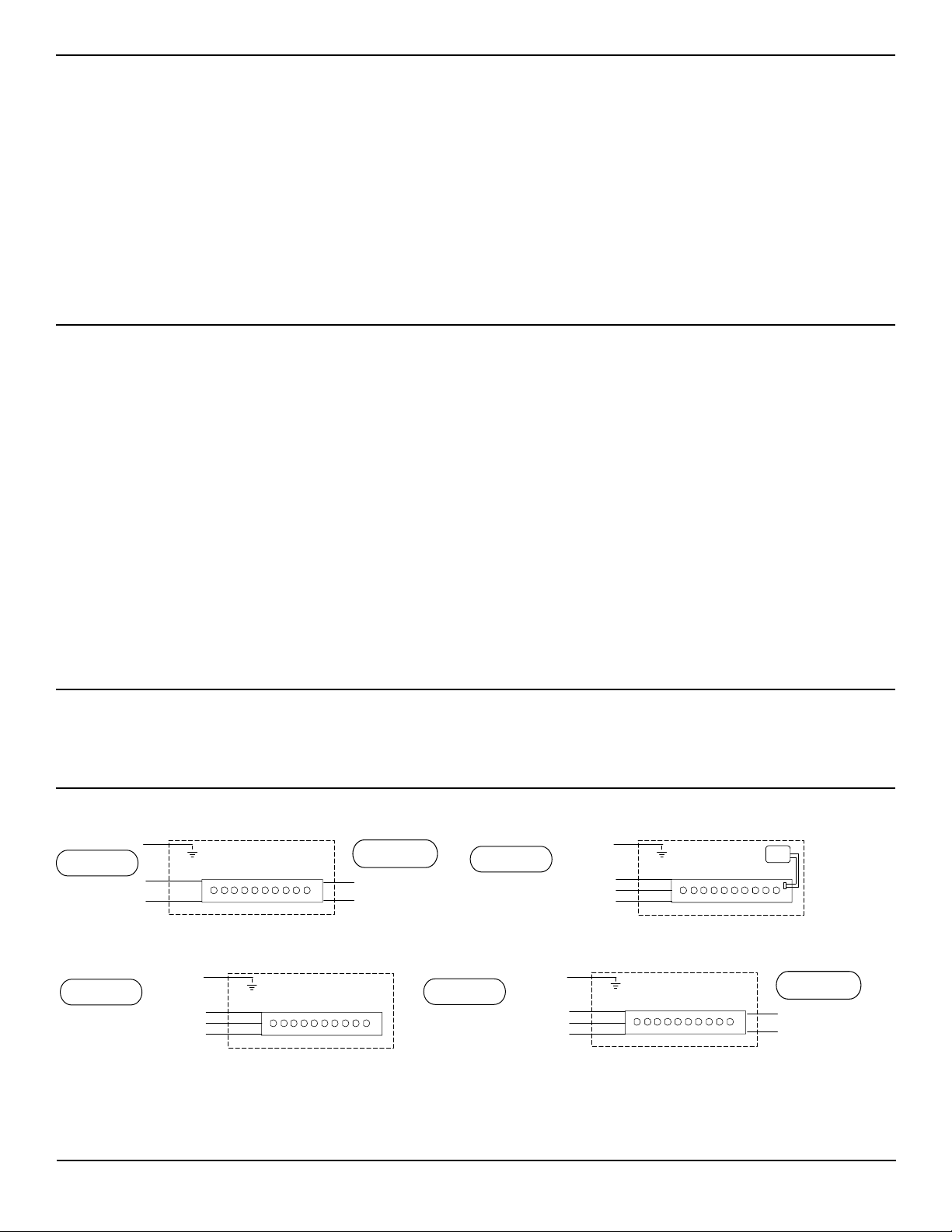

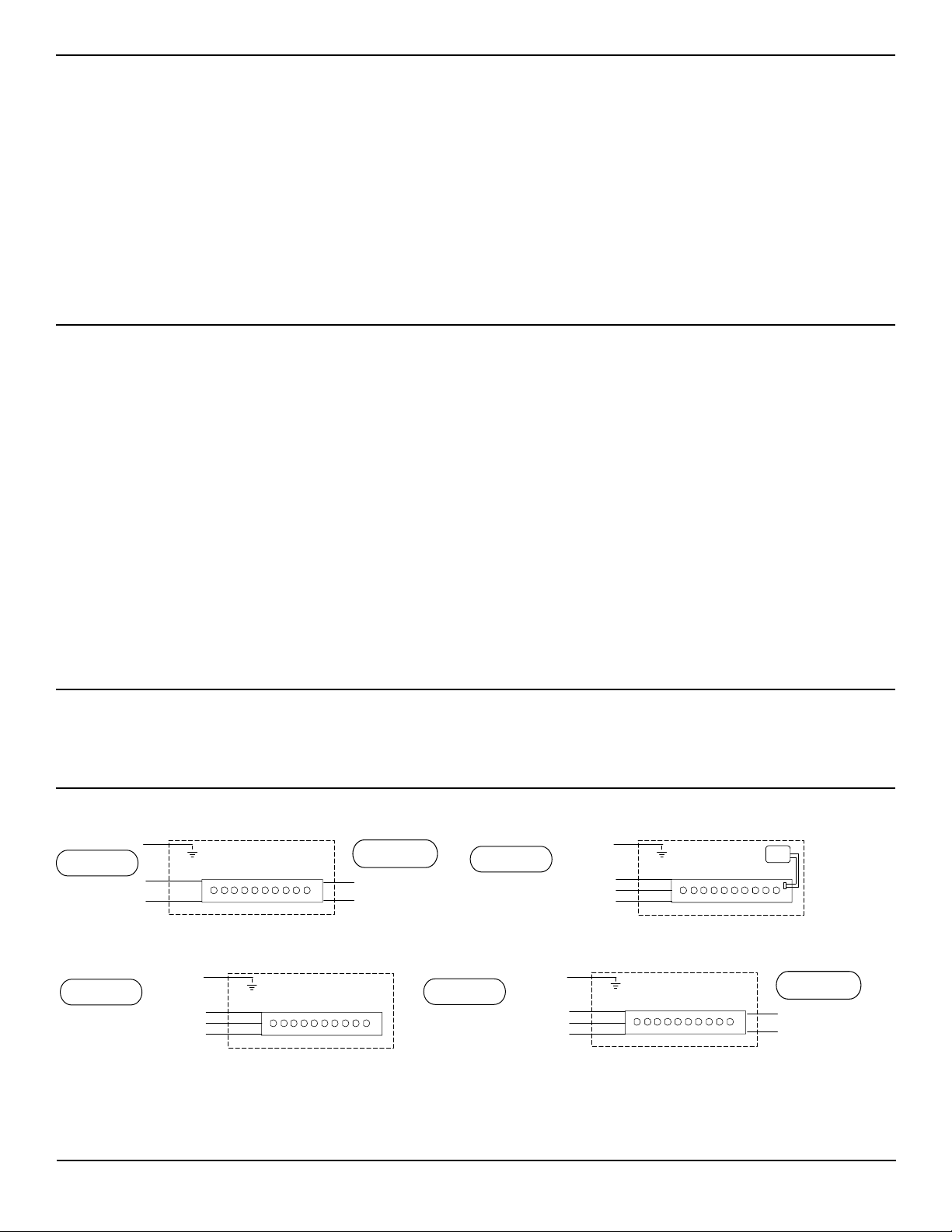

Chassis GND LED Board

AC ONLY SIGN

Chassis GND

GREEN Ground

BLACK 120VAC

RED 347VAC or ORANGE 200-277VAC

WHITE Neutral

LED Board

AC & UNIVERSAL DC SIGN

YELLOW Positive 6 to 24VDC

PURPLE Negative

Emergency Supply

FROM Battery Pack

Chassis GND

24 hours

Unswitched Supply

GREEN Ground

BLACK 105 to 360VAC

WHITE Neutral

LED Board

From Generator OR

Emergency Supply

BROWN 105 to 360VAC

BLUE Neutral

NOTE: Cap unused AC Wire!

NOTE: Cap unused AC Wire!

24 hours

Unswitched Supply

GREEN Ground

BLACK 120VAC

RED 347VAC or ORANGE 200-277VAC

WHITE Neutral

24 hours

Unswitched Supply

Chassis GND LED Board

NOTE: Cap unused AC Wire!

GREEN Ground

BLACK 120VAC

RED 347VAC or ORANGE 200-277VAC

WHITE Neutral

24 hours

Unswitched Supply

Ni-Cd

Battery

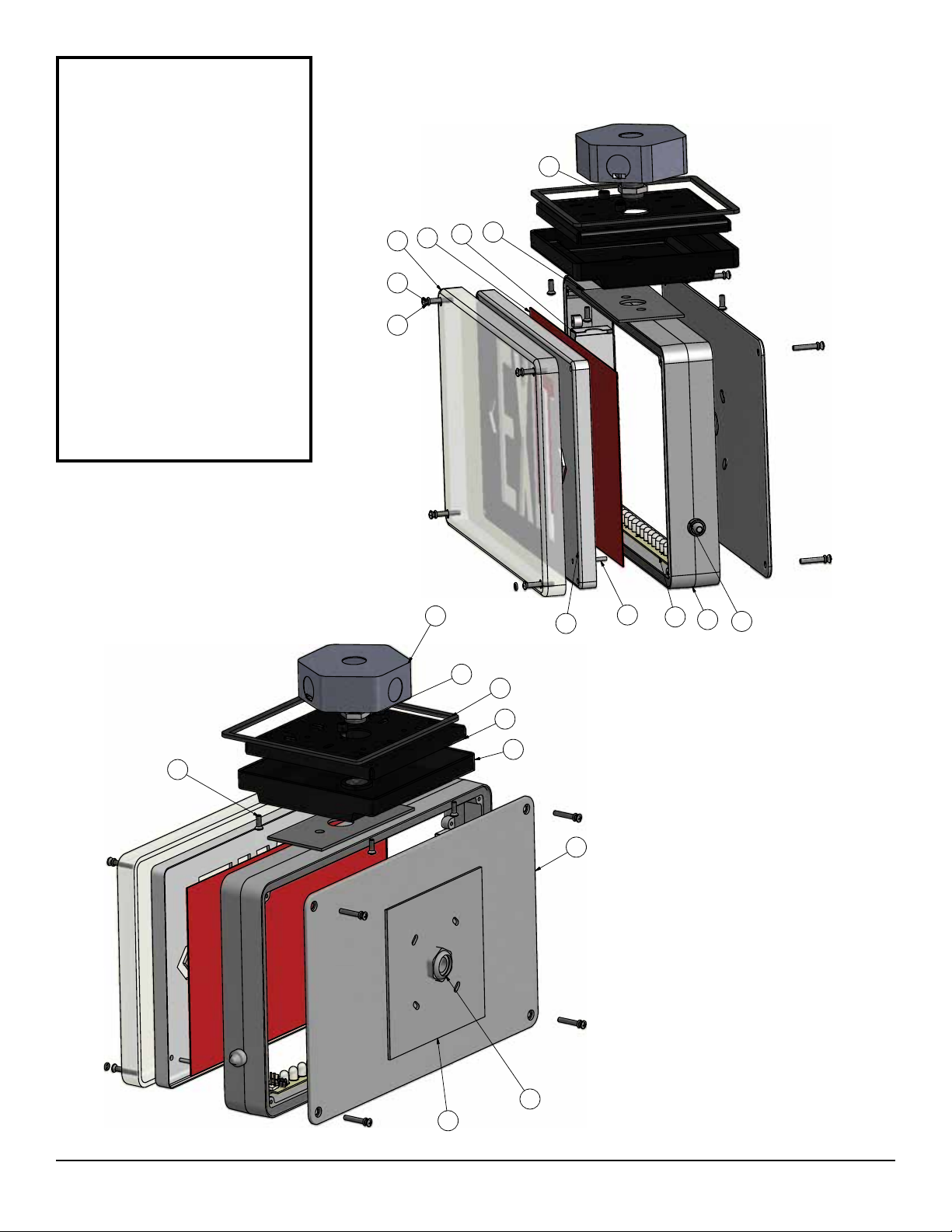

CEILING/END MOUNT INSTALLATION

WALL MOUNT INSTALLATION:

1. Remove torx screws (9) to release clear cover (1). There are 4 O-rings (10) inserted to the clear cover screw holes.

Release the stencil (2) from the clear cover (1). Knockout to remove the chevron as necessary from the stencil.

Peel off backing paper from the tape on the back of the stencil and carefully position and stick the colored fibre to the

stencil.

2. To install canopy kit, knockout on the top (for ceiling mount) or the knockout on the side (for end mount). Position

canopy gasket and the canopy (14). Install the cap screws and the washers. Attach canopy nuts and then tighten.

Install the liquid tight bushing (12), feed the lead wired through the bushing and tighten to complete the liquid tight

seal. Install the canopy mounting base (15) to the octagon box (11) (not supplied). Connect wires per diagram

provided. Caution! Failure to insulate unused wire may result in a shock hazard or unsafe condition as well as

equipment failure. The mounting base can be rotated for the desired mounting angle. Install the canopy (14) to the

mounting base (15) with the supplied screws.

3. Note: When installing the cover, be sure to align the light pipe (5) and LED indicator.

4. Apply power.

SELF-POWERED:

1. For models Max-SP, plug the battery into the circuit board per (wiring diagram) self-powered sign.

MAINTENANCE

1. Clean face(s) on a regular basis.

NOTE: The servicing of any parts should be performed by qualified service personnel only. The use of replacement

parts not furnished by Manufacturer may cause equipment failure and will void the warranty.

WIRING DIAGRAM

1. Remove torx screws (9) to release clear cover (1). There are 4 O-rings (10) inserted to the clear cover screw holes.

Release the stencil (2) from the clear face cover (1). Knockout to remove the chevron as necessary from the stencil.

Peel off backing paper from the tape on the back of the stencil (2) and carefully position and stick the colored fibre to

the stencil.

2. Remove the back plate (16) knockouts using applicable knockout holes. Install the liquid tight bushing into the large

centre knockout with the lock nut (12). Feed the lead wires through the bushing, tighten to complete the liquid tight

seal and install the wall gasket (18) then secure the back plate and housing to the wall. Connect wire per wiring

diagram provided. Caution! Failure to insulate unused wire may result in a shock hazard or unsafe condition as

well as equipment failure.

3. Replace faceplate, clear cover and torx screws. Note: When installing the cover, be sure to align the light pipe (5) and

LED indicator.

4. Apply power.

Headquarters: Isolite 31 Waterloo Avenue, Berwyn, PA, 19312 Phone: (610) 647-8200 Fax: (610) 296-8952

Western Office: Isolite 3563 Sueldo Suite M, San Luis Obispo, CA 93401 Phone: (800) 799-5343 Fax: (805) 546-9564