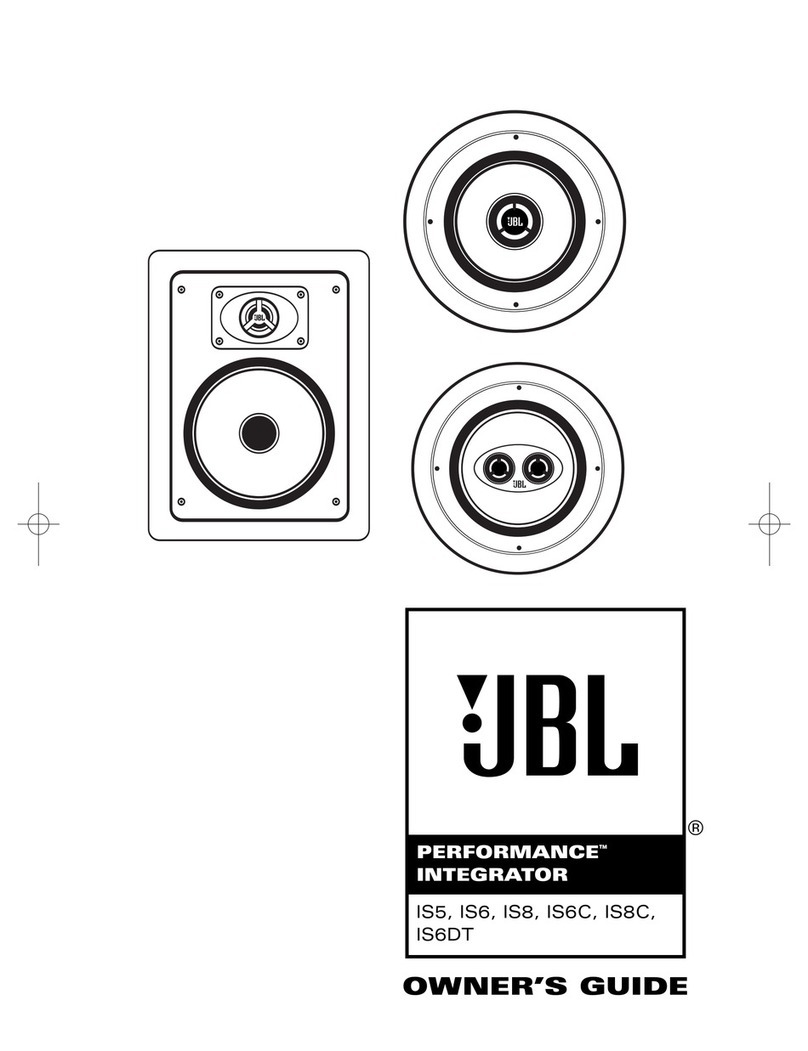

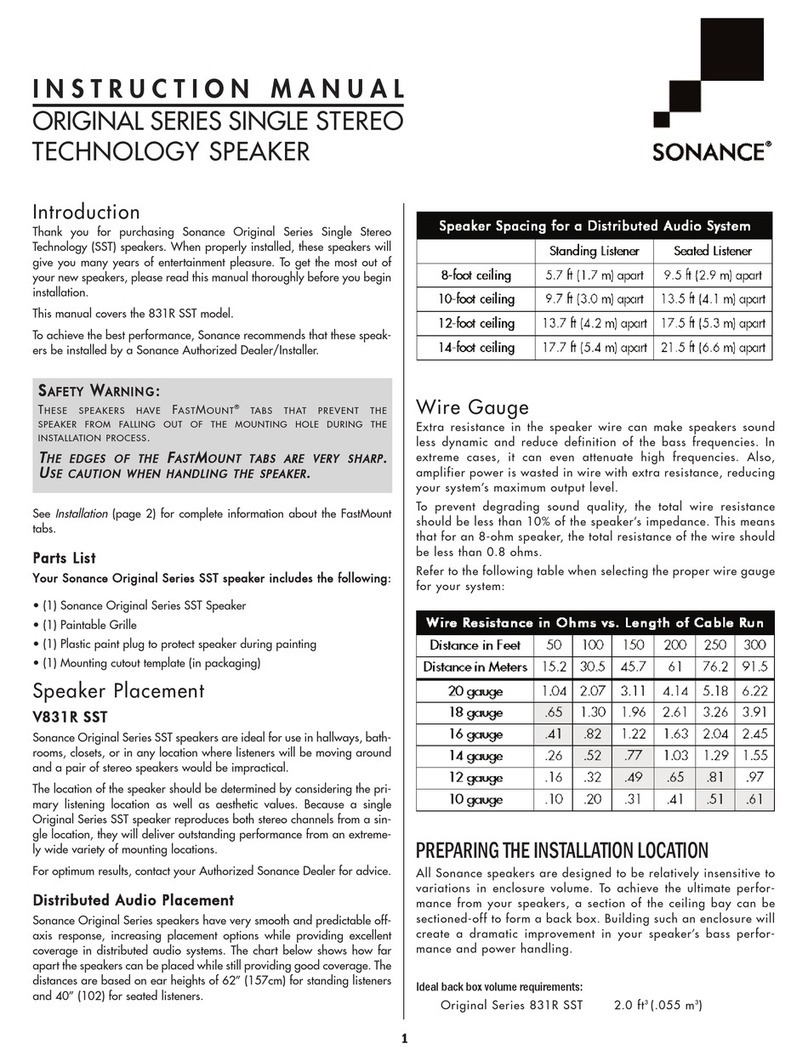

Figure 4:

C-Bracket

and

Tile Rail

Positioning on Ceiling Tile

Tile Rails: The tile rails are designed to fit either standard 24-inch wide tiles

or

600-mm wide tiles. The tile

rail pieces do

NOT

physically attach to the T-grid struts. Instead, the inverted-V shape at the ends

of

the rails

sit OVERthe T-grid strut. During normal operation, the rails are supported

by

the edge

of

the tile.

In

the

unlikely even that the tile comes out or falls apart, the ends

of

the supportrails are designed

to

catch onto the

T-grid, providing secure support to hold the loudspeaker assembly in place.

Vibration Reduction: These loudspeakers can generate substantial vibration, which can cause buzzing

of

the

ceiling materials

or

structure. Depending on the character

of

the ceiling tile and structure, the installer might

need to place neoprene

or

other dampening material under the tile rails

or

the edges

of

the tiles to eliminate

rattles.

Cutout Placement: The tile rails are pre-punched with attachment holes along their length. Placement is not

limited to the center

of

the tile as

is

the case with many other tile rail support systems.

Non-Suspended Ceiling

Types-

The C-bracket can be optionally used by itselfto shore

up the ceiling material and to spread out the clamping force from the tab clamps. Insert

the C-plate through the cut hole in the ceiling and place it

on

the back side

of

the hole

before inserting the speaker.

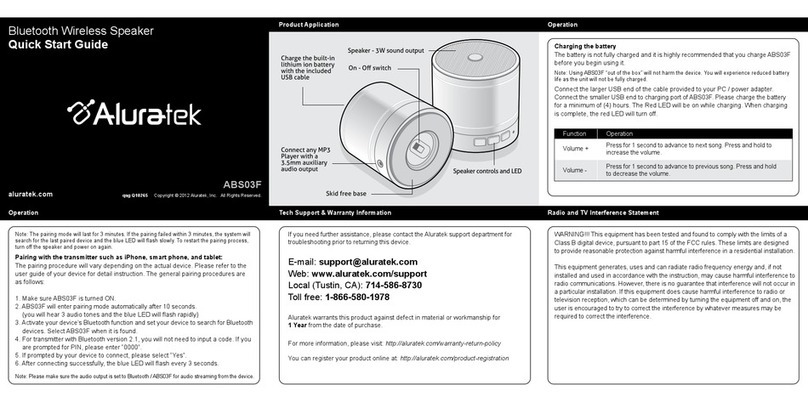

Step 3 -Connect the Wiring to the Removable Locking

Connector-

Connect the

wiring to the removable locking connector that is INCLUDED with the speaker by stripping

the insulation back about 5 mm (about 3/

16

inch), inserting the bare end

of

wire into the

connector and screwing down the hold-down screw until tight using a small flatblade

screwdriver. Tighten any unused screws to avoid vibration.

Figure

5:

Connecting Wires to

Removeable Locking Connector

7