IXXAT iPC-I 165 User manual

The expert for industrial and automotive communication

Hardware Manual

iPC-I 165

Intelligent PC/CAN Interface

IXXAT

Headquarter US Sales Office

IXXAT Automation GmbH IXXAT Inc.

Leibnizstr. 15 120 Bedford Center Road

D-88250 Weingarten USA-Bedford, NH 03110

Tel.: +49 (0)7 51 / 5 61 46-0 Phone: +1-603-471-0800

Fax: +49 (0)7 51 / 5 61 46-29 Fax: +1-603-471-0880

Internet: www.ixxat.de Internet: www.ixxat.com

Support

In case of unsolvable problems with this product or other IXXAT products

please contact IXXAT in written form by:

Fax: +49 (0)7 51 / 5 61 46-29

Copyright

Duplication (copying, printing, microfilm or other forms) and the electronic

distribution of this document is only allowed with explicit permission of

IXXAT Automation GmbH. IXXAT Automation GmbH reserves the right to

change technical data without prior announcement. The general business

conditions and the regulations of the license agreement do apply. All rights

are reserved.

Document number: 4.01.0045.20000

Version: 2.3

Contents

1Introduction................................................................................5

1.1 Overview ............................................................................. 5

1.2 Features............................................................................... 5

1.3 Block diagram ..................................................................... 6

2Installation ..................................................................................7

2.1 Hardware installation ......................................................... 7

2.2 Software installation .......................................................... 7

3Configuration .............................................................................8

3.1 Settings on the interface .................................................... 8

3.1.1 Setting the base address ...........................................................9

3.1.2 Setting the PC interrupt ............................................................9

3.1.3 16 bit access mode.................................................................10

3.1.4 Zero wait states ......................................................................10

3.1.5 Bootstrap loader .....................................................................11

3.1.6 Reserved switches ...................................................................11

3.1.7 Providing current supply via CAN plug.....................................11

3.1.8 Bus termination resistors .........................................................12

3.1.9 Reset button and LED .............................................................12

3.2 Design of the CAN plugs................................................... 12

3.2.1 CAN bus connector.................................................................12

3.2.2 Serial RS232 interface .............................................................15

Appendix..........................................................................................16

Appendix A .............................................................................. 16

Technical Data .......................................................................... 16

EMC test................................................................................... 16

Appendix B............................................................................... 17

Delivery settings ...................................................................... 17

Appendix C............................................................................... 18

Supply sources for data sheets................................................ 18

Copyright IXXAT Automation GmbH iPC-I 165 - Manual, Version 2.3

3

Introduction

1 Introduction

1.1 Overview

With the IXXAT PC/CAN interface iPC-I 165 you have purchased a high-quality

electronic component which has been developed and manufactured according to

the latest technological standards.

The aim of this manual is to help you familiarize yourself with your interface, also

referred to in the following as iPC-I 165. Please read this manual before begin-

ning with the installation.

1.2 Features

• Design as ISA board

• 16 bit memory mapped access (12 Kbytes address space are required)

• Base address configurable via DIP switch (from C000h to FE00h in 16k steps)

• PC interrupts configurable via jumper (IRQ 3, 4, 5, 7, 9, 10, 11, 12, 14, 15)

• Microcontroller Siemens SAB C165 clocked with 20 MHz

• One ore two CAN lines with Philips SJA1000 and/or INTEL 82527 clocked with

16 MHz

• 8 Kbytes Dual-Port-RAM, 16 semaphore registers

• 512 Kbytes RAM (optional up to 2 Mbytes)

• 512 Kbytes Flash (optional up to 1 Mbytes)

• CAN bus connector according to ISO/IS 11898 on board (optional galvanic

decoupled); alternative bus interfaces can be realized via piggy-back board

• Optional CAN protection circuits on-board

• Optional developer equipment with reset button, LED and DIP switch for spe-

cial functions

• Download of INTEL HEX files into the SRAM or FLASH

• EMC safe design of circuit board (6 layer PCB)

Copyright IXXAT Automation GmbH iPC-I 165 - Manual, Version 2.3

5

Introduction

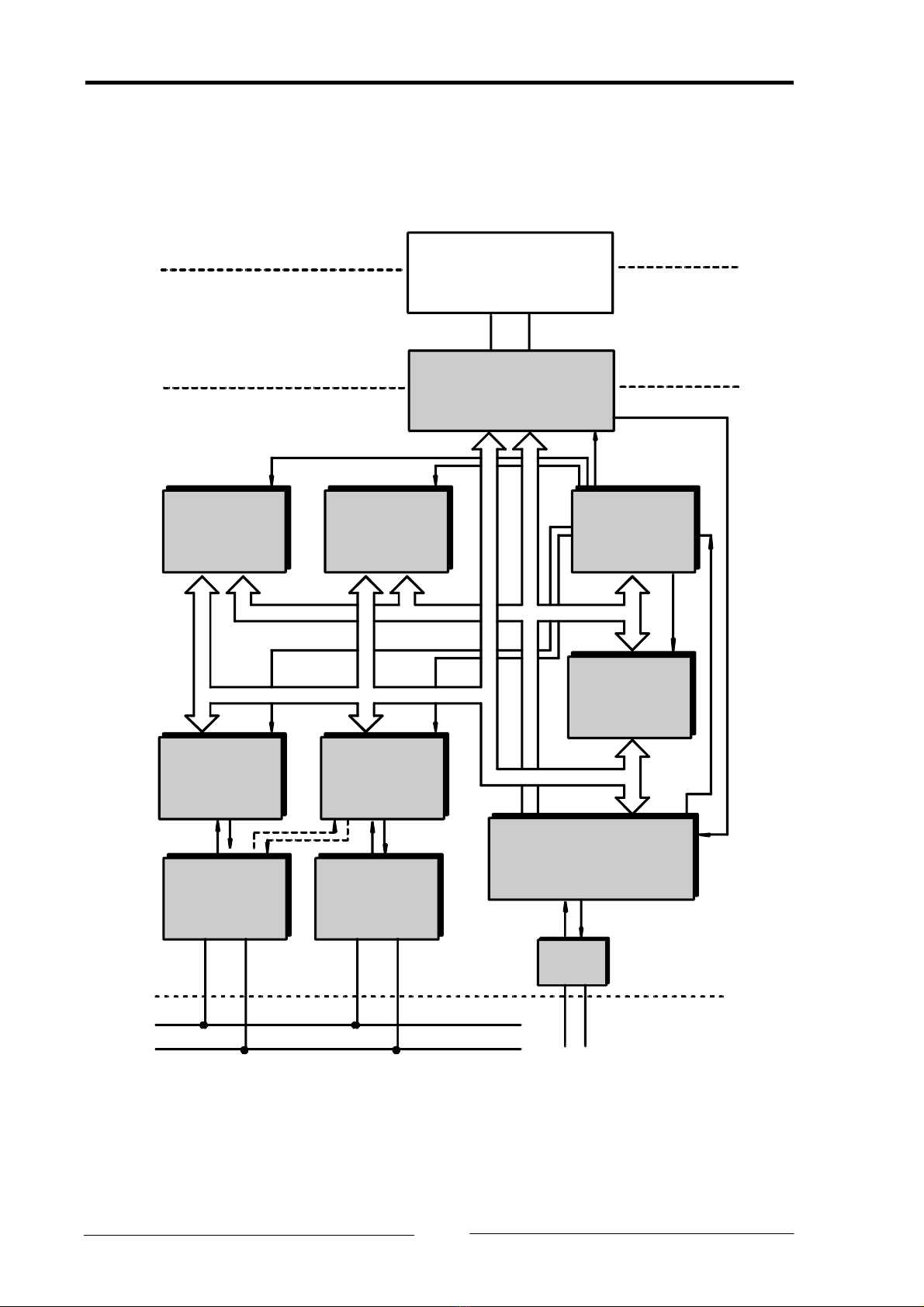

1.3 Block diagram

Interfacelogic

(DPRAMand Flags)

Flash

(max. 1MB)

Microcontroller

SAB C165LM

CAN Bus

A 0..23

ISA-Bus

PC

iPC-I 165

AD0..15

A 0..23

SRAM

(max. 2 MB) Address

Decoder

2. CAN

Controller

82C200/82527

CAN Bus-

Interface

EPROM

32 kB

RESET

RS232

TxD RxD

CAN High

CANLow

1. CAN

Controller

82C200/82527

CAN Bus-

Interface

AD0..15

CS

Copyright IXXAT Automation GmbH iPC-I 165 - Manual, Version 2.3

6

Installation

2 Installation

2.1 Hardware installation

For all work on the PC and interface, you must be statically discharged. The work

must be carried out on an earthed, anti-static work-mat.

Carry out the following work in sequence:

(1) Establish a free memory segment on the PC of at least 16 kbyte in the range

< 1MB (ISA memory range) and a free IRQ. For this, read the manual of

your PC.

(2) Set this memory segment and the IRQ on the interface, as described in Sec-

tion 3.1.

(3) Switch off the PC and remove the mains plug.

(4) Open the PC according to the instructions of the PC-manufacturer and de-

termine a suitable plug-in space.

The interface is designed according to the PC-standard and can be easily

built into the computer. Do not use force when plugging in.

(5) Ensure that the interface is held safely in place in the PC.

(6) If your interface is assembled with 2 separate CAN circuits, you must fix the

additional slot plate and plug in the header on the interface (see Section

3.2).

(7) Close the PC; the hardware installation is now completed.

2.2 Software installation

To operate the interface, a driver is required. For the installation of the CAN driver

VCI please read the VCI installation manual.

Copyright IXXAT Automation GmbH iPC-I 165 - Manual, Version 2.3

7

Configuration

3 Configuration

3.1 Settings on the interface

The diagram Fig. 3-1 shows the positions of the plugs and jumpers on the inter-

face board.

Ground pin

First CAN line

Second

CAN line

Fig. 3-1: iPC-I 165 interface board

Serial

interface

Copyright IXXAT Automation GmbH iPC-I 165 - Manual, Version 2.3

8

Configuration

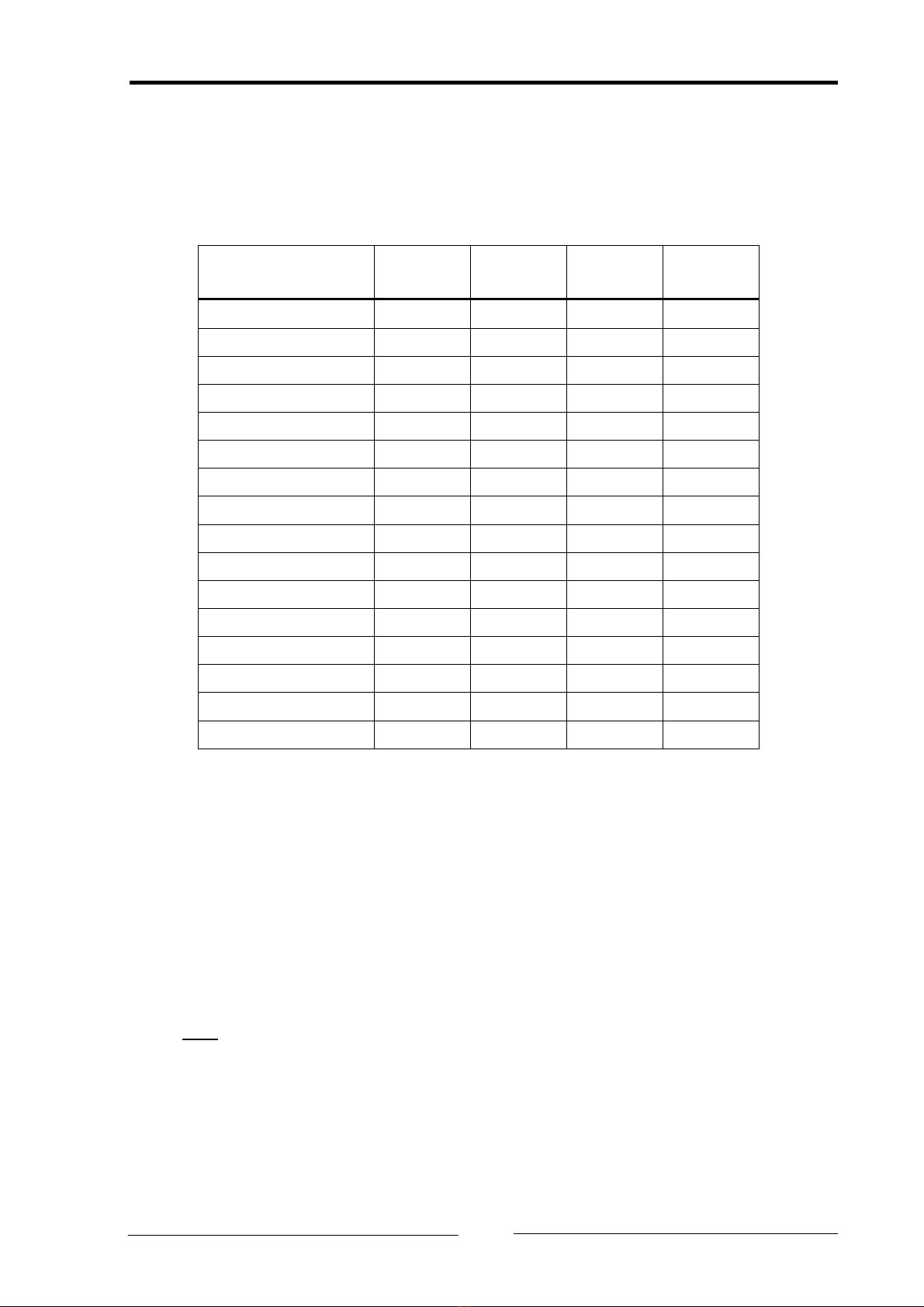

3.1.1 Setting the base address

To set the base address the switches 1 to 4 of the DIP switch SW1 are used. The

following table shows the possible settings (default = factory setting).

Base address SW1

1

SW1

2

SW1

3

SW1

4

C000h ON ON ON ON

C400h ON ON ON OFF

C800h ON ON OFF ON

CC00h ON ON OFF OFF

D000h (default) ON OFF ON ON

D400h ON OFF ON OFF

D800h ON OFF OFF ON

DC00h ON OFF OFF OFF

E000h OFF ON ON ON

E400h OFF ON ON OFF

E800h OFF ON OFF ON

EC00h OFF ON OFF OFF

F000h OFF OFF ON ON

F400h OFF OFF ON OFF

F800h OFF OFF OFF ON

FC00h OFF OFF OFF OFF

The address zone of the interface must not overlap with any other sys-

tem components in the PC.

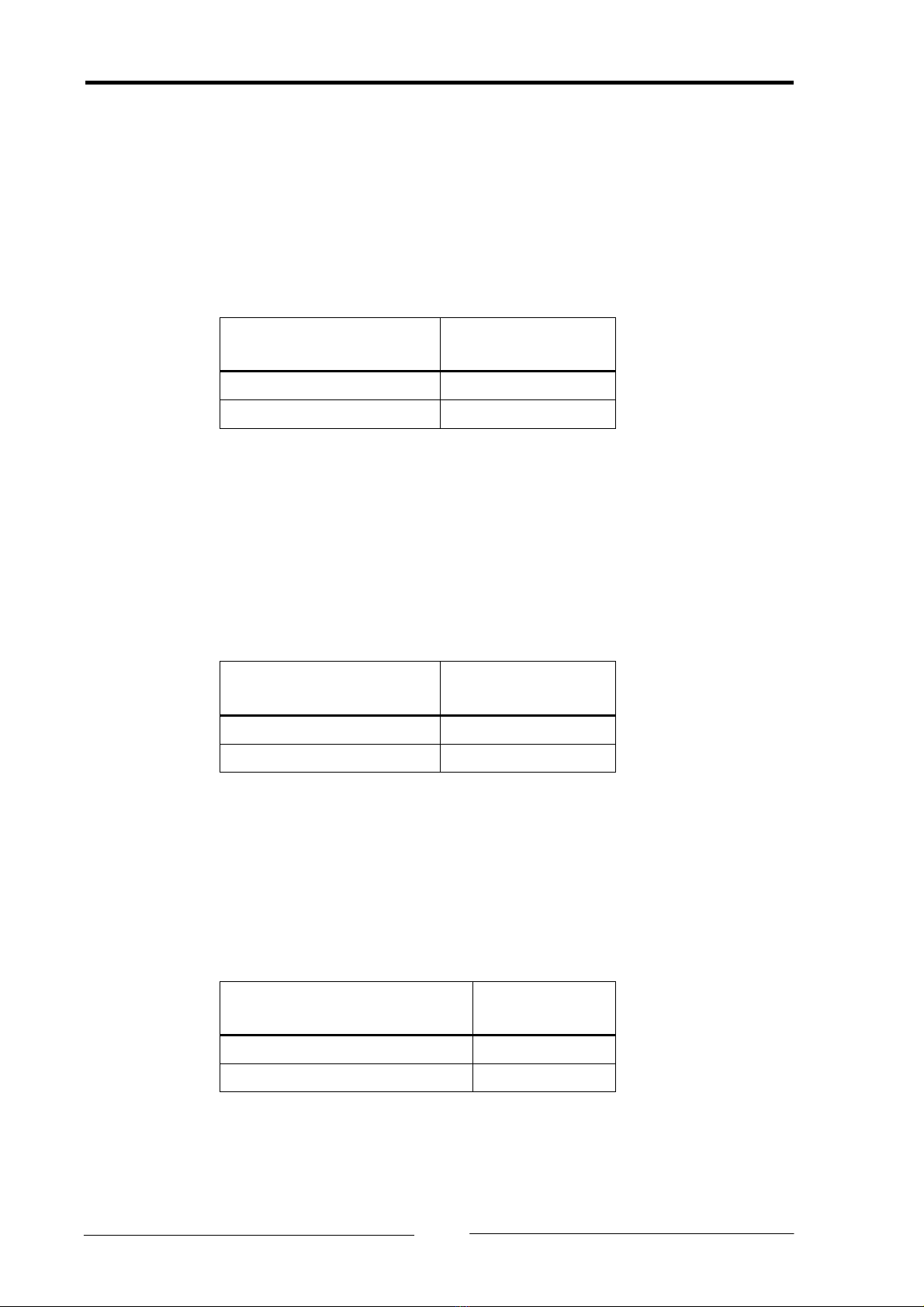

3.1.2 Setting the PC interrupt

The required interrupt is set with the jumper board JP1 by connecting the jumper

pair belonging to the requested IRQ.

Only one interrupt may be selected for the iPC-I 165!

If no interrupt is required, no pin may be bridged on JP1. The factory setting of

the interface is IRQ 5.

Copyright IXXAT Automation GmbH iPC-I 165 - Manual, Version 2.3

9

Configuration

It should be ensured that no other system component is occupying the selected

interrupt, except for cards which work with shared interrupts.

In PC systems it is possible that several cards share an interrupt. Further informa-

tion on this subject can be found in the hardware manuals for the PC. The

iPC-I 165 supports shared interrupts by enabling the level of the interrupt im-

pulses to be adjusted with switch 2 of the DIP switch SW3. For shared interrupts

the DIP switch SW3-2 must be set to OFF position.

IRQ level SW3

2

Low impulse (default) OFF

High impulse ON

3.1.3 16 bit access mode

By setting the switch 5 of DIP switch SW1 to OFF, the 16 bit access for the

iPC-I 165 can be activated. Then iPC-I 165 will be accessed with 16 bit bus cycles

from the ISA bus. If the 16 bit access is switched off the interface is accessed with

8 bit wide bus cycles.

Access mode SW1

5

16 bit (default) OFF

8 bit ON

3.1.4 Zero wait states

By setting the switch 6 of DIP switch SW1 to OFF, a shortened ISA bus cycle (0

wait states) can be activated. If SW1-6 is set to ON, the PC performs a standard

bus cycle.

Wait states SW1

6

No wait states OFF

With wait states (default) ON

Copyright IXXAT Automation GmbH iPC-I 165 - Manual, Version 2.3

10

Table of contents

Other IXXAT Recording Equipment manuals

IXXAT

IXXAT iPC-I XC16/PCI User manual

IXXAT

IXXAT iPC-I 165/PCI User manual

IXXAT

IXXAT CANblue User manual

IXXAT

IXXAT iPC-I 320/PCI II User manual

IXXAT

IXXAT PC-I 04/104 User manual

IXXAT

IXXAT CAN-IB Series User manual

IXXAT

IXXAT USB-to-CAN II User manual

IXXAT

IXXAT VCI User manual

IXXAT

IXXAT USB-to-CAN compact User manual

IXXAT

IXXAT CAN@net II User manual