S pe z ia l el e kt r o ni k G mb H

Bautzner Landstr. 23 http://www.iseg-hv.de Fax ++ 49 (0) 351 / 26 996 - 21

D - 01454 Radeberg/ Rossendorf 3

Table of Contents

1

Safety instructions ............................................................................................................................................................5

2

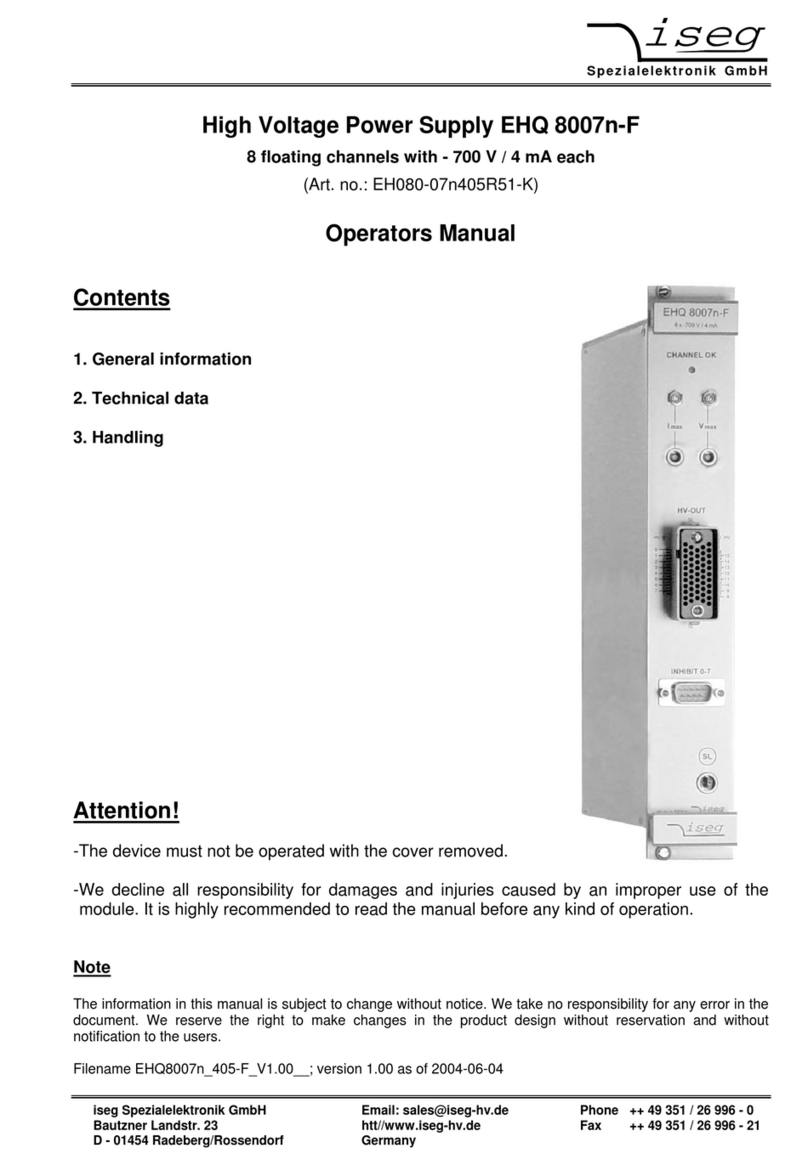

Device description ............................................................................................................................................................6

2.1

Technical data device class HPS, 300 W ......................................................................................................................7

2.2

Technical data device class HPS, 800 W ......................................................................................................................9

2.3

Electrical wiring of the high voltage output...................................................................................................................10

2.4

Dimensions ..................................................................................................................................................................11

3

Functional description.....................................................................................................................................................12

3.1

Operation states...........................................................................................................................................................12

3.2

Monitoring ....................................................................................................................................................................13

3.3

Interlock .......................................................................................................................................................................14

3.4

ARC Management .......................................................................................................................................................14

3.5

KillEnable.....................................................................................................................................................................15

4

Pinout .............................................................................................................................................................................15

4.1

Supply..........................................................................................................................................................................15

4.2

HV connection..............................................................................................................................................................15

4.3

OV connection .............................................................................................................................................................15

4.4

IL connection................................................................................................................................................................15

4.5

Interface connection.....................................................................................................................................................15

5

Operation........................................................................................................................................................................16

5.1

Operating mode ...........................................................................................................................................................16

5.2

Front panel operation...................................................................................................................................................16

5.3

Interface control ...........................................................................................................................................................19

5.4

Description of the Analogue I/O interface (AIO)...........................................................................................................25

6

Troubleshooting..............................................................................................................................................................27

6.1

Error messages on Displays ........................................................................................................................................27

6.2

Further Errors...............................................................................................................................................................27

7

Maintenance...................................................................................................................................................................27

List of Figures

Figure 2.1: Electrical wiring of the high voltage output ............................................................................................................10

Figure 2.2: Dimensioned drawing, in mm................................................................................................................................11

Figure 3.1: Operating area of the device.................................................................................................................................12

Figure 3.2: Power reduction vs. input voltage .........................................................................................................................14

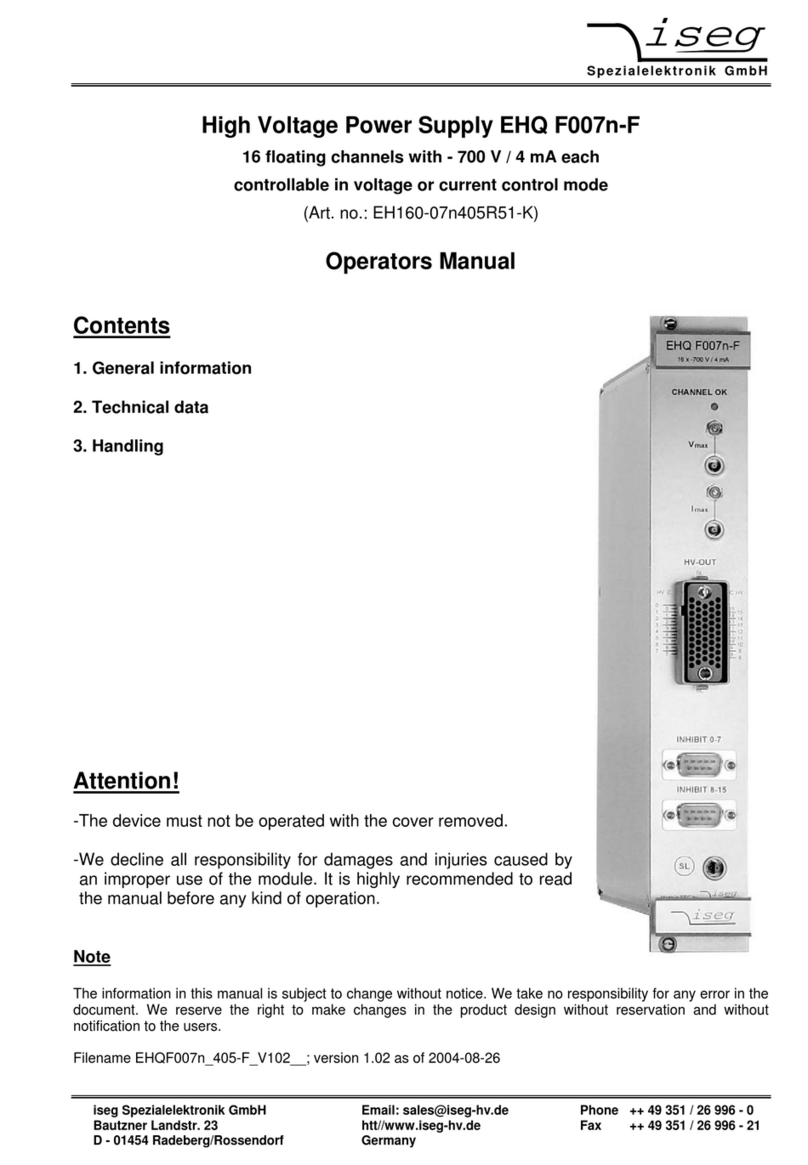

Figure 5.1: Back panel of the device .......................................................................................................................................15

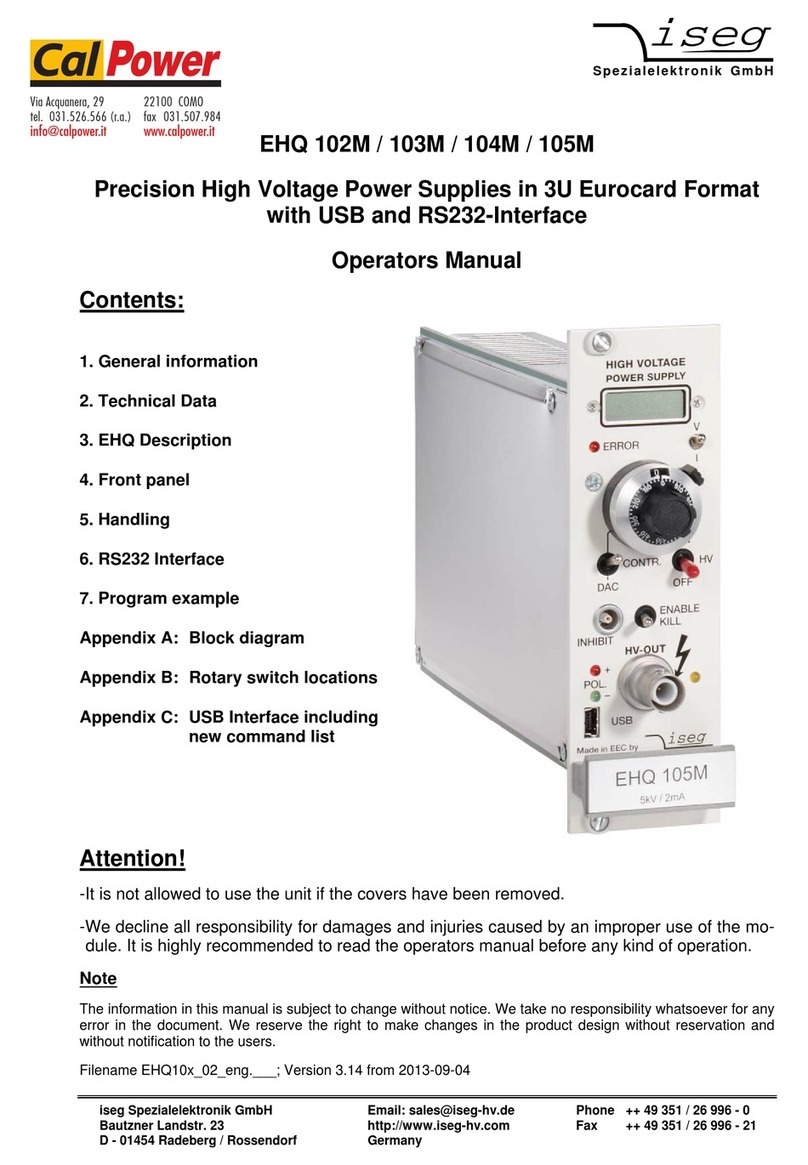

Figure 6.1: Front panel (HV connector at the front).................................................................................................................16

Figure 6.2: Set values the display in HV OFF state.................................................................................................................16

Figure 6.3: Set values the display in HV ON state ..................................................................................................................16

Figure 5.4: Electrical wiring of the analogue and digital in- and outputs..................................................................................26