1-2

SECTION 1 –

INTRODUCTION

This manual will aid you in the proper

operation and service of your Nitrogen

Toolbar (NTB). It is the responsibility of the

user to read the operator’s manual and

comply with the correct and safe operating

procedures, as well as maintain the product

accordingtotheserviceinformationprovided

in the Maintenance and Storage Section

elsewhere in this manual.

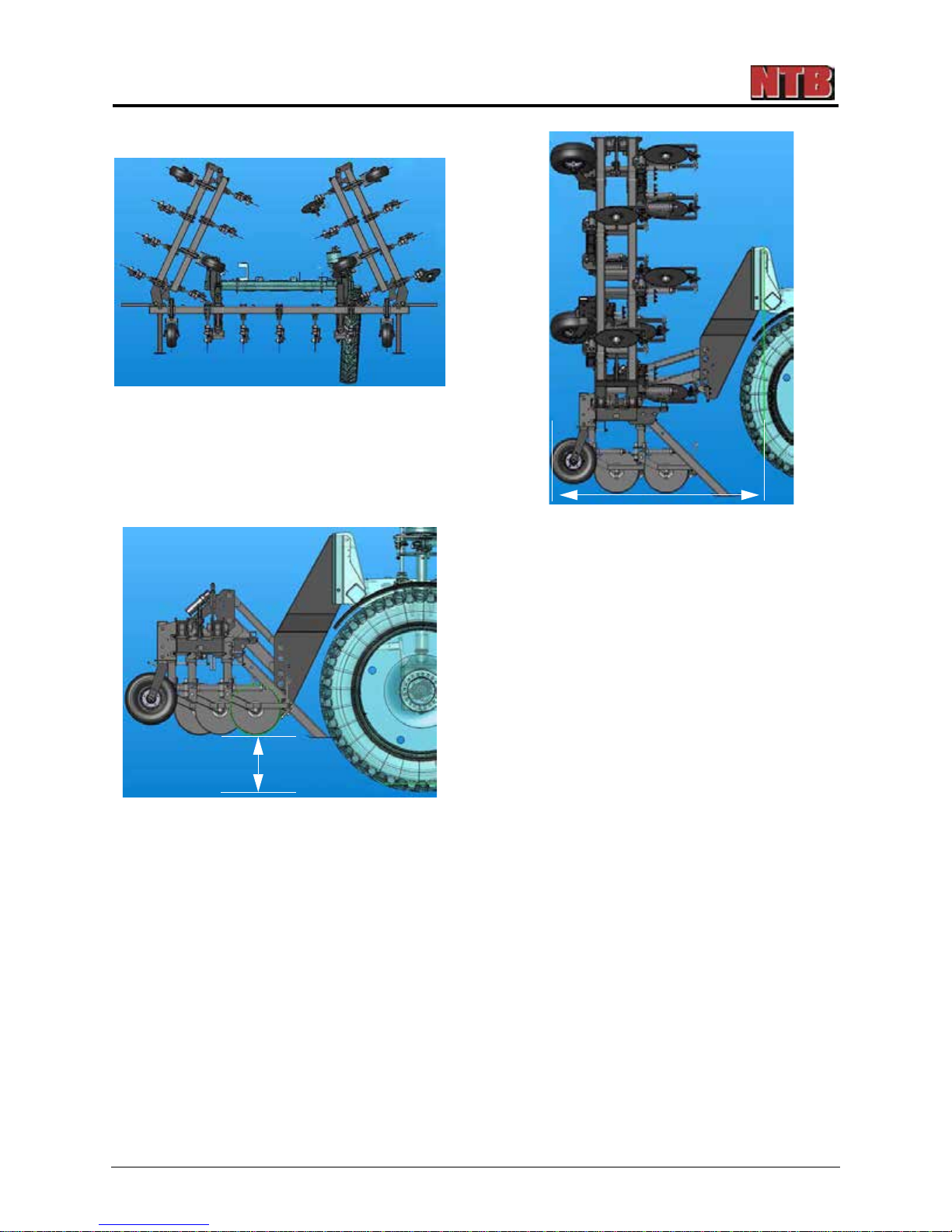

Photographs and illustrations used in this

manual are of general nature only. Some of

the equipment described and/or shown may

or may not be available on your NTB.

Information described in this manual was

correct at the time of printing. Because of

HagieManufacturingCompany’s continuous

product improvement, certain information

maynot beincluded inthis manual. Toobtain

the most current operator’s manual for your

attachment, please visit www.hagiehelp.com.

Keepthis manualin aconvenient placefor

easy reference. This manual is considered a

permanent fixture of the product. In the event

of resale, this manual should accompany the

NTB.

If you do not understand any part of this

manual or require additional information or

service, contact Hagie Customer Support for

assistance.

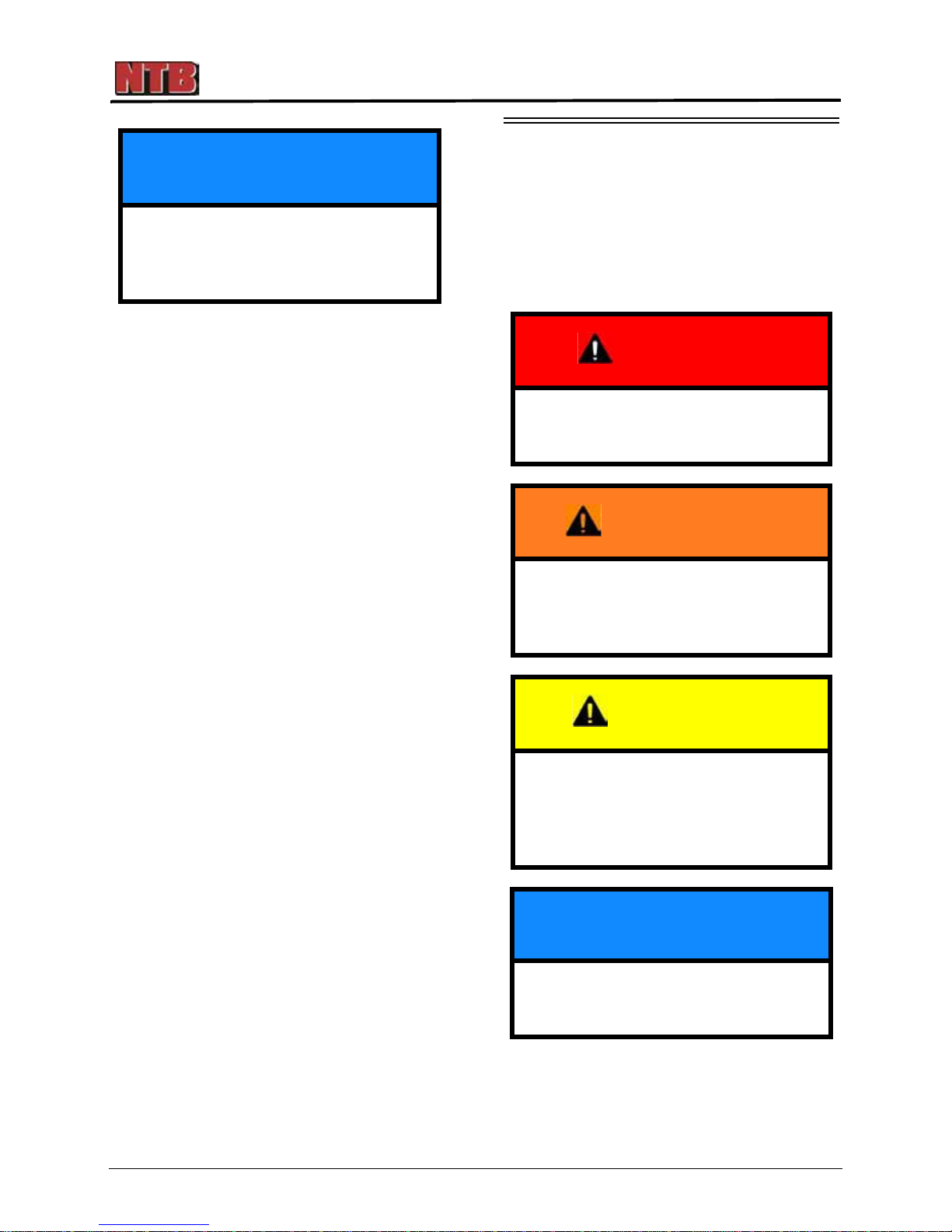

SAFETY MESSAGES USED

IN THIS MANUAL

The following safety messages found

throughout this manual alert you of situations

that could become potentially dangerous to

the operator, service personnel, or

equipment.

NOTE: A “Note” is intended to make special

mention of, or remark on.

NOTICE

Reference to right and left-hand used

throughout this manual refers to the

position when seated in the operator’s

seat facing forward.

DANGER

This symbol indicates a hazardous

situationwhich,if notavoided,will result

in serious injury or death.

WARNING

This symbol indicates a potentially

hazardous situation which, if not

avoided, could result in moderate/

serious injury or death.

CAUTION

This symbol indicates a potentially

hazardous situation which, if not

avoided, may result in minor or

moderate injury. It may also be used to

alert against unsafe practices.

NOTICE

This symbol indicates operator

awareness which, if not avoided, may

result in personal or property damage.