Spezialelektronik GmbH

Bautzner Landstr. 23 http://www.iseg-hv.de Fax ++ 49 (0) 351 / 26 996 - 21

D - 01454 Radeberg/ Rossendorf 7

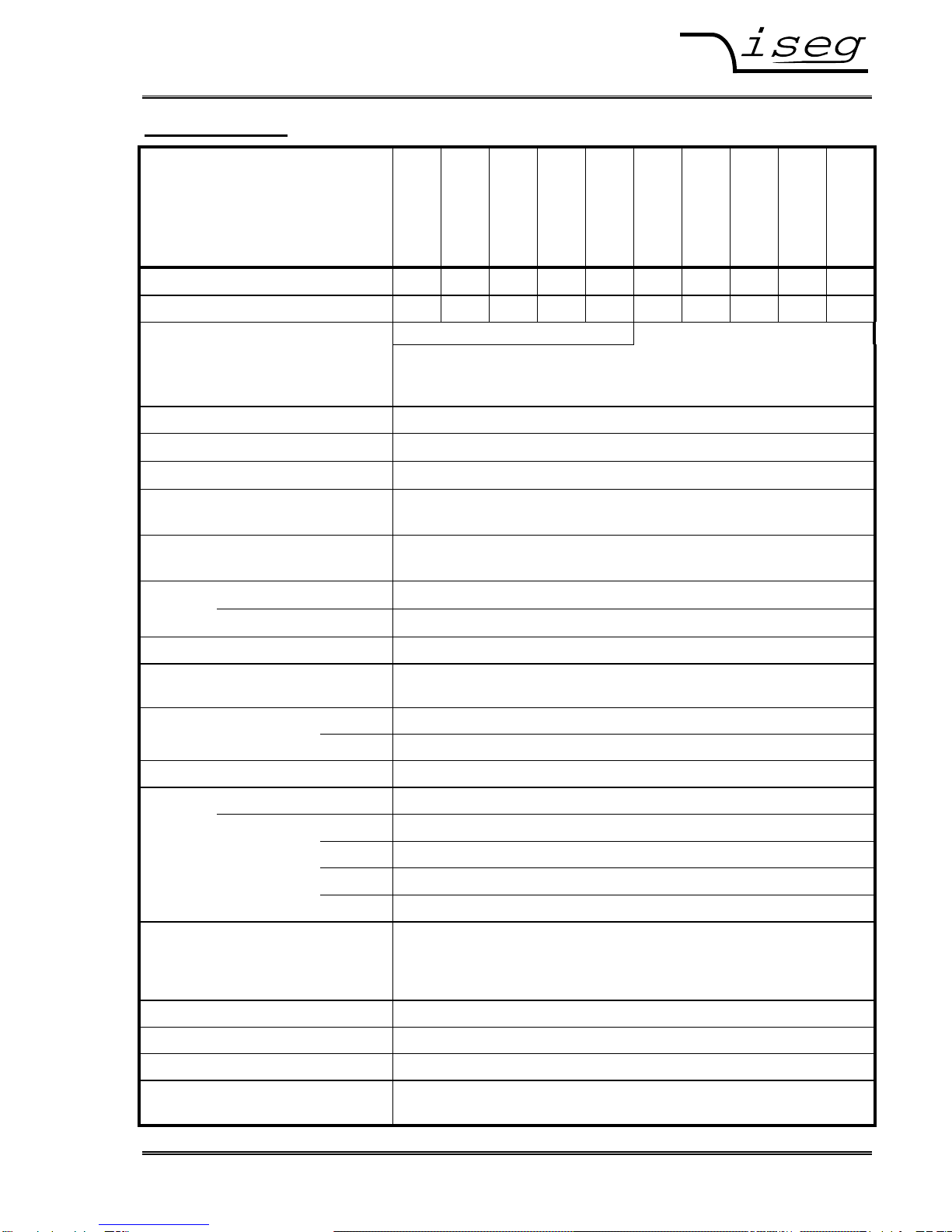

3. Technical Data

19“ / 1U - series HPx)1 300 W

HPx)1 10 307

HPx)1 20 157

HPx)1 30 107

HPx)1 40 756

HPx)1 60 506

HPx)1 80 356

HPx)1 120 256

HPx)1 150 206

HPx)1 200 156

HPx)1 300 106

Output voltage VOUT max [kV] 1 2 3 4 6 8 12 15 20 30

Output current IOUT [mA] 300 150 100 75 50 35 25 20 15 10

HV-connector SHV front side (opt. rear side) Lemo-HV-connector rear side

V

OUTmax ≤16kV: Lemo ERA.1Y.416.CLL

V

OUTmax > 16kV: Lemo ERA.3Y.425.CLL

Attention: Use with connected HV connector only !

Output power max. 300 W

Polarity Factory fixed ⇒)1x = p: positive ⇒)1x = n: negative

Ripple & noise < 1 ∗10-4 ∗VOUTmax (VP-P)

Voltage stability < 1 ∗10-4 ∗VOUTmax (load to no load, ∆VIN and repeatability)

in the output voltage range: 5 V ≤VOUT ≤VOUTmax

Current stability < 2 ∗10-3 ∗IOUTmax ( RLmin ≤RL< no load and ∆VIN)

in the output voltage range: 5 V ≤VOUT ≤VOUTmax

Accuracy voltage measurement ± (0,05% ∗Vout + 0,02% ∗Vout max + 1 digit) for one year

current measurement

± (0,05% ∗Iout + 0,02% ∗Iout max + 1 digit) for one year

Display 4-digit LED-Display for current and voltage

Resolution of voltage and current

measurement via Interface: VOUTmax / 50000 via Display: limited to 4 digit

I

OUTmax / 50000

Resolution of settings LOCAL VOUTmax / 2000 and IOUTmax / 2000

Voltage / Current REmote VOUTmax / 50000 and IOUTmax / 50000

Switching of output voltage with button “ON/OFF” or via remote control

Control LOCAL 10-turn potentiometer for voltage and current

(REMote) CAN via CAN-Interface (also for diagnosis / software update)

RS232 via RS232-Interface

optional: aIF via indirect coupled analogue I/O instead of RS232-Interface

optional: IEEE via IEEE-Interface additionally

Supply VIN = 85 up to 264 V-AC with PFC

IIN = 1,7 A at 230V-AC / 3,5 A at 115 V-AC

via mains connector and switch “POWER“, isolated from HV-output,

fused with 2 ∗6,3 A / slow.

Dimension / Weight 1U -19“ compatible / depth: 450 mm / ca. 5,7 kg

Cooling Internal fan

Protection Over load and short circuit , voltage supply and temperature

Environment conditions Operating temperature: 5 up to 35 °C

Humidity: 30% up to 80 %, no condensation