TECHNICAL MANUAL Drive 2000 Mini Evo

October 2016-Rev. 1 3

1. Introduction

The servo-amplifiers series 2000 Mini are intended for the control of 3 phases brushless

servo-motors and asynchronous servo-motors.

The motors regulated by the series 2000 Mini servo-amplifiers should have the following

characteristics:

Rotor constructed with permanent magnets or winding cage arranged in 1, 2, 3, 4,

5 or 6 pole pairs, without commutator.

Stator constructed with 3 windings connected in star or delta.

Brushless motors: electronic commutation is performed by means of a feedback

type:

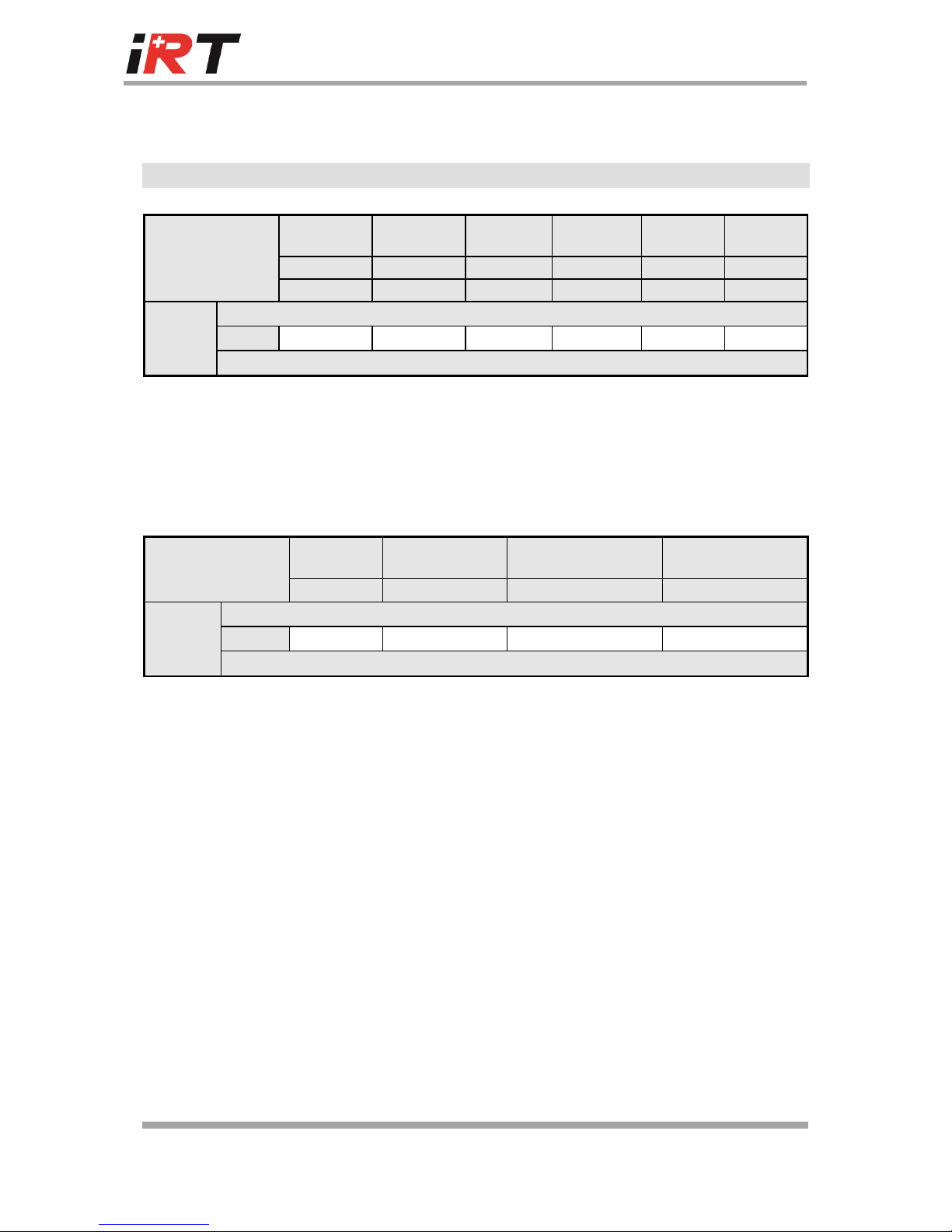

With control unit 2001

Speed one resolver

Incremental encoder with U, V and W signals

With control unit 2002

Absolute encoder SinCos Hiperface® compatible

EnDat 2.1

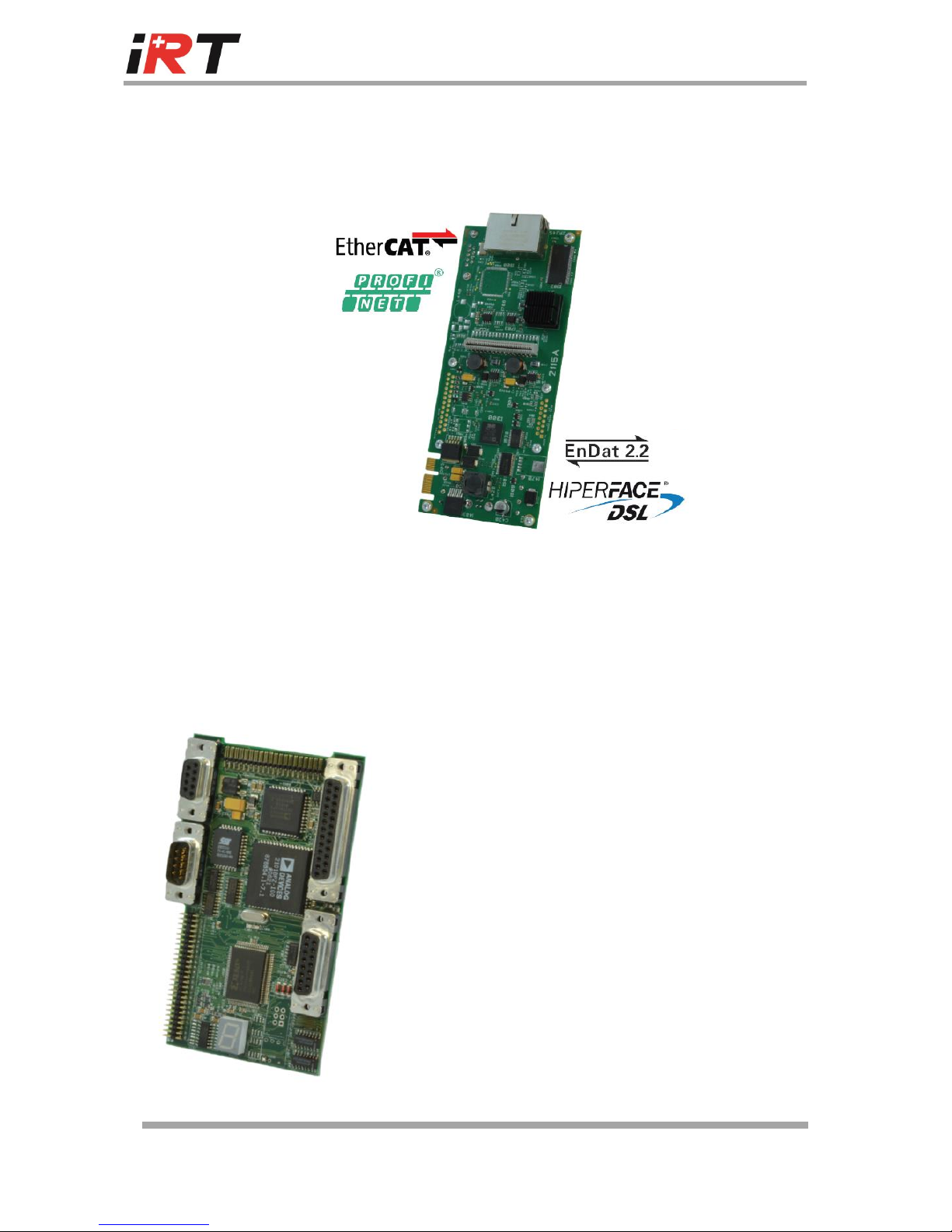

With control unit 2115

Speed one resolver

EnDat 2.1 / 2.2

Hiperface® DSL (single cable solution)

Asynchronous motors: electronic commutation is only performed by means of a

feedback type:

Speed one resolver

Incremental encoder.

Motors with Hall effect sensors and tachogenerator are not suitable.

The servo-amplifiers 2004 MiniEvoultion are fully digital. High-performance torque, speed

and positioning control fulfils all requirements for rapid response and control accuracy.