INTENSEcycles TAZER User manual

USER MANUAL // TAZER

table of contents //

Introduction / Registration 2

Unboxing 4

Get Charged / Build 5

Connect the System. 7

Suspension Setup 8

Frame Features / Component Spec 10

Geometry 11

Exploded View and B.O.M. 12

Torque Chart 15

Unique Identiers 16

About the Battery 17

Installing / Removing Battery 20

Turning the Power On / Off 22

Cycle Computer Display and Setting 23

Assist and Shift Switches 24

Maintenance 26

Troubleshooting 28

E-bike Declaration of Conformity 30

At Intense, we have one goal -

to provide the ride of your life //

Our team of designers, engineers and product experts are focused on

one thing every day: your experience on the bike. We build bikes that

are as thrilling to look at as they are to ride, and we build them for the

select few of you who understand the difference and refuse to settle for

anything else. From the early days of Intense, when founder Jeff Steber

worked alone in his garage to today, where a crew of talented people work

in a Temecula, CA factory, Intense has been a brand built on passion by

forward thinkers who, even today, love nothing more than to throw a leg

over a sweet bike and head out for a rip. We’re so glad you’ve joined us.

Welcome to Intense, enjoy your experience.

the tazer //

More than an eBike, think of the Tazer as an Intense bike that happens

to have an E-assist feature. Built with aggressive trail geometry, Jeff

Steber tuned kinematics and 29”/27.5” front and rear wheel sizes, this

bike delivers a unique ride for an eMTB that won’t feel cumbersome and

has a seamless pedal-to-power transition.

#NOSHUTTLEREQUIRED

register your bike //

www.intensecycles.com/warranty-card/

technical assistance

951 - 307-9 211

Welcome to

th e fam i ly

2// tazer user manual INTENSE CYCLES // 3

4// tazer user manual INTENSE CYCLES // 5

setup

Preface //

Before you can get out there and rip up the trails,

we need to get your bike unpacked and built up.

This is a good chance for you to become familiar

with your bike and to ensure the performance and

ride characteristics of the Tazer is optimised for you.

Tools needed

• shock pump

• small ruler or measuring device

• torque wrench

• Intense Carbon Paste

Unboxing your tazer //

Careful attention has been given to the packaging of your Intense Tazer

to not only ensure that it arrives safely and undamaged, but also that

you are able to re-use the packaging for situations in which you need to

safely transport your bike.

1. Rest the box on the ground or stable surface

with the top side facing up.

2. Pull the aps and open the top lid.

3. Remove the INTENSE accessory box, which contains

your user manual, torque wrench, and shock pump.

4. Everything in the box is numbered. Remove th e inserts

in chronological order taking care not to rip or tear the

cardbard so that they can be reused in the future.

5. After removing the handlebar and control protector (#7), raise the

dropper post by activating the trigger located on the handlebar.

6. Mount the frame onto a bike stand using the seatpost as your

clamping surface. WARNING: Do not clamp onto any of the carbon

surfaces of the frame as this could severely damage the frame.

7. Continue by removing the remaining protectors from the bike.

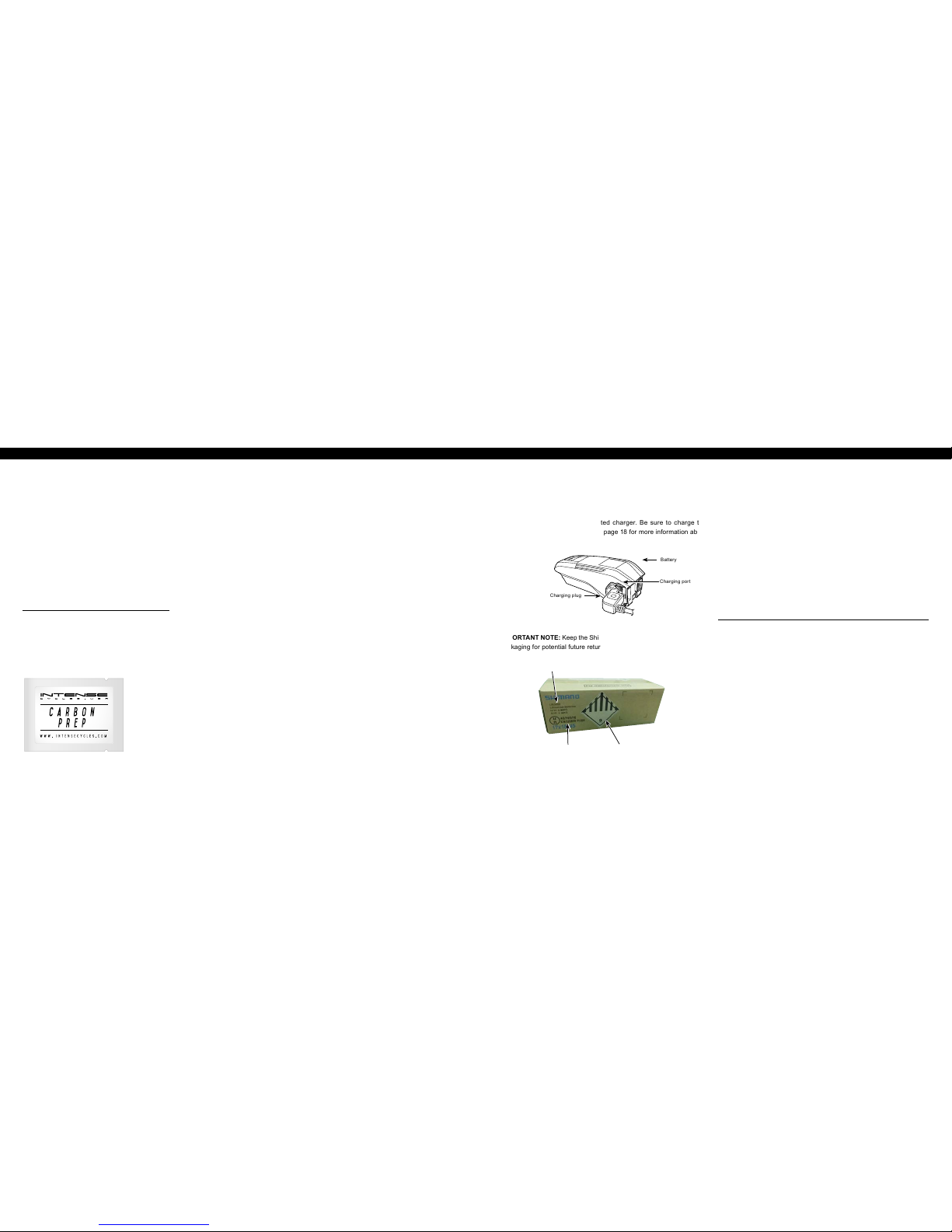

Get charged //

The battery is not fully charged at the time of purchase, so before you start

building your Tazer, take a moment to unpack and charge the supplied

Shimano battery using its dedicated charger. Be sure to charge the

battery until it is fully charged. See page 18 for more information about

charging the battery.

Charging plug

Battery

Charging port

IMPORTANT NOTE: Keep the Shimano battery box and original internal

packaging for potential future returns to Shimano.

packaging identifiers

1. Frame spacer

2. Wheel stabilizer (front wheel)

3. Wheel stabilizer (rear wheel)

4. Rear wheel cover

5. Front wheel cover

6. Cassette cover

7. Handlebar and

control protector

8. Fork cover

9. Downtube / toptube protector

building your tazer //

Once all the protectors have been removed from the bike, we can begin

the process of mounting the components onto the frame.

Handlebar Installation

1. Spin the stem around so that the faceplate is facing forward.

2. Using a 4 mm allen key, remove the faceplate from the stem.

3. Making sure that all the cables are oriented properly, place

the handlebar into the stem and reinstall the faceplate.

With the handlebar centered, torque the faceplate bolts to

6 Nm / 54 in-lbs. NOTE: Take your time when installing the

faceplate bolts to prevent any type of cross threading.

p r o t i p

When installing the faceplate, always tighten the stem bolts in a cross

pattern (top left – bottom right, bottom left – Top right).

Mounting the Derailleur

1. Using a knife or scissors, carefully remove the bubble wrap

and zipties from the rear derailleur, chain, and B-screw.

2. With a 5mm allen key, mount the rear derailleur onto the

derailleur hanger being careful to avoid cross threading.

3. Using a torque wrench, tighten the derailleur

bolt to 8-10 Nm / 70-90 in-lbs.

UN number

Hazardous goods labelPackaging code

6// tazer user manual INTENS E CYCLES // 7

Installing the rear wheel

1. Remove the brake pad spacers from the rear brake. Be sure

to keep this in a safe spot so it can be reused in the future.

2. Remove the rear axle.

3. Grab the rear wheel and carefully remove the disc

guard. Check the disc guard to make sure the end

cap is not accidentally removed with the guard.

4. Pull the derailleur back and slide the rear wheel

into the rear triangle of the bike, setting the chain

on the smallest gear of the cassette.

5. From the non-drive side, slide the axle through the dropout and

wheel assembly, threading it by hand in a clockwise direction.

6. Using a 5mm allen key from the drive side, tighten the axle in

a counter clockwise direction. Torque to 11 Nm / 100 in-lbs.

7. From the non-drive side, tighten the cone spacer with

a 5mm allen key. Torque to 14 Nm / 125 in-lbs.

Installing the front wheel

1. Grab the front wheel and carefully remove the disc guard.

2. Remove the front axle as well as the pad spacer from the front

brake. Be sure to keep the pad spacer in a safe spot for future use.

3. With the rotor side of the wheel on the non-drive side

of the bike, line the brake caliper up with the disc rotor

carefuly sliding the front wheel between the fork legs.

4. Slide the axle through the fork dropout and wheel assembly

and tighten by turning in a clockwise direction. NOTE: To

prevent accidental opening of the quick release lever while

riding, always lock the lever in an upward direction (parallel

to the fork leg) or horizontally towards the rear of the bike.

Quick Component Check

All INTENSE bicycles are delivered "Ride Ready", meaning you can

expect the bikes to come with the brakes and drivetrain all properly

adjusted. However, to ensure that nothing happened during shipping,

we recommend that you check that all the components are operating

correctly before heading out to the trail.

1. One wheel at a time, spin the wheels to make sure there

is no rotor rub from the brake pads. Give the brakes a

squeeze to make sure everything feels alright.

2. Check that the derailleur is adjusted properly by

running up and down the gears making sure that

everything is functioning nice and smoothly.

setting preload on the headset

and tightening the stem

1. Remove the bike from the stand and place it onto the ground.

2. Check that front wheel is inline with the stem.

PRO TIP: You can line up the back of the handlebar with

the front of the fork crown to help with alignment.

3. Set the preload on the headset by tightening

the bolt in the center cap.

4. Tighten stem bolts with 5mm allen key

and torque to 8 Nm / 70 in-lbs.

connecting the system //

Now that your bike is built, we need to plug the electric wire that can be

found coming out of the down tube (drive side) into the back of the cycling

computer as shown below.

seat post

When inserting the seat post, apply a liberal coat carbon paste and

gently slide it into the seat tube. With a minimum seat post insertion of

4" (100mm), tighten seat post clamp to 5 Nm / 45 in-lbs. NOTE: Over

tightening the seat post clamp will inhibit the movement of the seat post

and potentially damage seat post and/or seat tube.

connecting the electric wire

Use the Shimano original tool (TL-EW02) for installation and removal of

the electric wire. Set so that the projection on the connector is aligned

with the groove on the narrow end of the tool.

When installing the electric wire, do not forcibly bend the connector. It

may result in a poor contact. When connecting the electric wire, push it

in until it clicks in place.

Connector Shimano Installation Tool

(TL- EW 02)

min. seat height

4”

(100mm)

8// tazer user manual INTENSE CYCLES // 9

Travel 155 mm (6.1")

Shock Stroke 55 mm (2.15")

Shock Sag 30% when sitting on the bike

Fork Sag 20% when sitting on the bike

Shock Fox Float DPX2 Shock 185 x 55 mm

RIDER WEIGHT

(LBS/KGS)

Air Pressure

(PSI)

REBOUND

(clicks out from fully closed)

Closed is Clockwise

Open is Counter Clockwise

Low Speed

Compression

100 lbs/ 45 kgs 130 11

10 Clicks Out

110 lbs/ 50 kgs 145 10

120 lbs/ 54 kgs 160 9

130 lbs/ 59 kgs 175 9

140 lbs/ 63.5 kgs 190 8

150/ 68 kgs 205 8

8 Clicks Out

160/ 73 kgs 220 7

170/ 77 kgs 235 7

180/ 82 kgs 250 6

190/ 86 kgs 265 6

200/ 91 kgs 280 5

6 Clicks Out

210/ 95 kgs 295 5

220/ 100 kgs 310 4

230/ 104 kgs 325 3

240/ 109 kgs 340 2

250/ 113 kgs 350 2

shock setup //

Proper set up and tuning can vary from shock to shock. Please consult

the Fox manual included with your bike for complete information about

set up, tuning and general maintenance or visit www.foxracingshox.com

setting the sag //

1. Remove fork and shock air caps and be sure you have a

shock pump and a small ruler or measuring device handy.

2. Go ahead and hop on the bike. Be sure to place

all your weight on the seat with the dropper in the

up position and both hands on the grips.

3. Give the bike 5-6 moderate bounces and

sit back down on the saddle.

4. Now have your friend slide both the rear shock and the front fork

o-rings down against the seal lip of the damper bodys (Image #1).

5. Step off the bike nice and easy. Be sure to not compress

the suspension after the o-rings have been set.

P r o T i p

Here is where having a friend helps. Have them straddle the front

wheel and pull the handle bars in a upward direction as to not allow the

suspension to compress as you get off (Image #4).

6. Using your measuring device, measure the gap between

the suspension seal lip and the o-ring. Using the chart

on the following page will tell you if you need more air

pressure or less air pressure (Images #2, #3).

7. Adjust air pressure with your shock pump accordingly (Image #5).

8. Re-visit steps 2-6 until your desired sag

measurement have been reached.

9. Install valve caps.

20%

(30mm)

While suspension

is compressed on

fork or rear shock,

slide o-ring down

against the seal lip

of damper body.

Release compression.

Measure gap from

o-ring to seal lip.

4

21

3 5

cm 1 2 3 4 5 6 7 8 9 10

30%

(16.5 mm)

FOX FLOAT dpx2

185 x 55mm

NOTE:

• FLOAT DPX2 shocks have a maximum

pressure of 350psi (24.1 bar).

• Max rider weight for the DPX2 shock on

the Tazer is 250 lbs / 113 kg based on

30% sag requirement and DPX2 shock

max air pressure of 350 psi.

• Max rider weight for TAZER frame

is 300 lbs / 136 kg.

• Please contact the Intense Cycles Tech

Center for shock tment options.

10 // tazer user manual INTENSE CYCLES // 1 1

Geometry //

A

B

BB Drop

C

F

E

D

G

H

L

K

I

J

GEOMETRY NOTE

Geometry taken at top out with 567mm axle to

crown length and 51mm fork offset.

Component spec NOTE

The Tazer is designed around the use of a single

chain ring only. Use of a double or triple ring set will

not allow proper clearance with the frame.

Frame Features //

• Rear Travel: 155mm / 6.1

inches with metric 185 x 55

stroke shock

• 29” Front Wheel size, 27.5” x

2.80” Plus Rear Wheel size

• Progressive Shock Curve

• Integrated 148 x 12mm

dropouts

• Internal Cable Routing

• Flack Guard: Downtube,

Chainstay, Seatstay and

Seattube protection

• Molded: Rear Fender

• Tapered Head Tube

• Replaceable Grease Zerk on

back of Lower Link

• Max Bearings and Dedicated

Frame Hardware

• Molded Skid plate

• Removable Battery

Component Spec //

• Fork: Accepts 1.125” straight

steer or 1.125”/1.5” tapered

steer, 160mm travel/ 6.3

inches, 567mm Axle to Crown,

51mm Offset

• Shock: 185mm x 55mm Metric

Shock, Trunnion with 20mm x

8mm Reducers on shock

• Seat post: 31.6mm

• Headset: Zero Stack 49mm

Upper/ 56mm Lower

• Rear Axle: BOOST 148 x 12mm

• Brake Mount: Post Mount for

200mm rotor

• Shimano E8000 Motor

• Shimano E8010 Battery

SMALL MEDIUM LARGE

AWheel Base: 1199.4 mm/ 47.2” 1230 mm/ 48.4” 1260 mm/ 49.6”

BTop Tu b e L engt h: 577 mm/ 22.7” 605 mm/ 23.8” 633.4 mm/ 25”

CChain Stay Length: 450 mm/ 17.7” 450 mm/ 17.7” 450 mm/ 17.7”

DHead Tube Length: 100 mm/ 3.94” 115 mm/ 4.5” 125 mm/ 4.9”

EHead Tube Angle: 64.9˚ 64.9˚ 64.9˚

FReach: 425 mm/ 16.7” 450 mm/ 17.7” 475 mm/ 18.7”

GStack: 610 mm/ 24” 623 mm / 24.54” 632 mm/ 24.9”

HBB Height: 347 mm/ 13.65” 347 mm/ 13.65” 347 mm/ 13.65”

BB Drop 12 mm/ 0.47” 12 mm/ 0.47” 12 mm/ 0.47”

ISeat Tube Angle

(Effective): 75.4˚ 75.4˚ 75.4˚

JSeat Tube Angle (Actual): 72.9˚ 72.9˚ 72.9˚

KSeat Tube Length: 394 mm/ 15.5” 419 mm/ 16.5” 445 mm/ 17.5”

LStandover Height: 806 mm/ 31.7” 814.1 mm/ 32” 822 mm/ 32.4”

getting to

know your

tazer

W A R N I N G

Use the supplied key to remove the battery from the

frame to perform battery swap or for charging. Do

not move or alter the battery frame mounts from their

factory position in the downtube as this could result

in subpar performance, may lead to battery and or

frame damage and is not covered under warranty.

Please contact Intense Cycles Tech Center if you

have any questions relating to the battery mounts.

12 // tazer user manual INTENSE CYCLES // 1 3

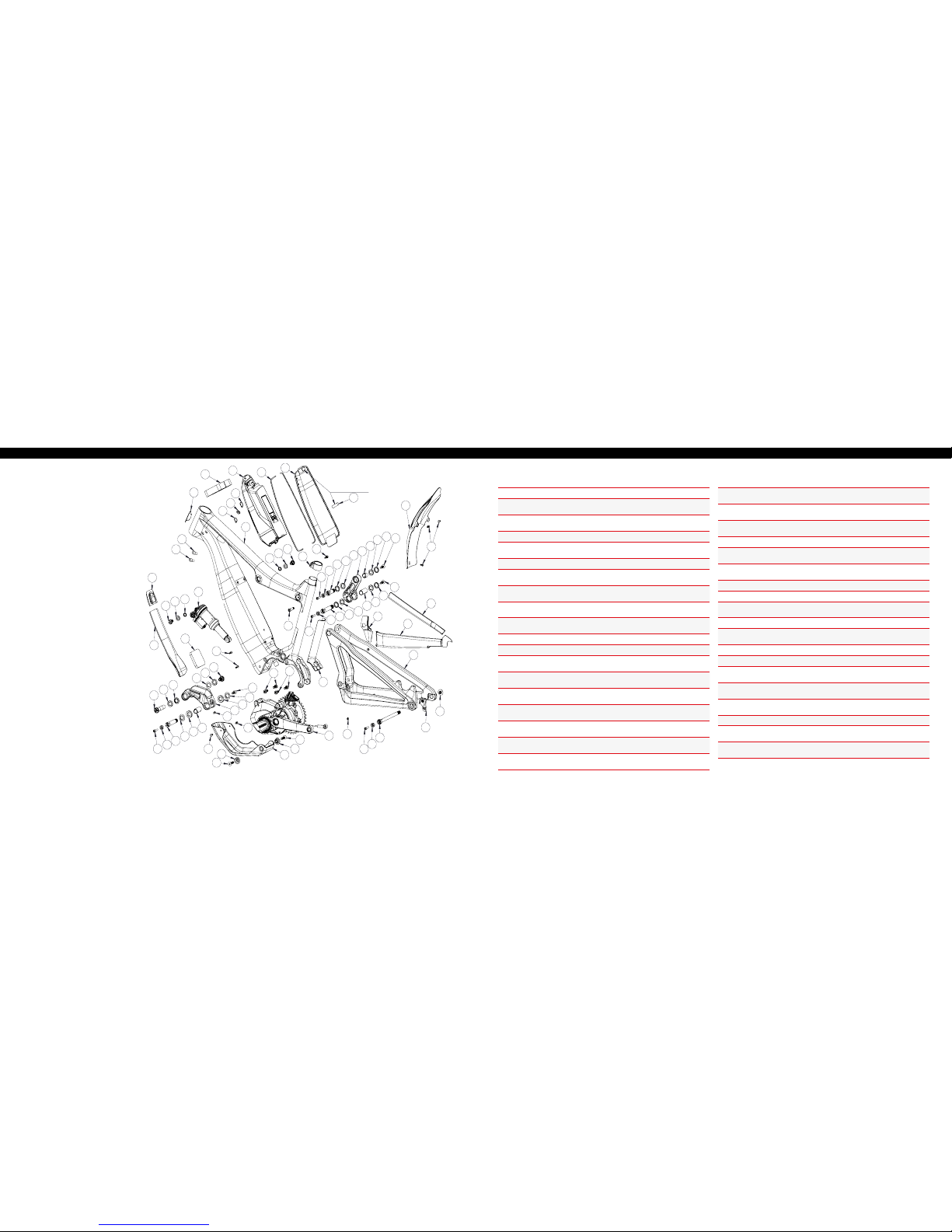

exploded view and b.o.m. //

52

15

45

24

28

54

47

15

26

36

20

41

44

3

12

14

10

44

3

3

8

6

2

56

55

22

23

43

5

46

37

11

39

1

4

17

7

9

38

13

23

23

44

3

19

9

38

44

38

9

43

46

17

4

28

28

25

45

16

16

42

34

40

49

48

29

57

50

42

42 21

27

21

22

18 18

32

33

30

31

Foam in Door Latch

53

9

38

51

35

(continued on next page)

ITEM

NO. ITEM PART

NUMBER DESCRIPTION QTY. TORQUE SPEC.

1Bearing Spacer 130754 Lower Link Bearing Spacer 1 N/A

2Rear Axle 130757 Axle Rear

148 x 12mm Boost 111 Nm /

100 in -lbs

3Bearing Cap 130765 Upper Link Bearing Cap,

24mm 4 N/A

4Bearing Cap 130778 Lower Link Bearing Cap, 28mm 2 N/A

5Pivot Bolt 130785 Lower Link Pivot Bolt 120 Nm /

175 in-lbs

6Hanger 130790 Derailleur Hanger, Forged 1 N/A

7Pivot Bolt 130795 Lower Link Expander Bolt

(Lower Pivot) 17 Nm /

60 in-lbs

8Hanger Bolt 130798 Derailleur Hanger Bolt 111 Nm /

100 in -lbs

9Cone Adjuster 130807 Cone Adjuster,

8.3 mm Height 4 N/A

10 Bearing Spacer 130847 Upper Link Bearing Spacer

(Upper Pivot) 1 N/A

11 Lower Link 130848 Forged Lower Link Tazer, Blk 1 N/A

12 Forged Top Link 130849 Forged Top Link Tazer, Blk 1 N/A

13 Axle Lower 130850 Axle Lower Pivot Tazer 120 Nm /

175 in-lbs

14 Bearing Spacer 1308 51 Upper Link Bearing Spacer

(Lower Pivot) 1 N/A

15 Bearing Spacer 130852 Shock Mount Bearing

Spacer (Trunion Pivot) 2 N/A

16 Shock Bolt 130853 Trunion Pivot Shock Bolt 216 Nm /

140 in-lbs

17 Bearing Spacer 130860 Lower Link Bearing Spacer

(Upper Pivot) 2 N/A

18 Drive Unit Bolt 130862 Drive Unit Bolt M8 x 18 with

T40 B r o ach 410 Nm /

88 in-lbs

19 Pivot Bolt 130863 Upper Link Expander Bolt

(Upper Pivot) 17 Nm /

60 in-lbs

ITEM

NO. ITEM PART

NUMBER DESCRIPTION QTY. TORQUE SPEC.

20 Pivot Bolt 130864 Upper Link Expander Bolt

(Lower Pivot) 17 Nm /

60 in-lbs

21 Skidplate

Spacer 130867 Skidplate Spacer 2 N/A

22 FHCS M8 x 30 130868 Drive Unit /Skid Plate Bolt

M8 x 1.25 x 30 mm 210 Nm /

88 in-lbs

23 Plug 14003 8 Lower Link Pivot Plug 3 N/A

24 Cable Guide

Plug 140039 Cable Guide Plug, Solid 1 N/A

25 Cable Guide

Plug 140040 Guide Cable Plug, 5mm ID 1 N/A

26 Battery Door 140050 Battery Door 1 N/A

27 Skid Plate 140 0 51 Skid Plate 1 N/A

28 Cable Guide

Plug 1400 52 Guide Cable Plug, 4mm ID 3

29 Rear Fender 140054 Rear Fender 1 N/A

30 Battery Pull

Strap 140055 Batter y Pull Strap 1 N/A

31 Foam Pad 140056 Battery Door Foam Pad 1 N/A

32 Gasket 14 0057 Battery Door Gasket 1 N/A

33 Foam Pad 140058 Battery Compartment

Foam Pad 1 N/A

34 Battery Charge

Window 140059 Battery Charge Window 1 N/A

35 Grommet 14006 0 Speed Sensor Wire

Grommet 1 N/A

36 Seat Clamp 340342 Bolt-on Seat Clamp 1 N/A

37 Zerk Fitting 401011 M6 x 1.0 15 Nm /

40 in-lbs

38 SHCS M6 x 22 410009 Cone Adjuster Bolt, Socket

Head, M6 x 22 414 Nm /

125 in-lbs

14 // tazer user manual INTENSE CYCLES // 1 5

ITEM

NO. ITEM PART

NUMBER DESCRIPTION QTY. TORQUE SPEC.

39 BHCS M5 X 12 410010 Skid Plate Bolt, Button

Head, M5 X 12 26 Nm /

54 in-lbs

40 SHCS M8 x 35 410045 Shock Bolt, M8 x 35 Steel 116 Nm /

140 in-lbs

41 SHCS M6 x 18 4100 4 8 Seat Clamp Bolt, Socket

Head, M6 x 18 15 Nm /

45 in-lbs

42 M5 x 11 410068 Fender / Skidplate Bolt, Low

prole Socket Head, M5 x 11 5

1 Nm /9 in- lb s

(Fender)

2 Nm/18 in -lbs

(Skidplate)

43 Bearing 7902 430007 15 x 28 x 7 2RS

MAX Angular Contact Bearing 2 N/A

44 Bearing 6802 430008 15 x 24 x 5 2RS

MAX Radial Bearing 4 N/A

45 Bearing 6800 43 00 11 10 x 19 x 5 2RS

MAX Radial Bearing 2 N/A

46 Bearing 3802 430014 15 x 24 x 7,

Double Row Radial Bearing 2 N/A

47 Flack Guard

Downtube 500301 Flack Guard Tazer

Downtube 1 N/A

48 Flack Guard CS 500302 Flack Guard Tazer

Chainstay 1 N/A

49 Flack Guard 500303 Flack Guard Tazer Seatstay 1 N/A

50 Flack Guard 500304 Flack Guard Tazer

Seat Tube Protector 1 N/A

51 Flack Guard 500305 Flack Guard Tazer RT Strut 1 N/A

52 Head Badge 500335 Head Badge Flame Logo 1 N/A

53 Rear Shock 185 x 55, Trunnion 1 N/A

54 Battery Shimano E8010 1 N/A

55 Front Triangle Carbon, 3 Sizes 1 N/A

56 Motor Shimano E8000 1 N/A

57 Rear Triangle Carbon, 1 Size 1 N/A

16 Nm / 140 in-lbs

5 Nm / 45 in-lbs

16 Nm / 140 in-lbs

M8 HEX 7 Nm / 60 in-lbs

M5 HEX 14 Nm / 125 in-lbs

20 Nm / 175 in-lbs

M8 HEX 7 Nm / 60 in-lbs

M5 HEX 14 Nm / 125 in-lbs

M8 HEX 7 Nm / 60 in-lbs

M5 HEX 14 Nm / 125 in-lbs

Derailleur Cap: 11 Nm / 100 in-lbs

Axle (non-drive side): 11 Nm / 100 in-lbs

Adjuster cone (non-drive side): M5 HEX

14 Nm / 125 in-lbs

torque specifications //

Achieving proper torque is vital to ensuring the safe performance and function

of the tazer frame. Failure to do so could result in sub-optimal performance

of your frame as well as premature wear and tear of individual parts.

additional reference

In addition to this chart, torque valuesare laser etched

onto corresponding hardware for your reference.

about the battery //

16 // tazer user manual INTENSE CYCLES // 1 7

DANGER

Use the Shimano specied charger and observe the specied charging

conditions when charging the specied battery. Not doing so may cause

overheating, bursting, or ignition of the battery.

CAUTION

• When removing the battery charger power plug from the outlet or the

charging plug from the battery, do not pull it out by the cord.

• When charging the battery while it is mounted on the bicycle, be careful

not to trip over the charger cord or get anything caught on it. This may

lead to injury or cause the bicycle to fall over, damaging the components.

RIDING THE BICYCLE

1. Turn on the power.

a. You cannot use the battery immediately after shipment.

Refer to ”CHARGING THE BATTERY”

b. Do not place your feet on the pedals when turning

the power on. A system error may result.

c. Power cannot be turned on while charging.

2. Select your preferred assist mode.

3. Assistance will start when the pedals start turning.

4. Change the assist mode in accordance with the riding conditions.

5. Turn the power off when parking the bicycle.

a. Do not place your feet on the pedals when turning

the power off. A system error may result.

Intense bicycle identification //

It’s important to keep track of your Tazer’s serial number as well as the

serial numbers of its important components for warranty and replacement

purposes. Included in your ACCESSORY KIT is a serial number sheet so

this information can easily be tracked and stored in a safe place.

REgistering / replacing

your abus battery key

Worried about losing your key or need to order a spare? No worries.

However, to successfully order a replacement, you’re going to need a few

bits of information so, before its too late, do yourself a favor and document

and register the unique identiers of your key.

key type: wafer

key code:

key profile:

To order your new key, head over

to https://mobilesecurity.abus.com

and click "Order Key" or visit your

local ABUS dealer for help.

key code

key

prole

Handling and charging the battery

• Charging can be carried out at any time regardless of the amount of

charge remaining, but you should charge the battery until it is fully charged

• Be sure to use the dedicated charger when recharging the battery.

• The battery is not fully charged at the time of purchase. Before

riding, be sure to charge the battery until it is fully charged.

• If the battery has become fully spent, charge it as soon as possible. If you

leave the battery without charging, it will cause the battery to deteriorate.

• If the bicycle will not be ridden over an extended period of time,

store it away with approximately 70% battery capacity remaining. In

addition, take care not to let the battery become completely empty

by charging it every 6 months.

• The use of a genuine Shimano battery is recommended. Connect

to E-TUBE PROJECT and click [Connection check] to conrm

whether the battery in use is a genuine Shimano battery. If using a

battery from another manufacturer, make sure to carefully read the

instruction manual for the battery before use.

18 // tazer user manual INTENSE CYCLES // 1 9

Battery Level Indication

The current battery level can be checked by pressing the battery's

power button. NOTE: When remaining battery capacity is low, system

functions begin to shut off in the following order.

1. Power assistance (Assist mode automatically switches to

[ECO] and then assistance shuts off. The switch to [ECO]

occurs earlier if a battery-powered light is connected.)

2. Gear shifting

3. Light

Battery level indication*1 Battery level

0% - 20%

21% - 40%

41% - 60%

61% - 80%

81% - 99%

100%

*1 : No light : Lit up : Blinking

About the Battery LED Lamp

You can check the current charging status on the LED lamp on the battery.

Battery LED lamps

Lit up Charging (Within 1 hour after the completion of charging)

Blinking Charging error

Tur ne d o f f

Battery disconnected

(1 hour or more after the completion of charging)

About the Charger LED Lamp

After charging has started, the LED lamp on the charger lights up.

Charger LED lamp

Battery Charging

• Battery can be charged in the Tazer

frame or outside of Tazer frame.

• Pull back tab of rubberized cover

on the back of the battery to

access plug interface.

• For best charging results plug

Shimano charger directly into a

wall outlet, then plug charger into

side of battery.

• Both the Shimano Battery and

Shimano Charger indicator lights

should light up, the yellow charger

light shows it’s charging. While

the Green lights on the battery will

blink as they are charging and be

completely solid when fully charged.

• When Battery is completely

charged, both it and the charger

will turn off.

Charging plug

Battery Charging port

<BT-E8010>

charging time for the

504 Wh Model battery

• 80% in 2.5 hours

• 100% in 5 hours

Battery level indication*1 Battery level

100% - 81%

80% - 61%

60% - 41%

40% - 21%

20% - 1%

0%

(When battery is not installed on bicycle)

0%, Power off / Shutdown

(When battery is installed on bicycle)

*1 : No light : Lit up : Blinking

(Charging-in-Progress Indication)

20 // tazer user manual INTENSE CYCLES // 2 1

removing the battery //

ARemove battery door by using

two ngers to compress or pull

the snap lock tab back toward

the door. This will allow the door

to pivot open so it is now angled

off the downtube (Images #1, #2).

BLift the door up at the angle it’s

at, freeing the lower locating tab

from the frame (Image #3).

CWith your right hand, insert

battery key into lock.

DWith your left hand, unfold and

hold battery pull strap.

ETurn battery key a quarter turn

with right hand (Image #4).

FPull battery strap with left hand

until the battery has moved past

the front lock (Image #5).

GRelease the key. The key can

now be removed and placed in a

safe, easy to access location.

HContinue pulling battery pull

strap with left hand while holding

onto the top of battery with right

hand. The battery will continue to

pivot off the lower mount and out

of the downtube (Image # 6).

ILift the battery out and away from

the downtube (Image #7).

installing the battery //

APlace pull strap on battery as

shown, then lift battery up with

two hands, left hand on the pull

strap and right hand at top of

battery (Image #1).

BAngle the bottom of battery into the

lower mount of the downtube and

push it into the lower mount. The

bottom of the battery should now be

hooked into the lower battery mount.

With it hooked it should now pivot

into the lower battery mount as the

top of the battery is pushed toward

the upper battery mount (Image #2).

CContinue pushing the top of the

battery so that it slides into the

upper mount then clicks and locks

into place.

DConrm the battery has clicked

and is fully seated in the top

battery mount by tugging on the

battery pull strap. If battery moves

away from the mount then push it

back against mount until battery

is fully seated (Image #3). The

battery pull strap can now be

folded onto itself so it doesn’t

obstruct the battery door.

ERe-install the battery door

with the lower tab tting into the

downtube opening rst (Image #4).

FOnce the battery door fully slides

down into the door opening, pivot

the door in a closing motion

(Image #5) .

GAs the door is nearing the closed

position at the top of the door give

the door a good push to allow the

door’s snap lock feature to engage

into the downtube (Image #6).

6

2

2

5

7

1

3 4

4

53

1

6

about the

controls

22 // tazer user manual INTENSE CYCLES // 2 3

Battery Level Indicator

You can check the battery level on the cycle computer while riding.

display Battery level

81% - 100%

61% - 80%

41% - 60%

21% - 40%

1% - 20%*

0%

*The battery level indicator blinks red when remaining battery

capacity falls to this level.

Basic Screen Display

Displays the status of the power assisted bicycle, traveling data.

(A) (B)

(C)(D)(E)

A. Battery level indicator

Displays the current battery level.

B. Gear position

Displays the currently set gear

position. (Only displays when

electronic gear shifting is in use)

C. Assist gauge

Displays the assistance.

D. Assist mode display

Displays the current assist mode.

(Assist mode automatically switches

to [ECO] as remaining battery

capacity declines. The switch to

[ECO] occurs earlier if a battery–

powered light is connected.)

E. Current speed

Displays the current speed. The

display can be switched between

km/h and mph.

A. Cycle computer

B. Assist switch

C. Shift switch

(not spec'd for Tazer)

D. Drive unit

E. TL-EW02

CYCLE COMPUTER DISPLAY AND SETTING //

turning the power on/off //

cable connecting //

connecting switches and the

drive unit to the cycle computer

Turning the power ON and OFF

via the battery

• Press the power button on the battery. The LED lamps

will light up indicating remaining battery capacity.

NOTE:

• When turning on the power, check that the battery is

rmly attached to the holder.

• Power cannot be turned on while charging.

• Do not place your foot on the pedals when turning on.

A system error may result.

Automatic power off function

If the bicycle has not moved for over 10 minutes, the power

will automatically turn off. NOTE: the system can be forced

to power off by holding down the power button for 6 seconds.

(A)

(D)

(E)

(B) (C)

NOTE:

• Be sure to attach dummy plugs to any unused ports.

• The electric wire connector can be connected to any port of

the cycle computer, but we recommend you connect the assist

switch to the switch-side port.

24 // tazer user manual INTENSE CYCLES // 2 5

NOTEs on walk assist mode

• If Y is not pressed for one minute or more, the mode active before

[WALK] mode was set, is re-activated.

• If the bicycle is not moved after [WALK] mode is activated, walk

assist is automatically inactivated. To re-activate [WALK] mode,

momentarily release Y and then hold down Y.

• The walk assist function can operate at a maximum of 3.7 mph.

• The assistance level and speed vary with the gear position.

• The intelligent walk assist function activates when an electric shifting

system such as XTR, DEORE XT SEIS is connected. System

individually supplies assist power to detect gear position.

• "Intelligent walk assist" support rider more torque output in steep

climb condition in lower side gears.

• "Quick walk assist" function works by holding down SW from any mode.

BOOST

WALK

TRAIL

ECO

OFF

BOOST: Assist boost

TRAIL: Assist trail

ECO: Assist eco

OFF: Assist off

WALK: Walk assist

23

Changing assist mode

Press X1 or Y1 to switch assist modes.

X1Y1

SW-E8000-L/SC-E8000

X1

Y1

SW-E6000/SC-E6010

SC-E8000

SC-E6010

Assist high

Assist normal

Assist eco

Assist off

Walk assist

: Short press Y1

: Short press X1

: Long press Y1

: Short press X1 (This operation is for canceling

[WALK] mode)

BOOST

WALK

TRAIL

ECO

OFF

: Short press X

23

Changing assist mode

Press X1 or Y1 to switch assist modes.

X1Y1

SW-E8000-L/SC-E8000

X1

Y1

SW-E6000/SC-E6010

SC-E8000

SC-E6010

Assist high

Assist normal

Assist eco

Assist off

Walk assist

: Short press Y1

: Short press X1

: Long press Y1

: Short press X1 (This operation is for canceling

[WALK] mode)

BOOST

WALK

TRAIL

ECO

OFF

: Short press Y

23

Changing assist mode

Press X1 or Y1 to switch assist modes.

X1Y1

SW-E8000-L/SC-E8000

X1

Y1

SW-E6000/SC-E6010

SC-E8000

SC-E6010

Assist high

Assist normal

Assist eco

Assist off

Walk assist

: Short press Y1

: Short press X1

: Long press Y1

: Short press X1 (This operation is for canceling

[WALK] mode)

BOOST

WALK

TRAIL

ECO

OFF

: Long press Y

23

Changing assist mode

Press X1 or Y1 to switch assist modes.

X1Y1

SW-E8000-L/SC-E8000

X1

Y1

SW-E6000/SC-E6010

SC-E8000

SC-E6010

Assist high

Assist normal

Assist eco

Assist off

Walk assist

: Short press Y1

: Short press X1

: Long press Y1

: Short press X1 (This operation is for canceling

[WALK] mode)

BOOST

WALK

TRAIL

ECO

OFF

: Short press X

(This op eration is for cancel ing [WAL K] mode)

*The Walk assist mode function may not

be able to be used in cer tain regions.

(SC-E8000)

X

Y

XY

(SW-E6000-L / SC-E8000)

assist modes

To help maximize battery performance and efficiency, select an

appropriate assist mode for your specic application.

Changing assist mode

Press X or Y to switch assist modes.

switching to walk assist mode

1. With your feet off the pedals and current speed

at [0 mph], hold down Y until [WALK] displays.

NOTE: A warning tone will sound while switching

is in progress if it is not possible to switch to

[WALK] mode because the current speed is not

[0 mph] or there is pressure on the pedals etc.

2. Release Y when (WALK) displays.

3. Hold down Y again to activate walk assist. Walk

assist remains active provided Y is being held down.

4. To cancel (WALK) mode, release Y and press X.

When (WALK) mode is canceled, the mode active

before (WALK) mode was set, is re-activated.

YX

Y

B O O S T //

Use when powerful assistance is required, such as when riding up

steep uphill slopes. This mode is designed for use on steep inclines

and precipitous mountains. When riding on level public roads with

trafc lights, the assistance provided may be excessive, in which

case, switch to [ECO] mode.

t r a i l //

Use when an intermediate level of assistance is needed, such as

when you want to enjoy riding comfortably on a gentle slope or

level ground.

eco //

Use when you want to enjoy long distance riding on level ground.

When pedaling is not very strong, the amount of assistance is

reduced and energy consumption is lessened.

walk //

This mode is particularly useful when walking the bicycle, taking

the bicycle out up an incline or when it is bearing a heavy load.

It is also useful when walking the bicycle across uneven terrain

such as rocky areas.

assist and shift switches //

X

Y

A

SW-E6000-L

XSwitching assist modes: the level of assistance becomes stronger

YSwitching assist modes: the level of assistance becomes weaker

AChanging the cycle computer display

26 // tazer user manual INTENSE CYCLES // 2 7

maintenance maintenance SchedulE* //

Action Every Ride 500 Miles or

1 Month

2000 Miles or 6

Months

4000 Miles or

1 Year

Tires Check air pressure, inspect tread and sidewalls for tears and

punctures X

Chain Brush off and lubricate X

Brakes Squeeze brakes and conrm function X

General Clean complete bike of mud and debris X

Headset Check adjustment X

Box Link Add grease thru zerk ttings X

Frame Pivots Check torques X

Spokes Inspect for damage, check tension X

Shock and Fork Check air pressure, inspect for leaks X

Deraileur Cables Inspect and lube X

Seatpost Clean and regrease interface with frame X

Frame Pivots Remove pivot bolts, check bearings for pitting and wear X

Headset Disassemble stem, headset and fork. Check bearings for

pitting and wear X

Hubs Pull wheels off, check hub bearings for pitting and wear X

Bottom Bracket Remove crank arms and check BB bearings for pitting and

wear X

Brakes Replace brake pads X

Chain Inspect for damage and check for stretching X

General Complete Tune-Up X

Shock and Fork Overhaul See MFG Recommendations

general service and care //

You have purchased a high performance bicycle

which requires a certain level of service and

maintenance to sustain the level of performance

your frame was designed around. Proper care will

also ensure the bike is safe to ride at all levels. It

is important to read and understand the carbon

care information as well as follow the maintenance

schedule and inspect your bicycle before each ride.

These will not only help to limit or avoid costly

repairs but will also help to avoid injury due to

service neglect and component failure.

carbon care //

Intense Cycles employs advanced composite techniques and materials

in our frames which do require a certain level of care and maintenance

to ensure a safe experience at the high level of performance each frame

is designed around. Not following these guidelines will decrease the level

of performance and possibly cause injury or death.

• Use a soft cloth with warm soapy water to clean the carbon surfaces.

Do not use high pressure washers, abrasive cloths or cleaners.

• Be sure all frame surfaces in contact with cables are protected.

Cable housing rubbing on carbon can wear over time.

• Be sure brake levers, handle bar ends and the fork crown do not

contact the frame at full rotation.

• Never clamp any part of a carbon frame in a bike stand or car rack.

• Always inspect your frame if you experience any chain suck.

• Always inspect your frame in full after a crash to be sure there is

no damage. Look for cracks, dents or loose bers. If you discover

damage in any degree it’s best to have your frame inspected by a

qualied Intense Cycles dealer. Any direct impact to the frame can

cause serious structural damage.

• Use high grade waterproof grease on seat post, BB and head set

bearing contact areas with the carbon.

• Never ream or face a carbon frame.

• Be sure to follow all recommended torque settings.

• Use only genuine replacement parts for safety-critical components.

* The above maintenance schedule is only a guideline. Refer to component manufactuter for specic instruction on maintaining their parts.

28 // tazer user manual INTENSE CYCLES // 2 9

Error indication type Indication condition

Lighting pattern *1

Recovery

System error Communication error with

the bicycle system

Make sure that the cable is not loose or improperly connected. If the

situation does not improve, contact the place of purchase.

Temperature

protection

If the temperature exceeds

the guaranteed operating

range, the battery output

is turned off.

Leave the battery in a cool place away from direct sunlight until the

internal temperature of the battery decreases sufciently. If the situation

does not improve, contact the place of purchase.

Security

authentication

error

This is displayed if a

genuine drive unit is not

connected.

This is displayed if

any of the cables are

disconnected.

Connect a genuine battery and drive unit.

Check the condition of the cables.

If the situation does not improve, contact the place of purchase.

Charging error This is displayed if an error

occurs during charging.

Remove the charger from the battery and press the power button. If an

error appears contact an agency.

Battery malfunction Electrical failure inside

the battery

Connect the charger to the battery and then remove the charger. Press

the power button with only the battery connected.

If an error appears with only the battery connected, contact the place of purchase.

*1 : No light : Lighting up : Blinking

Code Display preconditions

Operational restriction when an error is being displayed

Remedy

W010

Temperature of the drive unit

is higher than it is during times

of normal operation.

Power assistance may be lower than usual.

Stop using the assist function until the temperature of the

drive unit drops. If the situation does not improve, contact

the place of purchase.

W011 The traveling speed cannot be

detected.

The maximum speed up to which power

assistance is provided may be lower than

usual.

Check that the speed sensor is properly installed. If the

situation does not improve, contact the place of purchase.

W013

Initialization of torque

sensor was not completed

successfully.

Power assistance may be lower than usual.

With your foot off the pedal, press the battery power

button and turn on the power again. If the situation does

not improve, contact the place of purchase.

W032

An electronic derailleur may

have been installed in place of

a mechanical derailleur.

Power assistance provided in [WALK] mode

may be lower than usual.

The walk assist mode function may not be

able to be used in certain regions.

Reinstall the derailleur for which the system is congured

to support. If the situation does not improve, contact the

place of purchase.

Warning Messages on the Cycle Computer

This disappears if the error is xed.

TROUBLESHOOTING //

Battery LED Lamp Error Indications

System errors and similar warnings are indicated by the battery LED lamps through various lighting patterns.

Reference //

Shimano Steps E8000 User Manual: http://si.shimano.com/pdfs/um/UM-72F0A-006-00-ENG.pdf

INTENSE CYCLES // 3 130 // This declaration of conformity is specic to countries following CE marking directives.

INTENSE TAZER MANuAL //

Declaration of Conformity

Hereby confirms the following products:

Product Name: INTENSE TAZER e-Bike

Year of Construction: 2018 / 2019

Conformity with all applicable provisions from

the Machinery Directive (2006/42/EC).

The machine conforms to all applicable provisions of the

Directive 2014/30/EU Electromagnetic Compatibility Directive.

These standards were applied:

EN 15194 / 2017 Bicycles:

Electrically power assisted bicycles, EPAC Bicycles.

ISO 4210-2 Bicycles: Safety requirements for bicycles.

Technical documentation from:

INTENSE CYCLES

42380 Rio Nedo

Temecula, CA 92590-3708, USA

TEL: 1.951.296.9596

Place and Date of issue of this

Declaration of Conformity:

Temecula, CA, August 15, 2018.

Jeff Steber

CEO/ Founder

Chad Peterson

COO/ Product Manager

Chris Knutson

Engineer

The Manufacturer

INTENSE CYCLES

42380 Rio Nedo

Temecula, CA 92590-3708, USA

TEL: 1.951.296.9596

Tazer intended for Offroad Use.

P h o n e :

+1(951)-307-9211

Customer Service:

techcenter@intensecycles.com

General Info:

info@intensecycles.com

Media, Marketing, Sponsorship:

marketing@intensecycles.com

Intense Cycles USA 42380 rio nedo Temecula, Ca. 92590

www.INTENSeCYCLES.com

330026

Table of contents

Other INTENSEcycles Bicycle manuals

INTENSEcycles

INTENSEcycles M9 PRO User manual

INTENSEcycles

INTENSEcycles Sniper Trail User manual

INTENSEcycles

INTENSEcycles PRIMER 29 User manual

INTENSEcycles

INTENSEcycles M16 Carbon User manual

INTENSEcycles

INTENSEcycles ACV User manual

INTENSEcycles

INTENSEcycles ACV User manual

INTENSEcycles

INTENSEcycles 951 Series User manual

INTENSEcycles

INTENSEcycles PRIMER 29 User manual

INTENSEcycles

INTENSEcycles carbine 275 User manual

INTENSEcycles

INTENSEcycles Recluse User manual