Introduction

Thank you for purchasing the MC-E controller by Irritrol. The MC-E controller is a solid-state irrigation controller,

capable of storing eight independent programs designed to meet the needs of commercial and contractor applications. The

MC-E is an enhancement to the existing MC controller with many more functions and display features. The new MC-E is

designed to be compatible with the previous MC Plus B cabinets and wiring connections.

Parts Diagram

1- 32-Character Dot Matrix LCD

2- Timing Mechanism Quick Release

3- Active Station Indicator Display

4- Function Dial

5- Flow Alarm Indicator LED

6- Master Valve Active Indicator LED

7- Power Supply Indicator LED

- Activates the LCD Display Backlight

- Use to navigate through the menu options

Table of Contents

Introduction -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -Pg. 3

Parts Diagram -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -Pg. 3

Cabinet Installation - -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- Pg. 4

Electrical Conduits Installation - -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- Pg. 4

Control Wires Installation -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- Pg. 5

Rain Sensor Installation (Purchased Separately) -- -- -- -- -- -- -- -- -- -- -- Pg. 6

Start Sensor Installation (Purchased Separately) -- -- -- -- -- -- -- -- -- -- -- Pg. 6

CLIMATE LOGICTM Weather Sensor Installation (Purchased Separately) -- Pg. 6

Power Source Installation -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- Pg. 7

Circuit Breaker Diagnostic System -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- Pg. 7

Power On / Reset Mode - -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- Pg. 8

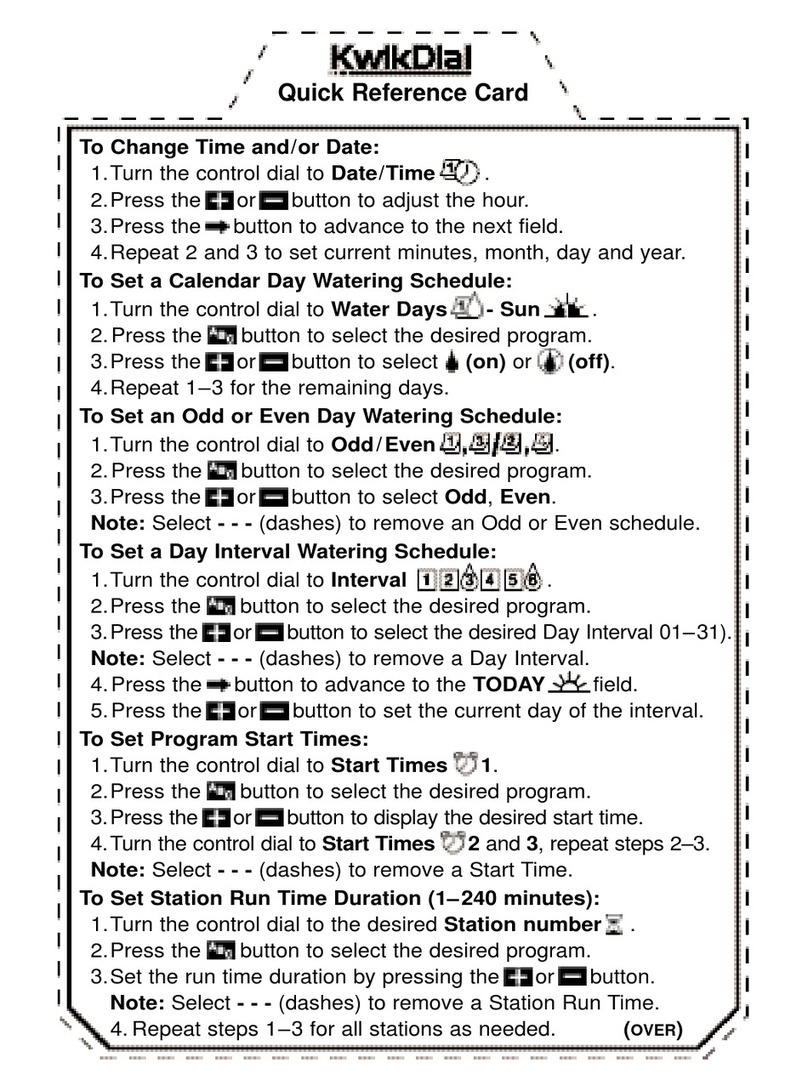

System SETUP

Time/Date Format- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- Pg. 8

Current Date ---------------------------------------------- Pgs. 8–9

Current Time -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- Pg. 9

Security Password -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- - Pg. 10

Set Master Valve ON or OFF per Station ------------------------ Pg. 11

Program SETUP

Assign Station & Runtime to a Program -------------------- Pgs. 12–13

Program Start Time - -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- --Pgs. 14–15

Station Delay Time ------------------------------------------ Pg. 16

Looping Start Time -------------------------------------- Pgs. 17–18

Watering Day Schedule -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- - Pgs. 19–22

Water Budget -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- - Pg. 23

Program Review -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- - Pg. 24

Program Erase

Single Program -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- - Pg. 25

Complete Program Reset -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- - Pg. 26

Complete Controller Reset ------------------------------------ Pg. 26

Station Test -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- - Pg. 27

Options

Option 1 ---------------------------------------------------- Pg. 28

Option 2 - -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- Pg. 28

Option 3 -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- - Pg. 29

Option 4 ---------------------------------------------------- Pg. 29

Option 5 -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- - Pg. 30

Rain Off -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- - Pg. 30

Semi-Auto Operation -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- - Pg. 31

Manual Operation -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- - Pg. 32

Remote Control (Purchased Separately) -- -- -- -- -- -- -- -- -- -- -- -- -- -- - Pg. 33

Flow Sensor -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- - Pgs. 34–38

Specications -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- - Pg. 39

Electromagnetic Compatibility - -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- Back Cover