About This Manual ...............................................5

Special Installation Requirements .................5

UL-Listed Installations .............................5

UL-Canada Listed Installations ................6

California State Fire Marshall

Listed Installations ....................................6

Planning the Installation ........................................6

Standard Panel ...............................................6

SuperBus 2000 Touchpads .............................6

SuperBus 2000 RF Receivers ........................6

Power Line Carrier Card ................................7

Phone Supervision Card .................................7

Supervised Wireless Siren .............................7

SuperBus 2000 Phone Interface/Voice

Module ...........................................................7

SnapCards ......................................................7

SuperBus 2000 8Z Input

Module (HIM) ................................................7

SuperBus 2000 4-Relay Output

Module (HOM) ..............................................7

Interrogator 200 Audio

Verification Module .......................................7

Installing the System .............................................7

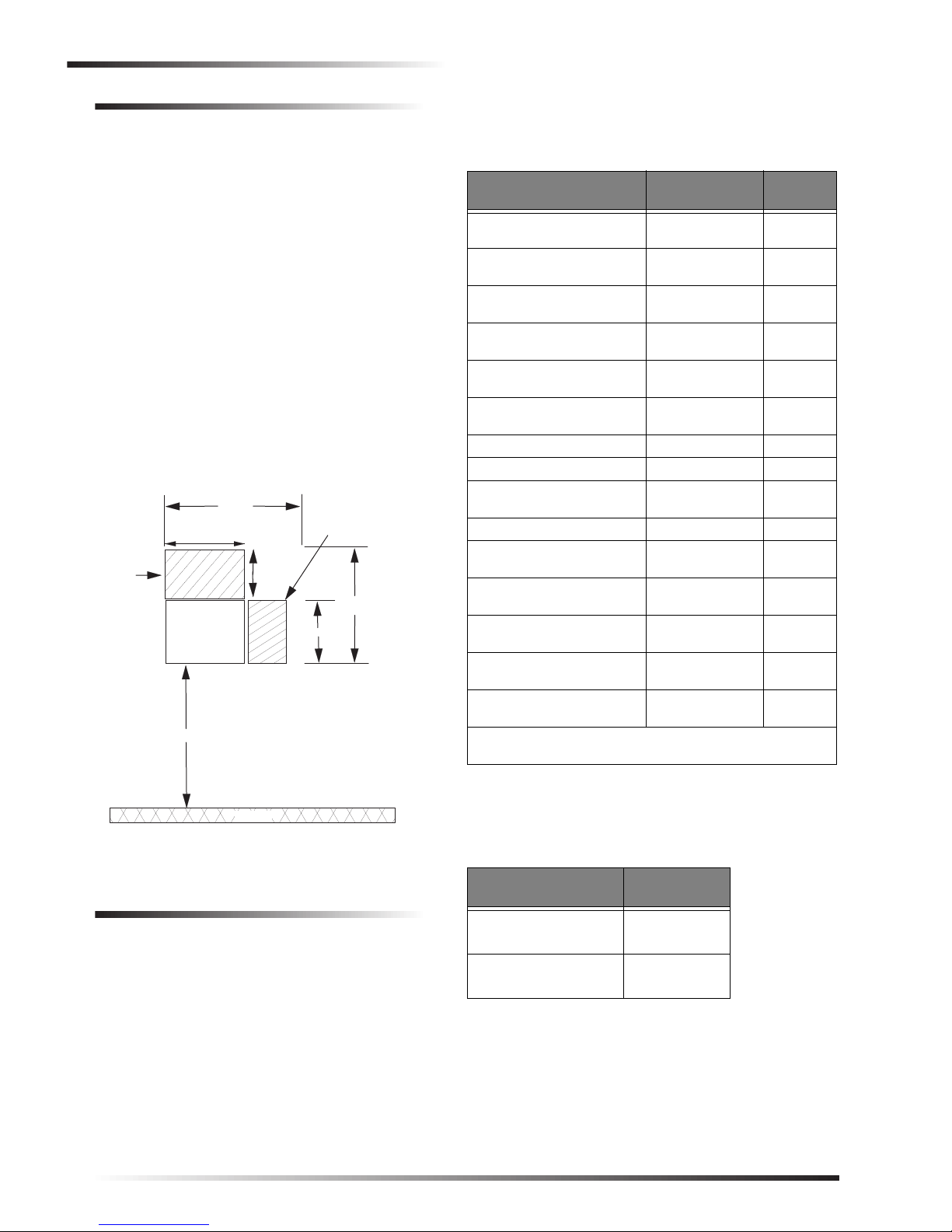

Determine the Panel Location ........................8

Total System Power and Wire Length

Guidelines ......................................................8

Mounting the Panel ........................................9

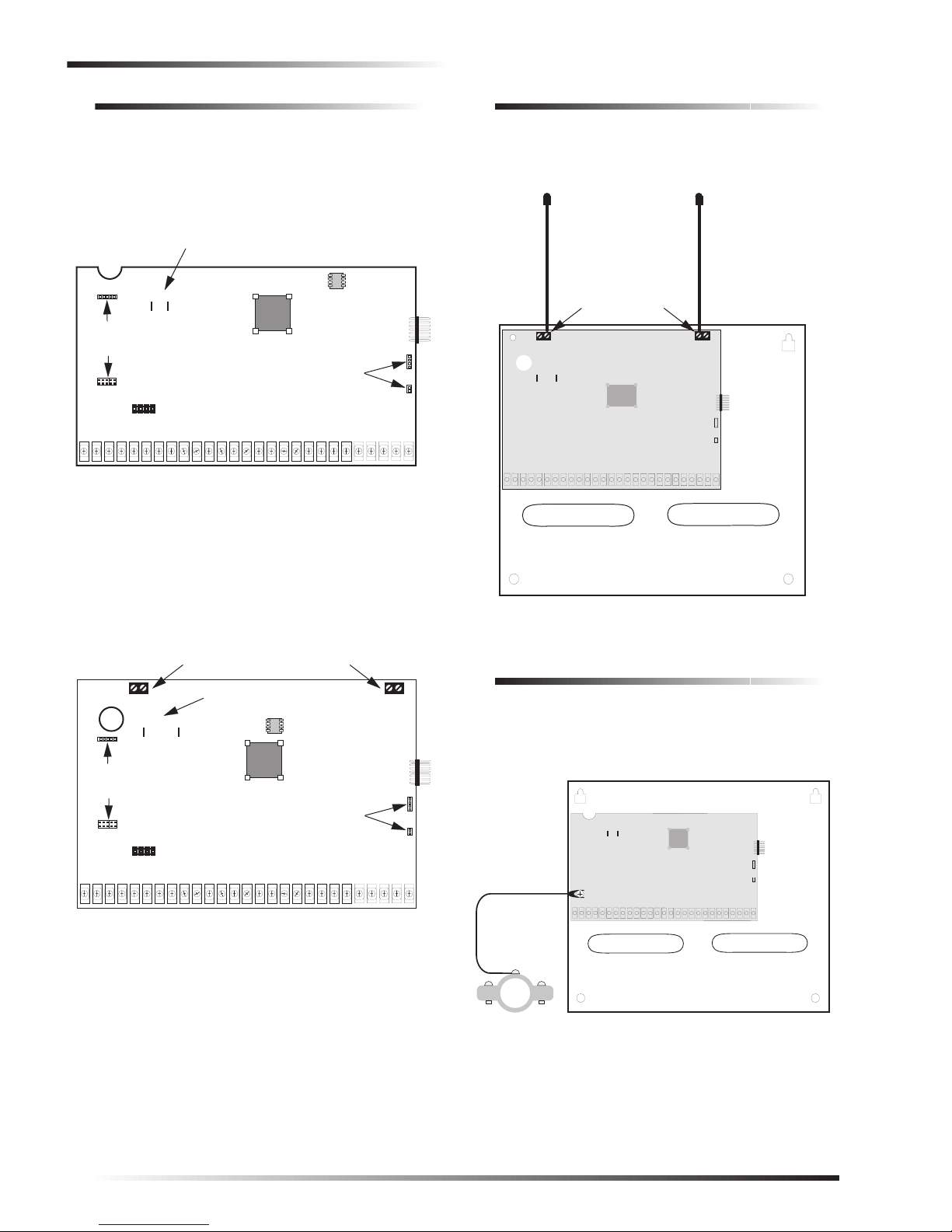

Identify Panel Components ..........................10

Installing Antennas ......................................10

Connecting the Panel to Earth Ground ........10

Installing the Optional Power Line

Carrier Card ................................................. 11

Installing the Optional Phone

Supervision Card .......................................... 11

Installing Optional SnapCards ..................... 11

Connecting Detection Devices to Panel

Zone Inputs ..................................................12

Connecting Intrusion Detection Devices 12

Connecting 2-Wire Smoke Detectors .....12

Connecting 4-Wire Smoke Detectors .....13

Connecting Speakers ....................................13

15-Watt Speaker ......................................14

Hardwire Interior Speaker ......................14

Connecting Piezo Sirens ..............................14

Exterior Sirens ........................................15

Interior Sirens .........................................15

Installing Supervised

Wireless Sirens .............................................15

Connecting an Interrogator 200

Audio Verification Module ..........................16

Connecting Alphanumeric and

Fixed Display Touchpads .............................16

Installing SuperBus 2000 Modules ..............17

SuperBus 2000 RF Receiver

(60-764-01-95R-16Z/32Z/MAX) ...........17

SuperBus 2000 Phone

Interface/Voice Module............................18

Energy Saver Module...............................19

SuperBus 2000 8Z Input Module.............19

4-Relay Output Module ..........................20

Setting Device Address on SuperBus

2000 Devices ................................................20

Installing an RJ-31X Phone Jack .................20

Connecting the Phone Line to the

Panel with a DB-8 Cord ...............................21

Connecting the AC Power Transformer .......21

Powering Up the Panel .................................22

Programming the Panel .......................................22

Entering Program Mode ...............................22

Touchpad Button Programming Functions ..23

Moving Through Program Mode

Tiers and Menus ...........................................23

Programming Tier 1 Menu Items .................24

Programming Tier 2 Menu Items .................24

Using Shortcut Numbers .........................25

Security Menu .........................................25

Phones Menu ...........................................27

Phone Options Menu ...............................30

Timers Menu ...........................................34

Light Control Menu ................................36

Touchpad Options Menu .........................36

Reporting Menu ......................................37

Siren Options Menu ................................41

Sensors Menu ..........................................42

Audio Verification Menu ........................44

Accessory Modules Menu .......................45

Onboard Options Menu ...........................48

Exiting Programming Mode .........................50

Entering User Programming Mode ..............50

Time and Date Menu ...............................50

User Codes Menu ....................................50

Options Menu ..........................................52

Set Up Schedules Menu ..........................53

Attach Schedules to Events Menu ..........53

Energy Saver Menu .................................55

Attach Lights to Sensors Menu ...............55

System Version Menu .............................55

Downloader Programming ...........................56

ToolBox Downloader Programming .......56

Document No. 466-1512-01 August 2, 2000

Preliminary

Installation Instructions

This document describes the installation, programming, testing,

and troubleshooting procedures for installing Concord 2.0 secu-

rity systems.