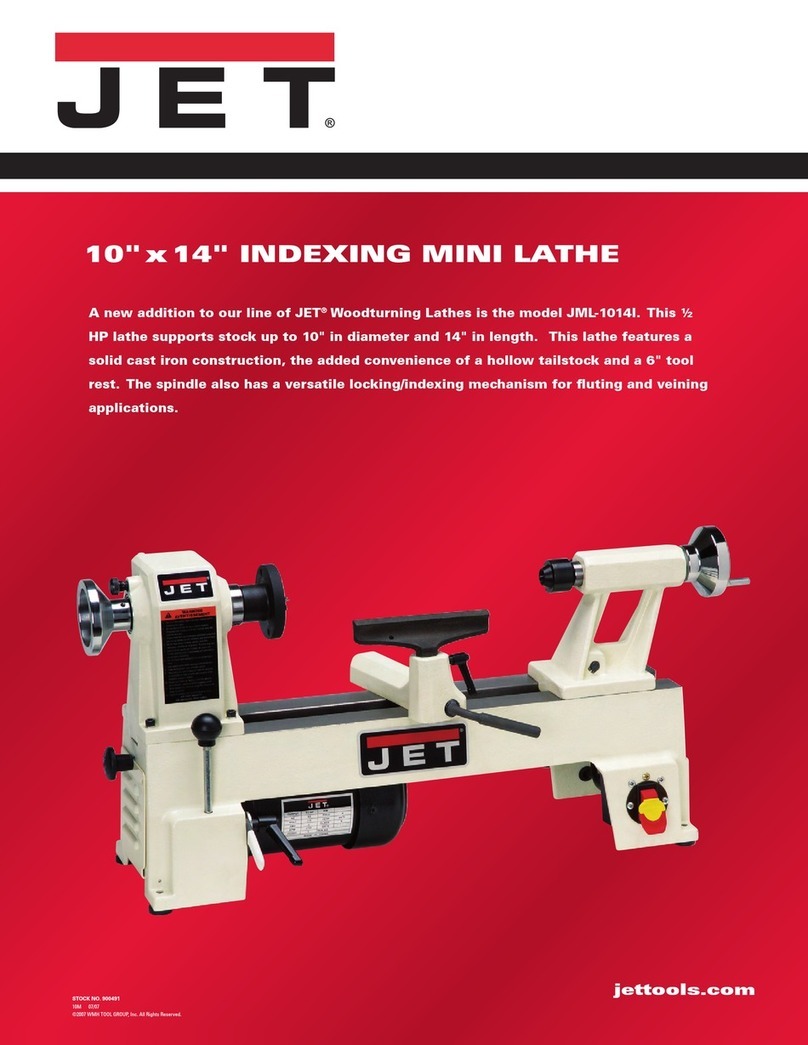

The large diameter spindle has a 1

¼” by 8 threads per inch nose that

supports the large chucks typically

used with a lathe of this size. The

outboard end of the spindle is fitted

with a barrel-type grip for turning the

spindle by hand.

The spindle also has internal

indexing built in that allows locking

it in 36 positions which translates to

10-degree increments for drilling,

fluting, grooving and other

operations. The spindle is indexed with a screw in pin that is provided with the lathe. A

pushbutton spindle lock on the front of the headstock provides a simple, tool-free way to

temporarily lock the spindle for installing/removing the faceplate, chuck or other screw-

on accessories.

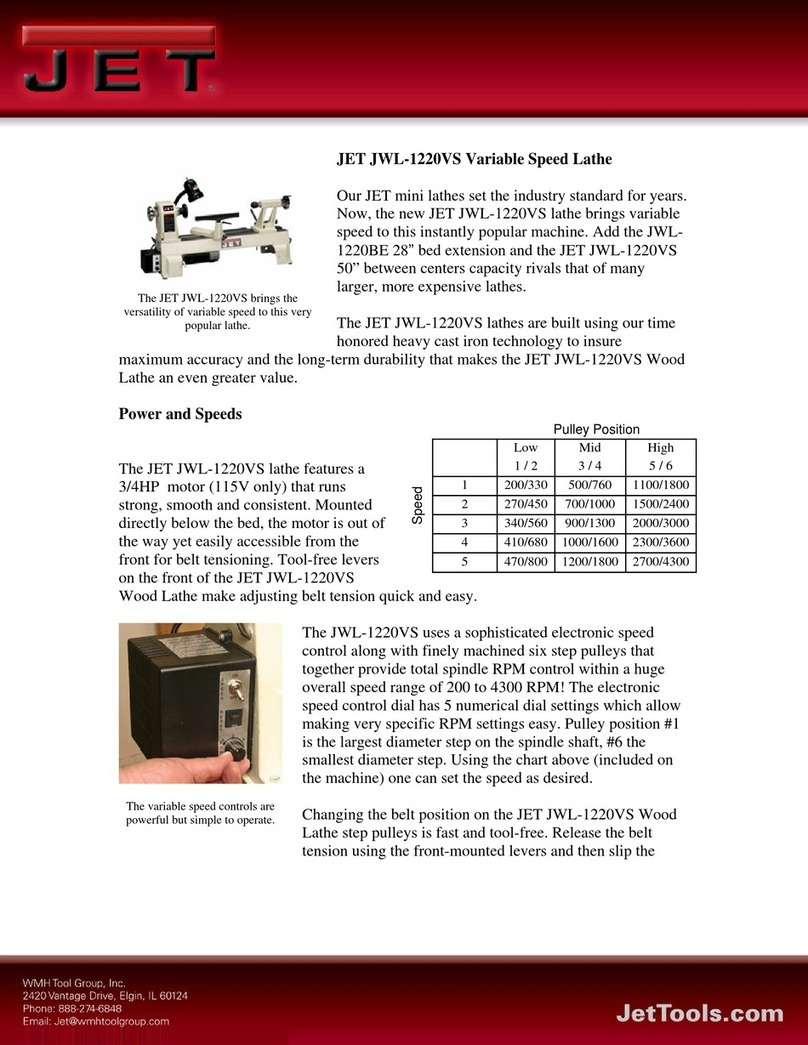

The headstock is extremely rigid and is fitted with large-diameter

ball bearings to support the high-strength spindle. (left)

The stepped drive pulleys (right) are accessible through a front-

mounted door for fast, easy speed range changes.

A 3/8”-diameter through hole provides access for removing

the drive spur from the spindle with the included knock out

rod.

To maximize the versatility of the JET JWL-1642EVS &

JWL-1642EVS-2 Wood Lathes, the headstock can be

moved to any position along the bed by simply releasing

the headstock lock with an easy to use handle. The

headstock does not pivot but can be repositioned across the

length of the ways. This is particularly useful when moved

to the end of the bed for tuning oversized bowl and platter

blanks “off the end”! When turning at the end of the bed

we offer a free standing tool rest (#708349) as an accessory

to accommodate large blanks that can’t be handled when

using the standard banjo and tool rest.

The headstock can be positioned

anywhere along the bed, including

at the very end for turning large

diameter blanks “off the bed”,

providing even more versatility.

We include a heavy wire

guard that helps protect the

operator from large chips

and chunks that can come

free while rounding blanks.

A special mount on the rear of the headstock accepts a heavy

gauge wire guard (provided with the lathe). A spring-loaded pin

indexes the guard up or down to make mounting and removing

turned objects easy. This guard acts as great shield between the

work and the operator when turning blanks where large chips and

chunks can be considered dangerous projectiles to the operator

otherwise.