OVERVIEW & OPERATION

The LDT-700 series is a 2-pole dual technology line voltage

wall switch sensor designed to fit in a standard NEMA wall

box for automatic lighting control. This state-of-the-art wall

switch sensor combines digital Passive Infrared and

advanced High Frequency Dopplersensing technologies into

an aesthetically pleasing housing to provide excellent

occupancy/vacancy sensing performance within its 180° field

of view detection range.

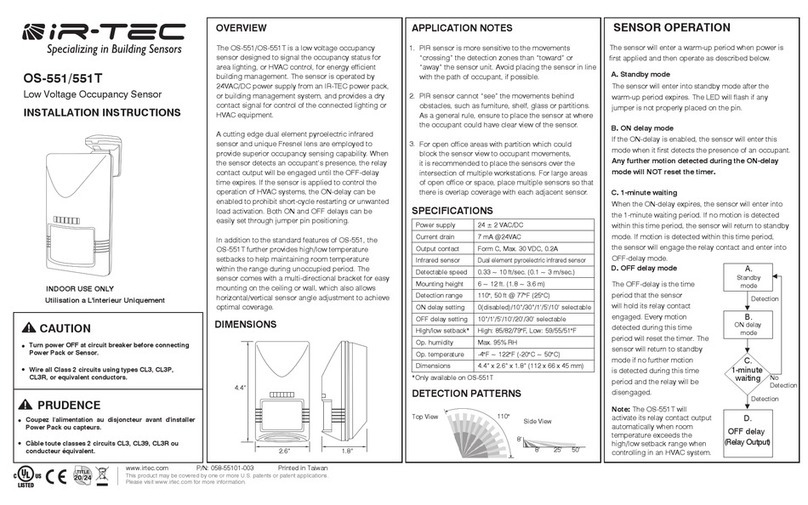

The LDT-700 contains two relays and two push buttons, for

controlling two lighting loads independently. A dual color LED

indicates the sensor detection, BLUE for PIR and GREEN for

HFD. Pressing the push-button will change the state of relay

contacts manually. The sensor provides typical occupancy

sensing (Auto-ON, Auto-OFF) control on pole-1 and vacancy

sensing (Manual-ON, Auto-OFF) control on pole-2. Different

control modes of each pole can be programmed via DIP

switch settings. Presentation Mode (PM) allows the occupant

to switch OFF the load as desired by pressing the specific

push-button. The load will remain OFF if motion is detected

before the time delay elapses. Pressing the push-button

again will turn the load back ON and the sensor will operate

as per sensor setting. If no motion has been detected and the

time delay expires, sensor will return to normal operation and

turn ON the load with the next sensed motion.

INSTALLATION NOTES

SPECIFICATIONS

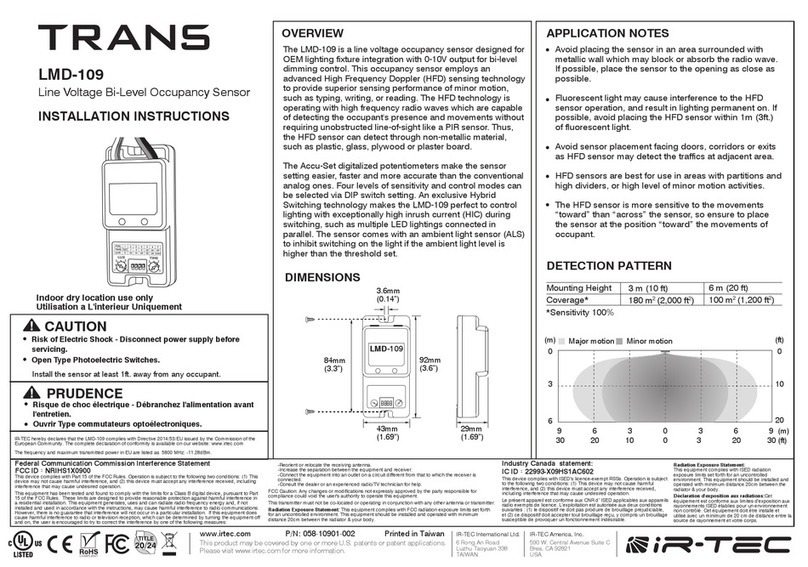

Line Voltage Dual-Tech Wall Switch Sensor

INSTALLATION INSTRUCTIONS

LDT-700 series

Power supply

Sensing technology

Inrush current

Load switching

Detectable speed

Mounting height

Ambient light level

Delay time setting

Op. humidity

Op. temperature

Dimensions

Detection coverage

Maximum load,

per pole

120/277VAC, 60Hz

Digital PIR & High Frequency Doppler

Incandescent/Halogen – 800W (VA)

Fluorescent Ballast/CFL – 800W (VA)

Ballast Electronic (LED) – 500/800VA@120/277V

Motor – 1/6 HP

Max. 80A, 16.7 ms @60Hz, per pole

Zero-cross Hybrid-Switching

1~10 ft./sec. (0.3~3 m/sec)

3~5 ft. (90~150 cm) above the floor

Major motion - 30 ft x 40 ft (W x L) @4 ft high

Minor motion - 20 ft x 20 ft (W x L) @4 ft high

7 levels, from dark to 24 Hour

T/1’/3’/5’/10’/20’/30’, T=10 sec. for testing

Max. 95% RH, non-condensate

-40°F ~ 131°F (-40°C ~ 55°C)

4.13”H x 1.77”W x 1.65”D (w/mounting plate)

INDOOR USE ONLY

Utilisation a L'interieur Uniquement

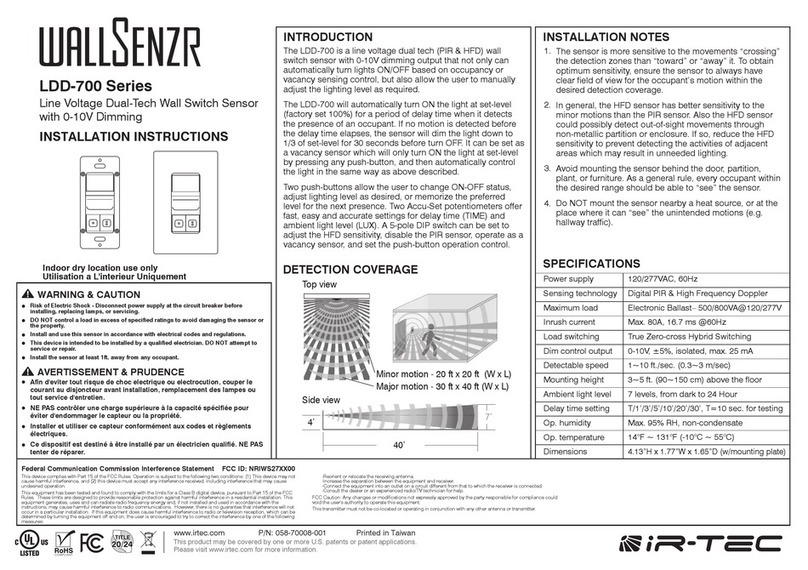

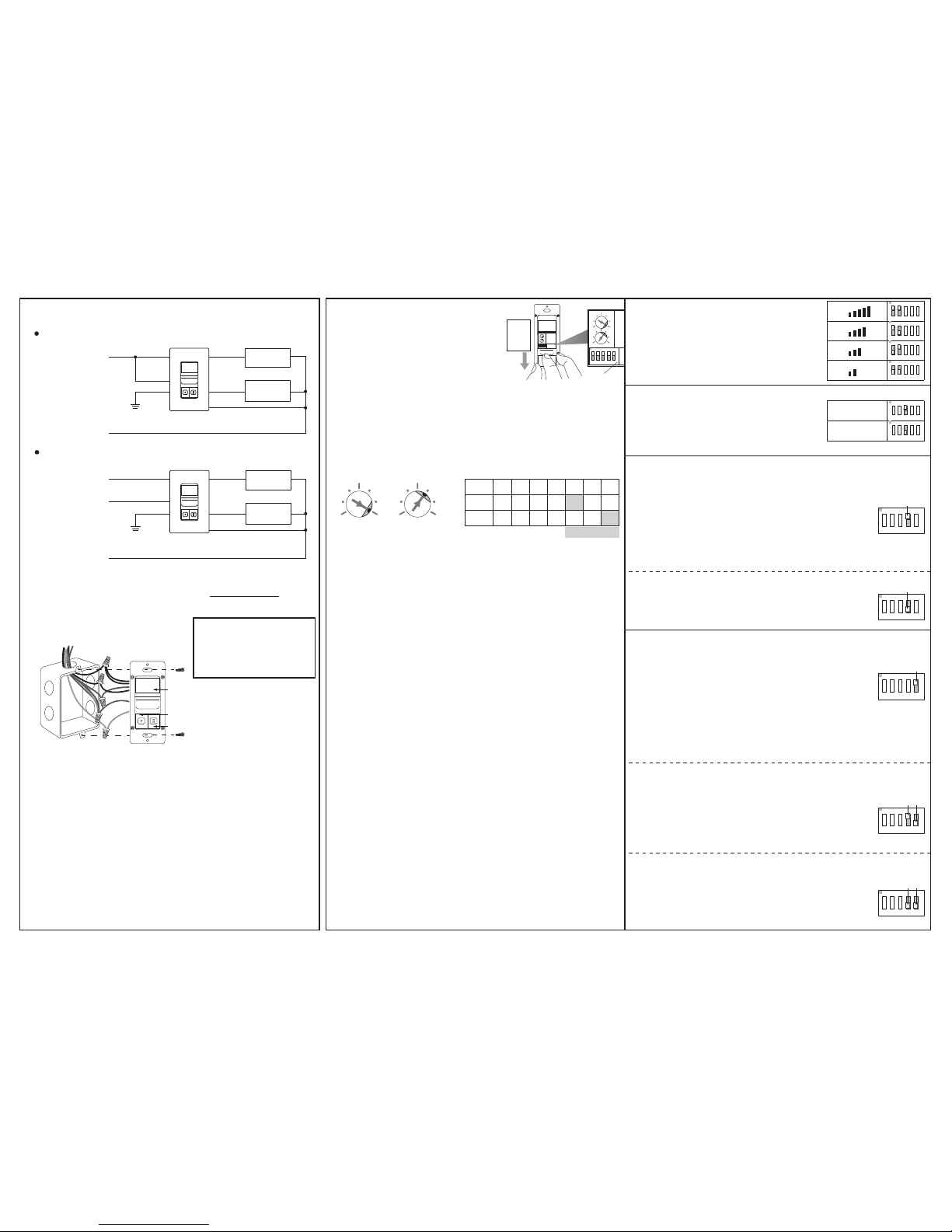

DETECTION COVERAGE

40’

Top view

Side view

4’ 7’

30’

40’

Minor motion

20’

20’

Major motion 180°, 30 ft x 40 ft (W x L)

Risk of Electric Shock - Disconnect power supply at the circuit breaker

before installing, replacing lamps, or servicing.

DO NOT control a load in excess of specified ratings to avoid damaging the

sensor or the property.

Install and use this sensor in accordance with electrical codes and regulations.

This device is intended to be installed by a qualified electrician. DO NOT

attempt to service or repair.

Afin d'eviter tout risque de choc electrique ou electrocution, couper le

courant au disjoncteur avant installation, remplacement des lampes ou

tout service d'entretien.

NE PAS contrôler une charge supérieure à la capacité spécifiée pour éviter

d'endommager le capteur ou la propriété.

Installer et utiliser ce capteur conformément aux codes et règlements

électriques.

Ce dispositif est destiné à être installé par un électricien qualifié. NE PAS

tenter de réparer.

This device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions:

(1)This device may not cause harmful interference,

(2)This device must accept any interference received,

Including interference that may cause undesired operation.

FCC NOTICE

WARNING & CAUTION

AVERTISSEMENT & PRUDENCE

Install the sensor at least 1ft. away from any occupant.

The sensor is more sensitive to the movements

“crossing” the detection zones than “toward” or “away”

the sensor. To obtain better sensitivity, ensure the sensor

to have clear field of view for the occupant’s motion

within the desired coverage.

The closer movement is to the sensor, the more

sensitive the sensor is.

The sensor should be mounted within the specified

mounting height for optimal performance.

Avoid blocking the sensor with any obstacles, such as

door, plant, partition or furniture. As a general rule, every

occupant within the desired range should be able to

clearly see the sensor.

Do NOT mount the sensor directly above or nearby a

heat source, or where unintended motion (e.g. hallway

traffic) will be “seen” by the sensor.

1.

2.

3.

4.

5.

P/N: 058-70005-004 Printed in Taiwanwww.irtec.com

This product may be covered by one or more U.S. patents or patent applications.

Please visit www.irtec.com for more information.