Installing the Panel

Pa

e 7

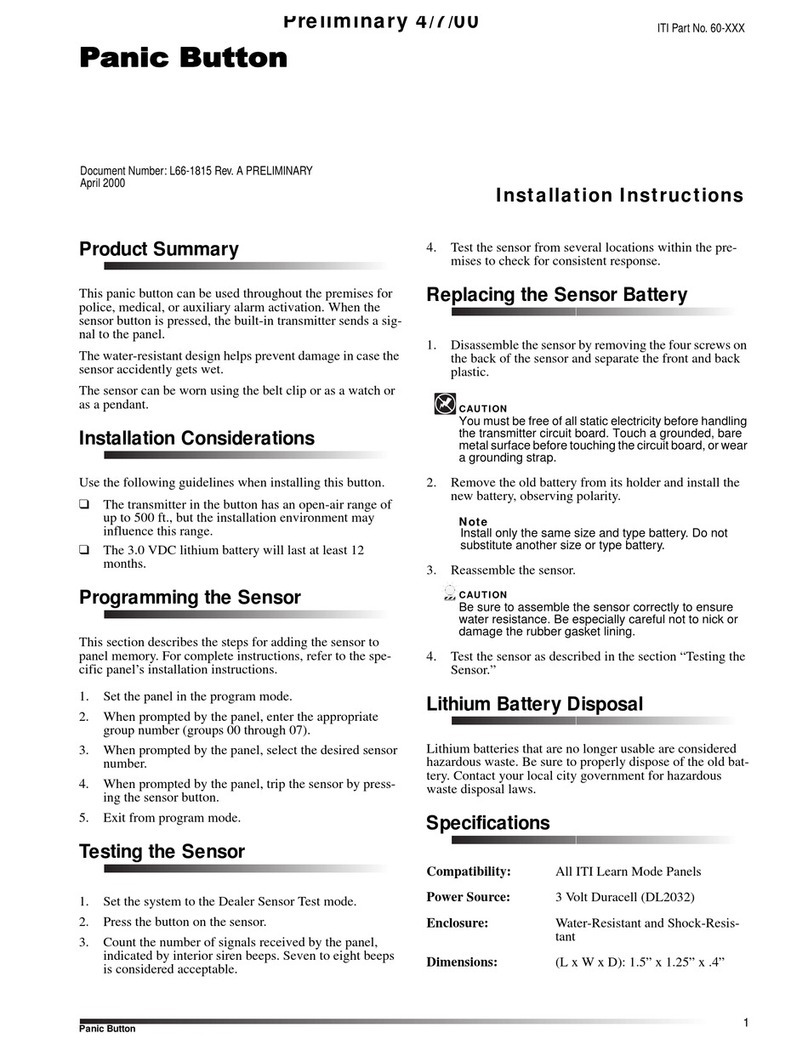

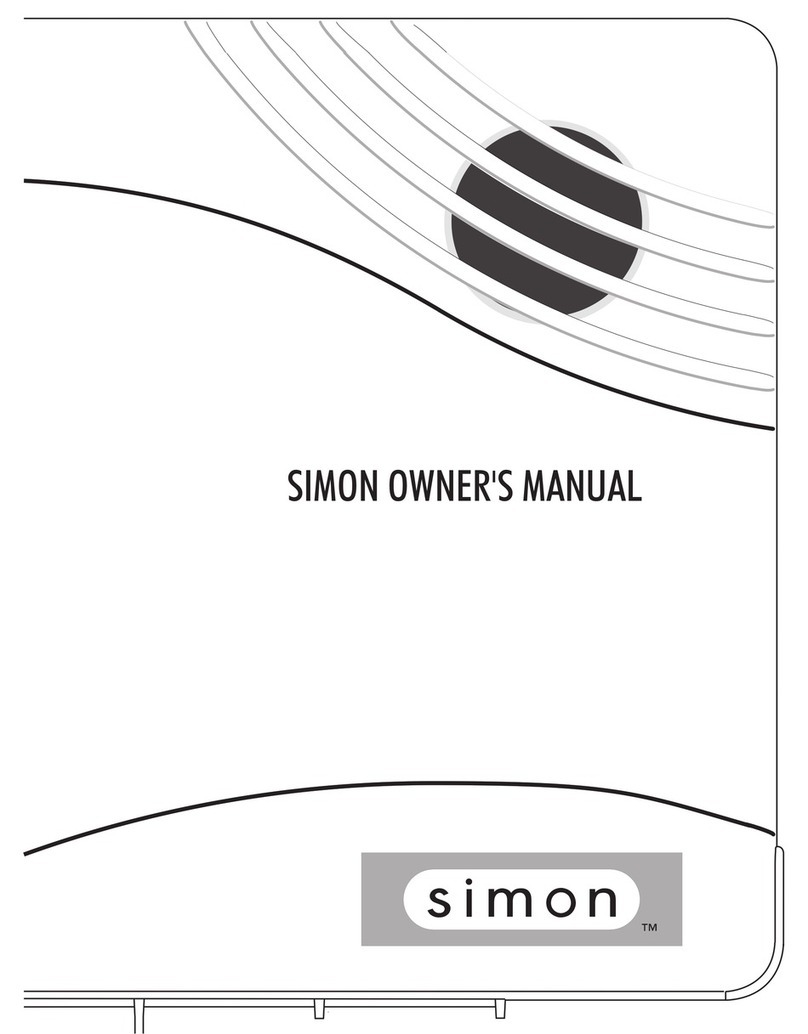

Figure 19. Positioning the Battery Door

Plugging In the Panel

After you have made all the wiring and phone connections

to the panel and installed the backup batteries, plug in the

panel to power up the system and activate the backup batter-

ies.

To plug in the panel:

1) Plug the transformer into an outlet that is not controlled

by a switch.

The Power and Ready LEDs turn on, and the panel

announces,

System nn, sensor mm

, where

nn

is the

software version number and

mm

is the wireless sensor

capacity for the panel (from 01 to 17).

Note: The first time the panel is powered up, the sys-

tem sounds trouble beeps and all LEDs are on

steady, indicating that nothing has been pro-

grammed into memory yet.

If the Power and Ready LEDs are off and no voice

message is announced, unplug the transformer and

refer to Appendix D “Troubleshooting.”

Note: If the TROUBLE LED blinks, it may be because

the NiCd batteries are low. The batteries may

need to be charged for 24 hours. Although the

panel can charge low batteries, the TROUBLE

LED may blink for up to 24 hours while the batter-

ies are charging.

Note: If you’re installing NiCd batteries, make sure the

batteries are fully charged before installing them

(see Appendix D “Troubleshooting“). Fully

charged batteries are at least 1.2 VDC per bat-

tery or 7.2 VDC for six batteries.

2) Press STATUS to check the system’s condition.

3) Unplug the transformer, then remove the existing screw

securing the AC outlet cover.

CAUTION: Use extreme caution when securing the

transformer to a metal outlet cover. You

could receive a serious shock if the metal

outlet cover drops down onto the prongs

of the plug while you are securing the

transformer and cover to the outlet box.

4) Hold the outlet cover in place and plug the transformer

into the lower receptacle.

5) Use the screw supplied with the transformer to tighten

the transformer to the outlet cover.

Adjusting the Panel Speaker Volume

The panel speaker has eight volume levels for status sounds

and status messages. Alarm sounds and messages are always

at full volume.

To adjust the panel speaker volume:

Press and hold COMMAND until the panel volume

reaches the desired level.

The panel repeats,

Hello …

once for each of the eight

available volume levels. It starts at level 8 (full vol-

ume) and ends with level 1 (low volume). When the

volume reaches level 1, it returns to level 8.

P

OWER

READY

STAY

A

WAY

N

O

D

ELAY

T

ROUBLE

12345

67890

BYPASS COMMAND

POLICE

FIRE

AUX

STATUS

PLACE BATTERY DOOR IN THIS POSITION,

THEN SLIDE UP

8333G65B.DS4