Copyright IXXAT Automation GmbH FlexRay CCM Manual, Version 2.4

Contents

3

1Introduction ..............................................................................5

1.1 Overview .............................................................................5

1.2 Features ..............................................................................5

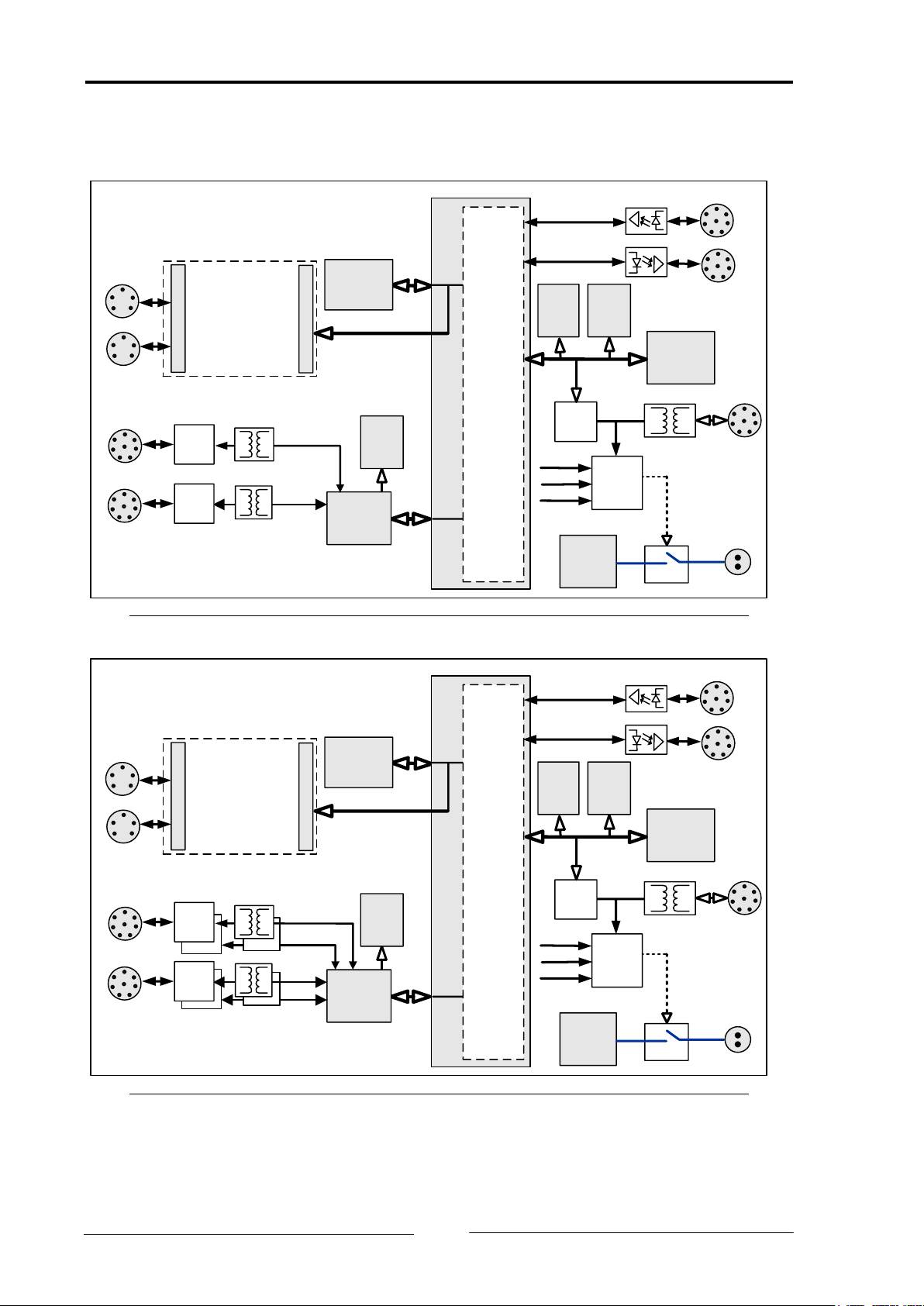

1.3 Block diagram .....................................................................6

1.4 Support...............................................................................7

1.5 Returning hardware............................................................8

2Installation.................................................................................8

2.1 Hardware installation .........................................................8

2.2 Software installation ..........................................................8

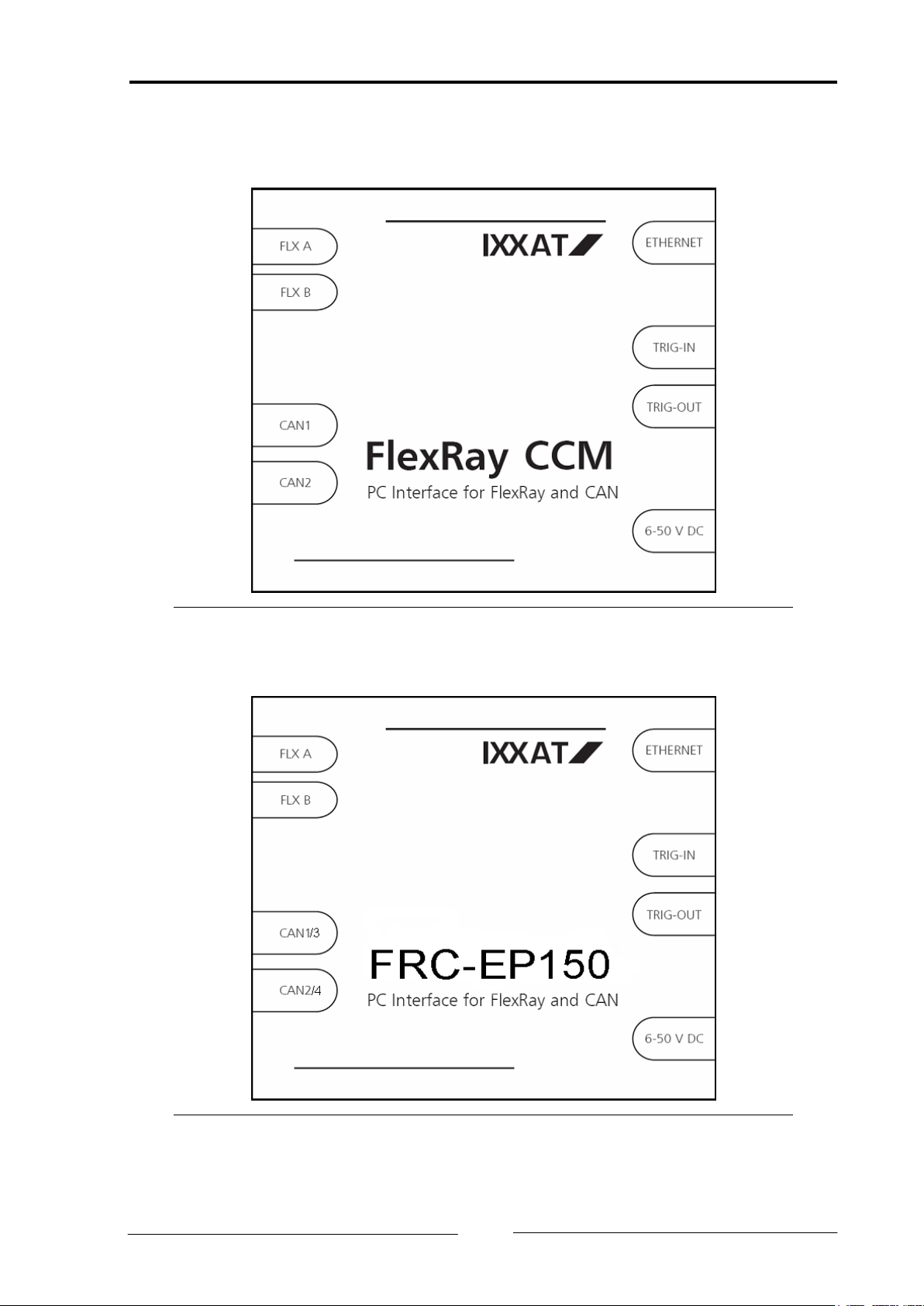

3Connections...............................................................................9

3.1 Pin assignment .................................................................10

3.1.1 FlexRay connector (FLX A & FLX B) ........................................... 11

3.1.2 FlexRay CCM CAN connector (CAN1 & CAN2) .......................... 12

3.1.3 FRC-EP150 CAN connector (CAN1/3 & CAN2/4)....................... 12

3.1.4 Power connector (6 - 50 V DC) ................................................ 13

3.1.5 Ethernet connector (ETHERNET)............................................... 14

3.1.6 Trigger/Digital-Out connector (TRIG-OUT)................................ 15

3.1.7 Trigger-In connector (TRIG-IN) ................................................. 15

3.2 Shielding...........................................................................16

3.3 Trigger/Digital output .......................................................17

3.4 Trigger input .....................................................................20

4Displays ...................................................................................21

5Firmware updates....................................................................22

Appendix ........................................................................................23

Technical specifications ...........................................................23

Ordering codes ........................................................................24

Accessories ..............................................................................25

Information on disposal of waste equipment.........................30

Information on EMC ................................................................30

Declaration of conformity .......................................................31

FCC Compliance.......................................................................32