)

•27.5” Wheel size

•Integrated BOOST 148 x 12 dropouts

•6.15 lbs / 2,790 grams = Standard frame w/ alloy link, no shock

•5.7 lbs / 2,568 grams = SL Super Light frame w/ carbon link, no shock

•INTERNAL CABLE ROUTING

•Internal Seat Tube Cable Routing for dropper posts

•Monocoque front triangle

•FLack GuaRD Downtube and Chainstay protection

•Tapered Head Tube

•Angular Contact/Collet Bearing System with replaceable Grease Zerks

Component Spec //

•Fork – 1.5” tapered steer, 165mm Travel, 552mm lower leg length, 42mm offset

•Shock – 216mm x 63.5mm (8.5” x 2.5”), 22mm x 6mm and 22mm x 8mm reducers

•Seat post – 31.6mm

•Headset – Cane Creek, 40, Alloy Cartridge (www.canecreek.com)

•Bottom bracket - PF92

•Rear Axle – BOOST 148 x 12 T/A

•Brake Mount – post mount - direct 180mm

•Crank set - BOOST 148 Compatible - single ring only

•Rear Wheel - BOOST 148 Compatible

SMALL MEDIUM LARGE XLARGE

AWheel Base: 1154 mm/ 45.4” 1181 mm/ 46.5” 1207 mm/ 47.5” 1235 mm/ 48.6”

BTop Tube Length: 571 mm/ 22.5” 597 mm/ 23.5” 622 mm/ 24.5” 649 mm/ 25.5”

CChain Stay Length: 432 mm/ 17” 432 mm/ 17” 432 mm/ 17” 432 mm/ 17”

DHead Tube Length: 102 mm/ 4” 115 mm/ 4.5” 119 mm/ 4.7” 130 mm/ 5.1”

EHead Tube Angle: 65.5˚ 65.5˚ 65.5˚ 65.5˚

F Reach: 414 mm/ 16.3” 436 mm/ 17.2” 460 mm/ 18.1” 483 mm/ 19”

G Stack: 589 mm/ 23.2” 600 mm / 23.6” 604 mm/ 23.8” 614 mm/ 24.2”

HBB Height: 343 mm/ 13.5” 343 mm/ 13.5” 343 mm/ 13.5” 343 mm/ 13.5”

ISeat Tube Angle (Effective): 75˚ 75˚ 75˚ 75˚

JSeat Tube Angle (Actual): 71˚ 71˚ 71˚ 71˚

KSeat Tube Length: 396 mm/ 15.6” 434 mm/ 17” 459 mm/ 18” 485 mm/ 19”

LStandover Height: 795 mm/ 31.3” 801 mm/ 31.6” 805 mm/ 31.7” 813 mm/ 32”

6// tracer carbon user manual INTENSE CYCLES // 7

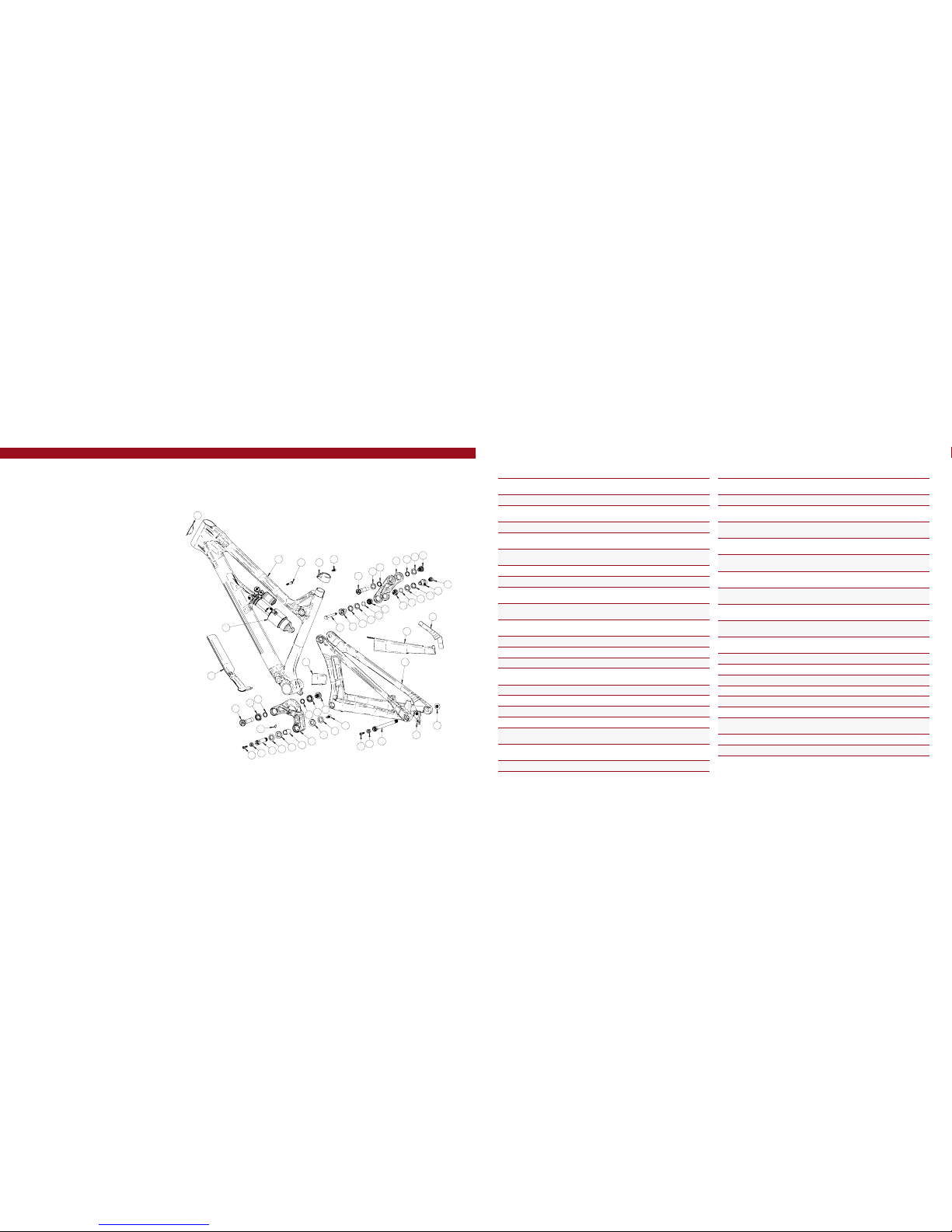

exploded view

and b.o.m.

36

38

22

29

5

29 6

39

33

10

1

8

3

7

25 16

4

28

4

21

28

27

37

9

34

24

29

3

29

31

13

19

7

17

14

20

12

22

15

30

7

7

30

11

26

23

12

18 16

25

2

32

ITEM

NO. ITEM PART

NUMBER DESCRIPTION QTY. TORQUE

SPEC.

1Rear Axle 130757 Axle 148 x 12 Boost 111 Nm /

100 in-lbs

2Bearing Spacer 130758 Lower Link Bearing Spacer 1N/A

3Bearing Cap

24mm OD 130765 Top Link Bearing Spacer

(Lower) 2N/A

4Bearing Cap 130778 Lower Link Bearing Cap 2N/A

5Axle Upper 130780 Top Link Pivot Axle

(U p p e r) 120 Nm /

175 in-lbs

6Bolt Shoulder 130785 Top Link Pivot Bolt 120 Nm /

175 in-lbs

7Spacer 130789 Bearing Spacer 4N/A

8Hanger 130790 Derailleur Hanger Forged 1N/A

9Bolt Main Pivot 130791 Lower Link Expander Bolt 17 Nm /

60 in-lbs

10 Hanger Bolt 130798 Derailleur Hanger Bolt 111 Nm /

100 in-lbs

11 Axle Lower 130800 Lower Link Axle 120 Nm /

175 in-lbs

12 Link Spacer 130801 Upper Link Spacer 2N/A

13 D-Lock Reducer 130803 Non-Drive Side Reducer 1N/A

14 D-Lock Reducer 130805 Drive Side Reducer 1N /A

15 Bolt Shoulder 130806 Lower Link Pivot Bolt 120 Nm /

175 in-lbs

16 Cone Adjuster 130807 Cone Adjuster Blk, 8.3 mm Height 2N/A

17 Top Link Standard 130811 Forged Top Link 1N /A

17 Top Link SL 130809 Carbon Top Link 1N /A

18 Lower Link 130812 Forged Lower Link 1N/A

19 Shock Bolt 130813 D-Lock Bolt 116 Nm /

140 in-lbs

20 Shock Bolt Nut 130814 D-Lock Nut 116 Nm /

140 in-lbs

21 Push Rivet 140038 Lower Link Push Rivet SR-0817BK 1N /A

ITEM

NO. ITEM PART

NUMBER DESCRIPTION QTY. TORQUE

SPEC.

22 O-Ring 140044 Upper LInk O-Ring

13.8 mm ID x 2.4 mm Width 2N /A

23 Seat Clamp 340342 Tracer Carbon Seat Clamp 1N /A

24 Zerk Fitting

M6 x 1.0 401011 M6 x 1.0 15 Nm /

40 in-lbs

25 SHCS M6 x 22 410009 Cone Adjuster Bolt,

Socket Head, M6 x 22 214 Nm /

125 in-lbs

25 SHCS M6 x 22 410032 Cone Adjuster Bolt,

Socket Head, M6 x 22 Titanium 214 Nm /

125 in-lbs

26 SHCS M6 x 18 410048 Seat Clamp Bolt,

Socket Head, M6 x 18 114 Nm /

125 in-lbs

27 SHCS M6 x 40 410053 Front Shock Bolt,

Socket Head, M6 x 40 17 Nm /

60 in-lbs

27 SHCS M6 x 40 410050 Front Shock Bolt,

Socket Head, M6 x 40 Titanium 17 Nm /

60 in-lbs

28 Bearing 7902 430007 15 x 28 x 7 2RS

MAX Angular Contact Bearing 2N /A

29 Bearing 6802 430008 15 x 24 x 5 2RS

MAX Radial Bearing 4N/A

30 Bearing 6902 430009 15 x 28 x 7 2RS

MAX Radial Bearing 2N/A

31 Guard Flack DT 500269 Flack Guard DT 1N/A

32 Guard Flack CS 500270 Flack Guard Chainstay 1N /A

33 Guard Flack Ststy 500271 Flack Guard Seat Stay 1N/A

34 Protector Chainstay 500272 Protector Chainstay 1N /A

35 Decal 500300 Decal California Bear 1N/A

36 Head Badge 500335 Head Badge Flame Logo 1N /A

37 Rear Shock 8.5in x 2.5in

(215.9mm x 63.5mm) 1N/A

38 Front Triangle Carbon - 4 Sizes 1N/A

39 Rear Triangle Carbon - 1 Size 1N/A

(ST)

(ST)

(ST)

(SL)

(SL)

(SL)

8// tracer carbon user manual INTENSE CYCLES // 9

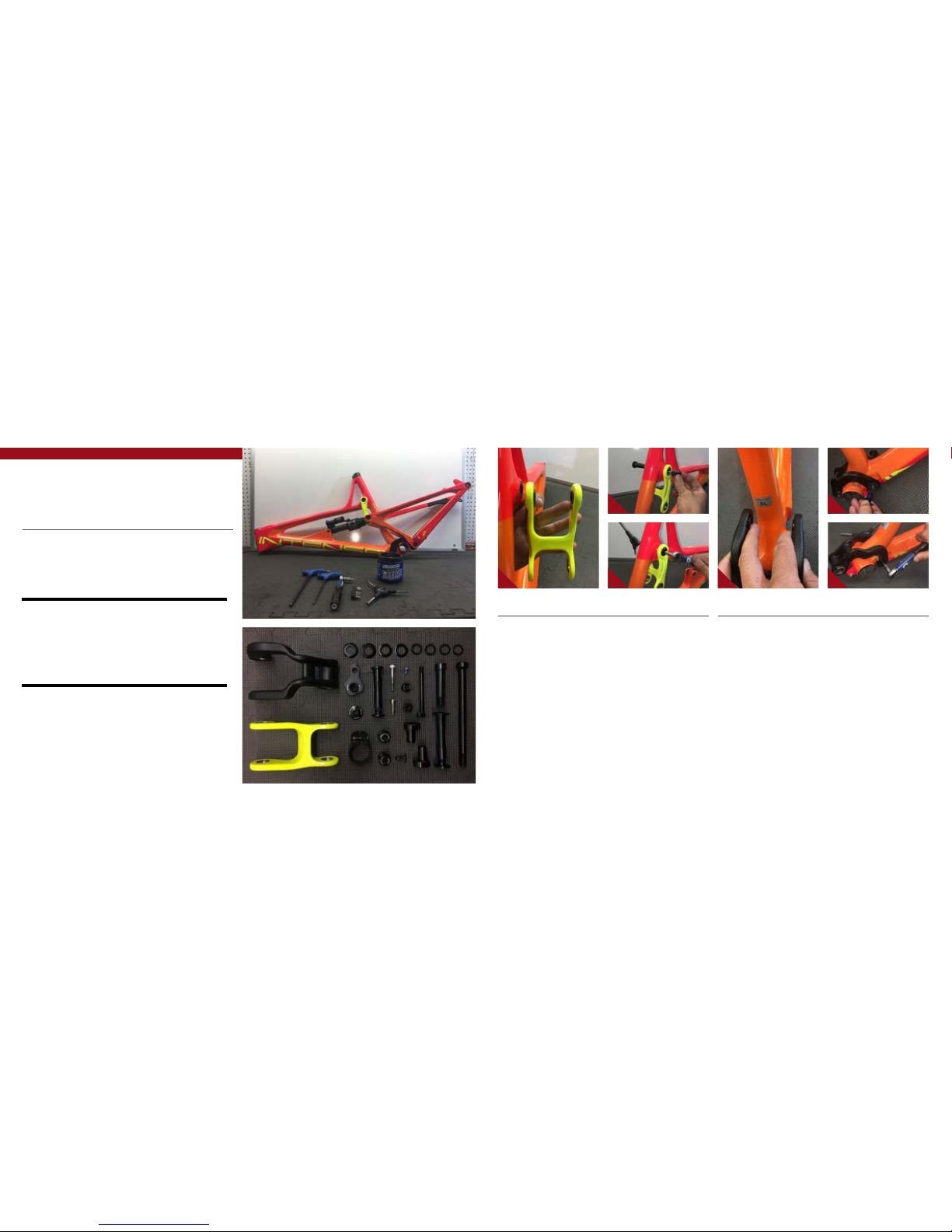

Assembly

Tools needed

•High Grade, waterproof grease (Maxima Waterproof Grease recommended)

•Blue Loctite®#243

•5mm HEX wrench x2

•6mm hex wrench

•8mm HEX wrench

•torque wrench

Recommendation

•APPLY A THIN COAT OF GREASE TO ALL PIVOT AXLES AND REAR AXLE to REDUCE THE

CHANCE OF CORROSION DUE TO MOISURE AND PREVENT POSSIBLE CREAKS.

•AFTER THE FIRST FEW RIDES THE COMPONENTS Are BROKEN IN AND SETTLED INTO

PLACE, GO THROUGH AND RE TORQUE ALL PIVOT AXLES. AFTER THIS FIRST ADJUSTMENT,

YOU WILL BE READY TO RIP FOR THE LONG HAUL.

•USE GREASE IN ANY ALLOY TO CARBON INTERFACE, INCLUDING BB AND HEADSET.

PR E FA C E //

Service and maintenance on an Intense bicycle requires special tools, abilities and

knowledge of working on bicycles. It is always recommended to use an authorized

Intense dealer for service and maintenance. Always wear eye protection. It is critical

to use the proper tools, loctite, grease and torque specs during assembly. Failure to

follow these instructions may result in serious bodily injury or death.

2 5

3 6

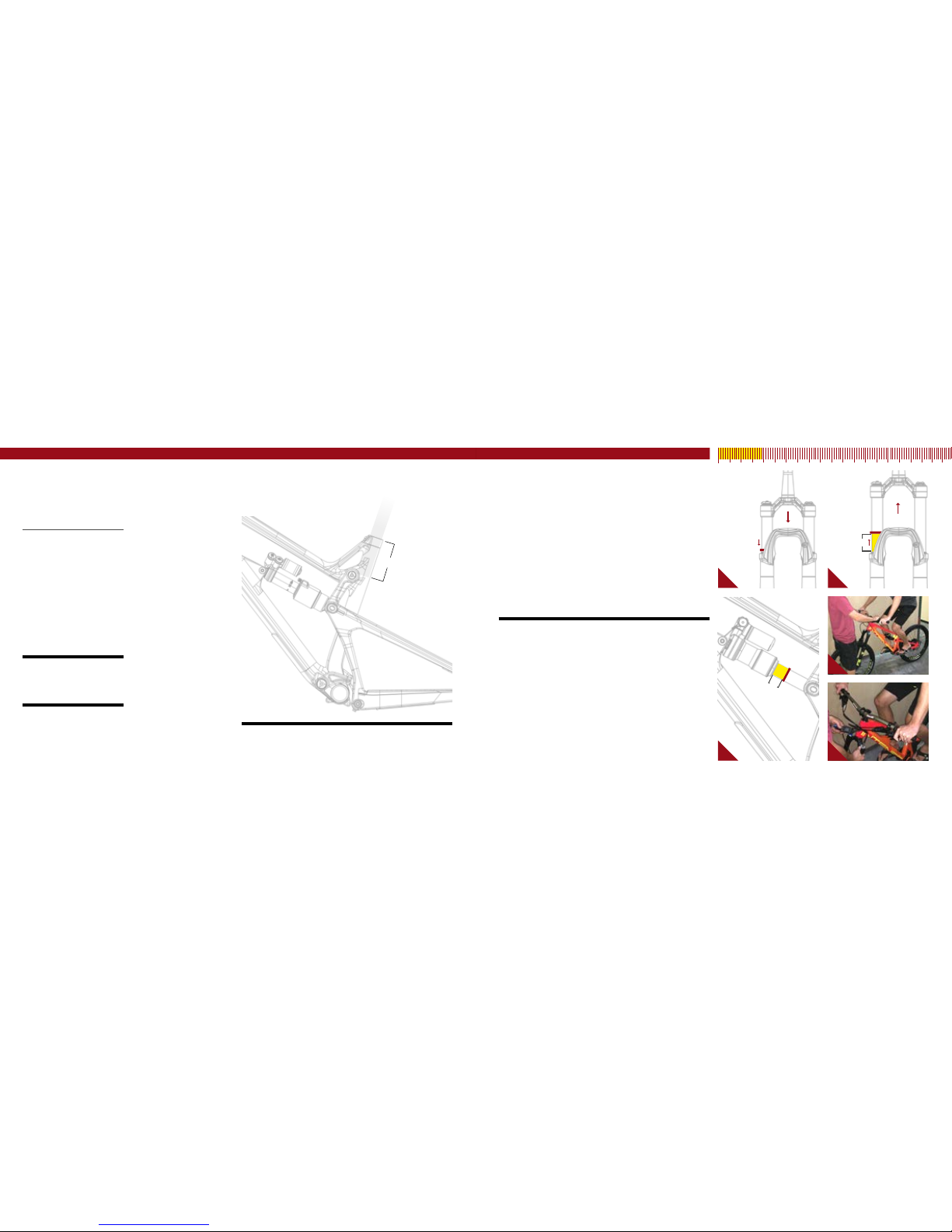

CONNECTING TOP LINK TO FRONT TRIANGLE //

AHolding top link (#130809) as oriented

in the above picture, with your fingertips,

hold upper link pivot bolt spacers

(#130789) against the inside of the

bearing races (IMAGE #1).

BMatch upper link to pivot point on the

top tube making sure the spacers do

not fall out.

CUsing upper pivot axle (#130780),

insert through non-drive side of top link

bearing and push through to drive side

bearing (IMAGE #2).

DThread shoulder bolt (#130785) using

5mm HEX wrench. Holding 5MM wrench

on non-drive side and 5MM torque wrench

on shoulder bolt, torque the assembly to

20 NM / 175 in/lbs (IMAGE #3).

CONNECTING BOX LINK TO FRONT TRIANGLE //

AHolding the lower link (#130812)

behind the seat tube, use your fingertips

to hold lower link spacers (#130789)

against the inside of the bearing races

(IMA G E #4).

BSlide over and match lower link to

pivot point on down tube making sure

the spacers do not fall out (IMAGE #4).

CUsing lower link pivot axle (#130800),

insert through non-drive side of lower

link bearing and push through to drive

side bearing (IMAGE #5).

DThread shoulder bolt (#130806) using

5mm HEX wrench. Holding 5MM wrench

on non-drive side and 5MM torque wrench

on shoulder bolt, torque the assembly to

20 NM / 175 in/lbs (IMAGE #6).

1 4

10 // tracer carbon user manual INTENSE CYCLES // 1 1

INSTALLING REAR SHOCK //

AUsing rear shock with the reservoir

facing up, match the body and reservoir

with the front triangle shock tabs. Insert

the M6 x 40MM shock bolt through the

assembly and torque down to 14 NM /

125 in/lbs (IMAGE #18).

BMatch the other end of the shock with

the D-Lock reducers and the link spacers

on the top link. Insert the keyed shock

shoulder bolt (#130813) making sure it

is keyed properly and is fully flushed with

the D-Lock reducer on non-drive side

(IMAGE #19).

CThread on shock nut (#130814) with

5MM allen key and torque down to 16 NM

/ 140 in/lbs (IMAGES #20, 21).

8

7911

10 12 13

201814 16

211915 17

CONNECTING REAR TRIANGLE TO BOX LINK //

APut a small dab of grease on the

outside bearing race as well as on

the contacting surface of the bearing

cap (#130778). This will help hold

the bearing caps in place during the

installation (IMAGE #7).

BSlide rear triangle over the lower link

and line up the pivot point over the

bearing caps (IMAGE #8).

CInsert greased main pivot bolt

(#130791) into non-drive side of lower

link. Insert 8MM torque wrench and

torque main pivot bolt down to 7 NM /

60 in/lbs (IMAGES #9, 10).

DGrease and insert cone adjuster

(#130807) into main pivot bolt with M6

x 22MM bolt (#410009) (IMAGE#11).

Torque down to 14 NM / 125 in/lbs

(IMAGE #12).

EInsert push rivet (#140038) on the

drive side in the pivot axle (IMAGE # 13).

CONNECTING REAR TRIANGLE TO TOP LINK //

APut a small dab of grease on the outside

bearing race as well as on the contacting

surface of the bearing cap (#130765).

This will help hold the bearing caps in

place during the installation (IMAGE #14).

BSwing the rear triangle up aligning the

pivot point with upper link bearing cap

(IMAGE #15).

CInsert the non-drive D-Lock reducer

(#130803) and the drive side D-Lock

reducer (#130805), joining the top swing

link with the rear triangle (IMAGE #16).

DTake the upper link spacer (#130801)

and slide it over the back side of the

D-Lock reducer on both drive and non-

drive sides. It will be a snug fit as there

is a small o-ring fitted to the inside

diameter of the tracer spacer. This

spacer will directly interface with the

shock hardware (IMAGE #17).

torque

Achieving proper torque is vital to

ensuring the safe performance and

function of the tracer carbon frame.

Failure to do so could result in sub-

optimal performance of your frame

as well as premature wear and tear

of individual parts.

additional reference

In addition to this chart, all torque

values are laser etched onto

corresponding hardware for your

reference.

12 // tracer carbon user manual INTENSE CYCLES // 1 3

torque chart

20 Nm / 175 in/lbs

20 Nm / 175 in/lbs

16 Nm / 140 in/lbs

14 Nm / 125 in/lbs

M8 HEX 7 Nm / 60 in/lbs

M6 HEX 14 Nm / 125 in/lbs

Derailleur Cap: 11 Nm / 100 in/lbs

Axle (drive side): 11 Nm / 100 in/lbs

Axle (non-drive side): 14 Nm / 125 in/lbs

REAR AXLE //

AInsert 148 x 12MM rear axle (#130757)

into axle opening on non-drive side

(IMA G E #24).

BFrom drive side, insert 5MM allen key

through the derailleur cap to reach the

5MM HEX interface on the axle. Turn

wrench in a counter clockwise direction

to tighten and clockwise to loosen. Torque

to 11 NM / 100 in/lbs (IMAGE #25).

CBack on the non-drive side, use the

5MM allen wrench to torque the cone

adjuster (#130807) with the M6 x 22MM

(#410032) down to 14 NM / 125 in/lbs

(IMAGE #26).

24

2625

2322

INSTALLING DERAILLEUR HANGER //

AApply a thin layer of grease to the

derailleur hanger (#130790) shank and

install into the keyed insert on the drive

side of the rear triangle (IMAGE #22).

BInstall derailleur cap (#130798) using

a 6MM allen key and torque to 11 NM /

100 in/lbs (IMAGE #23).

seatpost

make sure to insert seat post at least 4” into the main frame. Anything less than

this amount could cause damage to the frame or even failure.

14 // tracer carbon user manual INTENSE CYCLES // 1 5

set up

4”

setting the sag

1. Remove fork and shock air caps and be sure you have a shock

pump and a small ruler or measuring device handy.

2. Go ahead and hop on the bike. Be sure to place all your weight on the

seat with the dropper in the up position and both hands on the grips.

3. Give the bike 5-6 moderate bounces and sit back down on the saddle.

4. Now have your friend slide both the rear shock and the front fork

o-rings down against the seal lip of the damper bodys (IMAGE #1).

5. Step off the bike nice and easy. Be sure to not compress the suspension

after the o-rings have been set.

Pro Tip

Here is where having a friend helps. Have them straddle the front wheel and pull

the handle bars in a upward direction as to not allow the suspension to compress

as you get off (image #4).

6. Using your measuring device, measure the gap between the suspension

seal lip and the o-ring. Using the chart on the following page will tell you

if you need more air pressure or less air pressure (IMAGES #2, #3).

7. Adjust air pressure with your shock pump accordingly (IMAGE #5).

8. Re-visit steps 2-6 until your desired sag measurement have been reached.

9. Install valve caps.

10. Go ride your bike!

15% - 25%

While suspension

is compressed on

fork or rear shock,

slide o-ring down

against the seal lip

of damper body.

Release compression.

Measure gap from

o-ring to seal lip.

19mm

seatpost

PR E FA C E //

We are almost ready to rip. Just a few

more checkpoints and adjustments

to ensure the performance and ride

characteristics of the Tracer Carbon is

optimised for you.

Tools needed

•shock pump

•small ruler or measuring device

recommendation

When setting up the suspension sag,

ask a fellow ripper to help. but if

alone, using a wall to lean your

shoulder against will do just fine.

4

21

3 5

cm 1 2 3 4 5 6 7 8 9 10

16 // tracer carbon user manual INTENSE CYCLES // 1 7

shock setup

FOX FLOAT x2 performance elite / x2

216 x 63.5mm

set up and tune

proper set up and tuning can vary

from shock to shock. Please

consult the Fox manual included

with your bike for complete

information about set up, tuning

and general maintenance or visit

www.foxracingshox.com

Travel 165mm

Shock Stoke 63mm

Shock Sag 30% when sitting on the bike

Fork Sag 15-25% when sitting on the bike

SHOCK: FOX Float X2 Performance Elite

SHOCK: FOX Factory Float X2

RIDER WEIGHT(LBS/KGS) SPRING (PSI)

100 lbs/ 45 kgs 120 LSC 20

110 lbs/ 50 kgs 130 HSC 18

120 lbs/ 54 kgs 140 LSR 17

130 lbs/ 59 kgs 150 HSR 15

140 lbs/ 63.5 kgs 160 LSC 18

150 LBS / 68 KGS 170 HSC 16

160 LBS / 73 KGS 180 LSR 14

170 LBS / 77 KGS 190 HSR 12

180 LBS / 82 KGS 200

190 LBS / 86 KGS 210 LSC 17

200 LBS / 91 KGS 220 HSC 14

210 LBS / 95 KGS 230 LSR 13

220 LBS / 100 KGS 240 HSR 10

230 LBS / 104 KGS 250

240 LBS / 109 KGS n/a

n/a

250 LBS / 113 KGS n/a

260 LBS / 118 KGS n/a

270 LBS / 122 KGS n/a

280 LBS / 127 KGS n/a

290 LBS / 131.5 KGS n/a

300 LBS / 136 KGS n/a

set up and tune

proper set up and tuning can

vary from shock to shock. Please

consult the rockshox manual

included with your bike for complete

information about set up, tuning

and general maintenance or visit

www.sram.com/rockshox/products

Travel 165mm

Shock Stoke 63 mm

Shock Sag 30% when sitting on the bike

Fork Sag 15-25% when sitting on the bike

SHOCK: Rock Shox Monarch Plus R

SHOCK: Rock Shox Monarch Plus RT3

RIDER WEIGHT(LBS/KGS) SPRING (PSI) REBOUND (clicks out)

100 lbs/ 45 kgs 100

7-6

110 lbs/ 50 kgs 110

120 lbs/ 54 kgs 120

130 lbs/ 59 kgs 130

140 lbs/ 63.5 kgs 140

150 LBS / 68 KGS 150

6-5

160 LBS / 73 KGS 160

170 LBS / 77 KGS 170

180 LBS / 82 KGS 180

190 LBS / 86 KGS 190

200 LBS / 91 KGS 200

210 LBS / 95 KGS 210

220 LBS / 100 KGS 220

230 LBS / 104 KGS 230

4-3

240 LBS / 109 KGS 240

250 LBS / 113 KGS 250

260 LBS / 118 KGS 260

270 LBS / 122 KGS 270

280 LBS / 127 KGS 280

290 LBS / 131.5 KGS 290

300 LBS / 136 KGS 300

shock setup

rock shox monarch Plus r / rt3

216 x 63.5mm

18 // tracer carbon user manual INTENSE CYCLES // 1 9

maintenance maintenance Schedule*

Action Every Ride 500 Miles or

1 Month

2000 Miles or 6

Months

4000 Miles or

1 Year

Tires Check air pressure, inspect tread and sidewalls for tears and punctures X

Chain Brush off and lubricate X

Brakes Squeeze brakes and confirm function X

General Clean complete bike of mud and debris X

Headset Check adjustment X

Box Link Add grease thru zerk fittings X

Frame Pivots Check torques X

Spokes Inspect for damage, check tension X

Shock and Fork Check air pressure, inspect for leaks X

Deraileur Cables Inspect and lube X

Seatpost Clean and regrease interface with frame X

Frame Pivots Remove pivot bolts, check bearings for pitting and wear X

Headset Disassemble stem, headset and fork. Check bearings for pitting and wear X

Hubs Pull wheels off, check hub bearings for pitting and wear X

Bottom Bracket Remove crank arms and check BB bearings for pitting and wear X

Brakes Replace brake pads X

Chain Inspect for damage and check for stretching X

General Complete Tune-Up X

Shock and Fork Overhaul See MFG Recommendations

GENERAL SERVICE AND CARE //

You have purchased a high performance bicycle which requires a certain level of service

and maintenance to sustain the level of performance your frame was designed around.

Proper care will also ensure the bike is safe to ride at all levels. It is important to read

and understand the carbon care information as well as follow the maintenance schedule

and inspect your bicycle before each ride. These will not only help to limit or avoid costly

repairs but will also help to avoid injury due to service neglect and component failure.

carbon care

Intense Cycles employs advanced composite techniques and materials in

our frames which do require a certain level of care and maintenance to

ensure a safe experience at the high level of performance each frame is

designed around. Not following these guidelines will decrease the level

of performance and possibly cause injury or death.

• Use a soft cloth with warm soapy water to clean the carbon surfaces. Do

not use abrasive cloths or cleaners.

• Be sure all frame surfaces in contact with cables are protected. Cable

housing rubbing on carbon can wear over time.

• Be sure brake levers, handle bar ends and the fork crown do not contact

the frame at full rotation.

• Never clamp any part of a carbon frame in a bike stand or car rack.

• Always inspect your frame if you experience any chain suck. Intense

frames come equipped with steel chain suck plates but damage can still

be done in the event of chain suck.

• Always inspect your frame in full after a crash to be sure there is no

damage. Look for cracks, dents or loose fibers. If you discover damage

in any degree it’s best to have your frame inspected by a qualified

Intense Cycles dealer. Any direct impact to the frame can cause serious

structural damage.

• Use high grade waterproof grease on seat post, BB and head set bearing

contact areas with the carbon.

• Never ream or face a carbon frame.

• Be sure to follow all recommended torque settings.

*THE ABOVE MAINTENANCE SCHEDULE IS ONLY A GUIDELINE. refer to COMPONENT MANUFACTURER FOR SPECIFIC INSTRUCTION ON MAINTAINING THEIR PARTS.

phone: (951)-296-9596

Customer Service: cs@intensecycles.com

General Info: info@intensecycles.com

Media, Marketing, Sponsorship: marketing@intensecycles.com

Intense Cycles USA 42380 rio nedo Temecula, Ca. 92590

www.INTENSeCYCLES.com

330021

Table of contents

Other INTENSEcycles Bicycle manuals

INTENSEcycles

INTENSEcycles PRIMER 29 User manual

INTENSEcycles

INTENSEcycles 951 EVO User manual

INTENSEcycles

INTENSEcycles Spider 275 User manual

INTENSEcycles

INTENSEcycles ACV User manual

INTENSEcycles

INTENSEcycles M16 Carbon User manual

INTENSEcycles

INTENSEcycles M9 PRO User manual

INTENSEcycles

INTENSEcycles 951 Series User manual

INTENSEcycles

INTENSEcycles Recluse User manual

INTENSEcycles

INTENSEcycles TAZER User manual

INTENSEcycles

INTENSEcycles carbine 275 User manual