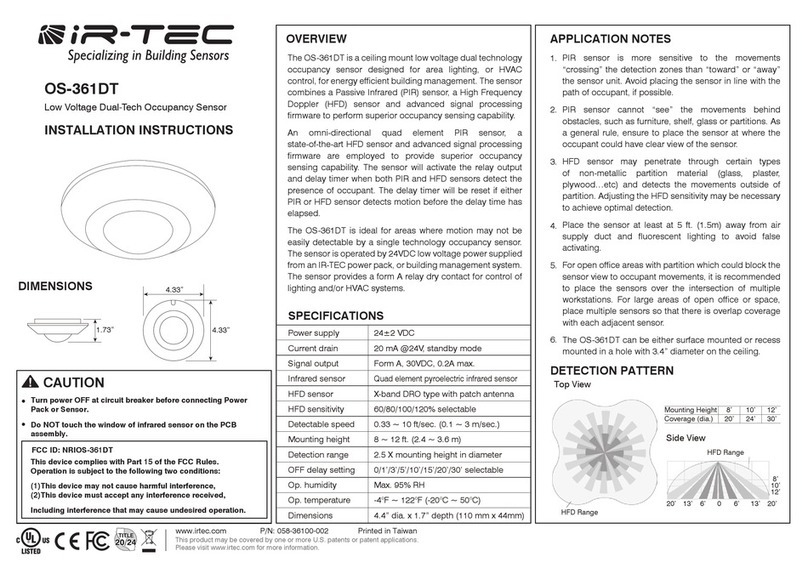

INSTALLATION

TESTING

Ensure the power has been turned OFF at the circuit breaker.

Prepare all wires with adequate length (cut the excessive

length if necessary) and properly striped.

Connect the wires of sensor with line voltage power and LED

driver ballast as the wiring diagram shown.

Carefully manage the wires to allow the sensor being

mounted in the wall box with screws. Do NOT use excessive

force when installing the sensor into the wall box as this

could bend the mounting plate and affect button operation.

Turn the circuit breaker ON. Refer to the TESTING section

and conduct sensor test if necessary. Snap-on the cover plate

after sensor test and setting complete.

1.

2.

4.

3.

5.

Apply power to the sensor*. Wait for the sensor to warm-up

(GREEN LED will blink during warm-up period).

*The connected light will be switched on as delay time set

(factory default 10 minutes) after the power applied. To speed

up the test, you may set the TIME potentiometer to position 1

(T) for shortest delay (10 seconds).

Walk within the desired range and observe the sensor LED

indication (GREEN blinks per 2 seconds to indicate PIR

detecting and BLUE blinks to indicate HFD detecting). Walk

outside of the desired range and observe if the HFD sensor

can detect the movement. If BLUE still blinks, reduce the HFD

sensitivity via DIP switch setting accordingly.

Replace the cover plate after testing and setting completed.

Do NOT forget to set the TIME at the desired position for

optimum delay after test.

1.

2.

3.

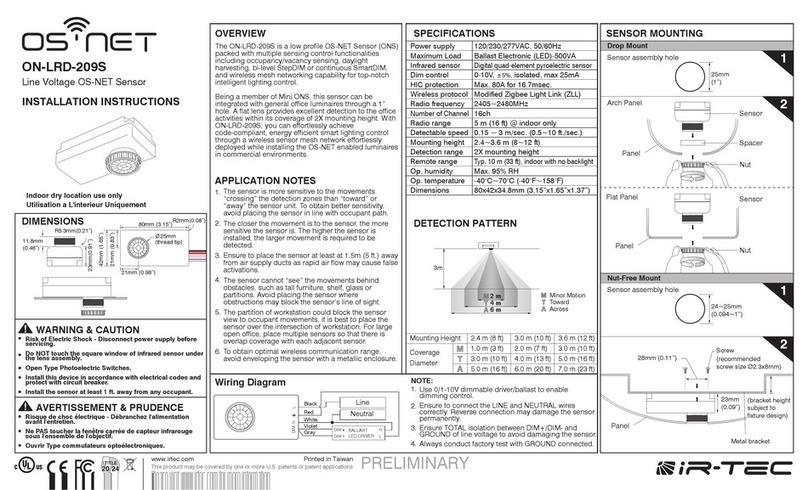

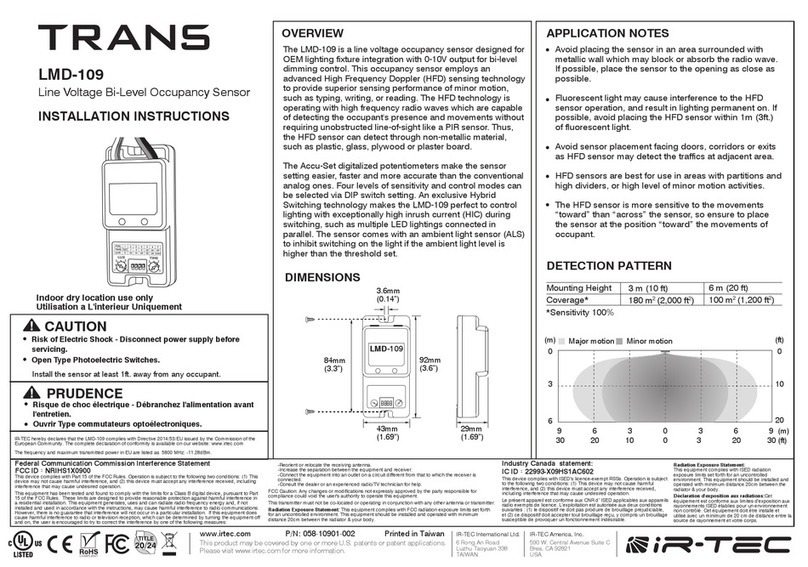

WIRING DIAGRAM

After installation complete, it is recommended to conduct

sensor test as instructed below;

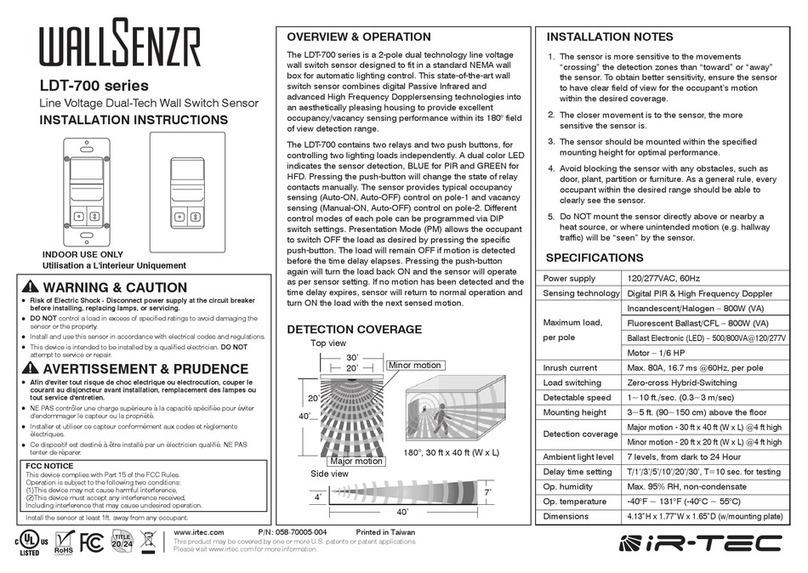

BUTTON OPERATION

Button operations allow the user to change

the ON-OFF status, temporarily adjust the

lighting level as desired, or memorize the

preferred level for the next presence.

Potentiometer

Sensor

Red

DIM+

0-10V Driver/Ballast

L

DIM N

Black

Line

120/277VAC

Green-Yellow

Gray

Violet

Ground

White

Neutral

LUX

1 7

2 6

3 5

4

TIME

1 7

2 6

3 5

4

LUX

TIME T

POS. 1 2 3 4 5 6 7

1’ 3’ 5’ 10’ 20’ 30’

10 20 35 50

100 150 24H

Factory Set

Connect the

GREEN-YELLOW wire to

the GROUND for safety.

NOTE:

To program the sensor control

mode or change the settings,

press the push-button cover and

slide it down as shown.

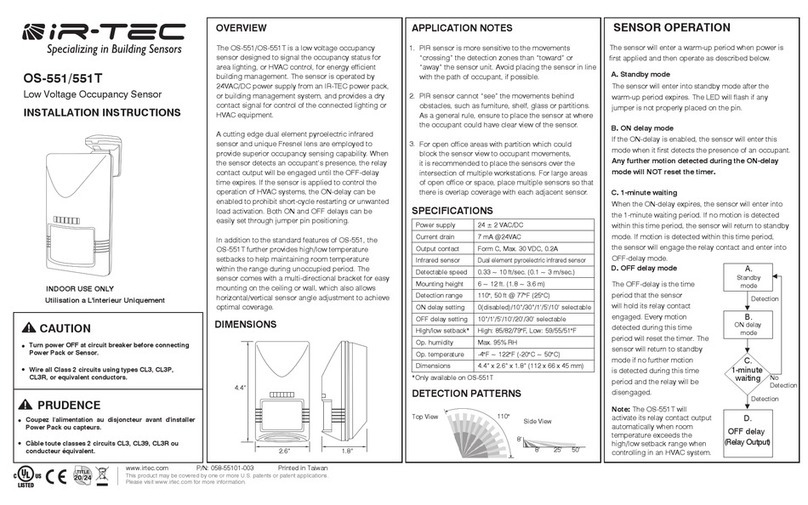

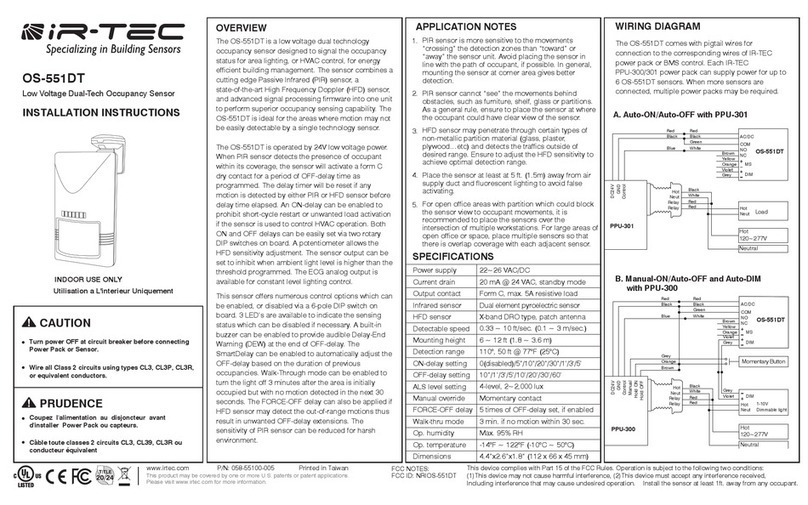

SETTING

Slide ON

1 2 3 4 5

TIME

LUX

Press

&

DIP

Switch

ON

1 2 3 4 5

TIME

LUX

LUX setting determines the threshold of ambient light level

that sensor will inhibit switching on the light. Factory set is

pointing at position 7 which allows sensor to switch on the

light anytime. Set the arrowhead to point different positions

for different ambient light level thresholds.

LUX – Ambient light level

TIME setting determines the delay time that sensor will hold

the light on after the last motion detected. Factory set is at 10

minutes and different times can be set by pointing the

arrowhead to different positions. NOTE: Set at position 1 will

shorten the delay to 10 seconds for 10 minutes. The delay

time will resume to 10 minutes if the potentiometer has not

been set to other position.

TIME - Delay time

4 levels of HFD sensitivity can be set

through different combinations of SW1 & 2.

DIP Switch

Switch #3 determines the operating

sensing technology of sensor. Setting it at

OFF position will disable the PIR sensor.

- SW5

Button Function Control

DUAL

HFD

ON

1 2 3 4 5

ON

1 2 3 4 5

ON

1 2 3 4 5

ON

1 2 3 4 5

Occ.

Vac.

ON

1 2 3 4 5

ON

1 2 3 4 5

ON/OFF

PM

Switch #4 sets the LDD-700 as an

occupancy sensor (factory default) or

vacancy sensor (SW4 is OFF).

Occupancy sensor – The sensor will turn on the light when PIR

detects the presence of an occupant, and turn the light OFF

automatically if no occupant activity has been detected by either

PIR or HFD sensor before the time delay elapses.

Vacancy sensor – Requires user to press any button of the

sensor to turn ON the light, and sensor will turn OFF the light

automatically if no occupant activity has been detected by either

PIR or HFD sensor before the time delay elapses.

Switch #5 determines the button

function control if the sensor is set as

an occupancy sensor (SW4 is ON).

ON/OFF (Manual Override) – Pressing ANY push-button will

turn OFF the load immediately and hold off until the button is

pressed again.

PM (Presentation Mode) – If PM mode is enabled (SW5 is

OFF), pressing any push-button will turn OFF the lights

immediately and hold off even with motion detected. Pressing

the push-button again will turn ON the lights and sensor

resumes its normal control. If no occupant activity is detected

before the delay time elapses, the sensor will resume its

normal control which means it will turn ON the light with the

next motion detected.

ON

1 2 3 4 5

ON

1 2 3 4 5

ON

1 2 3 4 5

ON

1 2 3 4 5

A short press on ANY button of an operating sensor will

change the ON-OFF status of controlled lighting.

NOTE: If the sensor is set as a vacancy sensor (SW4 at OFF)

and LUX is not at position 7, pressing the button will NOT turn

on the light if the ambient light level is HIGHER than the

threshold set.

Change the ON-OFF status

Press and hold the RIGHT button will continuously ramp the

lights up to the highest 100% (LED blinks in GREEN).

Intermittent press will increase the level step by step.

Press and hold the LEFT button will continuously dim the

lights down to the lowest 10% (LED blinks in BLUE).

Intermittent press will decrease the level step by step.

1.

2.

A long press on ANY button (>0.5 second) will enter into

Manual Dimming mode.

Adjust the lighting level

Press and hold BOTH buttons under Manual Dimming mode

until sensor LED indicates in Blue continuously.

Release both buttons, the LED will blink for 10 seconds and

sensor will save the current value as preferred level.

The controlled lights will flash ON and OFF for two times to

indicate saving complete.

1.

2.

3.

Memorize the preferred level

HFD Sensitivity - SW1 & 2

- SW3

Operating Sensor

- SW4Occupancy/Vacancy Sensor Selection

FADE

DOWN

RAMP

UP

LEFT RIGHT