Content

4

Note:

1- JFMáquinasAgrícolasLtdaaimsitsproductstobeconstantly

getting upgraded and improved in addition to having its own right to introduce

changesinitscomponentsandaccessorieswithoutpriornotice.

2- IllustrationsinthisManualaremerelyillustrative.

3- JF offers one free operation training at the factory. Contact JF Training

Departmentandaskforfurtherinformation.

1-Introduction 03

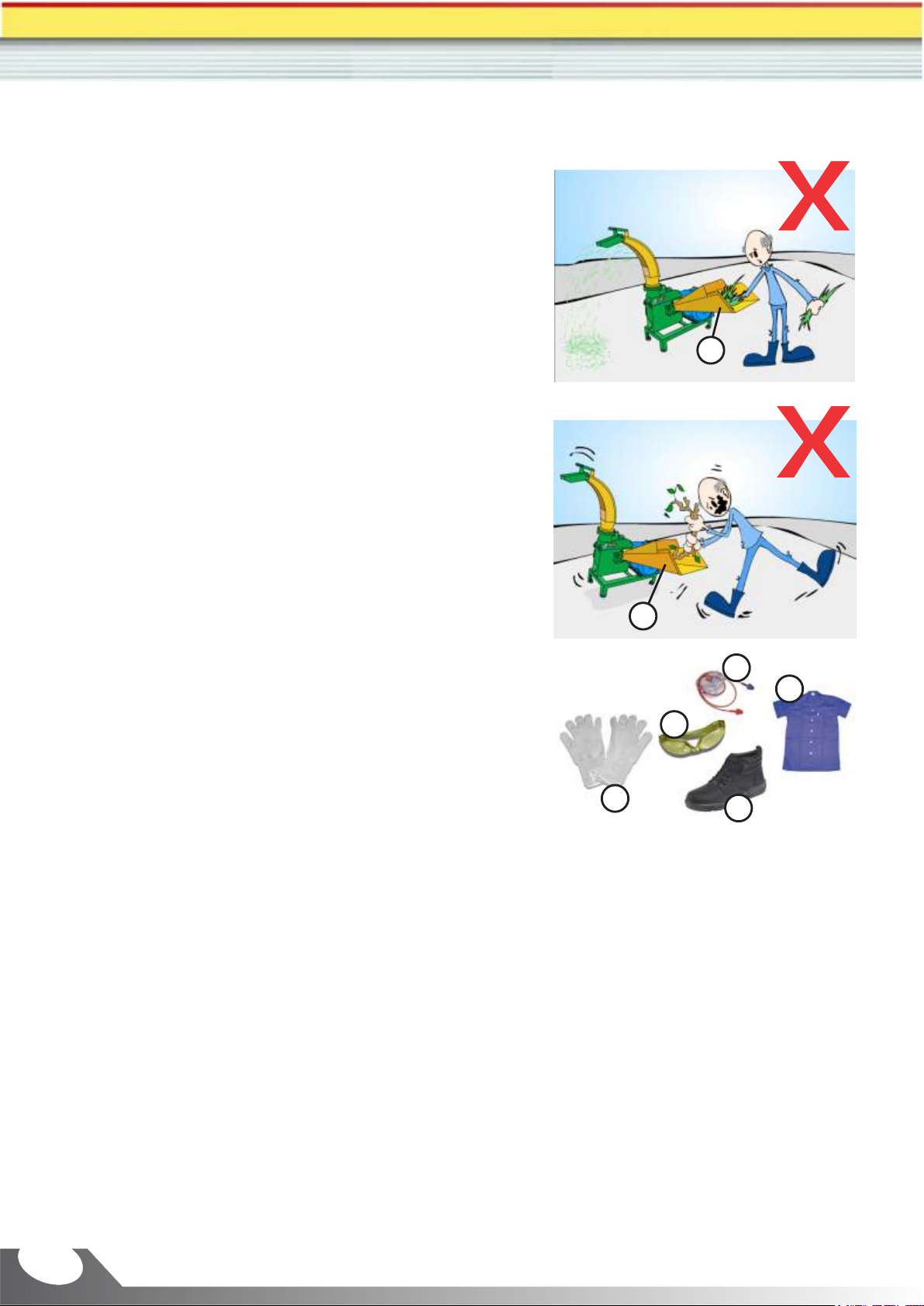

2-Safetyrecommendations 05

2.1-Whilereadingthemanual 05

2.2-WhenoperatingtheForageChopper 06

2.3-Whenmakingmaintenanceinthemachine 06

2.4-Transportontruck 06

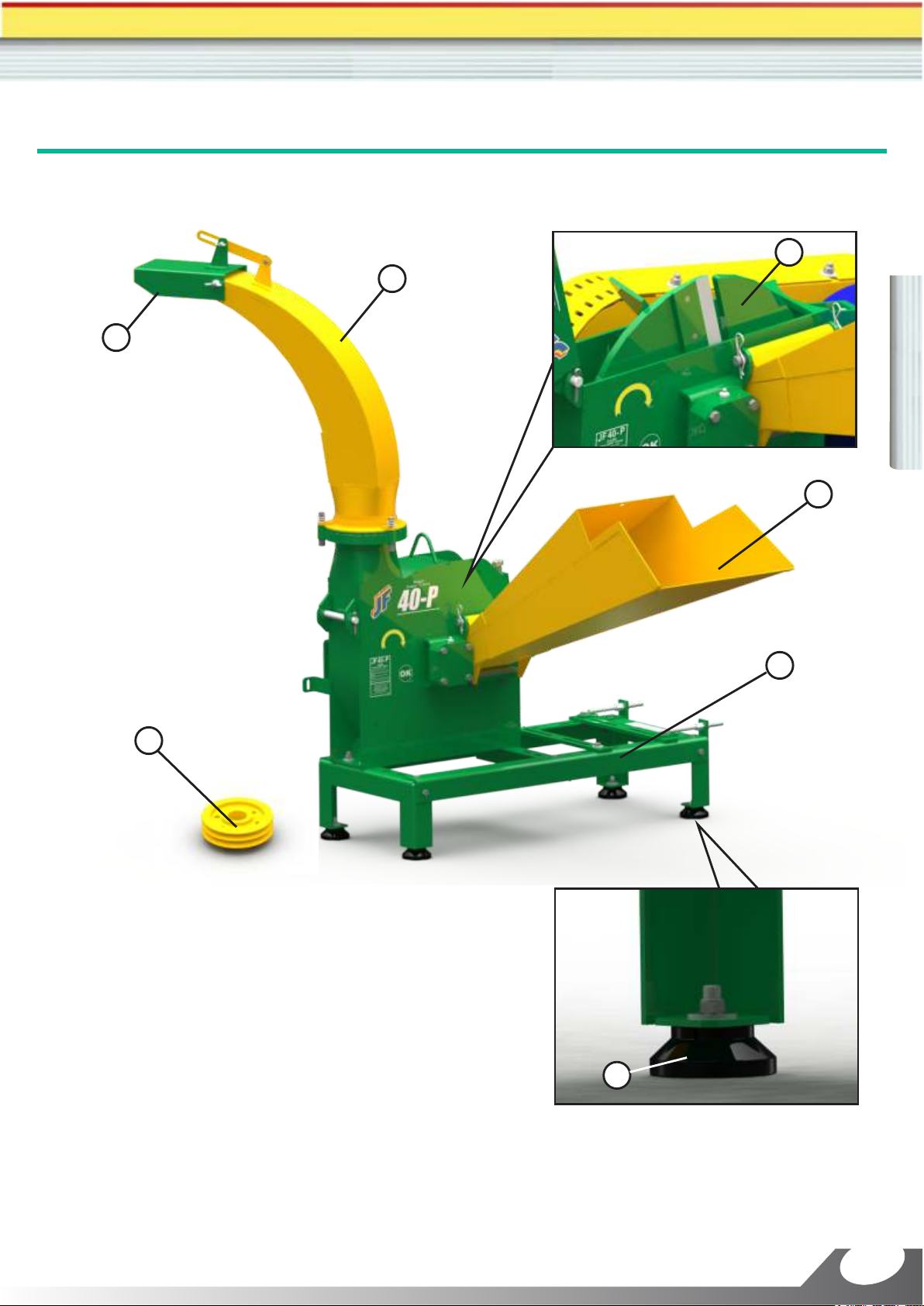

3-Machinepresentation 07

3.1-Partsidentification 07

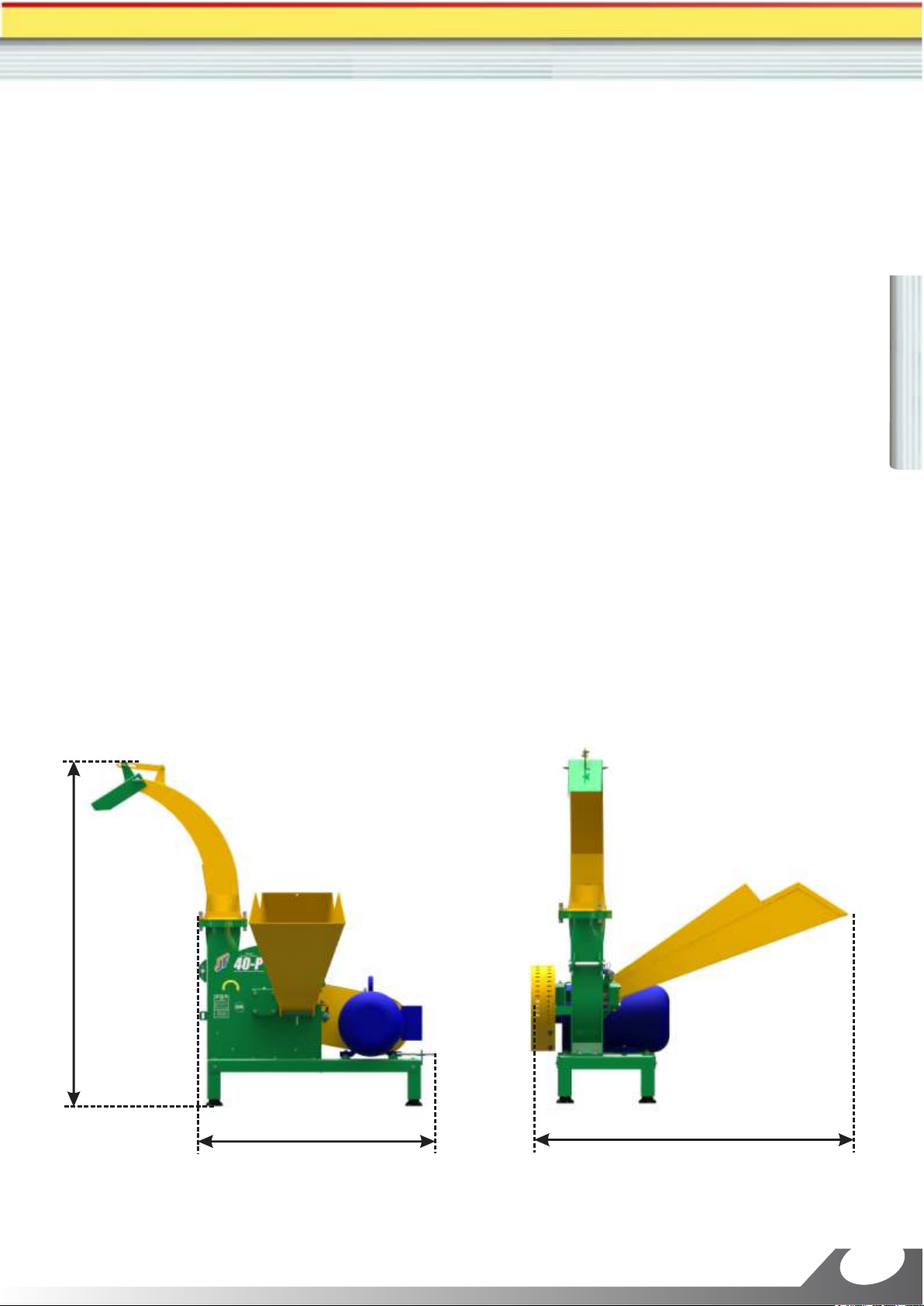

3.2-Operation 08

3.3-Technicalspecifications 09

4-Assemblyandadjustmentsbeforeoperating 10

4.1-Assemblyofthedetachedparts 10

4.2-Foragechopperadjustments 15

5-Stepbystepoperation 16

6-Maintenanceinstructions 17

6.1-Greaselubricatingpoints 17

6.2-Chopperknivessharpening 18

6.3-Gapadjustmentsbetweenknifeandcounterknife 19

6.4-Counterknife 20

6.5-Beltstensionadjustmentandreplacements 21

6.6-Foragechopperpreservation 22

7-Machineworkspeedadjustment 23

8-StickersfoundontheForageChopper 24

9-DetacheditemsthatcomealongwiththeForageChopper 25

10-Troubleshooting 26

11-Technicalassistance 27

11.1-Machineserialnumber 27

11.2-Warrantyterm 28

11.3-Technicaldeliveryreceipt 29