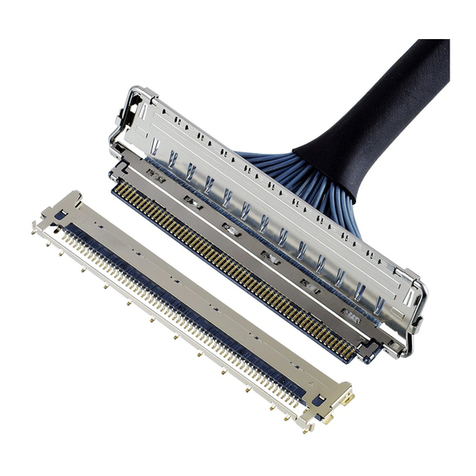

IPEX CABLINE-UA II PLUG User manual

Other IPEX Cables And Connectors manuals

IPEX

IPEX CABLINE-CAF User manual

IPEX

IPEX CABLINE-CA PLUG User manual

IPEX

IPEX 20613-0 E-0 Series User manual

IPEX

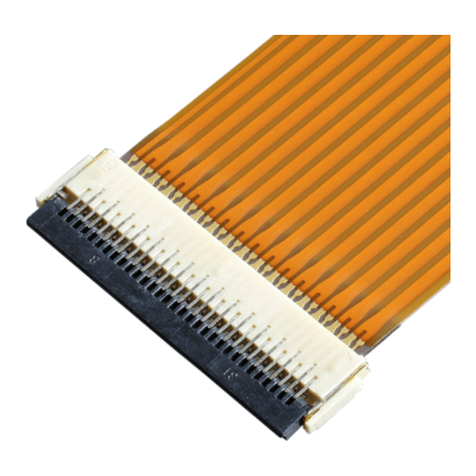

IPEX MINIFLEX 175-ST User manual

IPEX

IPEX AP-10 User manual

IPEX

IPEX CABLINE-UM User manual

IPEX

IPEX MHF I User manual

IPEX

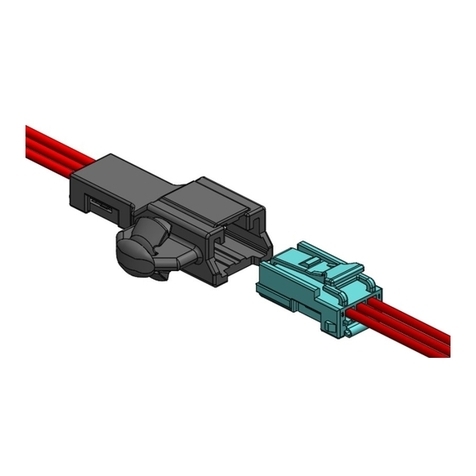

IPEX ISH User manual

IPEX

IPEX MINIFLEX 5-BF II User manual

IPEX

IPEX ISH User manual

IPEX

IPEX MP-A01 User manual

IPEX

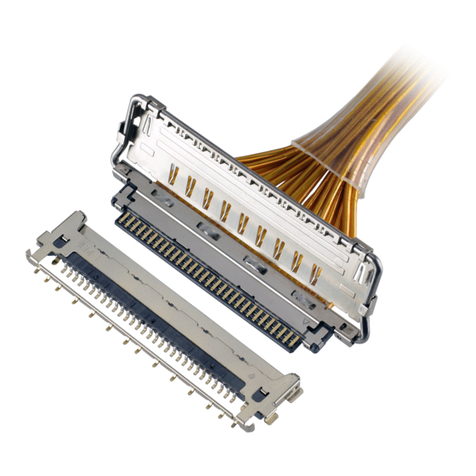

IPEX MINIFLEX 2-BF User manual

IPEX

IPEX CABLINE-VS IIF User manual

IPEX

IPEX CABLINE-VSF User manual

IPEX

IPEX NOVASTACK 35-HDP User manual

IPEX

IPEX CABLINE-VS II PLUG User manual

IPEX

IPEX CABLINE-UY 20857-0 T-0 Series User manual

IPEX

IPEX CABLINE-CAL PLUG User manual

IPEX

IPEX CABLINE-CAF User manual

IPEX

IPEX CABLINE-CX II With Cover User manual