IPEX ISH User manual

Other IPEX Cables And Connectors manuals

IPEX

IPEX CABLINE-CAF User manual

IPEX

IPEX ISH20P User manual

IPEX

IPEX CABLINE-VS II PLUG User manual

IPEX

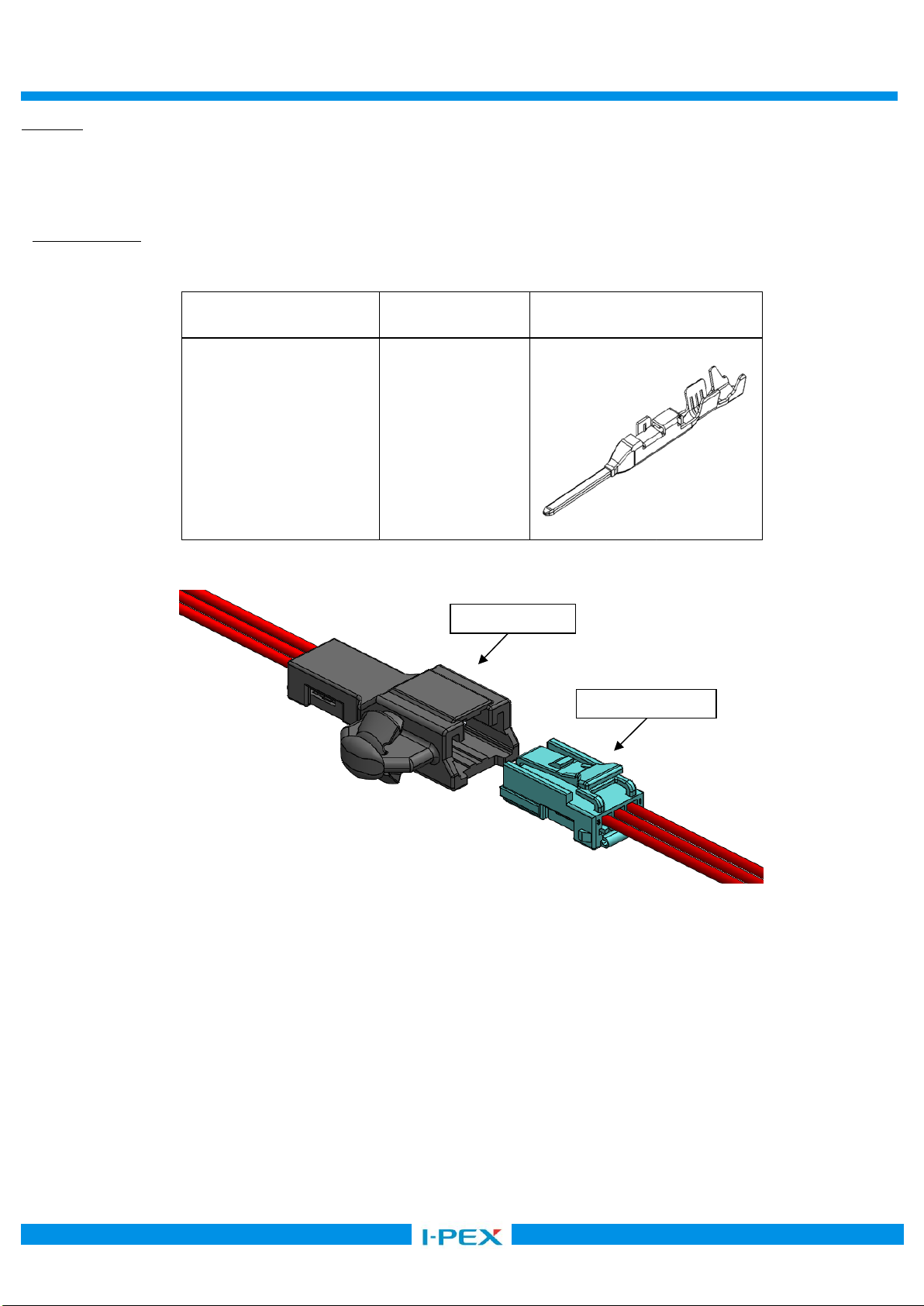

IPEX MP-A01 User manual

IPEX

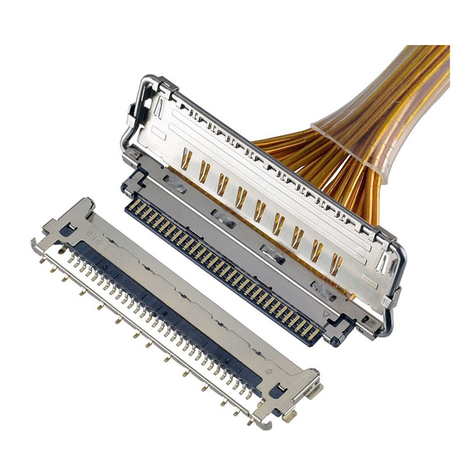

IPEX NOVASTACK 35-HDN User manual

IPEX

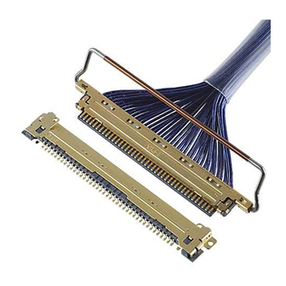

IPEX CABLINE-UY User manual

IPEX

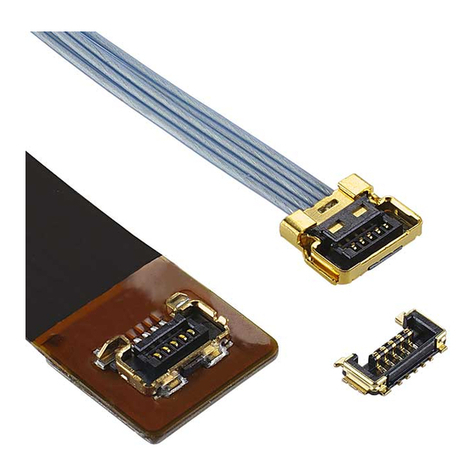

IPEX CABLINE-CAL PLUG User manual

IPEX

IPEX CABLINE-CAL User manual

IPEX

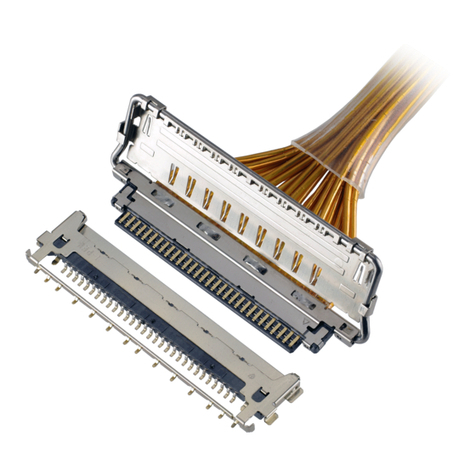

IPEX MP-A 03 User manual

IPEX

IPEX CABLINE-VS User manual

IPEX

IPEX CABLINE-VS IIF User manual

IPEX

IPEX CABLINE-VS PLUG User manual

IPEX

IPEX CABLINE-UY 20857-0 T-0 Series User manual

IPEX

IPEX NOVASTACK-B User manual

IPEX

IPEX CABLINE-CBL PLUG User manual

IPEX

IPEX CABLINE-VS IIF User manual

IPEX

IPEX ISH User manual

IPEX

IPEX ISH VW User manual

IPEX

IPEX MINIFLEX 5-BF II User manual

IPEX

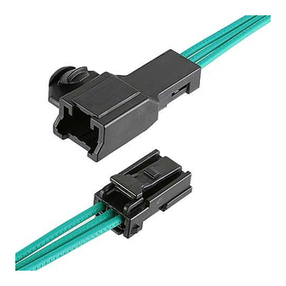

IPEX CABLINE-UA II PLUG User manual